Al-Si-Cu-Zn-X (X=Bi, Sb, Sr)压铸铝合金的显微组织、力学性能和腐蚀行为

来源期刊:中国有色金属学报(英文版)2016年第1期

论文作者:Saeed FARAHANY Ali OURDJINI Hamid Reza BAKHSHESHI-RAD

文章页码:28 - 38

关键词:压铸铝合金;熔体处理;力学性能;断裂;腐蚀

Key words:aluminium die cast alloy; melt treatment; mechanical properties; fracture; corrosion

摘 要:研究经Bi、Sb和Sr改性的Al-11Si-2Cu-0.80Zn压铸铝合金的显微组织演变、力学性能和腐蚀行为。力学性能测试结果表明,Bi、Sb和Sr的添加引起合金中共晶Si形貌发生改变,从而使合金的冲击韧性、极限抗拉强度和伸长率增加。断裂表面分析结果表明,添加Sr或少量Bi和Sb,合金表面呈韧性断裂,而非准解理脆性断裂。此外,添加Sr、Bi和Sb后,合金的质量指标由基体合金的102 MPa分别增加到164.7 MPa、156.3 MPa和152.6 MPa。在NaCl溶液中的极化腐蚀测试结果表明,分别添加Sb、Bi和Sr后,合金的腐蚀电位负移。浸泡腐蚀实验结果表明,由于Al和Si共晶相界面的增加,Sb、Bi和Sr元素的添加对合金的腐蚀速率具有决定性作用。

Abstract: The microstructure evolution, mechanical and corrosion properties of Al-11Si-2Cu-0.8Zn die cast alloy treated with Bi, Sb and Sr additions were investigated. The results of mechanical testing showed that all additions increased impact toughness, ultimate tensile strength, and elongation of the alloy as a result of change in eutectic Si morphology. The analysis of fracture surfaces revealed that with addition of Sr and to lesser extent Bi and Sb, the alloy exhibited a predominantly ductile fracture rather than quasi-cleavage brittle fracture. Moreover, with the additions of Sr, Bi and Sb, the quality index increased to 164.7 MPa, 156.3 MPa and 152.6 MPa respectively from 102 MPa for the base alloy. Polarization corrosion tests conducted in sodium chloride solution showed that the corrosion potential shifted to more negative values with additions of Sb, Bi and Sr, respectively. Corrosion immersion tests also revealed that the element additions have a detrimental effect on the corrosion rate of alloys, due to the increase of boundaries between the Al and eutectic Si phases.

Saeed FARAHANY1, Ali OURDJINI2, Hamid Reza BAKHSHESHI-RAD3

1. Department of Materials and Mechanical Engineering, Buein Zahra Technical University, Qazvin 3451745346, Iran;

2. Department of Mechanical Engineering, Faculty of Engineering, University of Ottawa,

Ottawa, 161 Louis Pasteur, KIN 6N5, Canada;

3. Department of Materials, Manufacturing and Industrial Engineering, Faculty of Mechanical Engineering,

Universiti Teknologi Malaysia (UTM), Johor Bahru 81310, Malaysia

Received 3 February 2015; accepted 12 October 2015

Abstract: The microstructure evolution, mechanical and corrosion properties of Al-11Si-2Cu-0.8Zn die cast alloy treated with Bi, Sb and Sr additions were investigated. The results of mechanical testing showed that all additions increased impact toughness, ultimate tensile strength, and elongation of the alloy as a result of change in eutectic Si morphology. The analysis of fracture surfaces revealed that with addition of Sr and to lesser extent Bi and Sb, the alloy exhibited a predominantly ductile fracture rather than quasi-cleavage brittle fracture. Moreover, with the additions of Sr, Bi and Sb, the quality index increased to 164.7 MPa, 156.3 MPa and 152.6 MPa respectively from 102 MPa for the base alloy.  Polarization corrosion tests conducted in sodium chloride solution showed that the corrosion potential shifted to more negative values with additions of Sb, Bi and Sr, respectively. Corrosion immersion tests also revealed that the element additions have a detrimental effect on the corrosion rate of alloys, due to the increase of boundaries between the Al and eutectic Si phases.

Polarization corrosion tests conducted in sodium chloride solution showed that the corrosion potential shifted to more negative values with additions of Sb, Bi and Sr, respectively. Corrosion immersion tests also revealed that the element additions have a detrimental effect on the corrosion rate of alloys, due to the increase of boundaries between the Al and eutectic Si phases.

Key words: aluminium die cast alloy; melt treatment; mechanical properties; fracture; corrosion

1 Introduction

The Al-Si system can be classified into the category of in-situ composites because the soft and ductile aluminum matrix is reinforced with hard and brittle eutectic Si particles, which form during solidification. Al-Si system possesses exceptional fluidity and resistance to hot tearing owing to its high silicon content that make it capable of producing intricate and thin-section castings. Because of these properties, Al-Si-Cu-Mg alloys are used to produce critical components in the aerospace and automotive industries [1]. High specific strength, high resistance to corrosion, good formability, good weldability and recycling potential of these alloys make them an ideal choice for light-mass components [2]. However, the size, distribution and shape of Si phase influence the mechanical properties of the system, i.e., in terms of hot workability [3] and fatigue properties [4]. Si appears as flaky or plate-like structure, and is acicular in sections. What this means is that upon loading, these acicular Si particles act as possible sites for stress concentration, which can lead to premature failure [5].

