悬浮炼铅过程数值仿真

陈卓1,谢德成1,夏中卫2,周萍1,廖舟2

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 株洲冶炼集团有限责任公司,湖南 株洲,412000)

摘要:应用CFD软件对悬浮炼铅过程进行仿真研究,建立炼铅过程的数值仿真模型,并对该过程开展气、粒两相多场耦合仿真计算。研究结果表明:数值仿真模型基本准确可靠;工业氧经氧焰喷嘴喷入反应塔后,形成明显的圆柱形高速气流柱;反应主要集中在氧焰喷嘴正下方约1 m处进行,高温区域位置集中在喷嘴至下方约2 m处。通过对其过程的数值仿真研究,可以直观地了解炉内速度场、温度场、气相浓度场以及颗粒轨迹,从而对悬浮炼铅炉的运行维护以及参数优化提供技术指导。

关键词:悬浮炼铅;气粒两相;多场耦合;数值仿真

中图分类号:TF812 文献标志码:A 文章编号:1672-7207(2014)10-3344-07

Numerical simulation of suspended lead smelting process

CHEN Zhuo1, XIE Decheng1, XIA Zhongwei2, ZHOU Ping1, LIAO Zhou2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Zhuzhou Smelter Group Co. Ltd., Zhuzhou 412000, China)

Abstract: The CFD software was used for numerical simulation of suspended lead smelting process. A computational model was developed and a multi-field coupling numerical simulation was carried out to study the gas-particle flow. The results show that the numerical simulation model is reliable; the industrial oxygen forms distinct cylindrical columns after spraying into the reaction shaft at a high speed through the concentrate nozzle; reactions mainly take place 1 m below the nozzle and the location of high-temperature region is about 2 m away from the nozzle. Through the simulation study of the lead smelting process, the distributions of the flow field, temperature field and concentration field as well as the particle trajectories inside the furnace can be investigated. Therefore, the technical guidance can be provided for the operation of the suspended lead smelting process.

Key words: suspended lead smelting; gas-particle flow; multi-field coupling; numerical simulation

悬浮炼铅工艺被认为是当今世界上先进、成熟且最为有效的直接炼铅工艺之一[1-2]。其整个过程都在一座密闭、紧凑的悬浮炼铅炉内完成,省去了烧结工序,能很好地满足当前能源节约、环境保护和可持续发展的要求[3]。悬浮炼铅工艺的最大特点是实现了氧化气氛与还原气氛的隔离,即用一道隔墙把悬浮炼铅炉分成反应塔氧化区域和电炉还原区域[4-5]。这种分离方法不但实现了铅的连续熔炼过程,而且大大提高了烟气中的SO2含量,解决了烟气污染与制酸难的问题。我国已成为全球铅生产和消费大国,其铅产量和铅消费量已连续多年位居世界第一[6-7]。为满足炼铅技术快速发展的要求,多年来国内外科研人员从不同方向进行了大量深入的研究工作。Tan等[8]在20世纪90年代末提出了直接炼铅过程的热动力学模型,成功预测了悬浮炼铅炉、QSL和Outokumpu等炼铅炉熔炼区和还原区产物中各元素的质量分数,其结果与工业数据相符。在此基础上,Tan等[9]研究了悬浮炼铅炉入口氧气与矿料之比对熔炼反应以及焦滤层热平衡的影响。汪金良等[10]建立了铅闪速熔炼多相平衡热力学模型,模拟计算了奥托昆普闪速炼铅半工业状态下的平衡组分,模拟结果与半工业试验结果相符。而迄今为止,对悬浮炼铅炉内炼铅过程的研究尚未采用数值仿真的方法。本文作者根据悬浮炼铅炉的设备结构特点,建立悬浮炼铅炉的物理与数学仿真模型,并开展气粒两相多场耦合仿真计算,分析炉内流场、温度场、浓度场等微观信息分布特点,以此为悬浮炼铅炉的运行维护与结构优化提供技术支持。

