浮动式动力卡盘静态夹持特性分析

王健健1,张建富1,冯平法1,徐万洪2

(1. 清华大学 机械工程系 摩擦学国家重点实验室,北京,100084;

2. 浙江万里扬变速器股份有限公司,浙江 金华,321025)

摘要:通过建立夹紧效率和夹持补正量的数学模型,对浮动式动力卡盘的静态夹持特性进行研究。研究结果表明:卡盘的夹紧效率不仅直接影响力传递系数,而且影响静态夹紧力的稳定性;夹紧效率越高的结构,由于润滑环境恶化而造成的静态夹紧力损失越小;浮动式动力卡盘在工作时,所夹持的工件的直径越小,卡盘的夹紧效率越低;浮动式动力卡盘的夹持补正量与杠杆传动比、浮动套和导套之间的配合间隙成正比,比例系数是浮动套的楔角和杠杆两臂的夹角的函数;通过建立浮动式动力卡盘的运动传递系数和夹持补正量之间数学关系,对浮动式卡盘的夹紧和补偿2个功能进行综合,实现浮动式卡盘的优化设计。

关键词:浮动式动力卡盘;静态夹持特性;夹紧效率

中图分类号:TP24 文献标志码:A 文章编号:1672-7207(2014)06-1847-07

Static clamping characteristics analysis of power-operated compensating chuck

WANG Jianjian1, ZHANG Jianfu1, FENG Pingfa1, XU Wanhong2

(1. National Tribology Laboratory, Department of Mechanical Engineering, Tsinghua University, Beijing 100084, China;

2. Zhejiang Wanliyang Transmission Co., Ltd., Jinhua 321025, China)

Abstract: In order to study the static clamping characteristics of power-operated compensating chuck, a mathematic model for the clamping efficiency and compensating dosage of the chuck was developed. The investigation performed shows that the clamping efficiency of chuck not only directly affects the coefficient of force transfer but also the stability of static clamping force against the deterioration of the lubrication. The chuck structure which has a higher clamping efficiency will have a fewer static clamping force loss caused by the enlargement of friction. While the compensating chuck is working, the smaller the diameter of workpiece chucked is, the lower the clamping efficiency will be. The compensating dosage is proportional to the product of lever ratio and the clearance space between the floating sleeve and the guide bushing, and its proportion depends on the wedge angle of floating sleeve and the angle between the two arms of lever. Based on the establishment of mathematical relationship between the coefficient of force transfer and compensating dosage, the optimized design method for floating chuck is put forward considering fully the realization of clamping and compensating function.

Key words: power-operated compensating chuck; static clamping characteristics; clamping efficiency

在数控机床上,为降低辅助夹紧时间和实现自动夹紧,以液压、气压和电磁为动力的动力卡盘得到广泛应用[1-2]。随着主轴系统转速与精度的提高[3]以及刀具系统的快速发展[4],动力卡盘发展滞后,这已成为数控机床发展的瓶颈[5]。而新型切削技术的发展特别是高速切削[6]、硬切削[7]技术的发展,对动力卡盘的性能提出了更高的要求[8]。动力卡盘的静态夹持特性包括夹紧效率[9]、静态夹持精度[10]等重要的性能指标,影响着数控机床的工作安全性和加工精度[11-12]。围绕动力卡盘的静态夹持特性,国内外学者进行了大量研究,研究对象主要集中在传统的楔式定心动力卡盘[13-14],对于具有特殊结构[15-16]的动力卡盘的研究却很少见诸文献。动力卡盘的静态夹持特性与其夹紧系统的结构有关,楔式定心卡盘的研究成果不能直接应用于其他结构的动力卡盘的设计和应用中。因此,系统地研究特殊动力卡盘的静态夹持特性对其优化设计和应用具有重要意义。浮动式动力卡盘是一种典型的特殊动力卡盘,相对于定心卡盘而言,由于具有特殊的结构,浮动式卡盘的3个爪能够实现不同步运动,这样就使其具有了补偿功能,能够夹持中心顶尖定位的形状不规则工件。由于使用中心顶尖定位,浮动式动力卡盘能有效提高轴类锻铸工件的机加工精度。对于浮动式动力卡盘,夹紧效率和夹持补正量是其2个主要的静态夹持特性指标。本文作者通过建立浮动式动力卡盘夹紧效率和夹持补正量的数学模型,对浮动式动力卡盘的静态夹持特性进行研究,分析夹紧传动机构的摩擦因素、卡盘的结构参数、夹持位置等对夹紧效率的影响,并明确夹持补正量与卡盘的结构参数的关系。根据理论研究结果,综合考虑浮动式卡盘的夹紧和补偿2个功能的实现,提出浮动式动力卡盘的设计方法,对浮动式动力卡盘的优化设计和应用具有指导意义。

