文章编号:1004-0609(2015)-03-0668-07

Cu-Cr-Zr-Nd合金高温热变形及组织演变

许倩倩1, 2,张 毅1, 2,柴 哲1, 2,田保红1, 2,刘 勇1, 2,刘 平3,陈小红3

(1. 河南科技大学 材料科学与工程学院,洛阳 471003;

2. 河南科技大学 有色金属共性技术河南省协同创新中心,洛阳 471003;

3. 上海理工大学 材料科学与工程学院,上海 200093)

摘 要:在Gleeble-1500D热模拟试验机上对Cu-Cr-Zr-Nd合金进行热压缩实验,对合金在应变速率分别为0.001、0.01、0.1、1、10 s-1,变形温度分别为650、750、850、900、950 ℃的高温变形过程中的流变应力行为、热变形过程中的组织演变和动态再结晶机制进行研究。结果表明:流变应力随变形温度的升高而减小,随应变速率的提高而增大。Cu-Cr-Zr-Nd合金在热变形过程中的动态再结晶机制受变形温度和应变速率的影响。当温度为900 ℃、应变速率为10 s-1时,Cu-Cr-Zr-Nd合金发生完全的动态再结晶。从流变应力、应变速率和温度的相关性,得出该合金高温热压缩变形时的热变形激活能Q为404.84 kJ/mol,同时利用逐步回归的方法建立该合金的流变应力方程。

关键词:Cu-Cr-Zr-Nd合金;高温压缩;流变应力方程;热激活能;动态再结晶

中图分类号:TG146.1 文献标志码:A

High temperature deformation behavior and microstructure evolution of Cu-Cr-Zr-Nd alloy

XU Qian-qian1, 2, ZHANG Yi1, 2, CHAI Zhe1, 2, TIAN Bao-hong1, 2, LIU Yong1, 2, LIU Ping3, CHEN Xiao-hong3

(1. College of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471003, China;

2. Collaborative Innovation Center of Nonferrous Metals, Henan University of Science and Technology, Luoyang 471003, China;

3. College of Materials Science and Engineering, University of Shanghai for Science and Technology, Shanghai 200093, China)

Abstract: The high temperature deformation behavior, microstructure evolution and dynamic recrystallization nucleation mechanisms of Cu-Cr-Zr-Nd alloy were investigated by compressive tests using Gleeble-1500D thermal-mechanical simulating tester at the deformation temperatures of 650, 750, 850, 900, 950 ℃ and strain rates of 0.001, 0.01, 0.1, 1, 10 s-1. The results show that the flow stress decreases with the increase of temperature, and the flow stress increases with the increase of strain rate. The dynamic recrystallization process of Cu-Cr-Zr-Nd alloy is controlled by deformation temperature and strain rate. The dynamic recrystallization is complete when the temperature and strain rate are 900 ℃ and 10 s-1, respectively. The hot deformation activation energy Q is 404.84 kJ/mol and constitutive equation is obtained from the correlativity of flow stress, strain rate and temperature by stepwise regression analysis.

Key words: Cu-Cr-Zr-Nd alloy; high temperature compression; constitutive equation; hot deformation activation energy; dynamic recrystallization

随着我国科技的不断发展,对电子产品的需求大幅度增长,电子产品的增加势必加大对电子元器件的需求。Cu-Cr-Zr合金是目前研制出来的少数能够满足超大规模集成电路性能要求的高强高导框架材料[1-3]。

目前集成电路引线框架材料主要有中强高导型Cu-Fe-P系合金、高强中导Cu-Ni-Si系合金、高强高导型Cu-Cr-Zr系合金等[4-5]。虽然应用最多的是Cu-Fe-P系合金,但对于具有高强度和高导电性的Cu-Cr-Zr系合金,仍是目前研究的重点。高强高导Cu-Cr-Zr合金作为高性能时效强化型铜合金以其优越的综合性能广泛应用于集成电路引线框架材料、热交换材料、电车和电力机车架空导线及电气化高速铁路用接触材料等诸多领域[6-7]。

我国经济的不断发展,对集成电路特别是大规模集成电路的需求也越来越大。“十二五”期间我国对集成电路引线框架的需求以10%~20%的速度递增[8-9]。这就要求我国在引线框架材料的质量上需要大幅提高。目前我国在该类材料的研制中做了大量的工作,如中铝洛阳铜业有限公司、北京有色金属研究总院、清华大学、中南大学等单位都在该合金领域做了有益的研究。但我国在引线框架合金的设计、熔炼技术以及后续加工技术上仍然存在一定的差距,急需在一些关键技术上取得突破,如合金成分设计、热轧工艺控制、时效工艺控制[10-11]。

