文章编号:1004-0609(2010)04-0599-07

Mg-15Gd-3Y挤压合金的时效强化

张 磊1,董选普1,李继强2,王爱华1,罗 可1,樊自田1

(1. 华中科技大学 材料成形与模具技术国家重点实验室,武汉 430074;

2. 浙江大学 宁波理工学院 机电与能源工程分院,宁波 315100)

摘 要:研究时效处理对挤压态Mg-15Gd-3Y合金显微硬度及力学性能的影响,采用透射电镜对时效析出相的形态进行分析。结果表明:225 ℃、14 h时效时合金获得最高硬度,为135 HV,此时,晶内弥散析出许多纳米β′亚稳相,且与基体有着良好的共格匹配性,使合金获得较高强度和硬度,同时塑性降低;在225 ℃、70 h过时效作用下,纳米β′亚稳相原位长大成β稳定相,且与基体失去共格匹配性,降低合金的强度和硬度,同时塑性有所回升;合金的最高强度出现在200 ℃、100 h时效处,此时,抗拉强度达到446.67 Mpa,合金中的β′ 亚稳相呈蠕虫状,沿亚晶界分布,有效地阻碍亚晶界和位错的运动,从而强化合金。

关键词:镁合金;挤压镁合金;Mg-15Gd-3Y合金;时效强化;显微组织;力学性能

中图分类号:TG 166.4 文献标志码:A

Aging strengthening of squeezed Mg-15Gd-3Y alloy

ZHANG Lei1, DONG Xuan-pu1, LI Ji-qiang2, WANG Ai-hua1, LUO Ke1, FAN Zi-tian1

(1. State Key Laboratory of Material Forming and Mould & Die Designing,

Huazhong University of Science and Technology, Wuhan 430074, China;

2. School of Mechanical and Energy, Ningbo Institute of Technology, Zhejiang University, Ningbo 315100, China)

Abstract: The effects of aging on the Vickers hardness and mechanical properties of the squeezed Mg-15Gd-3Y alloy were investigated, and TEM was used to observe the microstructure of the precipitates. The results show that a maximum hardness of 135 HV can be attained when aged at 225 ℃ for 14 h. The alloy exhibits good strength and hardness but poor plasticity due to the precipitation of the nanoscale β′ metastable phase, which has good coherence with the matrix. The β′ phase transforms into the β stable phase in-situ, and becomes incoherent with the matrix when aged at 225 ℃ for 70 h. This induces the decline of the strength and hardness, and somewhat the recovery of the plasticity. The alloy achieves a maximum tensile strength of 446.67 MPa when aged at 200 ℃ for 100 h, and the β′ phase shows a shape of helminth and distributes along the subgrain boundaries. The β′ phase baffles the movement of the subgrain boundaries and dislocation effectively, and strengthens the alloy.

Key words: magnesium alloy; squeezed magnesium alloy; Mg-15Gd-3Y alloy; aging strengthening; microstructure; mechanical properties

镁合金因具有高的比强度和比刚度、良好的减震降噪性能、电磁屏蔽性能、机械加工性能和易于回收等优点,已被广泛应用于汽车和航空等领域中[1-2]。常用的Mg-Al系和Mg-Zn系合金的耐热温度均低于 200 ℃, 能在200 ℃以上得到应用的镁合金主要是稀土镁合金,在镁合金中加入稀土元素后能显著提高合金的强度和耐热温度[3]。由于镁稀土合金主要通过沉淀强化的机制达到强化的目的,因此,时效处理对合金强韧化的作用显得尤为重要。以往研究均证实了时效中期析出的亚稳相是该系合金强化的主要原因[4-8],但目前对此类合金时效各阶段析出相的形貌尤其是强化机制方面的研究还不够充分,对低温下长时间时效析出相的研究较少。本文作者以挤压态Mg-15Gd-3Y合金为研究对象,采用透射电镜研究时效对该合金析出相演变和力学性能的影响,着重分析200 ℃下长时间时效析出相的形态,以揭示析出相的强化机理。

