DOI:10.19476/j.ysxb.1004.0609.2017.04.016

胀形间隙对核主泵转子屏蔽套真空热胀形的影响

朱 智,张立文,崔 岩,张 驰,李瑞琴

(大连理工大学 材料科学与工程学院,大连 116023)

摘 要:利用非线性有限元软件MSC.Marc建立转子屏蔽套真空热胀形过程的二维轴对称热力耦合有限元模型,计算并分析真空热胀形过程中转子屏蔽套和模具的径向位移变化,预测转子屏蔽套的胀形量和胀形后内径。此外,基于建立的有限元模型研究胀形间隙对转子屏蔽套胀形量和胀形后内径的影响。结果表明:对于确定的工艺,在其胀形能力范围内,随着胀形间隙的增大,转子屏蔽套的胀形量线性减小,且胀形后的内径不随胀形间隙的变化而变化。开展转子屏蔽套的真空热胀形实验,验证建立的有限元模型。

关键词:Hastelloy C-276合金;转子屏蔽套;真空热胀形;胀形间隙

文章编号:1004-0609(2017)-04-0789-06 中图分类号:TG146.1 文献标志码:A

转子屏蔽套是AP1000核主泵的关键部件之一,将其套装在转子外面,可以防止转子与泵内的冷却剂接触,避免转子受到冷却剂的侵蚀,转子屏蔽套的制造和装配精度及质量将直接影响核主泵的正常运转[1]。AP1000核主泵转子屏蔽套具有超薄大径厚比,其制造和装配难度非常大。核主泵转子屏蔽套采用Hastelloy C-276合金薄板经过剪切和焊接工艺制造而成,在装配前,AP1000转子屏蔽套的直径公差为±0.076 mm,对制造工艺的精度要求非常高[1]。焊接后,转子屏蔽套的表面特别是焊缝区附近会产生凹凸不平的褶皱,即使采用精密剪切和精密焊接,也难以满足精密装配前对转子屏蔽套的高精度要求,而且转子屏蔽套的内部产生较大的残余应力,严重影响后续热套装工艺的精度和质量。

针对剪裁、焊接后转子屏蔽套的精度很难达到套装前高精度的难点,提出了采用精密真空蠕变热胀形技术对焊接后的转子屏蔽套进行误差治理。该技术利用模具和转子屏蔽套间的热膨胀系数差异,在加热及保温过程中,依靠模具的热膨胀力使转子屏蔽套发生永久的塑性及蠕变变形,转子屏蔽套内表面与高精度模具外表面紧密贴合,冷却后转子屏蔽套的尺寸能够达到装配前的高精度要求。由于高温蠕变使转子屏蔽套内部的应力得到松弛,在胀形后,转子屏蔽套内部的残余应力也可以得到消除[2-3]。

真空热胀形的本质是蠕变成形,目前,国内外学者已经针对铝合金和钛合金零件的蠕变成形做了大量的研究,并且将其成功应用于航空航天领域[4-12],然而,对转子屏蔽套真空热胀形的研究却很少[3, 13]。

在实际转子屏蔽套的焊接过程中,由于焊缝附近各处膨胀和收缩不均匀,使得焊接后转子屏蔽套沿轴向各处的内径不同,从而导致了真空热胀形时转子屏蔽套各处的胀形间隙不同,研究胀形间隙对转子屏蔽套真空热胀形的影响有助于深刻理解采用真空热胀形技术对焊接后的转子屏蔽套进行误差治理的过程,而且为真空热胀形工艺参数的优化奠定基础。

本文作者利用有限元软件MSC.Marc对核主泵转子屏蔽套的真空热胀形过程进行有限元模拟,计算并分析真空热胀形过程中转子屏蔽套和模具的径向位移变化,预测转子屏蔽套真空热胀形的胀形量和胀形后的内径,研究转子屏蔽套和模具之间不同的胀形间隙尺寸对转子屏蔽套真空热胀形的影响规律,开展真空热胀形工艺实验验证模拟结果的准确性。