1 浮动式动力卡盘的工作原理

浮动式动力卡盘的关键零部件主要包括:盘体、顶尖、导套、中心轴、浮动套、杠杆、基爪、高爪等,其结构示意图如图1所示。

浮动式动力式卡盘使用中心顶尖对工件进行中心定位,同时安装在顶尖上的定位块能够对工件进行端面定位。导套与中心轴通过间隙配合实现导套的轴向运动,从而带动浮动套轴向运动。浮动套的轴向运动通过楔面-杠杆系统传递给基爪,使基爪实现径向运动,从而带动安装在基爪上的高爪夹紧工件。浮动套和导套之间的径向间隙,使浮动套能够径向浮动,浮动套的径向浮动最终通过楔面-杠杆系统体现为3个高爪一定程度的不同步运动,从而使卡盘具有补偿功能,能够夹持一些不太规则的特殊工件。

图1 浮动式动力卡盘结构和部件

Fig. 1 Structure and elements of compensating chuck

2 夹紧效率的研究

卡盘的夹紧效率η可通过以下公式来计算:

η=kFkL (1)

式中:kF为卡盘的力传递系数,可通过静态夹紧力与输入推拉力的比值来获得;kL为卡盘的运动传递系数,是卡盘结构参数的函数,可通过卡盘夹紧工件时高爪的径向速度与拉杆的轴向速度的比值来获得。

在一般情况下,卡盘的静态夹紧力是根据轴向动力和生产商给出的kF来确定,而对于特定的卡盘kL是一定的,由式(1)可知,卡盘的夹紧效率会直接影响到静态夹紧力;当卡盘的结构参数相同时,kL不变,此时机械效率越高,力传递系数越大;夹紧系统的摩擦因素相同时,机械效率越高的结构,kF的刚性越大,静态夹紧力在摩擦因素变化时的稳定性越好。动力卡盘在设计时不仅要求较大的力传递系数,而且要求力传递系数的保持性好,即静态夹紧力的稳定性高,能够尽量减小难控制因素(摩擦)的不利影响。

2.1 夹紧效率的数学模型

图2所示为浮动式动力卡盘的夹紧传动系统的几何模型图,以及浮动套和杠杆的受力示意图。图2中的中心虚线表示卡盘浮动套的中心轴线,点O表示杠杆的支轴线,点A表示杆杠与基爪直槽接触的圆柱的轴线,点B表示杠杆上与浮动套楔面接触的圆柱的轴线,点C1表示基爪直槽面和杠杆上臂的接触点,点C2表示杠杆与和浮动套的接触点,点C3表示杠杆支轴对杠杆正压力合力的作用点。坐标系xOy的x轴与中心虚线平行。D点的横坐标x表示浮动套的轴向位移,A点的纵坐标y表示高爪的径向位移。浮动式动力卡盘通过楔面-杠杆系统将浮动套受到的轴向动力Fa传递给卡爪,使卡爪产生对工件的夹紧力Fcm。摩擦是造成卡盘夹紧功率损失的主要因素,在浮动式动力卡盘的夹紧传动系统中存在着3组摩擦表面,即滑座直槽面、楔面、杠杆支轴面,分别以μ1,μ2和μ3表示3个摩擦面的摩擦因素。

