文章编号:1004-0609(2015)-05-2575-07

一元散体颗粒物料在回转窑截面上的运动与混合

陈 辉1,刘义伦1,赵先琼1,肖友刚2,刘 颖3

(1. 中南大学 机电工程学院,长沙 410083;

2. 中南大学 交通运输工程学院,长沙 410075;

3. 中南大学 建筑与艺术学院,长沙 410083)

摘 要:针对物料的散体颗粒性质,采用离散单元法建立颗粒物料的运动模型,计算物料在回转窑内的运动与混合过程。通过“颗粒接触数”定义混合指数,分析物料在回转窑内的径向混合。结果表明:模型所得物料的混合形态与实验观测结果相符,回转窑转动6至8圈后,径向混合形态趋于稳定;根据“颗粒接触数”定义的混合指数能更合理地描述物料的混合程度,物料混合指数与时间成指数函数关系;混合速度随回转窑转速的增加而增大,转速越高,混合程度达到饱和所需时间越短,但是所需的转动圈数会增多;转速较低时,混合速度随填充率的减小而增大,但是转速增加到20 r/min后,混合速度随填充料的减小而减小;回转窑转速越高,物料动能的耗散性越强。

关键词:回转窑;一元物料;固体颗粒;径向混合;离散单元法

中图分类号:TF 537 文献标志码:A

Motion and mixing of mono-disperse granular material in cross section of rotary kiln

CHEN Hui1, LIU Yi-lun1, ZHAO Xian-qiong1, XIAO You-gang2, LIU Yin3

(1. College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

2. College of Traffic and Transportation Engineering, Central South University, Changsha 410075, China;

3. School of Architecture and Art, Central South University, Changsha 410083, China)

Abstract: Accounting for the dispersed properties of granular materials, a motion model of granular materials was established using three-dimensional discrete element method, then, the motion and mixing process of material in the rotary kiln were calculated by the model. On this basis, the transverse mixing of granular material within the rotary kiln was analyzed using an improved mixing index which could evaluate the degree of mixing quantitatively. The results, being consistent with the experimental observations qualitatively, show that the transverse mixing becomes stable after six to eight revolutions of the rotary kiln. Mixing index improved on particle contact-numbers can evaluate the mixing degree of material more reasonably. There is an exponential function relationship between the mixing index and time, two kinds of materials have an initial state of complete separation. The mixing rate increases with increasing rotational speed of rotary kiln. Then, the higher the speed is, the shorter the time is needed for material to reach a complete mixing situation, but the number of revolution needed will be more. When the low rotating speed is less than 20 r/min, the mixing rate increases with the decrease of filling lever. The higher the speed, the stronger the kinetic energy dissipated in granular material.

Key words: rotary kiln; mono-disperse material; solid particle; transverse mixing; discrete element method

颗粒物料由大量的固体颗粒集合而成[1],被广泛应用于金属冶炼、水泥生产、矿物加工等行业中。回转窑是运输和处理颗粒物料最常见的设备[2-3]。物料在回转窑内的混合效果关系到物料的干燥、研磨及热工效率[4-6],物料良好的混合往往能提高产品的质量。因此,研究和掌握颗粒物料在会转窑内的运动和混合规律具有重要的理论意义和工程应用价值。

回转窑中物料的混合分为径向混合与轴向混合两个方面:1) 轴向混合主要由物料的自扩散引起,速度缓慢;2) 径向混合由颗粒的剪切和对流运动引起,混合效果强烈,在物料混合中占支配地位[7],因此,研究重点一般集中在的径向混合方面[8-14]。为研究回转窑中物料的混合效率,学者们早期通过对物料进行物理取样,以样本质量分数的方差变化率来评价物料混合速度[8-9],但是研究结果的差异较大,其中物料完全混合所需的时间相差达十倍以上。而后,van PUYVELDE等[10-11]以不同颗粒之间的接触数作为物料混合程度的评价指标,研究发现混合速度分别随回转窑转速与填充率呈线性增长。但SCHUTYSER等[12]与FINNIE等[13]的数值模拟结果却表明,混合速度随着回转窑转速和填充率的增加而减慢。近期,LIU等[14]发现物料的混合速度并非简单的单调函数,而是随着填充率的增加会出现一个最低值。可见,目前关于物料径向混合的研究还存在争议。