本文作者针对Cu-Cr-Zr引线框架合金的性能要求,在该合金中加入微量稀土元素Nd,同时探索该合金的热轧制工艺,即在变形温度为650~950 ℃,应变速率为0.001~10 s-1和变形量为60%的条件下,在Gleeble-1500D热模拟试验机上进行了圆柱体高温单道次轴对称压缩实验,研究了该合金动态再结晶行为以及组织转变。通过对合金热压缩变形流变应力与变形程度、应变速率以及变形温度之间的关系进行研究,计算出该合金的热变形激活能Q,并确定了其本构方程,从而为该合金在加工技术上提供理论依据。同时也为该合金在工业化生产中提供一些可参考依据。

1 实验

实验用Cu-Cr-Zr-Nd合金在10 kg中频感应熔炼炉中熔炼而成,材料质量分数为:wCr=0.8%,wZr=0.3%,wNd=0.05%,其余为铜。浇铸温度为1250~1300℃。合金的固溶处理在RJX-2.5-10型箱式电阻炉中进行,工艺为950 ℃、1.5 h,随后水淬。采用固溶后的合金在Gleeble-1500D热模拟机上进行压缩实验,压缩试样尺寸为d8 mm×12 mm,实验温度范围为650~950 ℃,应变速率为0.001~10 s-1,总压缩应变量约0.6(真应变)。热模拟实验的升温速率为5 ℃/s,保温时间为3 min。采用OLYMPUS PMG3型显微镜观察合金的显微组织。

2 结果与分析

2.1 Cu-Cr-Zr-Nd合金流变应力分析

图1所示为Cu-Cr-Zr-Nd合金在温度为650~950 ℃、应变速率为0.001~10 s-1、总压缩应变量约0.6(真应变)时进行热压缩变形时的真应力-真应变实验曲线。从图1中可以看出,变形温度和应变速率对Cu-Cr-Zr-Nd合金的流变应力均有显著影响,在一定的应变速率下,变形温度越高,所对应的流变应力值越低。当变形温度不变的时候,应变速率越高,所对应的流变应力也越大。结果表明:Cu-Cr-Zr-Nd合金是热敏感型和应变速率敏感型合金。

从图1中可以看出,真应力-真应变实验曲线存在3种类型。第一种是合金在较高温度高温压缩变形时真应力先增加到最高值后逐渐降低达到一个稳定值,表明热加工过程中发生了动态再结晶。如合金在变形温度为900 ℃时表现出明显的动态再结晶行为;第二种是应力-应变曲线中真应力先上升到一定值后,加工硬化和动态回复相互作用后曲线保持一个稳定值,如在850 ℃时的曲线。这是因为变形温度升高,材料易发生动态回复和动态再结晶,因此达到较小应变后,软化作用等于或稍大于硬化作用,使应力-应变曲线呈现水平或接近水平状;第三种是在较低温度,动态回复发生后加工硬化仍占上风,即在较大应变下,真应力-真应变曲线的最后阶段仍为上升,如在650 ℃时的应力-应变曲线。

2.2 Cu-Cr-Zr-Nd合金热变形方程的建立

热变形过程中,材料在任何应变或稳态下的高温流变应力σ强烈地取决于变形温度T和应变速率 。同时对不同铜合金的热加工数据的研究表明[ 12-15],可以引用Zener-Hollomon参数Z,表达式如下所示:

。同时对不同铜合金的热加工数据的研究表明[ 12-15],可以引用Zener-Hollomon参数Z,表达式如下所示:

(1)

(1)

式中:A、α为与材料有关的常数;n为与应变速率敏感性相关的指数。可将Z定义为

(2)

(2)

式中:Q为变形激活能,是材料发生塑性变形时金属原子发生剧烈的热运动需要跨越的一个能量值;R为摩尔气体常数,R为8.314 kJ/(mol·K)。

图1 Cu-Cr-Zr-Nd合金热压缩变形真应力-应变曲线

Fig. 1 True stress-true strain curves of Cu-Cr-Zr-Nd alloy at different hot compression temperatures and strain rates

将式(2)代入式(1)得:

(3)

(3)

将式(1)两边分别取偏微分可得:

(4)

(4)