图2 浮动式卡盘几何模型

Fig. 2 Geometric model of compensating chuck

根据几何关系可得卡盘的运动传递系数为

(2)

(2)

式中:

(3)

(3)

根据力平衡关系,可得卡盘的力传递系数为

(4)

(4)

式中:f为11元函数;y度量卡盘的夹紧位置;α,β,a,b和ri为卡盘的结构参数;摩擦因素μi与润滑条件有关。

2.2 夹紧效率特征

2.2.1 夹紧位置和摩擦因素对夹紧效率的影响

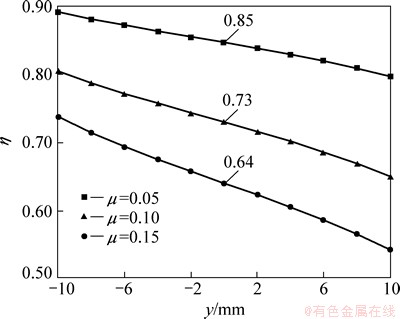

采用控制变量法,各结构参数的取值分别为:α=20°,β=155°,a=20,b=36,r1=17,r2=26,r3=10。当μ1=μ2=μ3=μ时,得到夹持位置与夹紧效率的关系如图3所示。

从图3可见:在不同的夹持位置处,夹紧效率不同;随着y的增大,夹紧效率逐渐减小;摩擦因素越大,夹紧效率减小得越快。浮动式动力卡盘在设计和使用时,可采用适当调整高爪与基爪的相对位置等方法,使夹紧位置y尽量小。另外,考虑到基爪直槽面与杠杆接触点C1在y=0时处于极限位置,此时基爪直槽面强度最强,卡盘的设计工作位置可以选在y等于0或y略小于0附近。

采用控制变量法,结构参数的取值不变,当卡盘的工作位置选在y=0时,得到不同摩擦面的摩擦因素位置与夹紧效率的关系如图4所示。

图3 夹持位置与夹紧效率的关系

Fig. 3 Relationship between clamping position and clamping efficiency

图4 摩擦因素与夹紧效率的关系

Fig. 4 Relationship between friction coefficient and clamping efficiency

从图4可见:在脂润滑摩擦因素μ=0.05~0.2范围内,浮动式动力卡盘的夹紧效率在57%到85%范围内变化。不同摩擦面的摩擦因素对卡盘夹紧效率的影响大小不同,其中滑座直槽面和杠杆支轴面处的摩擦因素对夹紧效率的影响基本相同,楔面处摩擦因素对夹紧效率的影响较大。在浮动式动力卡盘的使用中要特别注意对楔面处的润滑,并辅助以一定的热处理方法加强2个接触面的耐磨性。

2.2.2 卡盘结构参数对夹紧效率的影响

从式(1),(2)和(4)可知:浮动式卡盘的夹紧效率与其结构参数α,β,a,b和ri有关,涉及浮动套和杠杆2个零件的设计,合力的对卡盘的结构参数进行配置,也是减少夹紧效率损失的一种有效方法。

采用控制变量法,杠杆的各结构参数取值分别为:β=155°,a=20,b=36,r1=17,r2=26,r3=10。当卡盘的工作位置选在y=0,且μ1=μ2=μ3=μ时,得到浮动套的楔角α与夹紧效率的关系如图5所示。

图5 楔角与夹紧效率和力传递系数的关系

Fig. 5 Relationship among wedge angle, clamping efficiency and force transfer coefficient