由于固体颗粒的离散性和非透明性,实验研究中,如何无干扰地提取物料的运动信息并确定二元物料的混合程度具有一定难度。通过放射性颗粒追踪[15-16]等粒子示踪法可以对颗粒物料的运动轨迹和混合程度进行精确的描述,但这种研究方式对物料类型和回转窑的几何尺寸有较严格的限制,而且研究成本昂贵。近年来,离散单元法(Discrete element method, DEM)逐渐成为研究颗粒体系的重要数值试验工具,可以方便地获得颗粒体系内部的力学信息[17-19],且DEM在研究回转窑物料运动规律方面也已有应用[20-22]。本文作者采用三维DEM建立颗粒物料的运动模型,对回转窑中物料的运动过程进行了计算与模拟,得出了物料混合形态的变化过程,并通过改进物料混合程度的评价指数,分析了物料的径向混合速度与回转窑主要运行参数的关系,作为回转窑的高效运行研究的理论基础。

1 DEM模型建立

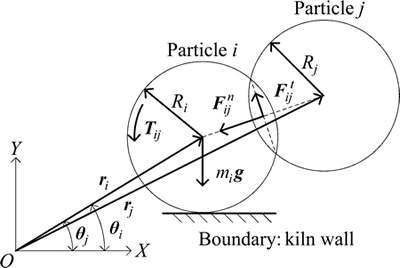

DEM模型由CUNDALL等[17]提出,主要用于散体颗粒物质的研究。物料的运动属于密集颗粒运动,采用软球颗粒表示颗粒物料。如图1所示,单个颗粒i在运动中受自身重力和相邻颗粒j的接触力作用,运动控制方程为

(1)

(1)

(2)

(2)

式中:mi、Ii分别为质量与转动惯量;ri(t)为颗粒的位置矢量;θi(t)为角位移;g为重力加速度; 、

、 分别为颗粒i与颗粒j之间接触力的法向、切向分量;Tij为接触力力矩。

分别为颗粒i与颗粒j之间接触力的法向、切向分量;Tij为接触力力矩。

图1 DEM颗粒模型

Fig. 1 Schematic diagram of DEM particle model

式(1)和(2)中,接触力计算方式主要有3种[18]:线性接触力模型、Hertz-Mindlin模型和无滑移Hertz-Mindlin模型。根据ALBERTO等[19]的研究结果,密集颗粒运动中颗粒接触力采用无滑移Hertz-Mindlin模型计算不但能保证计算精度,而且可以避免过多的计算量。因此,颗粒的接触力采用无滑移Hertz-Mindlin模型计算。 、

、 、Tij具体计算如下:

、Tij具体计算如下:

(3)

(3)

(4)

(4)

(5)

(5)

式中:颗粒等效半径R*=RiRj/(Ri+Rj);等效弹性模量E*=EiEj/[(1-ξ2i)Ei+(1-ξ2j)Ej];等效质量m*=mimj/(mi+ mj);等效切向模量G*=GiGj/[(1-ξ2i)Gi+(1-ξ2j)Gj];法向刚度Sn=2E*(R*α)0.5;切向刚度St=8G*(R*α)0.5,修正系数β= lne/(ln2e+π2)0.5(其中,Ri、Ei、ξi、mi、Gi与Rj、Ej、ξj、mj、Gj分别为颗粒i与颗粒j的半径、弹性模量、泊松比、质量、剪切模量;α、δ分别为颗粒之间的法向、切向重叠量;vnij、vtij分别为颗粒之间相对速度的法向、切向分量; 为颗粒i在接触点的单位角速度矢量;e为颗粒之间的恢复系数;μr为滚动摩擦因数;μt为滑动摩擦因数)。

