文章编号:1004-0609(2012)06-1770-08

钒钛磁铁矿提钒尾渣浸取钒

邓志敢,魏 昶,李兴彬,徐红胜,李旻廷,李存兄,樊 刚

(昆明理工大学 冶金与能源工程学院,昆明 650093)

摘 要:采用硫酸-氢氟酸-次氯酸钠组合浸出体系浸取钒钛磁铁矿提钒尾渣中的钒,研究浸出过程中试剂浓度、浸出液固比、浸出温度、浸出时间、物料粒度对钒浸出率的影响。结果表明:钒的浸出率随试剂浓度、液固比、温度和时间的升高而增大;当矿物粒度小于0.20 mm时,钒浸出率有随矿物粒度变小而减小的趋势。在物料粒度0.15~0.25 mm、初始硫酸浓度150 g/L、初始氢氟酸浓度30 g/L、次氯酸钠加入量为矿量1.5%、矿浆液固比6:1、浸出温度90 ℃、浸出时间6 h、搅拌速度500 r/min的条件下,钒的浸出率可达85%以上。

关键词:提钒尾渣;组合浸出剂;钒浸出率

中图分类号:TF803.21 文献标志码:A

Leaching vanadium from extracted vanadium residue of vanadium titanomagnetite

DENG Zhi-gan, WEI Chang, LI Xing-bin, XU Hong-sheng, LI Min-ting, LI Cun-xiong, FAN Gang

(Faculty of Metallurgical and Energy Engineering, Kunming University of Science and Technology,

Kunming 650093, China)

Abstract: Vanadium was leached by composed leaching reagent of sulphuric acid, hydrofluoric acid and sodium hypochlorite from extracted vanadium residues of vanadium titanomagnetite. The process parameters, which impact on the vanadium leaching percent, such as reagent concentration, ratio of liquid to solid, temperature, leaching time, mineral granularity, were investigated. The results show that the vanadium leaching rate increases with the increase of reagent concentration, ratio of liquid to solid, temperature, leaching time and decreases with diminishment of the mineral granularity when the mineral granularity is less than 0.20 mm. The effect of sodium hypochlorite is smaller. When the extracted vanadium residues is leached with granular size of 0.15-0.25 mm, sulphuric acid concentration of 135 g/L, hydrofluoric acid concentration of 30 g/L, sodium hypochlorite dosage of 1.5%, ratio of liquid to solid of 6:1, stirring velocity of 500 r/min at 90 ℃ for 6 h, the leaching rate of vanadium is above 85%.

Key words: extracted vanadium residue; composed leaching reagent; vanadium leaching rate

稀有金属元素钒是一种重要的战略物资,在工业领域有着广泛的应用。作为我国重要钒资源的钒钛磁铁矿,其有价元素以Fe、V、Ti为主,Fe、Ti紧密共生,V以类质同象赋存在钛磁铁矿中[1-5]。钒渣经数次提取V2O5之后,遗弃的废渣(即提钒尾渣)中V2O5含量约在1.5%(质量分数)左右,钒含量较高。每年约有数百万吨含钒废渣直接排放,大量废渣堆积如山,不仅造成钒资源的浪费,且占用大量土地,污染环 境[6-11]。现仅有研究采用加压成型-钠化焙烧工艺对此废渣进行钒的再提取,但该工艺钒提取率<40%[8]。无论从生产指标、环保要求,还是从经营成本上考虑都不是经济的。随着经济的发展,对钒的需求越来越大,而提钒尾渣中大量的钒由于没有清洁、有效的提取方法而得不到合理利用或利用率很低,因此,研究将含钒尾渣作为二次资源提取V2O5,不仅对钒资源有效利用意义重大,且可带来可观的经济、环境与社会效益[12-17]。