图5中呈增长趋势的3条曲线表示楔角α与夹紧效率的关系,呈下降趋势的曲线表示μ=0.05时,楔角α与力传递系数的关系。从图5可见:浮动式动力卡盘的夹紧效率随着浮动套的楔角的增大而增大,但是增长速度逐渐减小,在α>30°后增长不明显;α越大,摩擦因素对夹紧效率的影响越小,静态夹紧力的稳定性越好。同时,浮动式动力卡盘的力传递系数随着浮动套的楔角的增大而减小,减小速度逐渐减慢。浮动套楔角的过大,则会导致力传递系数过小,不能产生足够大的静态夹紧力;过小则会放大摩擦对卡盘夹紧效率的影响,影响静态夹紧力的稳定性。因此,在设计楔角α的大小时,要综合考虑其对力传递系数的大小和静态夹紧力稳定性的影响。

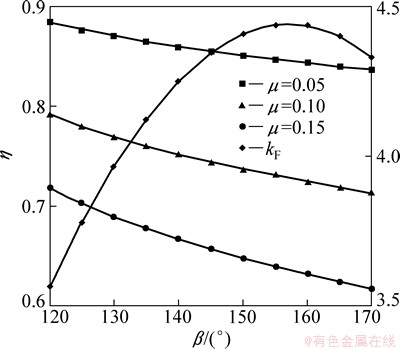

采用同样的方法(α=20°),得到杠杆两臂的夹角β与夹紧效率和力传递系数的关系如图6所示。

图6中呈下降趋势的3条曲线表示β与夹紧效率的关系,形状呈拱形的曲线表示μ=0.05时,β与力传递系数的关系。从图6可见:浮动式动力卡盘的夹紧效率随着β的增大而减小;β越小,摩擦因素对夹紧效率的影响越小,静态夹紧力的稳定性越好。同时,浮动式动力卡盘的力传递系数随着浮动套的楔角的增大先增大后减小,在β≈155°时达到峰值。设计时β过小,则会导致力传递系数过小,不能产生足够大的静态夹紧力;过大则会放大摩擦对卡盘夹紧效率的影响,影响静态夹紧力的稳定性。因此,在设计楔角β的大小时,要综合考虑其对力传递系数和静态夹紧力稳定性的影响。

图6 β与夹紧效率和力传递系数的关系

Fig. 6 Relationship between β, clamping efficiency and force transfer coefficient

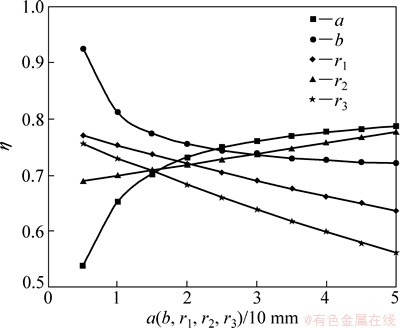

采用以上相同的方法,线性大小以10 mm为1个单位,初值取值如下:a=2,b=3.6,r1=1.7,r2=2.6,r3=1。当 μ=0.1时,得到杠杆的线性大小参数对夹紧效率的影响如图7所示。

从图7可见:浮动式卡盘的杠杆的两臂长度对夹紧效率具有较大影响,夹紧效率随着两臂长度比b/a的增大而减小,因此,在设计时中应该避免使用过大的杠杆比,虽然大的杠杆比有利于增大力传递系数,但是,不利于力传递系数的稳定性的提高;;另外,减小r1和增大r2都有利于夹紧效率的提高。杠杆轴的直径对夹持效率影响较大,设计时应在保证其强度足够的前提下,尽量选用较小的杠杆轴直径。