One way to modify the Si structure and improve the mechanical properties of the system is to introduce certain elements, such as sodium and strontium, into the melt, which alter the morphology of the Si phase [6,7]. Sr is widely used for modifying the morphology of eutectic Si [8] and also improves the fluidity and bendability of cast A356 alloys [9]. It has been noted, however, that the benefits associated with the addition of Sr can sometimes be outweighed by the altered porosity characteristics of the alloy [10]. As such, antimony is sometimes used as an alternative to Sr for the modification of eutectic Si [11]. The most important advantage of Sb is that it is stable in the melt, and is not affected by holding time, remelting and degassing. Bismuth is also used, especially in wrought Al alloys, because it is able to improve machinability, and to alter the Si morphology of Al-Si alloys [12,13]. On the other hand, it has been pointed out that the effect of Sb and Sr on mechanical properties is dependent on the solidification rate [14], and that the addition of both Sr and Sb improves the wear resistance of the A357 alloy [15]. Furthermore, OSORIO et al [16] noted that the corrosion resistance of the alloy modified by Sr is significantly decreased. Aside from the aforementioned studies, however, there is a dearth of comparison of the effect of Bi, Sb and Sr additions on the mechanical and corrosion properties of the Al-Si-Cu-Zn die cast alloy. Additionally, the correlation of these characteristic features has not been investigated in depth. Therefore, the main approach of the present study will be to investigate the microstructure, mechanical and corrosion properties of the base alloy in comparison to the treated alloys in order to enhance the performance of the products.

2 Experimental

2.1 Alloy preparation

A commercially available Al-11Si-2Cu-0.8Zn die cast alloy was cut into small pieces, dried and melted in a 2 kg capacity silicon carbide crucible in an electric resistance furnace. Then, weighted Bi, Sb and Sr in the form of pure metallic shots (99.99%, mass fraction), pure metallic granules (99.99%, mass fraction), and an Al-10Sr rod master alloy were respectively introduced separately into the fully molten alloy. Sr addition was used as a reference for comparison with the obtained results since it is a widely accepted modifier for Al-Si alloys. The selected levels of Bi, Sb and Sr additions were 1%, 0.5% and 0.04% (mass fraction), respectively, based on a previously published paper [17]. The final compositions of all samples were subsequently analyzed using a glow discharge spectrometer (LECO GDS-850A), with the results presented in Table 1. The untreated and treated alloys with Bi, Sb and Sr are labeled as AB, TBi, TSb and TSr, respectively.

2.2 Mechanical properties

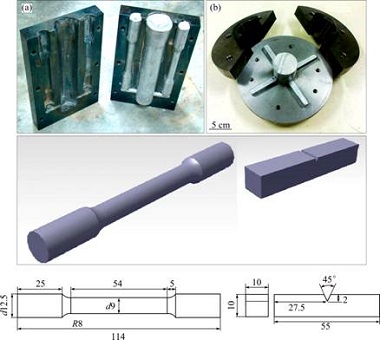

Using a permanent metal mold casting technique, samples for mechanical properties testing were produced, that is, both cylindrical tensile test specimens according to ASTM B-108 type bars and impact Charpy test specimens (Fig. 1). Two tensile and four impact test samples were prepared for each alloy composition. To ensure that the observed changes in microstructure and associated mechanical properties are related only to the element additions, and also to reduce the effect of cooling rate, the permanent molds were preheated to 500 °C for 30 min prior to pouring. Degassing of the melt was performed by using hexachloroethance tablets to minimize the effect of porosity on the scattering of mechanical properties testing results. Tensile testing was carried out on the prepared test bars using an Instron universal mechanical testing machine (model 5982) at a displacement rate of 1.0 mm/min and ambient temperature. The impact test was conducted based on Charpy type using a Zwick impact testing machine (D-7900), which used a 15 J hammer to measure the total absorbed energy. Hardness was measured using a Vicker’s hardness machine (Matsuzawa DVK-2) at an applied load of 5 N.

Table 1 Chemical compositions of alloys studied (mass fraction, %)

Fig. 1 Tensile test sample permanent mold (a) and impact test specimen casting and mold (b) along with corresponding dimensions according to standard (unit: mm)