1 实验

1.1 实验原料

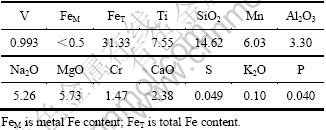

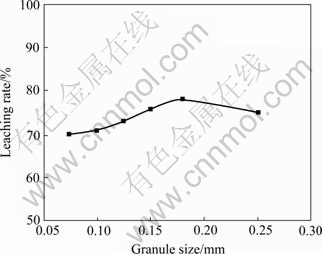

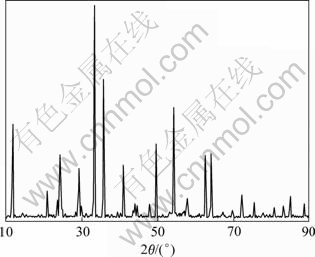

实验所用物料提钒尾渣取自攀枝花,外观为黑色细小颗粒。其主要化学成分如表1所列,X射线衍射分析如图1所示。

表1 提钒尾渣主要化学成分分析

Table 1 Chemical compositions of extracted vanadium residue (mass fraction, %)

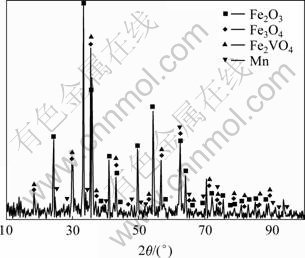

图1 提钒尾渣的XRD谱

Fig. 1 XRD pattern of extracted vanadium residue

由图1可知,提钒尾渣中铁、钒的主要物相分别为Fe2O3、Fe3O4、Fe2VO4,此外还含有少量的金属Mn等,钒主要以类质同象形式赋存在铁钒尖晶石Fe2VO4相中。

同时,由矿物X射线衍射物相分析可得,提钒尾渣大部分为磁性铁氧化物,鉴于扫描电镜的非磁性保护,故难进行此项分析。

1.2 实验原理

已有研究表明[2, 8, 18],提钒尾渣中的钒均以酸碱不溶性低价钒形式存在。因此,在浸出过程中将不溶性低价钒尽量多的转化为可溶性的高价钒,使其最大限度地转入到溶液中加以回收,才能保证较高的钒回收率。尖晶石是钒渣的主要矿相,其中钒尖晶石是难溶化合物,在硅酸盐熔体中的溶解度很小。钒渣中的钒不能完全被提取,其最主要原因是:1) 以硅酸盐为主体成分的熔化玻璃体包裹在尖晶石周围,阻碍氧的传质、扩散和钒酸盐的生成;2) 含钒尖晶石未能完全被氧化、钠化;3) 形成不溶性钒青铜。

尖晶石的矿物结构非常稳定,难以被水、酸和碱溶解,因此,要浸出这部分钒必须先破坏这些含钒矿物的晶体结构,使赋存在晶体结构中的钒释放出来,再使其氧化和转化[6, 18]。矿相分析表明:全部钒渣中尖晶石都是唯一的含钒结晶相,HF酸可破坏硅酸盐矿物的晶体结构。本文作者采用HF酸浸出来破坏含钒硅酸盐矿物的晶体结构,在浸出过程中加入氧化剂NaClO来实现钒的氧化转化[2, 6, 18],其反应可近似表示为

V2O3·X+2H2SO4+NaClO→

HFV2O2(SO4)2+NaCl+2H2O+X (1)

式中:X代表硅酸盐等脉石成分。

为此,本文作者提出常压下采用H2SO4-HF- NaClO组合浸出剂浸出提钒尾渣中的钒的技术工艺,使提钒尾渣中的钒实现较高的浸出率。

1.3 实验方法

实验采用2 L五口烧瓶作浸出容器,机械搅拌,水浴加热,双回流冷凝管。将分析纯H2SO4加水稀释至所需的质量比浓度,称取磨细至所需粒度的提钒尾渣150 g加入容器中,量取一定体积H2SO4,倒入烧瓶,摇匀。恒温浸出反应至一定时间后迅速打开瓶塞,矿浆用真空抽滤过滤,固液分离,浸出渣用一定量自来水洗涤数次,滤液量后保存,取浸出渣制样送检分析进行钒浸出率计算。

钒的浸出率(η)计算式为

(2)

(2)

式中:η为钒的浸出率;m1为浸出物料质量;m2为浸出渣质量;α为物料中钒V含量;γ为浸出渣中V含量。

2 结果与讨论

2.1 初始硫酸浓度的影响

实验条件如下:物料粒度小于74 μm(>90%),初始HF浓度20 g/L,NaClO加入量为矿量的0.5%,浸出液固比(溶液体积和物料质量的比)6:1,浸出温度 90 ℃,浸出时间6 h,搅拌速度500 r/min。