图7 杠杆的线性大小参数与夹紧效率的关系

Fig. 7 Relationship between lever parameter and clamping efficiency

3 夹持补正量的研究

由于浮动套与导套之间存在毫米量级的间隙,浮动式动力卡盘具有夹持中心顶尖定位的不太规则的轴类工件的能力,使用夹持补正量来度量这种补偿能力。

3.1 夹持补正量的数学模型

为便于问题的研究,设浮动套轴向位移为x时,浮动套才开始径向窜动,其几何模型如图8所示。

图8 补偿量数学模型示意图

Fig. 8 Model of compensating dosage

图8中的3条虚线表示3个杠杆的支轴线;点E表示浮动套在径向浮动之前的中心轴线位置,此时浮动套的中心轴线盘体的中心轴线重合;点G表示夹持中心定位的工件时,浮动套径向浮动后的中心轴线位置;d0表示盘体的中心轴线与3个杠杆的支轴线的距离;di(i=1,2,3)表示浮动套径向浮动后的中心轴线与杠杆i的支轴线的距离;以E为圆心,以R为直径的圆表示浮动套径向浮动时,其轴线的运动范围;2R等于浮动套的内径与导套的外径之差。

在点E处建立子坐标系x0Ey0,设点G在子坐标系上的坐标为(kcost,ksint),k∈[0,R],t∈[0,2π),利用点到直线的距离公式得

,i=1,2,3 (5)

,i=1,2,3 (5)

浮动卡盘的具体补偿量不仅与浮动套轴向位置有关,而且与其径向浮动后位置有关。要分析此问题,可以首先控制浮动套的轴向位置不动,让浮动套在径向任意浮动,然后对补偿效果进行统计。

浮动套径向浮动后,3个楔面-杠杆系统的参数d变为di,θ变为θi,y变为yi,得

(6)

(6)

假设某次夹持时的实际夹持补正量为

(7)

(7)

易证:当 ,n=1,2,…,6,且k=R时,δ(y,yi)有最大补正量δmax(y)。δmax(y)度量了该卡盘补偿能力。δmax(y)的函数图像如图9所示。

,n=1,2,…,6,且k=R时,δ(y,yi)有最大补正量δmax(y)。δmax(y)度量了该卡盘补偿能力。δmax(y)的函数图像如图9所示。

图9 δmax(y)的函数图像

Fig. 9 Graph of δmax(y)

从图9可见:最大补正量δmax随着y的增大而减小,且有 ,在不同夹持位置处的最大补正量变化不大;同时,浮动式动力卡盘的设计工作位置一般选在y=0附近,因此,可以取 δmax(0)为浮动卡盘的补正量设计指标,称为设计补正量。由式(6)和(7)可得δmax(0)与α,β,a和R/b有函数关系,表示为

,在不同夹持位置处的最大补正量变化不大;同时,浮动式动力卡盘的设计工作位置一般选在y=0附近,因此,可以取 δmax(0)为浮动卡盘的补正量设计指标,称为设计补正量。由式(6)和(7)可得δmax(0)与α,β,a和R/b有函数关系,表示为

(8)

(8)

式中:g是三元函数符号。

3.2 夹持补正量特征

3.2.1 R/b对设计补正量δmax(0)的影响

在α=20°,β=155°,a=20时,研究R/b对设计补正量δmax(0)的影响,得到两者关系如图10所示。

从图10可见:R/b与δmax(0)具有很强的线性相关性

(9)

(9)

v为二元函数符号。

图10 R/b对δmax(0)的影响

Fig. 10 Effect of R/b on δmax(0)

3.2.2 α和β对设计补正量δmax(0)的影响

α和β对主要通过对v(α,β)的影响来影响设计补正量δmax(0),如图11所示。

图11 α和β对δmax(0)的影响示意图

Fig. 11 Effect of α and β on δmax(0)

从图11可见:随着α和β的同时增大,设计补正量逐渐减小,减小的速度先增大后减小,呈现明显的瀑布现象;在瀑布处,α和β的稍微变化都能引起设计补正量的较大变化。在设计应该尽量避免α和β选值在瀑布附近,以防止α和β的稍微休正导致设计补正量指标不能满足。