1 炼铅过程数值仿真模型

1.1 物理模型

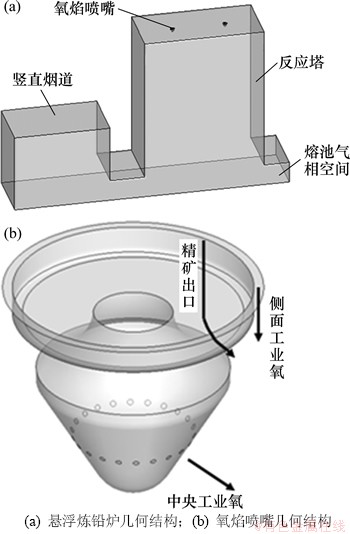

本文中的仿真计算主要侧重于研究悬浮炼铅炉内气、粒两相的流动、混合与反应过程,因此,建立的仿真计算物理模型包括氧焰喷嘴、反应塔、熔池气相空间以及竖直烟道等4部分[11]。由于悬浮炼铅炉炉体沿熔池长度方向具有良好的对称性,为有效减少模型网格数量与计算时间,建模时仅选取悬浮炼铅炉炉体一半作为仿真计算区域,如图1(a)所示。氧焰喷嘴主要包括环状的侧面工业氧出口、精矿出口以及环孔状中央氧出口,结构如图1(b)所示。悬浮炼铅炉网格划分如图2所示。

1.2 数学模型

悬浮炼铅工艺是典型的连续生产过程,因此数值仿真模型中采用了稳态控制方程组来描述闪速熔炼过程气、粒两相之间的传递过程。

1.2.1 气相控制方程

质量守恒方程为

(1)

(1)

动量守恒方程为

(2)

(2)

能量守恒方程为

图1 悬浮炼铅炉仿真模型示意图

Fig. 1 Schematic of computational domain of suspended lead smelting furnace

图2 悬浮炼铅炉网格划分示意图

Fig. 2 Schematic of mesh structure of suspended lead smelting furnace

(3)

(3)

化学组分守恒方程为

(4)

(4)

其中:ρ为流体密度;x为位移;u为速度;i和j为三维直角坐标系下的坐标方向;μe为有效黏度;μe为分子动力黏度μ0与湍流动力黏度μT之和, ;p为压强;σh和σY分别为能量方程和组分传输方程的普朗特常数;qr为来自热辐射或化学反应的热量;ws为燃烧或化学反应过程的物质生成率;Spm,Spv,Sph和SpYi分别为质量守恒方程、动量守恒方程、能量守恒方程、化学组分守恒方程中由颗粒相传递给气相的源项。

;p为压强;σh和σY分别为能量方程和组分传输方程的普朗特常数;qr为来自热辐射或化学反应的热量;ws为燃烧或化学反应过程的物质生成率;Spm,Spv,Sph和SpYi分别为质量守恒方程、动量守恒方程、能量守恒方程、化学组分守恒方程中由颗粒相传递给气相的源项。

1.2.2 湍流模型

研究中采用标准k-ε双方程模型来描述炉内的湍流流动[12]:

(5)

(5)

(6)

(6)

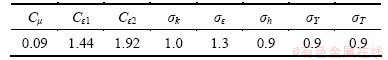

其中:Gk为由于平均速度梯度引起的湍动能k的产生项;Gb为由于浮力引起的湍动能k的产生项。式(1)~(6)中各常数如表1所示[13]。

表1 气相控制方程中的常数

Table 1 Constants in gaseous governing equations

1.2.3 颗粒相模型

对于每一组颗粒,有如下方程。

1) 颗粒相运动方程。运动过程采用拉格朗日法求解,其控制方程如下[14]:

(7)

(7)

其中:vp和v分别为颗粒相与气相速度;t为时间;g为重力加速度;ρp和ρ分别为颗粒与气相密度;F为颗粒相所受的除阻力、重力外的外力;FD为颗粒运动中受到的气相作用力, ;Re为雷诺数,

;Re为雷诺数, ;CD为阻力系数,CD=

;CD为阻力系数,CD= ;dp为颗粒的平均直径。

;dp为颗粒的平均直径。

2) 颗粒相的能量方程。颗粒相能量方程为

(8)

(8)