为颗粒i在接触点的单位角速度矢量;e为颗粒之间的恢复系数;μr为滚动摩擦因数;μt为滑动摩擦因数)。

回转窑为水平放置的转筒,为物料运动提供几何边界。由于端面挡板的摩擦力会改变物料原有的径向运动状态[4],为消除其影响,回转窑不设端面挡板,轴向方向设置为循环边界。

运动方程建立后,通过颗粒循环检索和时间差分法对式(1)和式(2)进行迭代求解,得出全体颗粒位移及速度随时间的变化规律。文中回转窑材料为钢材,物料为石英沙颗粒,计算参数来自实验测量及经验取值[21],如表1所示。基本算法程序可采用 (Universal distinct element code,UDEC)等DEM数值计算软件或自编程序实现[17-19],不再赘述。

图2所示为物料在回转窑中的初始状态(图中w为回转窑转速,φ为物料填充角)。由图2可看出,物料被分成质量相等的两份,一份标记为红色,另一份标记为黑色,分别装在回转窑的左右两边。随着回转窑的转动,物料开始运动并相互混合。运行参数为转速w和填充率f,且

(6)

(6)

图2 物料的初始状态

Fig. 2 Initial state of granular material

2 混合程度评价指数

物料混合程度与颗粒的位置状态相关,其评价指标主要有:Lacy混合指数[14]、混合熵[12-13]和颗粒接触数[10]。其中,Lacy混合指数和混合熵的评价精度受网格单元尺寸的影响,不如颗粒接触数能更准确地描述物料混合程度。以混合熵和颗粒接触数为例,如图3所示,图中的单元A、单元B、单元C分别表示物料3种不同的混合状态:根据混合熵的计算方式[12-13],3个单元的混合熵相等,不能区分各单元的混合程度,且误差会随着单元尺寸的增加而变大;而红色颗粒与黑色颗粒之间的接触数会随着混合程度的加深而增大。可见,颗粒接触数能更精确地描述混合程度。

实验中提取颗粒接触数量的可行性不强,van PUYVELDE等[10]是测量不同颜色颗粒之间的接触长度代替接触数量,况且,相同颜色颗粒之间的接触长度无法测量,不能描述物料的整体混合程度。

DEM程序则可以方便地记录颗粒之间的接触数量(见图1);颗粒之间的距离为|ri(t)-rj(t)|;颗粒半径分别为Ri、Rj;当|ri(t)-rj(t)|i+Rj时,判定颗粒i、j之间发生接触。如果颗粒i与颗粒j均为红色,则记录一个红色-红色接触数,循环记录后,可得红色-红色接触总数为nrr (t);同理,可得黑色-黑色接触总数为nbb(t)、红色-黑色接触总数为nrb(t)。定义物料的混合指数为M(t),且

(7)

(7)

求解式(7)后,可得出混合指数M(t)的变化规律。M取值范围为[0,1],且M越大,表示物料混合程度越高;当M=1时,表示物料达到图3中单元C的完全混合状态。

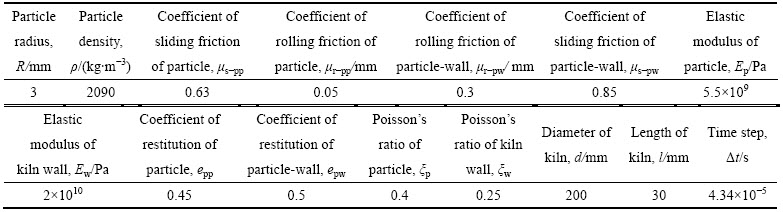

表1 DEM模型计算参数

Table 1 Calculation Parameters used in DEM model

图3 混合熵与颗粒接触数的对比

Fig. 3 Comparison between mixing entropy and contact numbers

3 结果分析

3.1 混合形态的实验对比

物料在回转窑中的运动模式分为6种[4]:滑移、塌落、滚落、泻落、抛落和离心运动。工程应用中,物料最常见的运动模式为滚落,KHAKHAR等[5]测试了滚落模式的物料在回转窑中的混合过程,并定性描述了物料的混合形态(见文献[5],图10)。