2.3 Corrosion test

Rectangular specimens with a surface area of 1 cm2 were molded into epoxy resin for electrochemical tests. The test was conducted at 25 °C in open air, within a glass cell containing 350 mL of 0.5 mol/L H2SO4 solution at pH 0.6 using a PARSTAT 2263 potentiostat/ galvanostat (Princeton Applied Research). A three- electrode cell was used for potentiodynamic polarization tests: the reference electrode being saturated calomel electrode (SCE), the counter electrode being a graphite rod, and the working electrode being the specimen. All experiments were carried out at a constant scan rate of 0.2 mV/s, from -250 mV to 250 mV (vs SCE) related to the open circuit potential. This fitting is inherently difficult, but the software has the ability to allow manual control. Tafel fitting was made by the selection of a segment of the curve from φcorr, and Jcorr was subsequently estimated from the value where the fit intercepted the potential value of the true φcorr. Each experiment was repeated twice to check the reproducibility of the results. All potentials were referred to the SCE. The immersion tests of the specimens were conducted according to the G31-72 standard. Thirty rectangular specimens with dimensions of 15 mm ×20 mm × 5 mm were cut and subsequently ground with 400-2000 grit SiC papers. The specimens were then washed entirely with distilled water, rinsed, ultrasonically degreased with ethanol, and then dried at room temperature. The specimens were then immersed into a beaker containing 200 mL of 0.5 mol/L H2SO4 solution. The beakers were sealed with a pH value of 0.6, and incubated at a constant temperature of 25 °C for 5, 10, 15 and 30 d, respectively. Afterwards, the specimens were rinsed with acetone and deionized water, and corrosion products were removed before mass measurement. The corrosion rate was calculated as follows:

(1)

(1)

where CR is the corrosion rate, Δm is the mass loss, A is the surface area exposed to the corrosive media, t is the exposure time, and d is the density.

2.4 Microstructure inspection

Samples for metallography observation were prepared according to standard procedures. The ground and polished specimens were then subjected to a final polishing with colloidal silica suspension. To examine the 3D morphology of eutectic silicon, the samples were deeply etched with a solution of 20% HCl acid and 80% ethanol for 4 h and ultrasonically cleaned with acetone for 30 min. The microstructural changes of samples associated with different additions and the fracture surface of tensile and impact tests were characterized using a field emission scanning electron microscope (Supra-35VP, Carl Zeiss, Germany).

3 Results and discussion

3.1 Microstructural analysis

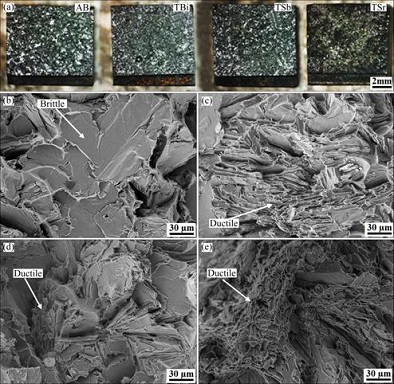

It has been shown that three main phase evolutions occur during the solidification phenomenon of Al-Si-Cu cast alloy: primary Al dendrite, eutectic Al-Si and the subsequent eutectic Al2Cu phase precipitate [18]. 3D observations of silicon morphologies of the base alloy and treated alloys after selective etching are shown in Fig. 2, which were solidified at slow cooling rate. Since the effect of cooling condition on the microstructure of alloys can be ignored in this controlled solidification, the structural alteration of Si is only related to different addition elements. Figure 2(a) shows the microstructure of the AB alloy. It clearly indicates that Si morphology is in coarse plate-like shape. Figures 2(b) and (c) show the microstructures of TBi and TSb alloys, respectively, in which the Si structure has been refined from large plate-like to fine lamellar morphology. However, when Sr is added to the AB alloy, Si changes completely. Si appears as a fine fibrous morphology being typical of modified Al-Si alloys, as shown in Fig. 2(d). From Fig. 2, it is evident that the size of Si particles decreases, and the density of Si increases remarkably, with the addition of Bi, Sb and Sr. It is found that Si morphology changes due to the addition of Bi, Sb and Sr, and can be correlated with the depression of the Al-Si eutectic growth temperature [19]. Recently, an investigation using μ-XRF in the synchrotron [20], and also atom probe tomography [6], have shown that Sr is co-segregated and distributed in the eutectic Si phase, providing strong evidence of the occurrence of growth restriction. It has been noted that Sb addition has an effect on the nucleation stage [21,22]. It has been found that Bi can reduce the surface tension of Al alloys because it is surface-active [23,24]. It seems that by reducing the liquid surface tension within the eutectic phase, which is a lamellar structure of Al and Si, Bi can decrease the contact angle between Al and Si, resulting in the Al phase being able to wet the Si particles more easily and encapsulate the Si growth front, thus limiting its growth [25].

Fig. 2 Deeply etched SEM images of AB (a), TBi (b), TSb (c) and TSr (d) specimens

3.2 Mechanical properties

The results of hardness measurements for all alloys with and without element additions are plotted in Fig. 3. The hardness testing was performed in areas occupied mainly by the Si phase and the reported hardness values are the average of five measurements. Figure 3 shows that the hardness for AB alloy is HV 78.6, which is increased to HV 79.9 for TBi, HV 79.6 for TSb and HV 80.5 for TSr alloy. It is clear from the results that the hardness only changed slightly with TSr alloy recording the highest value. The slight increase is likely attributed to the increase in eutectic Si fraction solid as a hard phase, leading to superior hardness value. It is well-known that the Si phase is harder than Al phase. Hence, the size, morphology and distribution of Si could affect the hardness of Al-Si alloy. Moreover, finer Si provides more obstacles to grain boundary sliding. Therefore, the treated alloys which have finer Si structure present higher hardness values compared with the AB alloy.