式中:mc为连续相中氧气的质量;Cp为氧气比定压热容;T为热力学温度; Qr为化学反应热;Qc为气相与颗粒表面的对流传热,

;d为颗粒平均直径;λ为颗粒导热系数;μ为动力黏度;Tg为气相温度;Tp为颗粒温度;Qrad为气相和颗粒相之间的辐射传热,

;d为颗粒平均直径;λ为颗粒导热系数;μ为动力黏度;Tg为气相温度;Tp为颗粒温度;Qrad为气相和颗粒相之间的辐射传热, ;

; 为颗粒表面发射率,εg为气体发射率;ag为气体吸收率;σ为斯忒藩-波耳兹曼常量。

为颗粒表面发射率,εg为气体发射率;ag为气体吸收率;σ为斯忒藩-波耳兹曼常量。

3) 颗粒相传质方程。在高温情况下,可认为化学反应主要由气固边界层的气体的扩散速度决定。在颗粒的氧化过程中,这个速率由O2从气体中向气固边界层迁移的速率决定。因此,可以通过如下的方程来控制反应速率:

(9)

(9)

式中:wc为气相中氧的质量分数;wF和wFG分别为气相和颗粒相中氧的质量分数。D为气相的质量组分的扩散率;Sh为舍伍德数,

;β为对流传质系数;dp为颗粒的平均直径[15]。

;β为对流传质系数;dp为颗粒的平均直径[15]。

1.2.4 炼铅过程反应模型

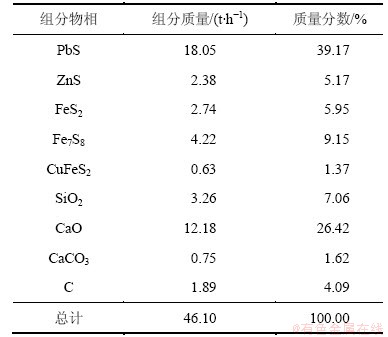

悬浮炼铅炉入炉物料成分复杂,入炉混合精矿中包含铅精矿、硫精矿、硫尾矿、石灰石、焦炭、石英砂等成分,各组分质量分数见表2。

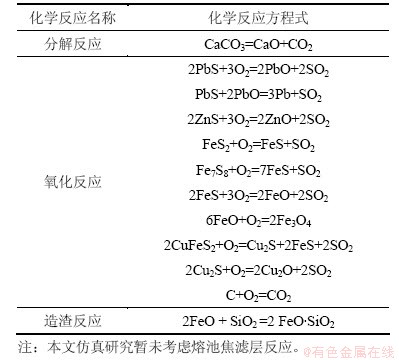

悬浮炼铅生产过程中硫化铅精矿颗粒通过氧焰喷嘴和工业氧一起喷入反应塔,在悬浮状态下进行氧化熔炼,其熔炼过程根据其反应特点大致可以划分为分解反应、氧化反应与造渣反应等几种反应类型,如表3所示。

表2 入炉精矿物相组成

Table 2 Composition of concentrates fed into reaction shaft

1.3 模型验证

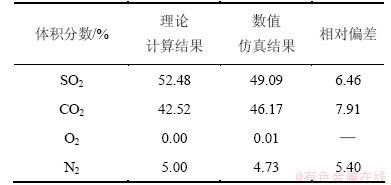

为了对仿真计算模型进行验证,研究中根据入炉物料元素表采用元素守恒法计算得理论出口烟气中各组分体积分数如表4所示。由表4可见:通过计算两者最大相对误差小于7.91%,由此证明本文所用数值模型准确可靠。

表3 铅精矿熔炼过程化学反应

Table 3 Reactions model of lead smelting process

表4 出口烟气中各组分体积分数

Table 4 Volume fraction of gaseous composition

2 炼铅过程数值仿真结果分析

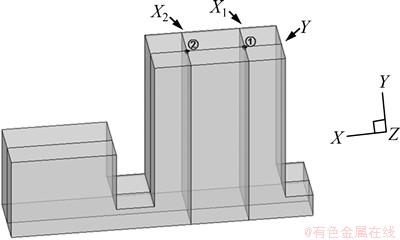

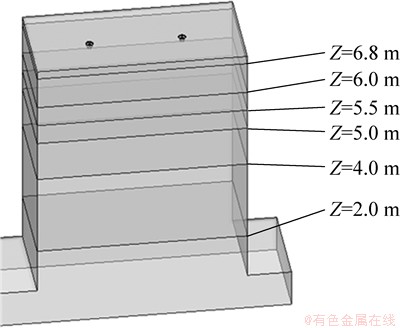

设定烟气从反应塔流向竖直烟道方向为X轴正方向,如图3所示。沿X轴正向观测时,截面编号依次为X1和X2;设X轴正向所指一侧为悬浮炼铅炉左侧;沿Y轴正向观测时,截面编号为Y;设Y轴正向所指一侧为悬浮炼铅炉后侧;喷嘴编号①和②如图3所示。