1 真空热胀形有限元模型

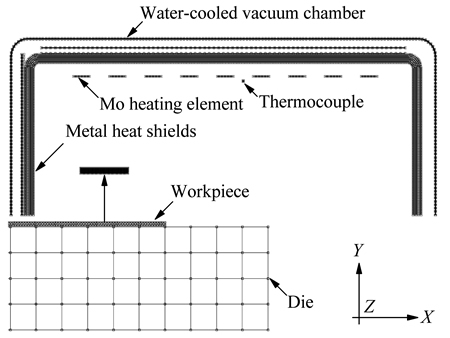

本文作者采用的真空热处理设备是IPsen公司生产的v6072型立式真空热处理炉,建模时将转子屏蔽套、模具和真空热处理炉简化成具有轴对称特性的实体,基于有限元软件MSC.Marc建立核主泵转子屏蔽套真空热胀形过程的二维轴对称有限元模型,如图1所示。为了提高模拟精度和计算效率,在金属隔热屏的最内层加密单元,外层则保持稀疏网格。

在真空热胀形过程中,真空热处理炉的水冷套内壁的外表面与循环水发生对流换热,炉体内部各层金属隔热屏、加热元件、监控热电偶、转子屏蔽套和模具等边界之间则通过热辐射进行换热,模型中,采用蒙特卡罗方法计算辐射视角系数,此外,将体热流作为边界条件施加到加热元件上,并利用子程序实现了真空热处理炉炉温的智能控制。

在真空热胀形过程中,转子屏蔽套和模具竖立放置在真空热处理炉内的载料台上,相当于一边固定,在固定端施加X方向位移约束条件。

真空热胀形通常在室温装炉,初始温度为20 ℃,假设在真空热胀形的初始时刻转子屏蔽套和模具内部的初始应力为0。

此外,在模拟转子屏蔽套的真空热胀形时,考虑了材料的热物理和力学性能参数与温度的非线性关系,转子屏蔽套和模具的材料分别为Hastelloy C-276合金和1Cr18Ni9Ti不锈钢,Hastelloy C-276合金的热导率、比热容、热膨胀系数以及1Cr18Ni9Ti不锈钢的热膨胀系数均由实验测得,其他材料参数则是通过查阅合金手册和用差值算法相结合得到的。

图1 真空热胀形有限元模型

Fig. 1 FE model of vacuum hot bulge forming

2 材料的蠕变本构模型

真空热胀形的本质是蠕变成形,在真空热胀形过程中,转子屏蔽套内部因应力松弛而发生了蠕变变形,因此,在模拟转子屏蔽套的真空热胀形过程时,需要建立能用来描述材料应力松弛行为的蠕变本构模型。为此,利用应力松弛实验建立Hastelloy C-276合金的蠕变本构方程[14]:

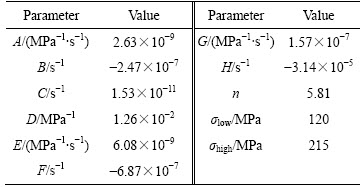

式中:A、B、C、D、E、F、G、H和n为材料常数;σhigh表示高应力区域与过渡区域的临界应力;σlow表示低应力区域与过渡区域的临界应力。800 ℃下,蠕变本构方程中的材料常数值如表1所示。

表1 800 ℃下蠕变本构方程的材料常数

Table 1 Constants of creep constitutive equations at 800 ℃

3 模拟结果与分析

利用建立的有限元模型模拟转子屏蔽套的真空热胀形过程,模拟中采用的真空热胀形工艺如下:首先将转子屏蔽套和模具经7500 s加热至800 ℃,然后保温7200 s,最后炉冷至室温。

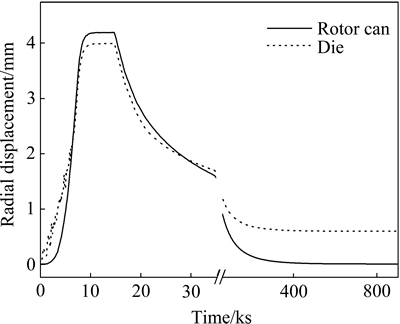

图2所示为真空热胀形过程中转子屏蔽套和模具的径向位移随时间的变化。在加热的初始阶段,转子屏蔽套和模具处于自由膨胀状态,随着温度的进一步升高,由于模具的热胀系数大于转子屏蔽套的热膨胀系数,模具的热膨胀速度快,膨胀量更大,约为6800 s时,转子屏蔽套的内壁与模具的外表面发生接触,并逐渐达到良好的贴模状态。

在保温阶段,当转子屏蔽套和模具达到保温温度后,两者的膨胀量不再发生变化。

图2 真空热胀形过程中转子屏蔽套和模具的径向位移变化

Fig. 2 Variation of radial displacement of rotor can and die during vacuum hot bulge forming process