Fig. 3 Hardness value and impact energy absorbed for fracture for AB, TBi, TSb and TSr alloys

The absorbed impact energy indicates the capacity of a material to resist external impact loading, and the load profile that a material experiences in an impact test is continuously varied until final macroscopic fracture occurs through crack initiation and propagation, as well as the plastic deformation of a material [26]. The Charpy type impact test highlights notch behavior by applying a high strain rate or rapid loading conditions. The relationship between the absorbed impact energy and the condition of samples shown in Fig. 3 clearly indicates that addition of elements results in the improved toughness compared with the base alloy. The TSr alloy exhibits the highest absorbed energy of 2.2 J compared with 1.62, 1.4 and 1.15 J for TBi, TSb and AB alloys, respectively. The values of impact energy plotted in Fig. 3 are the average value of four test pieces made from each casting. The impact toughness doubled with the addition of Sr compared with the AB alloy. The improvement in toughness is most likely attributed to the lamellar and fibrous Si induced by addition of Bi, Sb and Sr, which reduce the stress concentration sites and delay crack propagation.

The fracture surfaces of failed impact testing samples were also investigated to examine the type of failure. The macro observation (Fig. 4(a)) shows that the impact specimens of all alloys exhibit little plastic deformation prior to failure due to fast loading. The fracture surface of the AB alloy exhibits bright, smooth and faceted features, whereas the fracture surface of TSr alloy is dark and rough. Higher magnification fracture surfaces observed under FESEM are shown in Figs. 4(b)-(e). The AB alloy fails in a brittle mode as evidenced by the presence of cleavage, whereas the fracture surfaces of TBi and TSb samples show a mixed mode of ductile and brittle fractures as shown in Figs. 4(c) and (d), respectively. The areas related to ductile fracture are marked to differentiate from the brittle region. Fracture surface of the TSr alloy, however, exhibits fine Si planes associated with ductile fracture as shown in Fig. 4(e). Based on microstructural observations, there is an evidence that the changes in the eutectic Si characteristics are reflected on the impact toughness of Al-Si die casting alloy. The treated alloys with lamellar or fibrous Si morphologies adsorb more energy before fracture.

Figure 5(a) shows stress-strain curves of samples under tension stress. The tensile test results, including yield strength (YS), ultimate tensile strength (UTS) and elongation to fracture (EL) for the AB alloy and the treated alloys (TBi, TSb, TSr) are shown in Fig. 5(b). The results show that the yield strength obtained for the AB alloy (119.9 MPa) is almost similar to those of the TBi (119.2 MPa), TSb (120.2 MPa) and TSr (118.2 MPa) alloys. On the other hand, the AB alloy has the lowest UTS of 131.3 MPa, which increase to 151.8, 149.5 and 157.8 MPa with addition of Bi, Sb and Sr, respectively. The values of UTS appear to be more dependent on the shape of eutectic Si. With regard to elongation to fracture, the results show that the values of elongation increase by two-fold with additions of Bi, Sb and Sr, with the highest elongation observed in the TSr alloy at 1.29% compared with that recorded for the untreated AB alloy with a value of 0.6%. The increase in elongation is likely attributed to the change in Si morphology from flake-like to refined lamellar and fibrous structure with addition of Bi, Sb and Sr. The large plate-like structure of Si increases stress and help initiation and growth of microcracks. Si particle size and morphology are important factors affecting the embrittlement of the alloy. Hence, changes in the morphology achieved by way of element additions of Bi, Sb and Sr may impede the sequence of damage events, i.e., initiation of microcracks in the Si particles, growth of these cracks into cavities, and finally coalescence of these cavities [27]. From the tensile test, there is an evidence of a direct relationship between impact toughness and elongation. The highest and the lowest impact toughness and El are associated with TSr and AB alloys, respectively. Thus, it is clear that the change in eutectic Si from plate-like to refined morphology or modified morphology is beneficial to both impact toughness and ductility of castings.

Fig. 4 Fracture surfaces of alloy samples subjected to impact testing (a) and FESEM images of fracture surfaces of base alloy AB (b), TBi (c), TSb (d) and TSr (e) specimens

Fig. 5 Tensile stress-strain curves (a) and tensile test results composed of YS, UTS and El of AB, TBi, TSb and TSr alloys (b)