2.1 炉内速度场分布特点

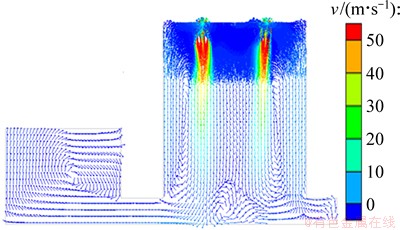

图4所示为悬浮炼铅炉Y截面气相速度分布仿真结果。从图4可以看出:侧面工业氧经①和②号氧焰喷嘴喷入反应塔后即迅速向塔下方运动,在喷嘴下方形成两股明显的高速气流,且侧面工业氧在向下运动的过程中逐渐膨胀并在喷嘴下方逐渐形成圆柱形气流柱;在接触熔池表面后,①号喷嘴下方气流在反应塔右侧空间形成回流;②号喷嘴下方气流主要向左流向竖直烟道,部分气流被左墙阻挡后形成回流。从图4同样可以看到:在反应塔底部中心与竖直烟道处也有局部回流产生。比较①和②号氧焰喷嘴中心轴上速度(v1和v2)沿竖直高度的变化(见图5)可以发现两者的变化趋势基本一致:2个喷嘴正下方均存在1个高度约为1 m的低速区,然后侧面工业氧开始汇合形成一股速度较大的高速气流柱。在塔高Z=6 m处气流速度可达50 m/s,沿塔高逐渐降低,接近熔池表面时速度降至10 m/s以下。

2.2 炉内温度场分布特点

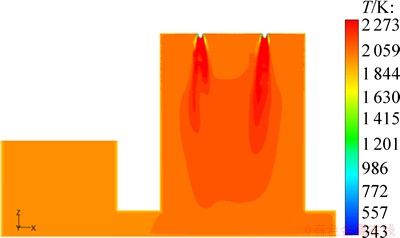

图6所示为悬浮炼铅炉Y截面上温度分布云图。由图6可以看出:高温区域呈喇叭状分布,主要集中在喷嘴至下方2 m处。从Z方向不同位置截面(见图7)上的温度分布图(如图8所示)可以看到:在塔高Z=6.8 m时高温区域外围存在一圈低温环。这是因为环形侧面工业氧是在常温下喷入反应塔的,温度较炉内平均温度低。沿塔高向下,侧面工业氧温度快速上升,放热反应逐渐增强,在塔高Z=5.0 m时高温区域达到最大;沿塔高继续向下,放热强度逐渐减弱,在塔高Z=2.0 m时反应塔内的温度分布已较均匀。

图3 悬浮炼铅炉截面及喷嘴编号示意图

Fig. 3 Schematic of cross-sections and nozzles of suspended lead smelting furnace