4 浮动式动力卡盘的设计方法

浮动式动力卡盘要同时满足夹紧和补偿2个主要功能,在设计过程中必须综合考虑各个变量的数量关系,对其进行合理配置。

浮动式卡盘主要有2个设计指标:y=0时的运动传递系数kL0和设计补正量δmax(0)。

由式(2)得

(10)

(10)

式中: ,可制成表方便查阅。

,可制成表方便查阅。

又由式(9)得

(11)

(11)

式中: ,可通过统计法求出。表1所示为

,可通过统计法求出。表1所示为 ,

, 时,求得的不同α和β取值对应的λ2,范围内的λ2其他取值可以用插值法求得。

时,求得的不同α和β取值对应的λ2,范围内的λ2其他取值可以用插值法求得。

表1 λ2与α和β对应的取值

Table 1 λ2 values corresponding to α and β

由式(10)和(11),可得

(12)

(12)

式(12)将代表浮动式卡盘夹紧功能的设计指标kL0和补偿功能的设计指标δmax(0)之间的关系建立起来。综合考虑夹紧效率等因素,得到浮动式动力卡盘的参考设计步骤如下:

(1) 根据工况确定期望的力传递系数kF0 (y=0),机械效率η取0.6~0.8,由式(1)确定设计指标kL0;根据所夹持工件的不规则程度确定设计指标δmax(0)。

(2) 在 ,

, 的范围内任选α和β,从而获得λ1和λ2。

的范围内任选α和β,从而获得λ1和λ2。

(3) 由给定设计指标kL0和δmax(0),根据式(12)确定浮动套和导套之间配合间隙的一半R。

(4) 由式(10)确定a/b,根据卡盘的轴向尺寸约束( )对a和b进行分配。

)对a和b进行分配。

(5) 根据a和b,考虑结构的强度和美观性,初步选择ri,由式(4)计算力传递系数kF0(μ=0.1)是否足够,若不够,则调整ri,直到计算获得的kF0足够大为止。

5 结论

(1) 浮动式卡盘的夹紧效率不仅直接影响力传递系数,而且影响静态夹紧力的稳定性;夹紧效率高的结构由润滑状态恶化造成的静态夹紧力损失小。

(2) 浮动式卡盘的夹紧效率除了与摩擦有关,也与卡盘的结构参数有关。对于同一卡盘,所夹持工件的直径越小,夹持效率越低;不同接触面的摩擦对卡盘夹持效率的影响不同,其中楔面处的摩擦影响最大;增大浮动套的楔角、杠杆两臂的夹角以及杠杆与楔面相切圆直径,减小杠杆轴直径、基爪直槽相切圆直径以及杠杆比,都有利于减小夹持效率的损失;适宜的杠杆两臂的夹角,可以实现力传递系数最大。

(3) 浮动式卡盘补正量与杠杆比、浮动套与导套的配合间隙成正比,比例系数与浮动套的楔角和杠杆两臂的夹角有关。

(4) 建立了代表浮动式卡盘夹紧功能的运动传递系数和代表补偿功能的补正量之间数学关系,综合考虑浮动式卡盘的夹紧和补偿2个功能的实现,提出了浮动式卡盘的优化设计方法。

参考文献:

[1] ZHOU Cheng, YANG Huayong, YANG Likui, et al. Piecewise model and experiment of power chuck’s gripping force loss during high speed turning[J]. Science China Technological Sciences, 2011, 54(4): 972-982.

[2] S lter J, Grote C, Brinksmeier E. Influence of clamping strategies on roundness deviations of turned rings[J]. Machining Science and Technology, 2011, 15(3): 338-355.

lter J, Grote C, Brinksmeier E. Influence of clamping strategies on roundness deviations of turned rings[J]. Machining Science and Technology, 2011, 15(3): 338-355.

[3] 胡志栋, 姜集海, 戴达军, 等. 动力卡盘对数控机床加工精度的影响[J]. 现代制造工程, 2009(8): 4-9.