图4所示为回转窑的转速ω=6 r/min,f=35%时DEM计算所得的物料混合过程。图中,nre表示回转窑转动的圈数。如图4(a)所示,物料在回转窑中的运动模式为滚落,即物料分为平流层和活动层两部分,平流层的颗粒随回转窑一起绕轴线运动,颗粒之间相对静止,活动层的颗粒向下快速崩落,并形成稳定的倾斜角。如4(b)所示,物料的混合形态与KHAKHAR等[5]的实验观测结果相符:初始阶段,两种不同颜色物料之间有清晰的分界线,且随着回转窑的转动,平流层的分界线保持不变,但是进入活动层的分界线被拉长,物料开始混合;随着转动圈数的增加,活动层内不断有颗粒越过分界线,分界线逐渐变模糊并最终消失,物料的混合程度也逐渐加深;最终,回转窑转动约6至8圈后,物料的混合程度达到饱和,混合形态也趋于稳定。

3.2 混合程度分析

通过DEM模型,分别对不同工况下物料在回转窑中的运动混合过程进行了计算,并根据式(7)对物料的混合程度进行了定量分析,其中,回转窑的转速ω分别为0.5、1、2、5、10、20和40 r/min,物料的填充率f分别为20%、35%和50%。

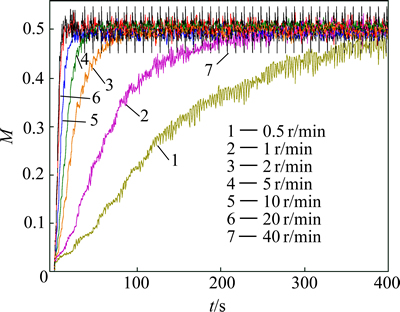

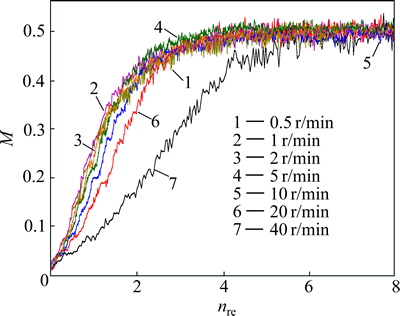

图5为 f=35%不同转速下混合指数M(t)的响应。由图5可知,混合指数随时间呈指数函数变化,即混合指数随时间先急剧增加而后趋于平稳。由于颗粒的运动会同时产生混合与分离两种作用,初始阶段,完全分离的两种物料随着颗粒的运动而快速混合,混合指数急剧上升,随着混合程度的增加,颗粒的分离作用逐渐加强,导致混合速度变慢,混合指数的增长也逐渐变缓,最后,颗粒的混合与分离作用互相平衡,物料混合程度达到饱和状态,混合指数也趋于平稳。混合指数稳定后在M=0.5上下波动,表明混合饱和后的物料并不是绝对均匀化的完全混合状态,而是颗粒混合与分离保持动态平衡的部分混合状态,这与实际情况相符。转速越大,混合指数达到稳定的时间越短,即物料的混合速度越大,但是随着转速的变大,这种影响逐渐变弱,当图中转速大于20 r/min之后,M达到稳定的时间几乎不再随转速的增加而变短。

图5中M(t)经拟合后为

(8)

(8)