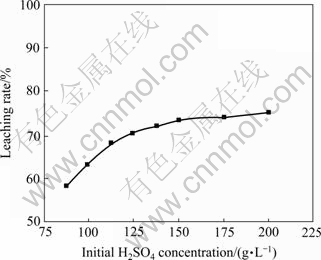

改变浸出反应的初始硫酸浓度,考察初始硫酸浓度对钒浸出率的影响,结果如图2所示。

图2 初始硫酸浓度对钒浸出率的影响

Fig. 2 Effect of initial H2SO4 concentration on leaching rate of vanadium

由图2可见,在一定范围内,钒浸出率随浸出剂(H2SO4)浓度的增加而升高。当H2SO4浓度为87.5 g/L时,钒浸出率仅为58.24%;当H2SO4浓度为200 g/L时,钒浸出率可达75.17%;当H2SO4浓度达到125 g/L时,钒浸出率已为70.2%;在H2SO4浓度超过125 g/L后,钒的浸出率上升缓慢。H2SO4浓度越大,则H+浓度就越大,进入矿物晶格的几率就越大,有利于破坏矿物结构,提高钒浸出率。但随着浸出剂浓度的升高,会带来经济成本的增加,也会给后面的净化工序带来较大困难,因此选用硫酸浓度为125~150 g/L。

2.2 HF浓度的影响

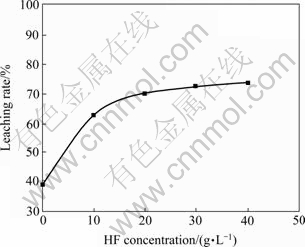

实验条件如下:物料粒度小于74 μm(>90%),浸出反应初始H2SO4浓度125 g/L,NaClO加入量为矿量的0.5%,浸出液固比6:1,浸出温度90 ℃,浸出时间6 h,搅拌速度500 r/min。改变浸出反应的初始氢氟酸浓度,考察初始HF浓度对钒浸出率的影响,结果如图3所示。

图3 HF浓度对钒浸出率的影响

Fig. 3 Effect of HF concentration on leaching rate of vanadium

由图3可见,随着HF浓度的增加,钒的浸出率提高。当未添加HF时,钒浸出率仅为39.01%;加入HF后,钒浸出率迅速上升,当HF浓度为20 g/L时,钒浸出率达到70.2%,继续增加HF浓度时,钒浸出率上升缓慢;当HF浓度为40 g/L时,钒浸出率可达73.92%。由于三价钒难溶于H2SO4,而易溶于HF,因此HF的引入有利于钒的溶解,且HF浓度越大,矿物晶格的破坏程度越大,越有利于H2SO4的进入和NaClO的氧化,使矿物中钒发生氧化转化进入溶液。因此,选定HF浓度在20~30 g/L比较合适。

2.3 NaClO用量的影响

实验条件如下:物料粒度小于74 μm(>90%),浸出反应初始H2SO4浓度125 g/L,初始HF浓度为20 g/L,浸出液固比6:1,浸出温度90 ℃,浸出时间6 h,搅拌速度500 r/min。

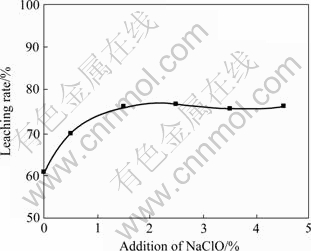

改变浸出反应的NaClO加入量(NaClO加入量以其与矿量的质量分数表示),考察NaClO加入量对钒浸出率的影响,结果如图4所示。

由图4可见,未加入NaClO时,钒的浸出率为61.43%;加入NaClO可在一定程度上提高钒的浸出率,但加大NaClO用量时,钒浸出率没有明显变化;当NaClO用量在0.5%时,钒浸出率为70.2%;当NaClO用量在1.5%时,钒浸出率达到较大值76.11%。由于HF的引入,可溶解原料中难溶性的三价钒,使其转入溶液中,而氧化剂NaClO的作用只是将其氧化后转化为在硫酸溶液更稳定存在的VOSO4,因此,NaClO加入量对钒浸出率的影响较弱,其用量宜选为1.5%~2%。