The results of ductility of the base alloy and treated samples can be reflected from the tensile fracture surfaces. Figure 6 shows a series of secondary electron images observed from the fracture surfaces and the corresponding optical micrographs of the cross-sectional fracture surfaces of AB, TBi, TSb and TSr specimens clearly showing different fracture surfaces. The fractographs presented in Figs. 6(a) and (b) characterize the nature of fracture in the AB alloy, which clearly indicate that the presence of cleavage (Fig. 6(a)). Moreover, the optical micrograph of the side view represents an intergranular fracture. These observations indicate that the fracture exhibits brittle behavior, which is attributed to the low ductility of the castings. A broken eutectic Si on the fracture surface suggests that cracks are initiated and propagated through coarse plate-like Si (Fig. 6(b)). The features of the TBi alloy fracture surfaces are represented in Figs. 6(c) and (d). The fracture mechanism changes from brittle (Figs. 6(a) and (b)) to mixed mode. More transgranular features can be seen in the TBi sample. The fracture of eutectic Si is shortened, and the sign of plastic deformation, i.e., dimples, is observed to occur at the Al matrix. Figures 6(e) and (f) show the fracture characteristics of the TSb alloy, where a mixed mode of fractures is clearly observable. The plastic deformation, which can be related to cavity nucleation, occurs around the Si particle. The FESEM analysis of the fracture surfaces confirms that the coarse Si particles are refined by the addition of Bi and Sb, which results in the improvement of ductility. By contrast, the TSr alloy exhibits substantial evidence of plastic deformation as shown in Fig. 6(g). Furthermore, the intergranular fracture changes to transgranular fracture in the TSr specimen (Fig. 6(h)). The surface exhibits the presence of dimples, indicating a failure of ductile fracture and plastic deformation, in contrast to the AB sample, which is dominated by brittle fracture. Overall, the results show that with addition of Bi, Sb and Sr to the base alloy, the ductility is improved, as indicated by the values of elongation to fracture. Generally, the strength of Al-Si alloys relies on Al dendrite, eutectic Si and intermetallic precipitations. Since in the current study, the addition of Bi, Sb and Sr affects the eutectic Si appearance, it can be assumed that the change in the strength of Al-Si alloy is related to the variation in the strength of Al-Si eutectic phase (σeu) according to Eq. (2):

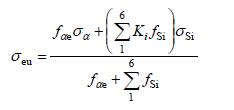

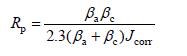

(2)

(2)

where fαe and σα are the mole fraction and strength of Al in Al-Si eutectic phase, σSi is the strength of Si, fSi is the mole fraction of Si, and Ki is dependent on Si morphology according to American Foundry Society (AFS) chart. It should be noted that the Si morphology and distribution are always not uniform in castings. Thus, the AFS standard chart is developed for Si shape in Al-Si system. Based on this standard, Si morphology is divided into 6 groups: 1) coarse, 2) lamellar, 3) partially modified, 4) absence of lamellar, 5) fibrous and 6) very fine fibrous Si. With regard to Fig. 2, the Si structure of the AB alloy can be categorized in Group 1, TBi and TSb in Groups 2 and 3 and TSr alloy in Groups 5 and 6.

Fig. 6 Fracture surfaces and fracture profiles of tensile test bar at room temperature for AB (a, b), TBi (c, d), TSb (e, f) and TSr (g, h) specimens

To evaluate the influence of Bi, Sb, and Sr additions on the performance of the alloys, quality index (Q) was employed. The quality index is described by DROUZY et al [28], and modified by CLOSSET and GRUZLESKI [29], as semi-logarithmic plot of UTS (σ0.2) versus elongation (δ) to fracture, Q=σ0.2+150lg δ. Since the quality index combines both strength and ductility, it is much more descriptive of the true tensile properties of a casting rather than tensile strength or elongation alone. The values of Q increased significantly from 102 MPa for the AB alloy, to 162.6 MPa and 156.3 MPa for the TBi and TSb alloys, respectively. The Q value increases to the highest value of 164.7 MPa for the TSr alloy. In summary, Bi, Sb and Sr addition introduced into Al-11Si-2Cu-0.8Zn alloys are effective in changing the morphology of eutectic Si, which in turn significantly improves the quality index of the castings.

3.3 Corrosion behavior

Potentiodynamic polarization test in 0.5 mol/L H2SO4 solution was performed to evaluate the corrosion behavior of Al-11Si-2Cu-0.8Zn alloy. From Fig. 7, it can be seen that the alloys treated with Bi, Sb and Sr have more negative corrosion potential compared with the base alloy, indicating the detrimental effect of addition elements on the corrosion behavior of the alloy. The corrosion potentials (vs SEC) of the alloys treated with Bi, Sb and Sr are -654.5, -624.3 and -748.1 mV respectively compared with the value of -557.7 mV obtained for the base alloy. The current densities also increase when the base alloy is treated with element additions, indicating their damaging effect on the corrosion rate of the alloy. Sr modified the structure and thus reduced the size of eutectic silicon particles and increased their density, providing more boundaries of Al/Si, resulting in an adverse effect on the corrosion resistance for A356 alloy [30]. The cathodic polarization curve is assumed to indicate hydrogen evolution via water reduction. The kinetic of cathodic reaction in the TSr alloy is faster than that of the TBi and TSb alloys. This phenomenon indicates that the cathodic reaction is kinetically more difficult in the base alloy compared with the treated one. The corrosion current density (Jcorr), corrosion potential (φcorr, vs SCE), cathodic Tafel slopes (βc), anodic Tafel slopes (βa) and corresponding corrosion rate (Pi) of specimens extracted from the polarization curves are shown in Table 2. Also, from the electrochemical parameters (Jcorr, βa and βc) of specimens, the polarization resistance (Rp) was calculated according to the following equation [31]:

(3)

(3)

With the addition of Bi, Sb and Sr, the polarization resistance, Rp decreases from 47.8 for the base alloy to 30.4, 34.2 and 21 kΩ·cm2, respectively. The decrease in polarization resistance of the treated alloys is attributed to the increase of boundaries between Al and Si particles, when compared with the base alloy. When 0.04% Sr (mass fraction) is added to the base alloy, the corrosion potential shifts to a more negative direction (-748.1 mV), and corrosion current density increases to 1.76 μA/cm2. However, in the absence of linearity in polarization curves, it is impossible to precisely assess the Tafel slope by way of the Tafel extrapolation of the anodic and cathodic branches. Hence, there is an uncertainty and source error in the numerical values of βa, βc and Jcorr calculated by the power suit software [32]. The corrosion current density, Jcorr (mA/cm2) is related to the corrosion rate, Pi, using the following equation [33]:

Pi=22.85Jcorr(4)

Therefore, the calculated corrosion rate (Pi) of the Al-11Si-2Cu-0.8Zn alloy is found to be in the following order: Pi(AB)

i(TSb)< Pi(TBi) < Pi(TSr).