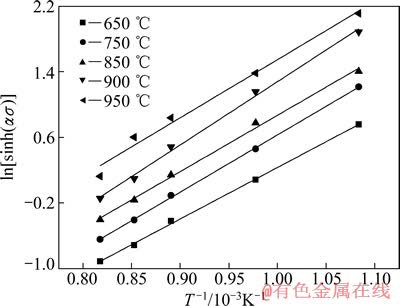

图2和3所示分别表示在热压缩过程中的稳态流变应力与变形温度和应变速率之间的关系,图4所示为应力与Z参数的关系。

为了获得该合金准确的本构方程,需确定A、n、α和Q的值。通过实验数值且根据图2~4的线性回归分析可获得上述参量的值为:A=e40.28,n=7.193,α=0.014,Q=404.84 kJ/mol。

由此可得该合金适用于工艺过程分析的本构方程为:

(5)

(5)

2.3 变形温度对Cu-Cr-Zr-Nd合金变形组织的影响

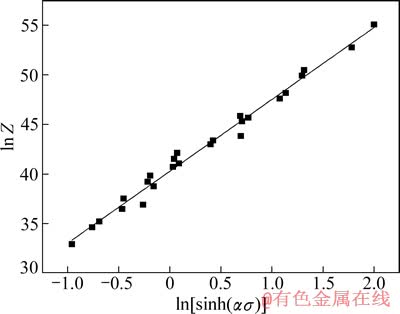

图5所示为Cu-Cr-Zr-Nd合金在变形速率为 =0.01 s-1时,不同温度下进行热压缩后的光学显微组织。图5(f)所示为Cu-Cr-Zr-Nd合金固溶处理图后的显微组织照片,横向为压缩方向。从图5(f)中可以看出,合金在热变形过程中组织变化对温度具有很强的敏感性。当温度较低的时候,原始晶粒发生畸变,显微组织还是以变形大晶粒为主,变形大晶粒垂直于变形方向被严重压长,显微组织特征为扁平状的晶粒,此时显微组织中未有动态再结晶晶粒出现,如图5(a)所示。当温度继续升高达到750和850 ℃时,如图5(b)和(c)所示,这时可以看到拉长的晶粒被分布在晶界处的大量等轴状、细小的再结晶晶粒所包围,表明此时动态再结晶开始形核。但在该温度下仍有大量的原始晶粒。随着温度的升高,原始晶粒会逐渐被新的动态再结晶晶粒所取代,晶粒进一步变形。当温度达到900 ℃时,如图5(d)可以看到原始晶粒几乎已完全被细小的再结晶晶粒取代。当温度达到950 ℃时,动态再结晶晶粒已明显长大,如图5(e)所示。

=0.01 s-1时,不同温度下进行热压缩后的光学显微组织。图5(f)所示为Cu-Cr-Zr-Nd合金固溶处理图后的显微组织照片,横向为压缩方向。从图5(f)中可以看出,合金在热变形过程中组织变化对温度具有很强的敏感性。当温度较低的时候,原始晶粒发生畸变,显微组织还是以变形大晶粒为主,变形大晶粒垂直于变形方向被严重压长,显微组织特征为扁平状的晶粒,此时显微组织中未有动态再结晶晶粒出现,如图5(a)所示。当温度继续升高达到750和850 ℃时,如图5(b)和(c)所示,这时可以看到拉长的晶粒被分布在晶界处的大量等轴状、细小的再结晶晶粒所包围,表明此时动态再结晶开始形核。但在该温度下仍有大量的原始晶粒。随着温度的升高,原始晶粒会逐渐被新的动态再结晶晶粒所取代,晶粒进一步变形。当温度达到900 ℃时,如图5(d)可以看到原始晶粒几乎已完全被细小的再结晶晶粒取代。当温度达到950 ℃时,动态再结晶晶粒已明显长大,如图5(e)所示。

图2 不同温度时峰值应力与应变速率之间的关系

Fig. 2 Relationship between peak stress and strain rate at different temperatures

图3 峰值应力与温度之间的关系

Fig. 3 Relationship between peak stress and temperature

图4 峰值应力与Z参数的关系

Fig. 4 Relationship between peak stress and Zener-Hollomon parameter

动态再结晶过程是通过形核和长大来完成的,其机理是大角度晶界(或亚晶界)向高密度位错的区域迁移,所以这是一个热激活的过程,这时热变形温度将会起到决定性的作用。再结晶晶核的形成与长大都需要原子的扩散,只有当变形温度高到足以激活原子,使其能够进行迁移,再结晶过程才能进行。因此相对较低的变形温度不利于晶界移动,也不利于位错的迁移,所以在光学显微镜下,在图5(a)中未观察到动态再结晶行为。当温度升高到900 ℃时,位错交滑移及晶界迁移能力增强,尽管此时的动态回复也会增强,减少了形变储存能,但高温依然促进再结晶形核和晶粒长大,如图5(d)和(e)所示,已出现大量的再结晶晶粒。