在冷却阶段,随着温度的降低,转子屏蔽套和模具同时收缩,由于模具的膨胀系数大,转子屏蔽套与模具的接触状态由紧到松,直到转子屏蔽套的内壁和模具的外表面分离;当冷却到室温时,转子屏蔽套发生了永久的变形,而模具由于只发生弹性变形和热膨胀回弹到真空热胀形前的初始尺寸。图2中转子屏蔽套的最终径向位移就是其真空热胀形的胀形量,而转子屏蔽套胀形前的内径与胀形量之和就是其胀形后的内径。

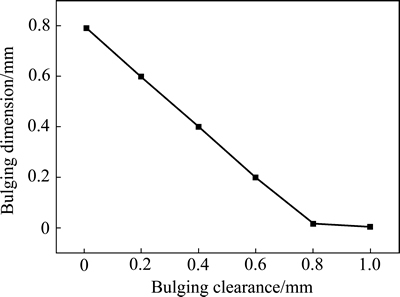

胀形间隙是影响转子屏蔽套真空热胀形的重要工艺参数,为了研究胀形间隙对转子屏蔽套真空热胀形的影响,在其他工艺参数保持不变的情况下,胀形间隙依次取0.01、0.20、0.40、0.60、0.80和1.00 mm。图3所示为胀形间隙对转子屏蔽套的胀形量的影响。从图3可以看到,当胀形间隙小于0.80 mm时,转子屏蔽套的胀形量与胀形间隙近似成反比关系,即胀形量随着胀形间隙的增大线性减小,而当胀形间隙接近或大于0.80mm时,胀形量几乎为0,说明此时的胀形间隙已经超出了此套模具和工艺的胀形能力范围。

图3 胀形间隙对转子屏蔽套胀形量的影响

Fig. 3 Effect of bulging clearance on bulging dimension of rotor can

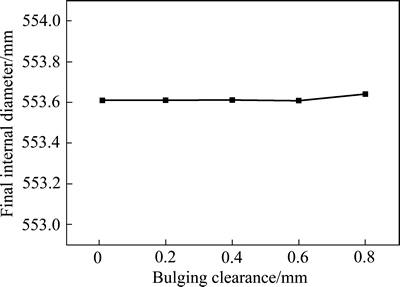

图4所示为胀形间隙对真空热胀形后转子屏蔽套内径的影响。由图4可以看到,当胀形间隙处于0~0.80 mm范围内时,转子屏蔽套胀形后的内径几乎不随胀形间隙的变化而变化,也就是说,只要经过剪切和焊接制造的转子屏蔽套的胀形间隙处于0~0.80 mm范围内,就可以通过设计的胀形工艺胀到近似相同的尺寸,这也说明真空热胀形工艺具有较高的稳定性。

图4 胀形间隙对胀形后转子屏蔽套内径的影响

Fig. 4 Effect of bulging clearance on internal diameter of rotor can after vacuum hot bulging forming

4 真空热胀形实验

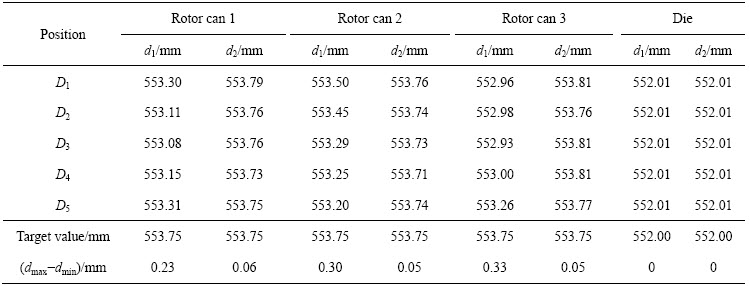

真空热胀形实验前,采用0.50 mm厚的Hastelloy C-276合金薄板加工成转子屏蔽套,屏蔽套的高度为480.00 mm,其胀形后的目标内径为553.75 mm,要求焊接后的转子屏蔽套内径与目标内径间为负偏差,根据模拟结果,最大负偏差不得大于1.60 mm。模具的材料为1Cr18Ni9Ti不锈钢,模具的厚度为20.00 mm,高度为500.00 mm,其目标外径值为552.00 mm,要求模具的外径加工精度为±0.02 mm。图5所示为真空热胀形模具和转子屏蔽套。