Fig. 7 Potentiodynamic polarization curves of base alloy and Bi-, Sb- and Sr-treated alloys

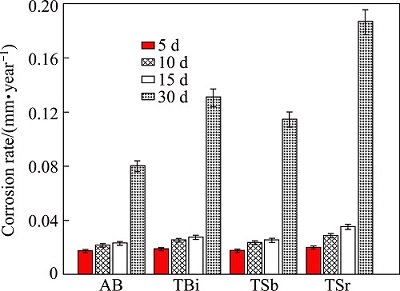

Figure 8 shows the average mass loss of Al-11Si-2Cu-0.8Zn as a function of various additions (Bi, Sb and Sr) in 0.5 mol/L H2SO4 solution for 5, 10, 15 and 30 d, respectively. The corrosion rates of all alloys increase with increasing immersion time in the first five days. Increasing the exposure time to 15 d increases the corrosion rate for the treated alloys, with a reduced slope compared with five-day exposure.

Table 2 Electrochemical parameters of base alloy and treated alloys in H2SO4 solution attained from polarization test

Fig. 8 Corrosion rates obtained by mass loss of base alloy and treated alloys as function of immersion durations of 5, 10, 15 and 30 d, respectively

This can be ascribed to the reduced surface area of the alloy for the corrosion process to take place. In the first few days of the exposure time, a larger surface area is exposed to the solution, resulting in more reactions, and thus increasing the corrosion rate. However, a longer immersion period led to the formation of protective films from the corrosion product on the surface of the alloys. This film prohibits direct contact of the specimens with the solution, hence reducing the corrosion rate of the alloys. However, the corrosion rates of all alloys increase with a prolonged exposure of 30 d. This can be ascribed to the non-uniform deposit film produced. Thus, fresh substrate is exposed to the corrosive solution, which leads to significant mass loss. The AB alloy shows a lower mass loss (0.080 mm/year) compared with the other alloys after exposure to H2SO4 solution for 30 d. The mass loss of the TBi alloy is approximately two times as high as that of AB alloy, indicating a serious corrosion attack on the Bi-treated alloy. The addition of Sr to the base alloy leads to an increase in the corrosion rate to the highest value, 0.186 mm/year. However, the TSb alloy shows a lower corrosion rate (0.114 mm/year) than the other treated alloys. This could be attributed to the effect of Sr on the density of eutectic Si particle, which is compared to that of the TBi and TSb alloys. Therefore, Sr provides more boundaries of Al/Si compared with the other additions, which leads to the decreased corrosion resistance of the base alloy.

It seems that there is a good relationship among the eutectic Si appearance, mechanical properties and corrosion rate of alloys after the addition of Bi, Sb, and Sr. As shown in Fig. 9, after the element addition to the base alloy, the flake-like Si morphology changes to a more refined and/or modified structure, which translates in a decrease in the size and aspect ratio of Si particles. As a result, a lower stress would be imposed by the Al matrix, which reduces the tendency for cracking. Hence, the Q value increases from 102 to 164.7 MPa and the performance of alloy is improved. In addition, the change in Si size causes an increase in the density of Si particles, providing more boundaries between the Al-rich phase and Si particles during growth from the melt. Because boundaries are more susceptible to corrosion attack, they causes a deleterious effect on the corrosion resistance of the alloy [34]. Consequently, the corrosion rate increases from 0.011 to 0.040 mm/year.

Fig. 9 Relationship among eutectic Si structure, ultimate tensile strength, and corrosion rate for base alloy and treated alloys

4 Conclusions

1) The application of Al-Si cast alloy is often restricted due to coarse Si particles. Therefore, the addition of elements in order to modify or refine the microstructure is of great importance to improve mechanical properties. In order to achieve a desired level of final properties, the correlation of microstructural changes with mechanical properties and corrosion behavior can be very useful for planning the manufacturing process. The Al-11Si-2Cu-0.8Zn alloy was treated with separate addition of Bi, Sb and Sr.

2) The addition of Bi and Sb to the Al-11Si- 2Cu-0.8Zn alloy produces a refinement of the eutectic Si structure, whereas addition of Sr modifies it into fibrous morphology.

3) The impact toughness increases remarkably when the alloy is treated with element addition with the Sr-treated alloy doubling its toughness compared with the base alloy.

4) Sr-treated alloy shows significant increase in its tensile properties compared with the Bi- and Sb-treated alloys.