式中:系数kt可以表示物料的混合速度,且kt越大,表示物料的混合速度越快。

图4 滚落状态的物料混合形态

Fig. 4 Mixing state of granular material in rolling regime

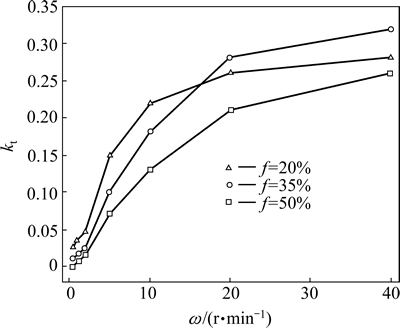

图6所示为所有工况下系数kt的拟合值。由图6可知,与van PUYVELDE[10-11]的研究结果相同,填充率一定时,物料混合速度随着回转窑转速的增加而增大,只是混合速度的增长幅度会逐渐变小;填充率越小,物料的混合速度越快,由于填充率减小后,物料处于活动层的颗粒数量占总颗粒数量的比例会上 升[4],从而有更多颗粒参与混合运动,使物料整体的混合速度变快。但是,当转速大于20 r/min之后,f=20%的混合速度却比f=35%的低,可见,回转窑转速较大的情况下,减小填充率反而会降低物料的混合速度,这是由于回转窑高速转动时,过小的填充率很难使物料形成有利于混合的抛落运动[4],从而抑制了混合速度。

图5 f=35%时混合指数M随时间t的响应

Fig. 5 Repose of mixing index M (t) with time at f=35%

图6 转速ω和填充率f对系数kt的影响

Fig. 6 Effects of rotation speed and filling degree on coefficient kt

SCHUTYEB等[12]研究中,常以回转窑转动圈数nre替代时间t为变量进行研究(nre=ωt/(2π)),所得结果往往与图6相反,即混合速度随转速增加而降低。图7所示为以回转窑转动圈数为nre变量得出不同转速下物料混合指数M随nre的响应,其中,f=35%。由图7可知,回转窑转动6至8圈后,混合指数M均趋于稳定,且转速越大,M达到稳定状态所需的转动圈数越多。以nre为自变量,M(nre)拟合后亦近似为指数函数:

(9)

(9)

式中:系数kn表示物料的混合速度,且kn越大,表示物料的混合速度越大。

图8所示为所有工况下系数kn的拟合值。由图8可知,物料的混合速度随转速的增大而降低,且转速越大,混合速度降低的幅度越明显,可见,此结果与SCHUTYSER等[12]与FINNIE等[13]的研究结果并不矛盾。需要注意的是,此时的混合速度是针对nre而言的,即转速越大,物料混合速度越低,混合达到饱和所需的转动圈数越多。

图7 填充率f=35%时混合指数M随转动圈数nre的响应

Fig. 7 Response of mixing index M(nre) with rotation number at f=35%

图8 转速ω和填充率f对系数kn的影响

Fig. 8 Effects of rotation speed and filling degree on coefficient kn

由以上分析可知,回转窑转速增大后,物料达到同一混合程度所需的转动圈数会增加,即回转窑运行效率降低,这是颗粒的运动速度并不随回转窑转速成比例增长的原因。图9所示为f=50%时全体颗粒运动无量纲速度γ的分布函数,图中,颗粒运动速度为vi,回转窑内壁线速度为(ωd)/2,γ为无量纲速度:

(10)

(10)

由图9可知,随着回转窑转速的增加,γ逐渐减小,且转速越高,γ减小的幅度越大,表明回转窑转速增大后,颗粒的速度并不随转速成比例增加。主要有两个原因:一方面,转速变高后,物料颗粒与回转窑内壁之间会产生滑动摩擦,损失一部分动能;另一方面,颗粒系统自身具有强耗散性[1],高速运动时颗粒之间的碰撞和摩擦会消耗大部分动能,且颗粒运动速度越大,耗散性越强。因此,在某些高速工况下,回转窑转速增加之后,物料的运动速度和混合速度会加快,但是物料的动能耗散也会增强,不能无限制地依靠增加回转窑的转速来增强物料的混合效果。