图4 NaClO用量对钒浸出率的影响

Fig. 4 Effect of addition of NaClO on leaching rate of vanadium

2.4 反应液固比的影响

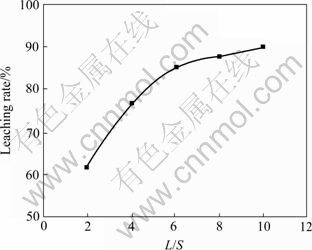

实验条件如下:物料粒度小于74 μm(>90%),浸出反应初始H2SO4浓度125 g/L,初始HF浓度20 g/L,NaClO加入量为矿量的0.5%,浸出温度90 ℃,浸出时间6 h,搅拌速度500 r/min。改变浸出反应的液固比,考察液固比对钒浸出率的影响,结果如图5所示。

图5 反应液固比对钒浸出率的影响

Fig. 5 Effect of reaction L/S on leaching rate of vanadium

由图5可见,液固比对钒的浸出率影响较大。当液固比为L/S=2时,钒的浸出率不到25%,随着液固比的逐渐增大,钒的浸出率明显升高。当液固比为6时,钒浸出率为70.2%,此后,增大液固比钒浸出率升高缓慢。由此可见,增大反应液固比可提高反应效果,有利于钒的浸出,但L/S>6后,增大液固比对钒浸出率的提升影响较弱,且反应的液固比过大,势必造成试剂用量加大,成本增加,同时导致后续溶液处理量加大,生产效率降低,因此,液固比宜选定为5~6。

2.5 反应温度的影响

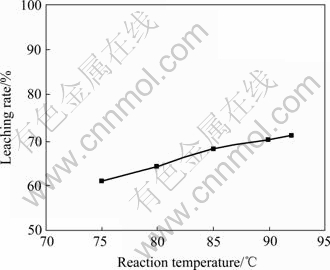

实验条件:物料粒度小于74 μm(>90%),浸出反应初始H2SO4浓度125 g/L,初始HF浓度为20 g/L,NaClO加入量为矿量的0.5%,浸出液固比6,浸出时间6 h,搅拌速度500 r/min。改变浸出反应温度,考察浸出温度对钒浸出率的影响,结果如图6所示。

图6 反应温度对钒浸出率的影响

Fig. 6 Effect of reaction temperature on leaching rate of vanadium

由图6可见,提高浸出反应温度时,钒浸出率缓慢上升。这是因为随着温度的升高,一方面浸出剂的反应活性增强,反应速度更快;另一方面使浸出剂中的HF和产物的扩散速度加快,浸出剂进入矿物晶格和产物扩散出来进入溶液都更加容易和迅速。由此可见,升高温度有利于钒的浸出,但当浸出温度高于85℃后,钒的浸出率变化不大。因此,浸出温度以85℃~90℃为宜。

2.6 反应时间的影响

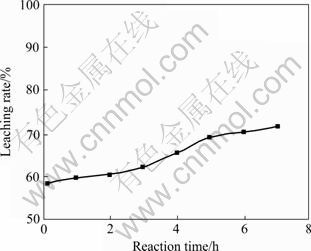

实验条件如下:物料粒度小于74 μm(>90%),浸出反应初始H2SO4浓度125 g/L,初始HF浓度为20 g/L,NaClO加入量为矿量的0.5%,浸出液固比6,浸出温度90 ℃,搅拌速度500 r/min。改变浸出反应时间,考察浸出时间对钒浸出率的影响,结果如图7所示。

由图7可见,随浸出反应时间的延长,钒浸出率逐渐增高,当浸出时间为2 h时,钒浸出率为60.41%;当浸出时间为5 h时,钒浸出率达到68.90%,此后进一步延长浸出时间钒浸出率上升缓慢;当浸出时间延

图7 反应时间对钒浸出率的影响

Fig. 7 Effect of reaction time on leaching rate of vanadium

长至6 h时,钒浸出率为70.2%,对钒浸出效果的影响已不大。同时由于反应时间越长会使得设备产能越低,能耗越高,不利于工业生产。因此,浸出时间不宜过长,可选为5~6 h。