1 实验

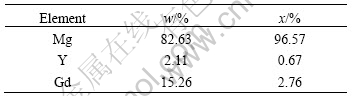

本研究所用合金的成分如表1所列。合金在电阻炉中熔炼浇注成锭后,先进行(520 ℃,8 h)的均匀化处理,并去除铸锭表面的氧化皮,用500 t的挤压机进行正向热挤压,挤压比(λ)为16?1,挤压速度为1 m/min,挤压温度在350~400 ℃的范围内。

表1 实验合金的化学成分

Table 1 Chemical composition of experimental alloy

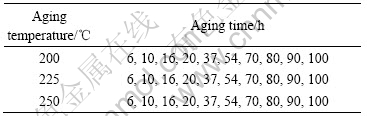

将加工好的试块置于箱式电阻炉中,然后放入油浴内进行时效,工艺方案如表2所列。试验中的所有温度以热电偶实测的油浴温度为准。

表2 挤压合金的时效处理工艺

Table 2 Aging parameters of squeezed alloy

时效后的试块经磨抛处理后,用2%盐酸水溶液腐蚀,用HV-1000显微硬度计测试显微硬度,载荷为9.8 N,保持30 s。用D8X型X射线衍射仪分析合金中的基本物相。用最大电压为200 kV JEM2100的高分辨透射电镜对时效后的析出相进行分析。

2 实验结果

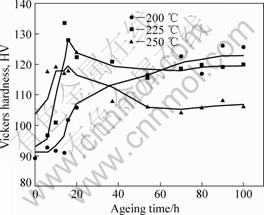

2.1 挤压合金的时效硬化规律

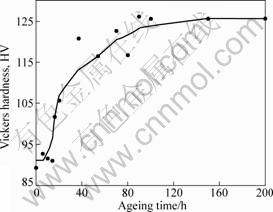

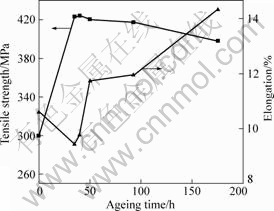

图1所示为合金在不同温度下的时效硬化曲线。由图1可以看出:在225 ℃时效时,到达硬度峰值的时间最短,约14 h后合金硬度达到最大值(135 HV),随后硬度值下降并逐渐趋于平缓;在250 ℃时效时,到达硬度峰值的时间相对于225 ℃时效时稍长且硬度值偏低,约20 h后到达硬度峰值(123.72 HV),随后硬度值下降并趋于平缓;在200 ℃低温时效时,时效早期硬度值上升缓慢且较低,但是随着时效时间的延长,硬度一直增大。实验中对200 ℃时效进行长时间(最长为200 h)处理,得出的硬化曲线如图2所示。由图2可知,在200 ℃时效时,在90 h左右达到硬度峰值126.09 HV,随后硬度值逐渐趋于平缓。综上所述可知,从时效硬化的角度讲,最佳时效工艺是(225 ℃,14~16 h)。

图1 不同温度时挤压态合金的时效硬化曲线

Fig.1 Aging curves of squeezed alloy at different temperatures

图2 200℃长时间时效后挤压态合金的硬化曲线

Fig.2 Aging curve of squeezed alloy at 200 ℃ for long time

2.2 挤压合金时效后的力学性能

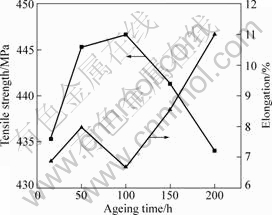

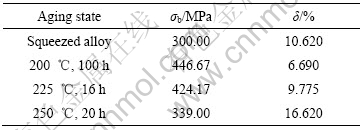

图3所示为在225 ℃时效不同时间后挤压态合金的力学性能。由图3可知,225 ℃时效的最高强度出现在14~16 h附近,其中16 h的抗拉强度为424.17 MPa,伸长率为9.78 %,之后抗拉强度缓慢下降而伸长率则逐步上升。由图4可见,200 ℃时效时最高强度出现在100 h左右,其抗拉强度为446.67 MPa,伸长率为6.69 %,之后抗拉强度缓慢下降而伸长率则逐步上升。表3所列为各个温度下峰值时效的拉伸性能,可见,从强度的角度看,最佳工艺并不是(225 ℃,14~16 h),而是(200 ℃,100 h)。