图9 无量纲速度γ的分布函数

Fig. 9 Probability distribution of dimensionless speed γ

4 结论

1) 物料因为颗粒之间的相对运动而产生混合,回转窑转动6至8圈之后,物料的径向混合形态趋于稳定,DEM模拟所得的混合形态与实验观测结果相符。

2) 根据颗粒接触数改进后的混合指数能更合理地描述物料的混合过程。初始阶段完全分离的两份物料,其混合程度与时间成指数函数关系,且混合程度饱和后的物料无法达到理想的完全混合状态,而是颗粒混合与分离保持动态平衡的部分混合状态。

3) 混合速度随回转窑转速增加而增大,转速越高,物料混合达到饱和所需时间越短。转速较低时,混合速度随填充率减小而增大;转速较高时,情况正好相反,文中回转窑转速大于20 r/min之后,f=20%时的混合速度比f=35%时的低。

4) 回转窑转速增大后,颗粒间的动能耗散会增多,物料混合达到饱和所需的转动圈数也会增加。

REFERENCES

[1] JAVEN T, JIE B, NICOLAS H, YANG R Y. Modeling collective dynamics of particulate systems under time-varying operating conditions based on Markov chains[J]. Advanced Powder Technology, 2013, 24(2): 451-458.

[2] 贺实月, 李会泉, 李少鹏, 李勇辉, 解 强. 煤粉炉高铝粉煤灰碱溶脱硅反应动力学[J]. 中国有色金属学报, 2014, 24(7): 1888-1894.

HE Shi-yue, LI Hui-quan, LI Shao-peng, LI Yong-hui, XIE Qiang. Kinetics of desilication process of fly ash with high aluminum from pulverized coal fired boiler in alkali solution[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1888-1894.

[3] 马德刚, 陈伟庆, 车晓梅. 炼镍转炉溅渣护炉的水模试验[J]. 中国有色金属学报, 2012, 12(1): 287-295.

MA De-gang, CHEN Wei-qing, CHE Xiao-mei. Hydraulic simulation of slag splashing in nickel converter[J]. The Chinese Journal of Nonferrous Metals, 2012, 12(1): 287-295.

[4] MELLMANN J. The transverse motion of solids in rotating cylinders-forms of motion and transition behavior[J]. Powder Technology, 2001, 118(3): 251-270.

[5] KHAKHAR D V, MCCARTHY J J, TROY SHINBROT, OTTINO J M. Transverse flow and mixing of granular materials in a rotating cylinder[J]. Phys Fluids, 1997, 9(1): 31-43.

[6] 陈文仲, 王春华. 炭素回转窑内物料停留时间的确定[J]. 东北大学学报(自然科学版), 2010, 31(9): 1313-1317.

CHEN Wen-zhong, WANG Chun-hua. Calculation of mean residence time of solids in Carbon rotary kilns[J]. Journal of Northeastern University (Natural Science), 2010, 31(9): 1313-1317.

[7] 尹洪超, 沈春艳, 刘 红, 李德付. 回转窑冷态射流和气固两相流数学计算[J]. 硅酸盐学报, 2013, 41(11): 1527-1533.

YIN Hong-chao, SHEN Chun-yan, LIU Hong, LI De-fu. Calculation of cold jet and gas-solid two phase flow in rotary kiln[J]. Journal of the Chinese Ceramic Society, 2013, 41(11): 1527-1533.

[8] 李德付, 尹洪超, 张 明, 刘 红, 解茂昭. 回转窑横截面颗粒流动特性数值模拟研究[J]. 哈尔滨工程大学学报, 2013, 34(6): 703-708.

