DOI: 10.11817/j.ysxb.1004.0609.2020-35795

TA7钛合金板材高温拉伸变形

张景祺1,林 健1,呼 啸2,魏瑞刚2,苑少乾2

(1. 北京工业大学 材料科学与工程学院,北京 100124;

2. 首都航天机械有限公司,北京 100076)

摘 要:利用Gleeble-1500D热模拟试验机对板厚为4 mm的TA7 ELI材料在变形温度为800、850、900、950和1000 ℃,应变速率为0.01 s-1和0.001 s-1下进行高温拉伸实验,获得材料发生超塑性变形的温度区间和应变速率范围。采用炉中高温拉伸实验对Gleeble实验结果进行验证。得出在950~1000 ℃范围内,应变速率低于0.001 s-1时,TA7 ELI钛合金高温拉伸会出现超塑性变形。伸长率最高可达260%。在应变速率0.001 s-1、800 ℃时,TA7钛合金的断口组织中有动态再结晶现象。1000 ℃时,断口出现较为粗大的层片状α组织和明显的晶粒长大现象。m和n值都随着温度的升高而增大,在950 ℃时到达最大值。硬化现象能够有效的抑制颈缩,变形温度为950 ℃时,材料的硬化和软化达到较好的平衡,易获得较大的伸长率。

关键词:TA7钛合金;超塑性;高温拉伸;应变硬化指数;应变速率敏感性指数

文章编号:1004-0609(2020)-05-1019-08 中图分类号:TG146.23 文献标志码:A

低温工程用材料的要求有:热传导率和热膨胀系数低,低温韧性好,比强度高等[1]。钛合金具有密度低、无磁性、耐腐蚀性好的特性,被广泛应用于宇航、超导和生物医学等低温工程领域[2-5]。其中Ti5Al2.5Sn又名TA7钛合金,是一种单相α钛合金,其在退火状态下有良好的强度和塑性。通过多镦多拔锻造工艺生产的TA7 ELI合金,其间隙元素(C,H,O,N)含量较低,在低温条件下具有充足的韧性储备,是一种综合性能优良的超低温用钛合金[6-8],可在温度低于20 K的环境使用,已被美日等国用于制造火箭储氢容器和超导发电部件[9];但其在塑性成形与使用过程中存在成品率低、易开裂和粘结磨损等问题[10-11]。目前,TA7 ELI钛合金板材成品率通常只有30%左右,属于难加工材料[12]。针对钛合金的高温超塑性变形行为已有大量的研究,其中,苏娟华等[13]对TA10钛合金在变形温度800~1050 ℃,应变速率0.01~5 s-1下的Gleeble拉伸变形行为进行了研究,结果表明在相变点以下的温度区间,随着变形温度的升高,TA10钛合金的强度和塑性下降。徐凯等[14]对TA12A板材在900~940 ℃,应变速率5×10-4~1×10-3 s-1下的高温炉中拉伸进行研究,发现拉伸段的晶粒尺寸变大是长时间保温和应变诱导共同作用的结果。GHASEMI等[15]研究Ti-6Al-1.5Cr-2.5Mo-0.5Fe-0.3Si合金在应变速率0.001~0.1 s-1、温度范围100~600 ℃的高温压缩流变行为,发现绝热加热会使实验材料出现内部流动局部化现象,并产生明显的负应变速率敏感性。东赟鹏等[16]通过热压缩试验研究了TA7钛合金在变形温度850~1000 ℃、应变速率0.001~0.1 s-1条件下的流变应力变化规律,结果表明:随着变形温度的升高和变形速率的降低,达到相同变形程度的合金试样的流变应力显著降低。

目前对TA7钛合金的研究多集中于不同的生产制备成形工艺对板材组织性能的影响以及对其低温变形机理的研究[17],对板材钛合金高温拉伸变形行为的研究较少,TA7钛合金的高温变形规律还不清楚。本研究针对板厚为4 mm的TA7 ELI材料进行高温状态下的力学性能研究,通过对比评价其高温变形行为,为TA7 ELI板材的高温塑性成形的制备过程提供理论依据。

1 实验

板材的高温拉伸实验在热模拟试验机Gleeble上进行,应力-应变曲线拟测量材料在高温下的拉伸曲线。高温段选取5个温度,分别为800、850、900、950和1000 ℃。在高温下,分别采用两种应变速率,0.01 s-1和0.001 s-1,由此,高温段的拉伸曲线共测量10种情况。Gleeble测试可以快速获得材料发生超塑性变形的温度区间和应变速率范围,但采用此方法,试样上温度分布不均匀,故采用炉中高温拉伸实验对Gleeble实验结果进行验证。测试材料在拉伸速率为0.02 mm/s时的伸长率和抗拉强度,记录拉伸过程的载荷-位移曲线,得出材料在950 ℃和1000 ℃下的高温拉伸曲线,来验证Gleeble热模拟所得出的材料超塑性变形规律。