真空热胀形实验所采用的胀形工艺与前面模拟中所采用的胀形工艺相同。为了科学地表征实验结果,分别在转子屏蔽套和模具的外表面从上至下等间距依次设置5个测量点(D 1~D5),在真空热胀形前后,依次测量这5个测量点处转子屏蔽套的内径和模具的外径,并计算出转子屏蔽套的胀形间隙和胀形量。

图6所示为转子屏蔽套真空热胀形胀形量的模拟结果和实验结果的对比。由图6可以看出,真空热胀形胀形量的实测值与胀形间隙近似呈线性关系,这与前面的模拟结果一致。因此,建立的转子屏蔽套真空热胀形有限元模型的模拟结果是准确的,模型是可靠的。

图5 真空热胀形模具和转子屏蔽套照片

Fig. 5 Photo of die and rotor can during vacuum hot bulge forming

图6 转子屏蔽套胀形量的模拟结果与实验结果对比

Fig. 6 Comparison between simulated and experimental results of bulging dimension of rotor can

表2给出了真空热胀形前后转子屏蔽套的内径和模具的外径尺寸的测量结果,从表2可以看出,真空热胀形前,转子屏蔽套的内径均匀度较差,即转子屏蔽套上5个测量点的内径测量值相差较大,最大偏差为0.33 mm,远远超出了工艺要求的直径公差(±0.076 mm),最大负偏差达到0.82 mm。在胀形后,一方面,转子屏蔽套都达到了很好的均匀度,3个屏蔽套内径的最大偏差仅有0.06 mm,满足工艺要求的直径公差;另一方面,也可以看出与热套装前的目标内径553.75 mm相比较,3个转子屏蔽套胀形后的内径与目标内径的偏差范围为-0.04~0.06 mm,满足要求的直径公差范围。也就是说焊接后即使转子屏蔽套各处的内径值相差较大,只要各处的内径值处于真空热胀形工艺的胀形能力范围内,都可以通过真空热胀形技术胀到近似相同的尺寸,满足套装前的高精度要求,且多次实验也表明真空热胀形技术具有较高的稳定性。

5 结论

1) 基于有限元软件MSC.Marc建立了转子屏蔽套真空热胀形过程的二维非线性轴对称热力耦合有限元模型,计算并分析了真空热胀形过程中转子屏蔽套和模具的径向位移变化,预测转子屏蔽套的胀形量和胀形后的内径。

2) 研究胀形间隙对转子屏蔽套真空热胀形的影响,结果表明在胀形能力范围内,转子屏蔽套的胀形量随胀形间隙的增大线性减小,转子屏蔽套胀形后的内径不随胀形间隙的变化而变化,说明在胀形能力范围内,真空热胀形工艺具有较高的稳定性。

表2 真空热胀形前后转子屏蔽套的内径和模具的外径

Table 2 Internal diameter of rotor can and external diameter of die before and after vacuum hot bulge forming

3) 进行转子屏蔽套真空热胀形工艺实验,模拟结果与实验结果吻合较好,验证有限元模型的准确性。

REFERENCES

[1] 关 锐, 高永军. AP1000反应堆主泵屏蔽套制造工艺浅析[J]. 中国核电, 2008, 1(1): 49-53.

GUAN Rui, GAO Yong-jun. Brief analysis on fabrication process of AP1000 reactor coolant pump can[J]. China Nuclear Power, 2008, 1(1): 49-53.

[2] WANG M W, ZHANG L W, PEI J B, LI C H, ZHANG F Y. Effect of temperature on vacuum hot bulge forming of BT20 titanium alloy cylindrical workpiece[J]. Transactions of Nonferrous Metals Society of China, 2007, 17: 957-962.

[3] ZHU Z, ZHANG L W, SONG G Y, WU D J. Study on creep deformation of reactor coolant pump rotor-can during vacuum hot bulge forming process[J]. Advanced Materials Research, 2011, 189/193: 2415-2420.

[4] HOLMAN M C. Autoclave age forming large aluminum aircraft panels[J]. Journal of Mechanical Working Technology, 1989, 20(9): 477-488.

[5] KOWALEWSKI Z L, HAYHURST D R, DYSON B F. Mechanisms-based creep constitutive equations for an aluminum alloy[J]. Journal of Strain Analysis, 1994, 29(4): 309-316.

[6] HO K C, LIN J G, DEAN T A. Modeling of springback in creep forming thick aluminum sheets[J]. International Journal of Plasticity, 2004, 20(4/5): 733-751.

[7] JEUNECHAMPS P P, HO K C, LIN J G, PONTHOT J P, DEAN T A. A closed form technique to predict springback in creep age-forming[J]. International Journal of Mechanical Sciences, 2006, 48: 621-629.