图3 225 ℃时效不同时间后挤压态合金的力学性能

Fig.3 Tensile properties of squeezed alloy aged at 225 ℃ for different times

图4 200 ℃时效不同时间后挤压态合金的力学性能

Fig.4 Tensile properties of squeezed alloy aged at 200 ℃

表3 各个温度下峰值时效挤压态合金的拉伸性能

Table 3 Tensile properties of squeezed alloy aged to peak hardness at different temperatures

由图4所示的拉伸性能曲线还可以看出,该合金的抗拉强度和伸长率是成反比例的,即强度高,伸长率就低,反之亦然;随着时效的进行,强度上升,伸长率就下降,反之亦然。对比强度曲线和硬化曲线可以发现,在时效过程中,强度和硬度有近似比例对应关系。

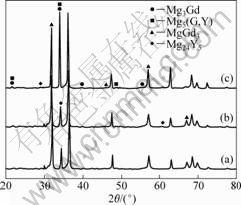

2.3 挤压态合金的时效析出相

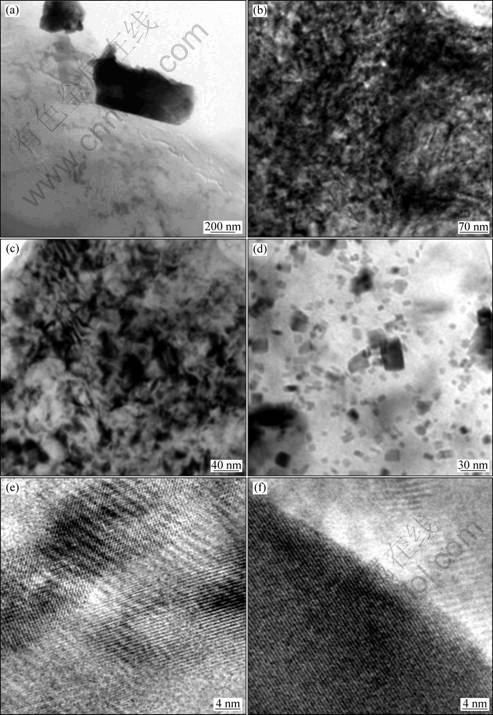

图5所示为挤压态及时效处理后合金的XRD谱。由图5可知,时效处理合金中的基本析出物相有Mg5(Gd,Y)、MgGd3、Mg3Gd和Mg24Y5等。图6所示为合金在225 ℃时效不同时间后的TEM像。由图6可知,原始态合金中没有时效析出相,但是有长方块状的镁-稀土非平衡结晶相(见图6(a));时效至10 h(见图6(b))后,合金中出现大量弥散分布的网状黑色物质,这是固溶体点阵内稀土原子以一定的比例偏聚富集、重新组合,为形成亚稳相做准备,同时伴随点阵畸变程度的增大,合金的力学性能提高。由文献[9]可知,时效初期出现的这种网状黑色析出相是具有DO19结构的β″相。时效时间延长至14 h(见图6(c)),合金中出现明显的黑色细小颗粒析出相,尺寸非常小(几到几十个纳米)且分布比较均匀,这是时效析出的β′亚稳相,这种纳米尺度的时效析出亚稳相是合金的主要强化相。图6(e)所示为此时的亚稳相和基体的界面结构高分辨照片,表明亚稳相和基体有很好的共格匹配性,这样,在两相界面附近会形成一个弹性共格的应变场或叫晶格畸变区,有效阻碍位错运动,从而强化合金。研究表明,析出相各状态的转变并没有严格的界限,在峰值时效状态时,β″相和β′相是共存的,它们对合金的峰值时效强化都有贡献[10]。70 h过时效状态下(见图6(d)),基体中的黑色细小β′相几乎全部转变为灰色方块状β稳定相,β相是β′相在原位转变但是沿着不同的方向生长的[11]。图6(f)所示为这种长大的析出相和基体的相界面,可见过时效的稳定析出相与基体失去共格匹配性,这会使点阵畸变剧烈减弱,合金强度显著降低,塑性提高。