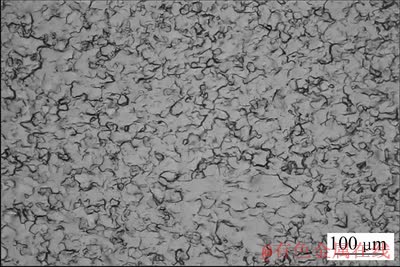

试验材料为TA7 ELI(相变点在1025 ℃左右),采购自宝钛集团,原始板材的尺寸为1100 mm×160 mm×4 mm。选取平行面(垂直试板的厚度方向)试样进行金相分析。试样的金相组织如图1所示,基体组织主要为单相α相。

图1 4 mm厚TA7 ELI钛合金的微观组织

Fig. 1 Microstructure of 4 mm thick TA7 ELI alloy

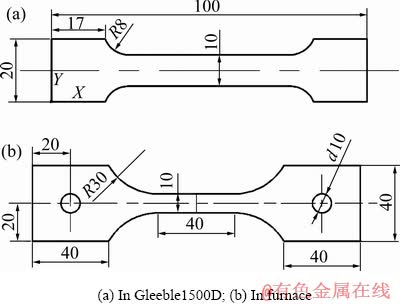

Gleeble热模拟的试样形状及尺寸如图2(a)所示,炉中高温拉伸试样的形状及尺寸如图2(b)所示。

图2 拉伸试样外形尺寸图

Fig. 2 Geometryshape and dimension of tensile specimens (Unit: mm)

2 结果与分析

2.1 热模拟实验结果

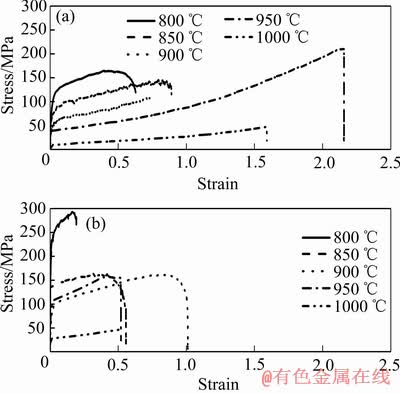

在不同应变速率和温度作用下,TA7钛合金板材的真应力-应变曲线如图3所示。在相同的应变速率 下,大部分的拉伸曲线中真应力s先随真应变e的增加而迅速上升,达到某值后又缓慢上升。随着温度的升高,流变应力在总应变的大约4/5处逐渐降低。当温度由950 ℃升高到1000 ℃,流动应力发生明显减小,最高应力和应变下降了1/3左右。比较图3(a)和(b)可知,应变速率越慢,流变应力越稳定,越容易获得高的伸长率。

下,大部分的拉伸曲线中真应力s先随真应变e的增加而迅速上升,达到某值后又缓慢上升。随着温度的升高,流变应力在总应变的大约4/5处逐渐降低。当温度由950 ℃升高到1000 ℃,流动应力发生明显减小,最高应力和应变下降了1/3左右。比较图3(a)和(b)可知,应变速率越慢,流变应力越稳定,越容易获得高的伸长率。

分析认为由于变形温度的升高,动态回复和动态再结晶更加容易进行[18],950 ℃前促使塑性提高的因素占主导,升温使软化作用充分,减小了材料流变应力。但温度的升高也将促使晶粒长大,当超过950 ℃时,晶粒严重长大促使塑性下降,伸长率降低。且1000 ℃左右时,实验中易出现误差,推测高温区温度超过TA7相变点,试样在 区开始变形,迅速形成粗大的

区开始变形,迅速形成粗大的 组织,随后以其为基体析出片状α组织,从而导致试样的脆性增大,加速断裂。

组织,随后以其为基体析出片状α组织,从而导致试样的脆性增大,加速断裂。

图3 0.001 s-1和0.01 s-1应变速率下的真应力-应变曲线

Fig. 3 Stress-strain curves at strain rates of 0.001 s-1(a) and 0.01 s-1(b)

从图3可以看出,相同温度下,流变应力会随着应变速率的增加而增大。分析认为,当应变速率较大时,板材变形速度较快,变形初期的位错塞积与钉扎作用使加工硬化占主导作用[19]。之后颈缩发展所需变形应力增大,使其不断向变形抗力更小的未发生颈缩的部位转移。当应变速率高于最佳应变速率时,颈缩位置易产生缺陷而断裂。综合温度和应变速率对试样伸长率的影响,认为在950 ℃到1000 ℃,应变速率0.001 s-1以下会有更明显的超塑性拉伸现象,因此在高温炉中进行验证实验。