5) Polarization test shows that the addition of Bi, Sb and Sr causes the corrosion potential to shift to more negative values, resulting in an increase in the degradation rate of the alloys.

References

[1] TZENG Y C, WU C T, BOR H Y, HORNG J L, TSAI M L, LEE S L. Effects of scandium addition on iron-bearing phases and tensile properties of Al-7Si-0.6Mg alloys [J]. Materials Science and Engineering A, 2014, 593: 103-110.

[2] BIROL Y. Impact of grain size on mechanical properties of AlSi7Mg0.3 alloy [J]. Materials Science and Engineering A, 2013, 559: 394-400.

[3] ZHAO Q, HOLMEDAL B. The effect of silicon on the strengthening and work hardening of aluminum at room temperature [J]. Materials Science and Engineering A, 2013, 563: 147-151.

[4] SIEGFANZ S, GIERTLER A, MICHELS W, KRUPP U. Influence of the microstructure on the fatigue damage behaviour of the aluminium cast alloy AlSi7Mg0.3 [J]. Materials Science and Engineering A, 2013, 565: 21-26.

[5] SHIN S S, KIM E S, YEOM G Y, LEE J C. Modification effect of Sr on the microstructures and mechanical properties of Al-10.5Si-2.0Cu recycled alloy for die casting [J]. Materials Science and Engineering A, 2012, 532: 151-157.

[6] TIMPEL M, WANDERKA N, SCHLESIGER R, YAMAMOTO T, LAZAREV N, ISHEIM D, SCHMITZ G, MATSUMURA S, BANHART J. The role of strontium in modifying aluminium-silicon alloys [J]. Acta Materialia, 2012, 60(9): 3920-3928.

[7] ZHANG X H, SU G C, JU C W, WANG W C, YAN W L. Effect of modification treatment on the microstructure and mechanical properties of Al-0.35%Mg-7.0%Si cast alloy [J]. Materials and Design, 2010, 31(9): 4408-4413.

[8] LIU G L, SI N C, SUN S C, WU Q F. Effects of grain refining and modification on mechanical properties and microstructures of Al-7.5Si-4Cu cast alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 946-953.

[9] MARZOUK M, JAIN M, SHANKAR S. Effect of Sr-modification on the bendability of cast aluminum alloy A356 using digital image correlation method [J]. Materials Science and Engineering A, 2014, 598: 277-287.

[10] DAHLE A K, NOGITA K, ZINDEL J W, MCDONALD S D, HOGAN L M. Eutectic nucleation and growth in hypoeutectic Al-Si alloys at different strontium levels [J]. Metallurgical and Materials Transactions A, 2001, 32: 949-960.

[11] HEGDE S, PRABHU K N. Modification of eutectic silicon in Al-Si alloys [J]. Journal of Materials Science, 2008, 43(9): 3009-3027.

[12] MACHOVEC C J, BYCZYNSKI G E, ZINDEL J W, GODLEWSKI L A. Effect of Bi-Sr interactions on Si morphology in a 319-type aluminum alloy [J]. AFS Transactions, 2000, 108(76): 439-444.

[13] FARAHANY S, OURDJINI A, IDRIS M H, THAI L T. Effect of bismuth on the microstructure of unmodified and Sr-modified Al-7%Si-0.4Mg alloy [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(6): 1455-1464.

[14] SHABESTARI S G, SHAHRI F. Influence of modification, solidification conditions and heat treatment on the microstructure and mechanical properties of A356 aluminum alloy [J]. Journal of Materials Science, 2004, 39: 2023-2032.

[15] YANG C Y, LEE S L, LEE C K, LIN J C. Effects of Sr and Sb modifiers on the sliding wear behavior of A357 alloy under varying pressure and speed conditions [J]. Wear, 2006, 261: 1348-1358.

[16] OSORIO W R, GARCIA L R, GOULART P R, GARCIA A. Effects of eutectic modification and T4 heat treatment on mechanical properties and corrosion resistance of an Al-9wt%Si casting alloy [J]. Materials Chemistry and Physics, 2007, 106: 343-349.

[17] FARAHANY S, OURDJINI A, IDRIS M H. The usage of computer-aided cooling curve thermal analysis to optimize eutectic refiner and modifier in Al-Si alloys [J]. Journal of Thermal Analysis and Calorimetry, 2012, 109(1): 105-111.

[18] FARAHANY S, OURDJINI A, IDRSI M H, SHABESTARI S G. Evaluation of the effect of Bi, Sb, Sr and cooling condition on eutectic phases in an Al-Si-Cu alloy (ADC12) by in situ thermal analysis [J]. Thermochimica Acta, 2013, 559: 59-68.

[19] DJURDJEVIC M, JIANG H, SOKOLOWSKI J H. On-line prediction of aluminum-silicon eutectic modification level using thermal analysis [J]. Materials Characterization, 2001, 46: 31-38.

[20] NOGITA K, YASUDA H, YOSHIDA K, UESUGI K, TAKEUCHI A, SUZUKI Y, DAHLE A K. Determination of strontium segregation in modified hypoeutectic Al-Si alloy by micro X-ray fluorescence analysis [J]. Scripta Materialia, 2006, 55(9): 787-790.