图5 挤压态及时效处理后合金的XRD谱

Fig.5 XRD patterns of squeezed and aged alloys:

(a) Squeezed alloy; (b) 225 ℃, 14 h; (c) 250 ℃, 14 h

图6 225 ℃时效不同时间后析出相的TEM像

Fig.6 TEM images of precipitates in squeezed alloys aged at 225 ℃ for different times: (a) Squeezed alloy; (b) Squeezed alloy aged at 225 ℃ for 10 h; (c) Squeezed alloy aged at 225 ℃ for 14 h; (d) Squeezed alloy aged at 225 ℃ for 70 h; (e) Interface between precipitate and matrix when aged at 225 ℃ for 14 h; (f) Interface between precipitate and matrix when aged at 225 ℃ for 70 h

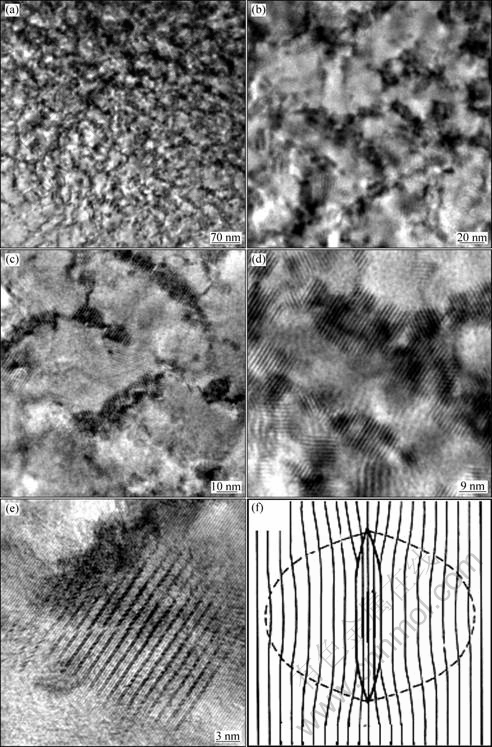

图7所示为对应最高强度的试样(200 ℃,100 h)

图7 200 ℃、100 h时效析出相的TEM像

Fig.7 TEM images of precipitates in squeezed alloy aged at 200 ℃ for 100 h ((a), (b), (c), (d), (e)) and schematic diagram of lattice distortion stress field between precipitate and matrix (f)

中析出相的TEM像。图7(a)所示为低倍时(200 ℃,100 h)峰值时效试样中析出相的分布特征,可见析出相非常细小而且弥散均匀分布,呈鱼鳞状分布在镁基体中。从图7(b)和(c)可以看出,析出相往往围成一圈分布在一个小范围内。分析认为这些析出相一般沿着晶界特别是亚晶界析出,这是由于挤压变形会使镁合金基体晶粒内形成很多的晶界和亚晶界,而晶界和亚晶界处最利于稀土相的析出、生长。从图7(d)和(e)可以看到,在低倍下呈蠕虫状的析出相,在高倍下稀土元素呈细长的针状,并呈梳子状平行排布于基体中。他们排列很整齐并具有明显的取向性,这说明析出相在基体晶粒中是沿着一定的位向形成和生长的。从图7(e)还可以看出,析出相的尺寸是十几到几十个纳米,并且和基体晶粒呈良好的共格关系。图7(f)所示为析出相与基体的界面处形成的共格畸变应力场的示意图。显然,这种呈网状或鱼鳞状的纳米时效析出相对晶粒内的亚晶界起钉扎作用,有效阻碍亚晶界的运动;析出相的形成会导致晶格常数的变化,起到强化晶格畸变的作用,有效阻碍位错的运动[12];析出相的弥散均匀分布对镁基体起到强化纳米颗粒的作用;所有这些都是合金具有高的强度和硬度的内在机制。

3 分析与讨论

从图1可以看出,挤压合金的时效有显著的温度依赖性,即温度越高,到达时效峰值的时间越短,但同时峰值硬度越低。其原因是和合金的时效析出过程有关,时效析出过程是合金元素在固溶体中扩散聚集形成新相的过程,这个过程需要升高温度来提供一定的热力学和动力学条件。文献[13]也得出同样的结论,并提出合金的时效过程是受热激活控制的,其动力学可用Arrhenius公式描述:

从式(1)可以看出,合金到达时效峰值的时间是和时效温度以及与扩散有关的表面激活能有关的,这是时效具有温度依赖性的内在原因。

该挤压合金的强化兼有时效析出强化、形变强化与固溶强化的机制。该合金由于高的Gd和Y固溶度而具有很大的时效析出潜力,在时效过程中析出相会经历从非平衡相向平衡相的变化[14],其中,时效中期析出的β′亚稳相与基体共格匹配性最好,由于亚稳相与基体之间不可能有完全相同的晶面,因此,在形成共格界面时,两相的晶格要产生一定的应变,在晶面附近,晶格常数较大的相受到压应力作用,晶格常数较小的相受到拉应力作用,即在界面附近造成一个弹性共格的应变场,或称晶格畸变区,如图7(f)所示,由于晶格畸变对位错运动的阻碍作用而使合金强度、硬度增加。当亚稳相转变为稳定相后,点阵畸变明显减弱,显著地降低合金的强度,而合金的塑性提高。这种强化机制也称为内应变强化和切过强化的综合作用[15]。

由于Gd和Y在该合金中高的固溶分数以及与基体原子较大的尺寸差,因而具有较强的固溶强化作用。传统观点认为,固溶强化的机理是由于溶质原子的应变场和位错的弹性相互作用。对于镁稀土合金,还应该从溶质原子与基体原子的化合价和分子动力学角度来解释其固溶强化机理[16]。此外,由于热挤压变形而在合金中产生动态再结晶细晶以及大量的位错、孪晶等,也是合金强化的重要机制。

4 结论

1) 时效能显著提高挤压合金的硬度和强度,显微硬度从未时效时的90 HV能上升到135 HV。从显微硬度的角度分析,(225 ℃,14~16 h)是最佳的时效处理工艺,能达最大值135 HV。但从抗拉强度分析,最佳时效工艺是(200 ℃,100 h),抗拉强度能达到446 MPa,但伸长率较低,为6.7%。

2) 在合金时效中期时析出的 β′亚稳相是该合金的主要强化相,β′相与基体共格匹配性好,引起的晶格畸变作用最强,β′相多沿着亚晶界围成圈分布,在低倍下呈蠕虫状,高倍下呈梳子状规则分布于基体中,对位错和亚晶界产生有效阻碍作用,从而使合金获得最高强度和硬度。该合金的强化是时效析出强化、固溶强化和形变强化综合作用的结果。

REFERENCES

[1] 刘 正, 张 奎, 曾小勤. 镁基轻质合金理论基础及应用[M]. 北京: 机械工业出版社, 2002: 1-2.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Academic basis and application of the magnesium based light alloy[M]. Beijing: China Machine Press, 2002: 1-2.

[2] CERR E, BARBAGALLO S. The influence of high temperature on ageing kinetics of a die cast magnesium alloy[J]. Materials Letters, 2002, 56(5): 716-720.

[3] 肖 阳, 张新明, 陈健美, 蒋 浩, 邓桢桢. 高强耐热Mg-9Gd-4Y-0. 6Zr合金的性能[J]. 中南大学学报: 自然科学版, 2006, 37(5): 850.

XIAO Yang, ZHANG Xin-ming, CHEN Jian-mei, JIANG Hao, DENG Zhen-zhen. Performance of Mg-9Gd-4Y-0.6Zr with high strength and heat-resistant alloy[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 850-855.

[4] PENG Qiu-ming, HOU Xiu-li, WANG Li-dong, WU Yao-ming, CAO Zhan-yi, WANG Li-min. Microstructure and mechanical properties of high performance Mg-Gd based alloys[J]. Mater Des, 2009, 30(2): 292-296.

[5] YANG Z, LI J P, GUO Y C, LIU T, XIA F, ZENG Z W, LIANG M X. Precipitation process and effect on mechanical properties of Mg-9Gd-3Y-0.6Zn-0.5Zr alloy[J]. Mater Sci Eng A, 2007, 454/455: 274-280.