2.4 变形速率对Cu-Cr-Zr-Nd合金变形组织的影响

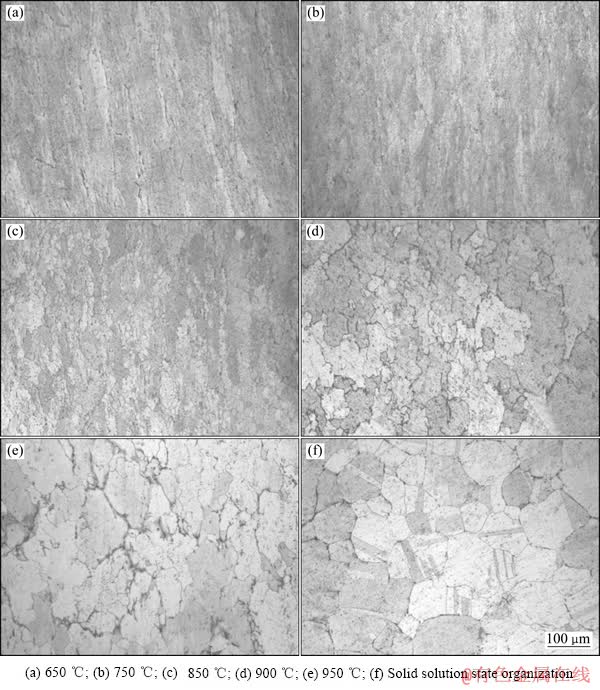

图6所示为Cu-Cr-Zr-Nd合金在变形温度为850℃时不同的变形速率压缩时的金相组织,变形速率分别为0.001、0.01、0.1、1、10 s-1,横向为压缩方向。从图6中可以看出,当应变速率较小时,动态再结晶已完全发生,且动态再结晶晶粒已经出现部分长大的情况,如图6(a)~(c)所示。随着变形速率的增大,动态再结晶晶粒变小,这是因为随应变速率的增大,位错来不及消失,缺陷增加,再结晶核心的增多导致形核的数量增多,所以动态再结晶晶粒越来越细小,如图6(d)和(e)所示。这是由于动态再结晶形核需要一定的孕育期,孕育期与畸变能大小、温度以及原子扩散速率有关系。从图6(a)的变形条件可以看出,850 ℃已经是一个较高的变形温度,从图5(e)可知在该温度下进行热压缩,合金已大部分发生动态再结晶,同时应变速率为0.01 s-1时该应变速率处在较小的应变速率范围内,应变速率越小,合金有充分的时间进行动态再结晶,从图6(a)~(c)可以看出,合金在该条件下进行热压缩,已发生完全的动态再结晶,同时有一些再结晶晶粒出现长大的现象。

图5  为0.01 s-1时Cu-Cr-Zr-Nd合金在不同温度的变形显微组织

为0.01 s-1时Cu-Cr-Zr-Nd合金在不同温度的变形显微组织

Fig. 5 Microstructures of Cu-Cr-Zr-Nd alloy hot deformed at different temperatures and  of 0.01 s-1

of 0.01 s-1

3 结论

1) 变形温度和应变速率对Cu-Cr-Zr-Nd合金的流变应力均有显著影响。当应变速率一定,变形温度越低,所对应的流变应力越大;当变形温度一定,应变速率越高,所对应的流变应力也越大。

图6 Cu-Cr-Zr-Nd合金在850°C下不同变形速率热压缩时的显微组织

Fig. 6 Microstructure of Cu-Cr-Zr-Nd alloy at different strain rates of hot compression at 950 ℃

2) 从流变应力、应变速率和温度的相关性,得出了Cu-Cr-Zr-Nd合金高温热压缩变形时的流变应力方程: 。

。

3) Cu-Cr-Zr-Nd合金在高温热压缩变形中变形温度越高,应变速率越小,越容易发生动态再结晶。当变形温度为900 ℃时,合金已发生完全的动态再结晶。

REFERENCES

[1] 赵 美, 王自东, 林 国, 张 鸿, 程志刚. 高强高导Cu-Cr-Zr系合金的研究进展[J]. 铸造, 2007, 56(5): 455-461.

ZHAO Mei, WANG Zi-dong, LIN Guo, ZHANG Hong, CHENG Zhi-gang. The research progress of high strength and high conductivity Cu-Cr-Zr alloy[J]. Casting, 2007, 56(5): 455-461.