HU Zhidong, JIANG Jihai, DAI Dajun, et al. Research on the effect of power chuck on the machining precision of numerical control machine tool[J]. Modern Manufacturing Engineering, 2009(8): 4-9.

[4] Kurtoglu A, Sohlenius G. The accuracy improvement of machine tools[J]. CIRP Annals-Manufacturing Technology, 1990, 39(1): 417-419.

[5] Ema S, Marui E. Chucking performance of a wedge-type power chuck[J]. Journal of Engineering for Industry, 1994, 116(1): 70-77.

[6] 艾兴. 高速切削加工技术[M]. 北京: 国防工业出版社, 2003: 196-197.

AI Xing. High speed machining technology[M]. Beingjing: National Defence Industry Press, 2003: 196-197.

[7] Liu C R, Mittal S. Single-step superfinish hard machining: Feasibility and feasible cutting conditions[J]. Robotics and Computer-Integrated Manufacturing, 1996, 12(1): 15-27.

[8] Byun J, Liu C R. Improving chucking accuracy and repeatability by reducing kinematic redundancy[J]. Journal of Manufacturing Science and Engineering, 2010, 132(6): 064501-064505.

[9] 冯平法, 郁鼎文, 吴志军. 楔面动力卡盘夹紧效率特性研究[J]. 工具技术, 2007, 41(7): 17-19.

FENG Pingfa, YU Dingwen, WU Zhijun. Clamping efficiency of power-operated wedge hook chuck[J]. Tool Engineering,2007, 41(7): 17-19.

[10] 王健健, 张建富, 冯平法, 等. 楔式动力卡盘静态夹持精度建模与综合[J]. 西安交通大学学报, 2013, 47(3): 90-95.

WANG Jianjian, ZHANG Jianfu, FENG Pingfa, et al. Modeling and optimizing of static chucking accuracy of power-operated wedge hook chuck[J]. Journal of Xi’an Jiaotong University, 2013, 47(3): 90-95.

[11] Feng P F. An improved computation model for critical bending force of three-jaw chucks[J]. Journal of Materials Processing Technology, 2008, 208(1/3): 124-129.

[12] Byun J, Liu C R. Methods for improving chucking accuracy[J]. Transactions of the ASME-B-Journ Manufacturing Science Engineering, 2012, 134(5): 051004.

[13] 杨华勇, 周城. 自定心液压动力卡盘的研究综述[J]. 中国机械工程, 2007(2): 244-251.

YANG Huayong, ZHOU Cheng. Self-centering hydraulic power chuck: current status and trends[J]. China Mechanical Engineering, 2007, 18(2): 244-251.

[14] Thornley R H, Wilson B. A review of some of the principals involved in chuck design[J]. Production Engineer, 1972, 51(3): 87-97.

[15] 胡仲杰, 张利明, 邓小军, 等. 杠杆式液压卡盘的设计及应用[J]. 探矿工程(岩土钻掘工程), 2007, 34(11): 51-53.

HU Zhongjie, ZHANG Liming, DENG Xiaojun, et al. Design and application of lever typed hydraulic chuck[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 2007, 34(11): 51-53.

[16] 辛德忠, 龚宪生, 王清峰, 等. 基于负载自适应的煤矿用钻机卡盘动态夹紧理论[J]. 煤炭学报, 2013, 38(3): 498-504.

XIN Dezhong, GONG Xiansheng, WANG Qingfeng, et al. S Dynamic clamping theory of chuck used in collieries drilling rig based on load self-adaptation[J]. Journal of China Coal Society, 2013, 38(3): 498-504.

(编辑 邓履翔)

收稿日期:2013-06-18;修回日期:2013-08-15

基金项目:国家科技重大专项资助项目(20122X04002-061);摩擦学国家重点实验室基金资助项目(SKLT11C7)

通信作者:冯平法(1966-),男,河北石家庄人,博士,教授,从事高速切削技术的研究;电话:010-62794075;E-mail:fengpf@mail.tsinghua.edu.cn