[6] HE S M, ZENG X Q, PENG L M, GAO X, NIE J F, DING W J. Precipitation in a Mg-10Gd-3Y-0.4Zr (wt%) alloy during isothermal ageing at 250 ℃[J]. J Alloys Compd, 2006, 421(1/2): 309-313.

[7] 黄 平. Mg-12Gd-3Y-0.5Zr(wt.%)合金晶粒细化和时效研究[D]. 南京: 南京理工大学, 2007.

HUANG Ping. Investigation on grain refinement and aging in Mg-12Gd-3Y-0.5Zr magnesium alloy[D]. Nanjing: Nanjing University of Science and Technology, 2007.

[8] 蒋 浩. Mg-Gd(Y) 耐热镁合金材料及其热处理研究[D]. 长沙: 中南大学, 2006.

JIANG Hao. Investigation on Mg-Gd(Y) heat-resistant magnesium alloy and its heat treatment[D]. Changsha: Central South University, 2006.

[9] 陈部湘, 张新明, 邓运来, 邓桢桢. 时效对Mg-9Gd-4Y-0.6Zr挤压合金组织与性能的影响[J]. 湖南有色金属, 2007, 23(1): 35-37.

CHEN Bu-xiang, ZHANG Xin-ming, DENG Yun-lai, DENG Zhen-zhen. Effect of aging on microstructure and properties of extruded Mg-9Gd-4Y-0.6Zr alloy[J]. Hunan Nonferrous Metals, 2007, 23(1): 35-37.

[10] YAO Su-juan, YI Dan-qing, YANG Sheng, LI Wang-xing. Aging characteristics and high temperature properties of Mg-9Gd-3Y-0.3Zr[J]. Trans Nonferrous Met Soc China, 2007, 17(1): 418-422.

[11] GAO X, HE S M, ZENG X Q, PENG L M, DING W J, NIE J F. Microstructure evolution in a Mg-15Gd-0.5Zr(wt.%) alloy during isothermal aging at 250 ℃[J]. Mater Sci Eng A, 2006, 431(1/2): 322-327.

[12] 崔忠圻. 金属学与热处理[M]. 北京: 机械工业出版社, 2006: 410.

CUI Zhong-qin. Metallography and heat treatment[M]. Beijing: China Machine Press, 2006: 410.

[13]

ZHENG Kai-yun, DONG Jie, ZENG Xiao-qin, DING Wen-jiang. Aging Characteristics and mechanical properties of cast and wrought Mg-11Gd-2Nd-0.5Zr alloys[C]//BEALS R S, LUO A A , NEELAMEGGHAM N R, PEKGULERYUZ M O. Magnesium Technology, USA: TMS, 2007: 413-420.

[14] 谢建昌, 李全安, 李建弘, 张兴渊. 时效时间对Mg-8Al-1Zn- 3Ca合金组织及力学性能的影响[J]. 材料热处理技术, 2008, 37(2): 64-72.

XIE Jian-chang, LI Quan-an, LI Jian-hong, ZHANG Xin-yuan. Influence of aging time on microstructure and mechanical properties of Mg-8Al-1Zn-3Ca alloy[J]. Material and Heat Treatment, 2008, 37(2): 64-72.

[15] 邹宏辉, 曾小勤, 翟春泉, 丁文江. 镁合金的强韧化进展[J]. 机械工程材料, 2004, 28(5): 1-3.

ZOU Hong-hui, ZENG Xiao-qin, ZHAI Chun-quan, DING Wen-jiang. Progress of the strengthening and toughening of magnesium alloy[J]. Materials for Mechanical Engineering, 2004, 28(5): 1-3.

[16] GAO L, CHEN R S, HAN E H. Effects of rare-earth elements Gd and Y on the solid solution strengthening of Mg alloys[J]. J Alloys Compd, 2009, 481(1/2): 379-384.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50775085);宁波市自然科学基金资助项目(2008A610049)

收稿日期:2009-07-30;修订日期:2009-11-13

通信作者:董选普,教授,博士;电话:027-87558252,13037116051;E-mail:dongxp@mail.hust.edu.cn