LI De-fu, YIN Hong-chao, ZHANG Ming, LIU Hong, XIE Mao-zhao. Numerical simulation of granular flow behavior in the cross section of a rotary kiln[J]. Journal of Harbin University, 2013, 34(6): 703-708.

[9] NIELSEN A R, ANIOL R W, LARSEN M B, GLARBORG P. Mixing large and small particles in a pilot scale rotary kiln[J]. Powder Technology, 2011, 210(3): 273-280.

[10] van PUYVELDE D R, YONG B R, WILSON M A. Experiment determination of transverse mixing kinetics in a rolling drum by image analysis [J]. Powder Technology, 1999, 106: 183-191.

[11] van PUYVELDE D R. Comparison of discrete elemental modelling to experimental data regarding mixing of solids in the transverse direction of a rotating kiln[J]. Chemical Engineering Science, 2006, 61: 4462-4465.

[12] SCHUTYER M A I, PADDING J T, WEBER F J. Discrete particle simulation predicting mixing behavior of solid substrate particles in a rotating drum fermenter[J]. Biotechnology and Bioengineering, 2001, 75(6): 665-675.

[13] FINNIE G J, KRUYT N P, YE M. Longitudinal and transverse mixing in rotary kilns: A discrete element method approach[J]. Chemical Engineering Science, 2005, 60: 4083-4091.

[14] LIU P Y, YANG R Y, YU A B. DEM study of the transverse mixing of wet particles in rotating drums[J]. Chemical Engineering Science, 2013, 86: 99-107.

[15] 李爱民, 蔡九菊, 王志, 魏砾宏. 固体废弃物在回转窑内混合特性的实验[J]. 东北大学学报(自然科学版), 2002, 23(2): 152-155.

LI Ai-ming, CAI Jiu-ju, WANG Zhi, WEI Li-hong. Experimental research on the mixing characteristics of solid waste in rotary kiln[J]. Journal of Northeastern University (Natural Science), 2002, 23(2): 152-155.

[16] DOUCET J, BERTRAND F, CHAOUKI J. An extended radioactive particle tracking method for systems with irregular moving boundaries[J]. Powder Technology, 2008, 181(2): 195-204.

[17] CUNDALL P A, STRACK O L. A discrete numerical model for granular assemblies[J]. Geotechnique, 1979, 29(1): 47-65.

[18] 陈 辉, 刘义伦, 赵先琼, 肖友刚. 基于离散单元法的回转窑物料崩落运动及接触力链研究[J]. 浙江大学学报(工学版), 2014, 48(12): 2277-2283.

CHEN Hui, LIU Yi-lun, ZHAO Xian-qiong, XIAO You-gang. Analysis on avalanching motion and force chains of bed material within rotating cylinder based on discrete element method[J]. Journal of Zhejiang University (Engineering Science), 2014, 48(12): 2277-2283.

[19] ALBERTO D R, FRANCESCO P D M. Comparison of contact-force models for the simulation of collisions in DEM-based granular flow codes[J]. Chemical Engineering Science, 2004, 59(13): 525-541.

[20] YIN H, ZHANG M, LIU H. Numerical simulation of three-dimensional unsteady granular flow in rotary kiln[J]. Powder Technology, 2014, 253: 138-145.

[21] ALIZADEH E, BERTRAND F, CHAOUKI J. Comparison of DEM results and Lagrangian experimental data for the flow and mixing of granules in a rotating drum[J]. AIChE Journal, 2014, 60(1): 60-75.

[22] KOMOSSA H, WIRTZ S, SCHERER V, HERZ F, SPECHT E. Transversal bed motion in rotating drums using spherical particles: Comparison of experiments with DEM simulations[J]. Powder Technology, 2014, 264: 96-104.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51374241, 51275531);湖南省研究生科研创新资助项目(CX2014B059)

收稿日期:2014-08-05;修订日期:2015-06-25

通信作者:刘义伦,教授,博士;电话:0731-88876734;E-mail: ylliu@csu.edu.cn