[8] 王明伟, 张立文, 原思宇, 戚 琳, 张凡云, 李辰辉. BT20钛合金筒形件真空热胀形过程热力耦合有限元分析[J]. 塑性工程学报, 2007, 14(2): 109-113.

WANG Ming-wei, ZHANG Li-wen, YUAN Si-yu, QI Lin, ZHANG Fan-yun, LI Chen-hui. Coupled thermo-mechanical FEM analysis of the vacuum hot bulge forming of BT20 Titanium alloy cylindrical workpiece[J]. Journal of Plasticity Engineering, 2007, 14(2): 109-113.

[9] HUANG L, WAN M, CHI C L, JI X S. FEM analysis of spring-backs in age forming of aluminum alloy plates[J]. Chinese Journal of Aeronautics, 2007, 20: 564-569.

[10] 王明伟, 张立文, 张凡云, 李辰辉. 钛合金筒形件真空热胀形壁厚效应的数值模拟[J]. 稀有金属材料与工程, 2007, 36(10): 1772-1775.

WANG Ming-wei, ZHANG Li-wen, ZHANG Fan-yun, LI Chen-hui. Numerical simulation of wall thickness effects in vacuum hot bulge forming process of titanium alloy cylindrical workpiece[J]. Rare Metal Materials and Engineering, 2007, 36(10): 1772-1775.

[11] 黄 硕, 曾元松, 黄 遐. 2324铝合金蠕变时效成形有限元分析[J]. 塑性工程学报, 2009, 16(4): 129-133.

HUANG Shuo, ZENG Yuan-song, HUANG Xia. FE analysis of creep age forming for aluminum alloy 2324[J]. Journal of Plasticity Engineering, 2007, 36(10): 1772-1775.

[12] 李 超, 万 敏, 金 兴, 黄 霖. 7B04铝合金时效成形本构模型研究与有限元应用[J]. 塑性工程学报, 2010, 17(5): 61-65.

LI Chao, WAN Min, JIN Xing, HUANG Lin. A creep forming constitutive model of 7B04 aluminum alloy and its application in FEM[J]. Journal of Plasticity Engineering, 2010, 17(5): 61-65.

[13] ZHU Z, ZHANG L W, GU S D. Finite element simulation of vacuum hot bulge forming process of reactor coolant pump rotor-can[J]. Materials Science Forum, 2011, 675/677: 909-912.

[14] 朱 智, 张立文, 顾森东. Hastelloy C-276合金应力松弛实验及蠕变本构方程[J]. 中国有色金属学报, 2012, 22(4): 1063-1067.

ZHU Zhi, ZHANG Li-wen, GU Sen-dong. Stress relaxation test of Hastelloy C-276 alloy and its creep constitutive equation[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(4): 1063-1067.

Effect of bulging clearance on vacuum hot bulge forming of reactor coolant pump rotor can

ZHU Zhi, ZHANG Li-wen, NIE Long-fei, CUI Yan, ZHANG Chi, LI Rui-qin

(School of Materials Science and Engineering, Dalian University of Technology, Dalian 116023, China)

Abstract: A 2-D axis-symmetrical thermo-mechanical coupled finite element model of vacuum hot bulge forming process of rotor can was established using non-linear finite element software MSC.Marc. The radius-direction displacement variation of rotor can and die were calculated and analyzed. The bulging dimension and internal diameter of rotor can after bulging forming were predicted. In addition, the effects of bulging clearance on the bulging dimension and internal diameter of rotor can after bulging forming were discussed on the basis of developed finite element model. The results indicate that, when the bulging clearance increases, the bulging dimension of rotor can decreases linearly and the internal diameter of rotor can after bulging forming never changes. The corresponding vacuum hot bulge forming experiments were conducted to verify the reliability of the finite element model.

Key words: Hastelloy C-276; rotor can; vacuum hot bulge forming; bulging clearance

Foundation item: Project(2015CB057305) supported by the National Basic Research Development Program of China

Received date: 2015-01-30; Accepted date: 2015-10-30

Corresponding author: ZHANG Li-wen; Tel: +86-411-84706087; E-mail: commat@mail.dlut.edu.cn

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2015CB057305)

收稿日期:2015-01-30;修订日期:2015-10-30

通信作者:张立文,教授,博士;电话:0411-84706087;E-mail: commat@mail.dlut.edu.cn