[2] BI Li-ming,LIU Ping,CHEN Xiao-hong,LIU Xin-kuan,LI Wei,MA Feng-cang. Analysis of phase in Cu-15%Cr-0.24%Zr alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(5): 1342-1348.

[3] 姜 锋, 陈小波, 蒋 龙, 陈 蒙. 铬锆微合金化高强高导铜合金的研究进展[J]. 材料热处理技术, 2009, 38(2): 1-8.

JIANG Feng, CHEN Xiao-bo, JIANG Long, CHEN Meng. Research progress of high strength and high conductivity copper alloys with Chromium zirconium microalloyed[J]. Material Heat Treatment Technology, 2009, 38(2): 1-8.

[4] SUZUKI S, SHIBUTANI N, MIMURA K,ISSHIKI M, WASEDA Y. Improvement in strength and electrical conductivity of CuNiSi alloy by aging and cold rolling[J]. Journal of Alloys and Compounds, 2006, 417: 116-120.

[5] 苏娟华, 刘 平, 董企铭, 李贺军, 任凤章, 田宝红.Cu-Cr-Zr合金时效强化机理[J]. 材料热处理学报, 2005, 26(6): 62-65.

SU Juan-hua, LIU Ping, DONG Qi-ming, LI He-jun, REN Feng-zhang, TIAN Bao-hong. Strengthening mechanism of aged Cu-Cr-Zr alloy[J]. Transactions of Materials and Heat Treatment, 2005, 26(6): 62-65.

[6] 赵冬梅, 董企铭, 刘 平, 金志浩, 黄金亮. 铜合金引线框架材料的发展[J]. 材料导报, 2001, 15(5): 18-20.

ZHAO Dong-mei, DONG Qi-ming, LIU Ping, JIN Zhi-hao, HUANG Jin-liang. The development of the copper alloy lead frame materials[J]. Material Review, 2001, 15(5): 18-20.

[7] 陶业卿, 刘 平, 贾淑果, 陈小红. 高强度高导电Cu-Cr-Zr合金的研究现状[J]. 材料热处理技术, 2010, 39(14): 31-36.

TAO Ye-qing, LIU Ping, JIA Shu-guo, CHEN Xiao-hong. Research statusof high strength and high conductivityCu-Cr-Zr alloy[J]. Material Heat Treatment Technology, 2010, 39(14): 31-36.

[8] HANZELKA P,MUSILOVA V,KRALIK T,VONKA J. Thermal conductivity of a CuCrZr alloy from 5K to room temperatures[J]. Cryogenics, 2010, 50(11/12): 737-742.

[9] JAYAKUMAR P K,BALASUBRAMANIAN K, RABINDRANATH T G. Recrystallisation and bonding behaviour of ultra fine grained copper and Cu-Cr-Zr alloy using ECAP[J]. Materials Science and Engineer A, 2012, 538(15): 7-13.

[10] ZHANG L, LI Z, LEI Q,QIU W T,LUO H T. Hot deformation behavior of Cu-8.0Ni-1.8Si-0.15Mg alloy[J]. Materials Science and Engineer A, 2011, 528(3): 1641-1647.

[11] DENG Ying, YIN Zhi-min, HUANG Ji-wu. Hot deformation behavior and microstructural evolution of homogenized 7050aluminum alloy during compression at elevated temperature[J]. Materials Science and Engineering A, 2011, 528: 1780-1786.

[12] MOMENI A, DEHGHANI K, POLETTI M C. Characterization of hot deformation behavior of 410 martensitic stainless steel using constitutive equations and processing maps[J]. Materials Science and Engineering A, 2010, 527(21): 5467-5473.

[13] SRINIVASAN N, PRASAD Y, RAO P R. Hot deformation behavior of Mg-3Al alloy study using processing map[J]. Materials Science and Engineering A, 2008, 476(2): 146-156.

[14] GRONOSTAJSKI Z. The deformation processing map for control of microstructure in CuAl9.2Fe3 aluminium bronze[J]. Journal of Materials Processing Technology, 2002, 125/126(9): 119-124.

[15] PRASAD Y, RAO K P. Processing maps for hot deformation of rolled AZ31 magnesium alloy plate: Anisotropy of hot workability[J]. Materials Science and Engineer A, 2012, 487(1/2): 316-327.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51101052);河南省高等学校青年骨干教师资助计划(2012GGJS-073)河南省教育厅自然科学研究计划(2011B430013)河南科技大学青年科学基金资助项目(2011QN48)

收稿日期:2014-07-29;修订日期:2014-12-11

通信作者:张 毅,副教授,博士;电话:0379-64231269;E-mail:zhshgu436@163.com