图4 悬浮炼铅炉Y截面上速度矢量图

Fig. 4 Velocity vectors of Y cross-section in suspended lead smelting furnace

图5 喷嘴中心轴上气相速度沿竖直高度变化

Fig. 5 Change of guseous speed along height of shaft under nozzles

图6 悬浮炼铅炉Y截面上温度分布图

Fig. 6 Temperature field of Y cross-section

图7 悬浮炼铅炉Z方向截面示意图

Fig. 7 Schematic of Z cross-sections

图8 悬浮炼铅炉Z方向各截面温度分布图

Fig. 8 Temperature field of Z cross-sections in suspended lead smelting furnace

2.3 炉内浓度场分布特点

图9所示为悬浮炼铅炉喷嘴中心轴上各气相物质体积分数沿塔高方向的变化曲线。由图9可见:①和②号氧焰喷嘴中心轴上各气相物质体积分数曲线(SO2体积分数分别记作S1和S2;同理,CO2体积分数分别记作C1和C2,O2体积分数分别记作O1和O2,N2体积分数分别记作N1和N2)的变化趋势基本一致。从氧焰喷嘴竖直向下约1 m处各参加反应的气相物质(N2是惰性气体)的体积分数变化剧烈,说明化学反应主要集中在此区域范围内;沿塔高继续向下,反应逐渐减弱。在Z=5 m时,各气相物质所占体积分数已基本平稳,说明化学反应已经基本完成。最终烟气中所含二氧化硫体积分数约为50%,二氧化碳体积分数约为45%,氧气已基本消耗完,整个过程中氮气体积分数基本保持5%左右不变。

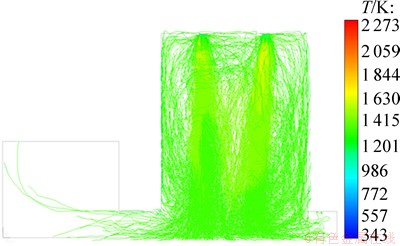

2.4 精矿颗粒轨迹仿真结果

颗粒温度随轨迹变化如图10所示。由图10可见:高温颗粒相主要集中在喷嘴正下方,沿塔高向下,颗粒温度逐渐降低。颗粒流偏移较小,没有直接打在壁面上,但是部分颗粒回流可能对炉墙形成冲刷损蚀。小部分颗粒在反应竖炉中盘桓,约有8.76%颗粒从竖直烟道流出。

图9 喷嘴中心轴上各气相体积分数沿竖直高度变化

Fig. 9 Change of gaseous volume fraction along height of shaft under nozzles

图10 精矿颗粒温度随轨迹变化

Fig. 10 Change of temperature along particle trajectory

3 结论

1) 建立的悬浮炼铅过程的数值模型基本准确,可以用来对悬浮炼铅炉进行分析与研究。

2) 环形侧面工业氧经氧焰喷嘴喷入反应塔后即迅速向塔下方运动,在喷嘴下方形成两股明显的圆柱形高速气流柱,接近熔池表面时速度逐渐低于10 m/s。

3) 炉内高温区域呈喇叭状分布,主要集中在喷嘴至下方2 m处,说明放热主要在这个区域内进行;继续往下炉内温度分布较为均匀,说明放热反应已经基本完成。

4) 从氧焰喷嘴竖直向下约1 m处各气相物质的体积分数变化剧烈,说明化学反应主要在这段距离内进行,然后反应强度逐渐减弱。当塔高等于5 m时,各气相体积分数已基本平稳,说明化学反应已基本完成。最终烟气成分如下:二氧化硫体积分数约为50%,二氧化碳体积分数约为45%,氧气已基本消耗完,整个过程中氮气体积分数基本保持5%左右不变。

5) 炉内精矿颗粒受气流影响显著,大部分颗粒下落至熔池中,部分颗粒在反应竖炉中盘桓,约8.76%的颗粒随烟气流动进入竖直烟道成为烟尘。

参考文献:

[1] 汪金良, 吴艳新, 张文海. 铅冶炼技术的发展现状及旋涡闪速炼铅工艺[J]. 有色金属科学与工程, 2011, 1(2): 14-18.

WANG Jinliang, WU Yanxin, ZHANG Wenhai. Development status of lead smelting technology and the lead vortex flash smelting process[J]. Nonferrous Metals Science and Engineering, 2011, 1(2): 14-18.

[2] Kulenov A S, Sannikov Y I, Slobodkin L V, et al. The KIVCET process: A unique technology for the smelting of raw material containing lead, zinc and/or copper[J]. Erzmetall: Journal for Exploration, Mining and Metallurgy, 1998, 51(4): 273-279.

[3] 叶国萍. 基夫赛特炼铅法[J]. 有色金属(冶炼部分), 2000(8): 20-24.

YE Guoping. Kivcet lead smelting method[J]. Nonferrous Metals (Extractive Metallurgy), 2000(8): 20-24.