由图8可见,随物料颗粒度的变化,钒浸出率无明显变化。但在粒度小于0.15 mm以下,随物料颗粒度的减小,钒的浸出率略有下降。对此,可能是物料粒度过细时,矿物的比表面积增大,与浸出剂的接触面积加大,使其中的铁元素浸出,而提钒尾渣中含有一定量的钠盐,在浸出过程中会解离出钠离子,随着浸出时间的延长,已浸出的铁在浸出液中钠离子的作用下产生黄钠铁矾,包裹在矿物颗粒表面,阻碍了钒的浸出,导致其浸出率下降。但酸浸提钒尾渣为液固反应,为有利于扩散和反应的进行,对尾渣粒度有一定的要求。图8表明在矿物粒度大于0.20 mm时,钒浸出率会随之降低,因此,矿物的粒度以0.15~ 0.25 mm为宜。

图8 物料粒度对钒浸出率的影响

Fig. 8 Effect of granule size on leaching rate of vanadium

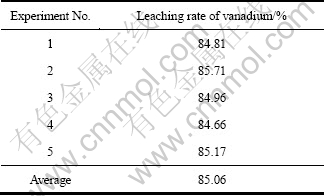

2.8 优化条件综合实验

通过上述条件实验,在考察了各技术参数对钒浸出率的影响的基础上,对实验条件进行优化,得出最佳浸出条件如下:物料粒度0.15~0.25 mm(>95%),初始H2SO4浓度为150 g/L,初始HF浓度为30 g/L,氧化剂NaClO加入量为矿量的1.5%,矿浆液固比为6,浸出温度为90 ℃,浸出时间为6 h,搅拌速度为 500 r/min。

为了检验各最佳参数点的实际效果,在上述实验条件下进行了验证实验,结果如表2所列。5组条件验证实验研究结果表明,在最优条件下,钒的浸出率可达85%以上。

表2 综合验证实验结果

Table 2 Confirmatory experiment results

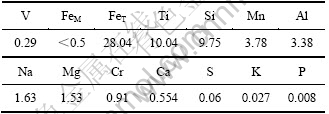

3 浸出渣表征

为了进一步了解提钒尾渣在浸出前后的矿物形态变化,对综合验证实验5号浸出渣,进行了化学元素分析、X射线衍射分析及扫描电镜分析,结果如表3和图9~11所示。

3.1 主要化学元素分析

表3 浸出渣主要化学成分分析

Table 3 Chemical compositions of leaching residue (mass fraction, %)

3.2 XRD分析

由图9可见,浸出渣主要物相为Fe2O3、FeV、SiO2等。对比图1提钒尾渣的X射线衍射物相分析结果可见,综合验证实验浸出渣与原提钒尾渣的主要物相发生了很大变化,Fe3O4和Fe2VO4消失,并出现了FeV;Fe2O3和SiO2在渣中富集,其含量比例相应增加。

图9 浸出渣的XRD谱

Fig. 9 XRD pattern of leaching residue

3.3 扫描电镜分析

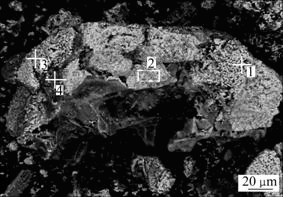

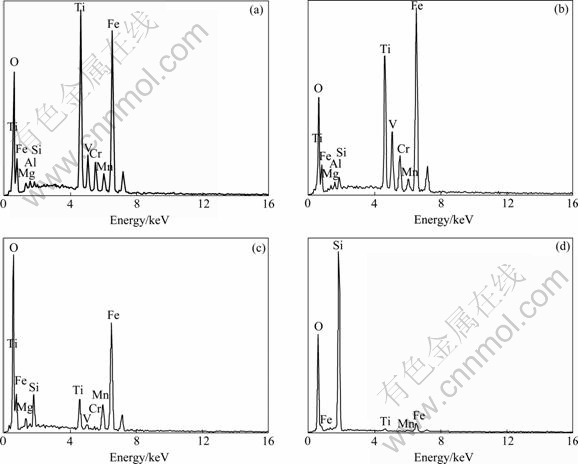

对综合验证实验浸出渣,进行了扫描电镜及微区能谱分析,结果如图10~11所示。

图11为图10的各点微区能谱,1、2点能谱显示V伴生在Fe、Ti中以氧化物形式存在;较亮白色颗粒3点能谱分析显示其主要为铁的氧化物;4点观察到的灰色颗粒能谱分析显示其主要为二氧化硅。扫描电镜分析表明:提钒尾渣物料中含钒物相的晶体结构已被破坏打开,钒得到较好的浸出。