[21] PRASADA RAO A K, DAS K, MURTY B S, CHAKRABORTY M. On the modification and segregation behavior of Sb in Al-7Si alloy during solidification [J]. Materials Letters, 2008, 62: 2013-2016.

[22] DAHLE A K, NOGITA K, McDONALD S D, DINNIS C, LU L. Eutectic modification and microstructure development in Al-Si alloys [J]. Materials Science and Engineering A, 2005, 413-414: 243-248.

[23] KOIKE J, MIKI K, TAKAHASHI H, MARUYAMA K. Effects of the liquid phase on tensile elongation of Al-Bi alloy [J]. Materials Science and Engineering A, 2000, 285(1-2): 158-164.

[24] ANAWATI H, NORDMARK H, DIPLAS S, WALMSLEY J C, NISANCIOGLU K. Surface segregation of trace element bismuth during heat treatment of aluminum [J]. Journal of the Electrochemical Society, 2012, 159(3): C137-C145.

[25] FARAHANY S, OURDJINI A, BAKAR T, IDRIS M. On the refinement mechanism of silicon in Al-Si-Cu-Zn alloy with addition of bismuth [J]. Metallurgical and Materials Transactions A, 2014, 45(3): 1085-1088.

[26] LEE C D. Variability in the impact properties of A356 aluminum alloy on microporosity variation [J]. Materials Science and Engineering A, 2013, 565: 187-195.

[27] DOGLIONE R. In situ investigations on the ductility of an Al-Si-Mg casting alloy [J]. JOM, 2012, 64(1): 51-57.

[28] DROUZY M, JACOB S, RICHARD M. Interpretation of tensile results by means of quality index and probable yield strength [J]. AFS International Cast Metals, 1980, 5: 43-50.

[29] CLOSSET B, GRUZLESKI J. Mechanical properties of A356.2 alloys modified with pure strontium [J]. AFS Transactions, 1982, 90: 453-464.

[30] LEE S L, CHENG Y C, CHEN W C, LEE C K, TAN A H. Effects of strontium and heat treatment on the wear-corrosion property of Al-7Si-0.3Mg alloy [J]. Materials Chemistry and Physics, 2012, 135(2-3): 503-509.

[31] ARRABAL R, PARDO A, MERINO M C, MOHEDANO M, CASAJUS P, PAUCAR K, GARCES G. Effect of Nd on the corrosion behaviour of AM50 and AZ91D magnesium alloys in 3.5wt.% NaCl solution [J]. Corrosion Science, 2012, 55: 301-312.

[32] SHI Z, ATRENS A. An innovative specimen configuration for the study of Mg corrosion [J]. Corrosion Science, 2011, 53(1): 226-246.

[33] BAKHSHESHI RAD H R, ABDUL-KADIR M R, IDRIS M H, FARAHANY S. Relationship between the corrosion behavior and the thermal characteristics and microstructure of Mg–0.5Ca–xZn alloys [J]. Corrosion Science, 2012, 64: 184-197.

[34] OSORIO W R, CHEUNG N, SPINELLI J, GOULART P, GARCIA A. The effects of a eutectic modifier on microstructure and surface corrosion behavior of Al-Si hypoeutectic alloys [J]. Journal of Solid State Electrochemistry, 2007, 11(10): 1421-1427.

Saeed FARAHANY1, Ali OURDJINI2, Hamid Reza BAKHSHESHI-RAD3

1. Department of Materials and Mechanical Engineering, Buein Zahra Technical University, Qazvin 3451745346, Iran;

2. Department of Mechanical Engineering, Faculty of Engineering, University of Ottawa,

Ottawa, 161 Louis Pasteur, KIN 6N5, Canada;

3. Department of Materials, Manufacturing and Industrial Engineering, Faculty of Mechanical Engineering,

Universiti Teknologi Malaysia (UTM), Johor Bahru 81310, Malaysia

摘 要:研究经Bi、Sb和Sr改性的Al-11Si-2Cu-0.80Zn压铸铝合金的显微组织演变、力学性能和腐蚀行为。力学性能测试结果表明,Bi、Sb和Sr的添加引起合金中共晶Si形貌发生改变,从而使合金的冲击韧性、极限抗拉强度和伸长率增加。断裂表面分析结果表明,添加Sr或少量Bi和Sb,合金表面呈韧性断裂,而非准解理脆性断裂。此外,添加Sr、Bi和Sb后,合金的质量指标由基体合金的102 MPa分别增加到164.7 MPa、156.3 MPa和152.6 MPa。在NaCl溶液中的极化腐蚀测试结果表明,分别添加Sb、Bi和Sr后,合金的腐蚀电位负移。浸泡腐蚀实验结果表明,由于Al和Si共晶相界面的增加,Sb、Bi和Sr元素的添加对合金的腐蚀速率具有决定性作用。

关键词:压铸铝合金;熔体处理;力学性能;断裂;腐蚀

(Edited by Wei-ping CHEN)

Corresponding author: Saeed FARAHANY; Tel: +60-127686357; Fax: +60-75566159; E-mail: saeedfarahany@gmail.com; farahany@bzte.ac.ir

DOI: 10.1016/S1003-6326(16)64085-2