[4] Sannikov Y I, Liamina M A, Shumskij V A, et al. Radashin M.V. Physical and chemical description of the Kivcet lead flash smelting process[J]. CIM Bulletin, 1998, 91: 76-81.

[5] 彭容秋. 铅冶金[M]. 长沙: 中南大学出版社. 2004: 26-65.

PENG Rongqiu. Lead metallurgy[M]. Changsha: Central South University Press. 2004: 26-65.

[6] 李卫锋, 张晓国, 郭学益, 等. 我国铅冶炼的技术现状及进展[J]. 中国有色冶金, 2010(2): 29-34.

LI Weifeng, ZHANG Xiaoguo, GUO Xueyi, et al. Status and progress of Chinese lead smelting technology[J]. China Nonferrous Metallurgy, 2010(2): 29-34.

[7] 贺菊香. 基夫赛特直接炼铅技术的应用前景[J]. 湖南有色金属, 2011(6): 20-23.

HE Juxiang. Application prospects of KIVCET direct lead smelting technology[J]. Hunan Nonferrous Metals, 2011(6): 20-23.

[8] TAN Pengfu, ZHANG Chuanfu. Thermodynamic modeling for direct lead processes[C]//Proceedings of the 1998 TMS Annual Meeting. San Antonio, TX, USA, 1998: 815-820.

[9] TAN Pengfu, Vix P. Thermodynamic modeling of KIVCET lead process[C]//EPD 2006 Congress. Warrendale, PA, USA, 2006: 8-10.

[10] 汪金良, 张传福, 张文海. 铅闪速熔炼过程的多相平衡模型[J]. 中南大学学报(自然科学版), 2012, 43(2): 429-434.

WANG Jinliang, ZHANG Chuanfu, ZHANG Wenhai. Multi-phase equilibrium model of lead flash smelting process[J]. Journal of Central South University (Science and Technology), 2012, 43(2): 429-434.

[11] 梅炽, 周孑民. 有色冶金炉窑仿真与优化[M]. 北京: 冶金工业出版社, 2001: 227-229.

MEI Chi, ZHOU Jiemin. Simulation and optimization of furnaces and kilns for nonferrous metallurgical engineering[M]. Beijing: Metallurgical Industry Press, 2001: 227-229.

[12] 周力行, 陈文芳, 林文漪. 湍流气粒两相流动和燃烧的理论与数值模拟[M]. 北京: 科学出版社, 1994: 12-16.

ZHOU Lixing, CHEN Wenfang, LIN Wenyi. Theory and numerical simulation for turbulent gas-particle flow and combustion[M]. Beijing: Science Press, 1994: 12-16.

[13] 陈卓, 周萍, 梅炽. 传递过程原理[M]. 长沙: 中南大学出版社, 2011: 26-65.

CHEN Zhuo, ZHOU Ping, MEI Chi. Principle of the transfer process[M]. Changsha: Central South University Press. 2011: 26-65.

[14] 陈卓, 毛永宁, 赵荣升, 等. 闪速炉熔炼配风对反应过程的影响[J]. 中南大学学报(自然科学版), 2011, 43(2): 730-737.

CHEN Zhuo, MAO Yongning, ZHAO Rongsheng, et al. The impact of winds on the reaction process during the flash furnace smelting[J]. Journal of Central South University (Science and Technology), 2011, 43(2): 730-737.

[15] 李欣峰. 铜闪速炉数值仿真[J].中南工业大学学报(自然科学版), 2001, 32(3): 262-266.

LI Xinfeng. Numerical simulation of copper flash smelting furnace[J]. Journal of Central South University of Technology (Natural Science), 2001, 32(3): 262-266.

(编辑 杨幼平)

收稿日期:2013-10-08;修回日期:2013-12-30

基金项目(Foundation item):国家高技术研究发展计划(“863”计划)项目(2010AA065200);湖南省科技厅科技计划项目(2011GK3207)(Project (2010AA065200) supported by National High Technology Research and Development Program of China; Project (2011GK3207) supported by Provincial Science and Technology Plan Project of Hunan Province)

通信作者:陈卓(1974-),女,湖南长沙人,博士,教授,从事热工过程及设备的仿真与优化研究;电话:13974891750;E-mail:chenzhuo@csu.edu.cn