图10 浸出渣的SEM像

Fig. 10 SEM image of leaching residue

图11 浸出渣的EDS谱

Fig. 11 EDS spectra of leaching residue shown in Fig. 10: (a) Point 1; (b) Point 2; (c) Point 3; (d) Point 4

4 结论

1) 采用硫酸-氢氟酸-次氯酸钠组合浸出体系浸取钒钛磁铁矿提钒尾渣中的钒的最佳浸出条件:物料粒度0.15~0.25 mm(>95%),初始H2SO4浓度为150 g/L,初始HF浓度为30 g/L,氧化剂NaClO加入量为矿量的1.5%,矿浆液固比为6,浸出温度为90 ℃,浸出时间为6 h,搅拌速度为500 r/min。在此条件下,钒的浸出率可达85%以上。

2) 采用硫酸-氢氟酸-次氯酸钠组合浸出体系浸取钒钛磁铁矿提钒尾渣可以破坏含钒物相的晶体结构,打开提钒尾渣脉石对钒的包裹,有利于钒的浸出。但物料粒度过细易形成新相重新包裹,不利于钒的浸出。

3) 对钒钛磁铁矿提钒尾渣采用酸浸提钒工艺进行钒的浸出,需在高硫酸用量和高氢氟酸用量的条件下才能得到较高的钒浸出率,因此如何降低酸耗有待进一步研究。

REFERENCES

[1] CHEN Xiang-yang, LAN Xin-zhe, ZHANG Qiu-li, MA Hong-zhou, ZHOU Jun. Leaching vanadium by high concentration sulfuric acid from stone coal[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S1): s118-s122.

[2] 陈 勇, 娜孜拉·扎曼别克, 潘丽英, 菲尔汉·汉杰儿, 王 涛. 从湿冶钒渣中回收V2O5的实验研究[J]. 干旱环境监测, 2001, 15(1): 6-8.

CHEN Yong, ZHAMANBIEKE·Nazila, PAN Li-ying, HANJIEER·Feierhan, WANG Tao. Experimental research of recovering V2O5 from wet smelting vanadium cinder[J]. Arid Environmental Monitoring, 2001, 15(1): 6-8.

[3] 杨静翎, 金 鑫. 酸浸法提钒新工艺的研究[J]. 北京化工大学学报, 2007, 34(3): 254-257.

YANG Jing-ling, JIN Xin. A new way of recovering vanadium from iron/vanadium slag[J]. Journal of Beijing University of Chemical Technology, 2007, 34(3): 254-257.

[4] 董元篪, 武杏荣, 余 亮, 李辽沙. 含钒钢渣中钒再资源化的基础研究[J]. 中国工程科学, 2007, 9(1): 63-68.

DONG Yuan-chi, WU Xing-rong, YU Liang, LI Liao-sha. Fundamental research on vanadium recovering from V-bearing steel making slag[J]. Engineering Science, 2007, 9(1): 63-68.

[5] 叶国华, 童 雄, 路 璐. 含钒钢渣的选矿预处理及其对后续浸出的影响[J]. 中国有色金属学报, 2010, 20(11): 2233-2238.

YE Guo-hua, TONG Xiong, LU Lu. Pretreatment for V-bearing steelmaking slag by beneficiation methods and its effect on followed leaching procedure[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2233-2238.

[6] 冯其明, 何东升, 张国范, 欧乐明, 卢毅屏. 石煤提钒过程中钒氧化和转化对钒浸出的影响[J]. 中国有色金属学报, 2008, 17(8): 1348-1352.

FENG Qi-ming, HE Dong-sheng, ZHANG Guo-fan, OU Le-ming, LU Yi-ping. Effect of vanadium oxidation and conversion on vanadium leaching in extraction process of vanadium from stone coal[J]. The Chinese Journal of Nonferrous Metals, 2008, 17(8): 1348-1352.

[7] 段 炼, 田庆华, 郭学益. 我国钒资源的生产及应用研究进展[J]. 湖南有色金属, 2006, 22(6): 17-20.

DUAN Lian, TIAN Qing-hua, GUO Xue-yi. Review on production and utilization resources in China[J]. Hunan Nonferrous Metal, 2006, 22(6): 17-20.

[8] 陈东辉, 岳庆丰. 从提钒废渣中再提钒的新技术研究[J]. 钒钛, 1992(4): 1-6.

CHEN Dong-hui, YUE Qing-feng. Study on process technology of vanadium extraction from extracted vanadium residue[J]. Vanadium Titanium, 1992(4): 1-6.

[9] LAN Yao-zhong, LIU Jin. Review of vanadium processing in China[J]. Engineer Science, 2005, 3(3): 58-62.

[10] MOSKALYK R R, ALFANTAZI A M. Processing of vanadium: A review[J]. Minerals Engineering, 2003, 16(9): 793-805.

[11] 熊 瑶, 李 春, 梁 斌, 谢 军. 盐酸浸出自然冷却含钛高炉渣[J]. 中国有色金属学报, 2008, 18(3): 557-563.

XIONG Yao, LI Chun, LIANG Bin, XIE Jun. Leaching behavior of air cooled Ti-bearing blast-furnace slag in hydrochloric acid[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 557-563.

[12] 梁建龙, 刘惠娟, 史文革, 胡鄂明, 李熙琪, 彭 军. 湿法冶金提钒浸出新工艺[J]. 中国矿业, 2006, 15(7): 64-66.

LIANG Jian-long, LIU Hui-juan, SHI Wen-ge, HU E-ming, LI Xi-qi, PENG Jun. A study of a new technology leaching of vanadium from vanadium ores with hydrometallurgy[J]. China Mining Magazine, 2006, 15(7): 64-66.

[13] LI Min-ting, WEI Chang, FAN Gang, LI Cun-xiong, DENG Zhi-gan, LI Xing-bin. Extraction of vanadium from black shale using pressure acid leaching[J]. Hydrometallurgy, 2009, 98(3): 308-313.

[14] CHMIELEWSKI A G, URBA?SKI T S, MIGDAL W. Separation technologies for metals recovery from industrial wastes[J]. Hydrometallurgy, 1997, 45: 333-344.

[15] JENA B C, DRESLER W, REILLY I G. Extraction of titanium, vanadium and iron from titanomagnetite deposits at Pipestone Lake, Manitoba, Canada[J]. Minerals Engineering, 1995, 8(1/2): 159-168.

[16] 史 玲, 王 娟, 谢建宏. 钠化法提钒工艺条件的研究[J]. 矿业工程, 2008, 28(1): 58-61.

SHI Ling, WANG Juan, XIE Jian-hong. Technology on vanadium extraction from bone coal by adding sodium chloride[J]. Mining and Metallurgical Engineering, 2008, 28(1): 58-61.

[17] 向小艳, 王明玉, 肖连生, 高泽斌. 石煤酸浸提钒工艺研究[J]. 稀有金属与硬质合金, 2007, 35(3): 10-13.

XIANG Xiao-yan, WANG Ming-yu, XIAO Lian-sheng, GAO Ze-bin. Study on acid leaching of vanadium from stone coal[J]. Rare Metals and Cemented Carbides, 2007, 35(3): 10-13.

[18] 叶国华, 童 雄, 路 璐. 含钒钢渣资源特性及其提钒的研究进展[J]. 稀有金属, 2010, 37(5): 769-775.

YE Guo-hua, TONG Xiong, LU Lu. Resource characteristics of vanadium-bearing steel slag and progress in extracting vanadium from it[J]. Rare Metals, 2010, 37(5): 769-775.

(编辑 李艳红)

基金项目:云南省科技厅资助项目(2007GA010)

收稿日期:2011-03-23;修订日期:2011-07-18

通信作者:魏 昶,教授,博士;电话:0871-5188819;E-mail: weichang2008@sina.com