2.2 炉中高温拉伸试验结果

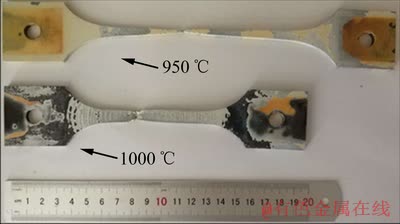

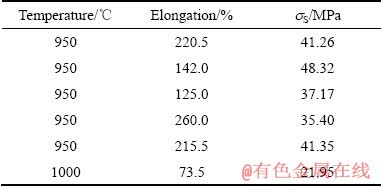

炉中高温拉伸后的试样形貌如图4所示,断后伸长率与屈服强度表1所示。除了一个在1000 ℃下进行拉伸的样品外,其他在950 ℃下拉伸的样品均出现了超塑性,其中最大伸长率达到260%。

图4 炉中高温拉伸后的TA7试样形貌

Fig. 4 Morphology of TA7 samples after high temperature tensile test in furnace

表1 TA7试样炉中高温拉伸实验结果

Table 1 Experimental results of TA7 samples after high temperature tensile test in furnace

炉中拉伸实验的真应力-应变曲线如图5所示,在此应变速率下,动态再结晶导致真应力逐渐减小,之后进入流变软化阶段。在950 ℃下,材料在bc阶段高温软化和拉伸硬化行为达到平衡,材料的变形在宏观上均匀程度很高,可实现较长时间的流变和较大的伸长率。而在1000 ℃下由于变形温度升高促进了位错的相消,加工硬化效应减弱,应力在断裂前一直呈现明显的下降趋势,伸长率较小。

图5 两种温度下的炉中高温拉伸真应力-应变曲线

Fig. 5 True stress-strain curves after high temperature tensile in furnace at two temperatures

综合比较两个实验结果,可以发现,在温度为950 ℃,应变速率低于0.001 s-1时,钛合金的最终变形伸长率最高可达260%,发生了超塑性变形。

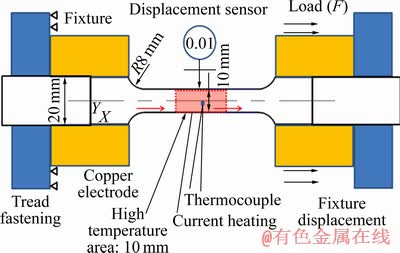

2.3 实验误差分析

Gleeble高温应力-应变曲线的测试原理如图6所示。测试过程中,试样夹持在两个循环水冷的铜电极之间,实时测试温度信号来对加热电流进行调整,使高温区域的温度能够按照输入的温度曲线进行变化。整个试样的温度分布是十分不均匀的,中间的高温区只有大概10 mm长,夹持部位为室温。由于中间区域在高温下的屈服强度较低,试样发生的屈服变形主要发生在中间的高温区域,在数据处理中,一般采用高温区域横向方向的位移量来推算其发生的工程应变。

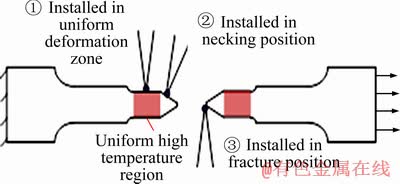

在试样发生颈缩破坏时,颈缩位置具有随机性,导致热电偶的位置存在如图7所示的三种情况。

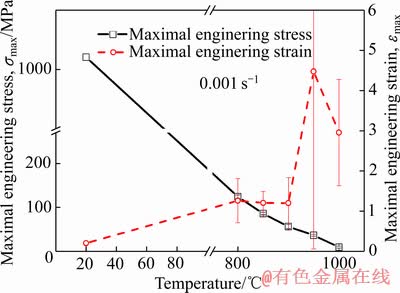

当热电偶安装在均匀变形区时,一旦试样发生颈缩,由于颈缩区域的横截面积迅速缩小,该区电阻和电流密度迅速增大,其温度很快高于均匀变形区(测量点)的温度,加速了破坏的进行,试样的最终整体变形量较小,而且由于断口处组织温度超过实际设定,也会导致最终断口处组织出现β转变体;当热电偶位于断裂位置时,颈缩破坏在指定的温度下持续进行,试样的最终整体变形量较大。图8所示为在0.001 s-1应变速率下拉伸试样的最大工程应力与最大工程应变随温度升高的变化情况,可以看出由于热电偶安装位置与试样发生颈缩破坏位置的不一致,材料破坏时测得的变形量相较于屈服强度的有较大的分散性,工程应变偏差范围在0.29到4.42之间。

图6 Gleeble高温应力-应变曲线的测试原理图

Fig. 6 Schematic diagram of Gleeble stress-strain test

图7 拉伸试验过程结束可能出现的三种热电偶位置

Fig. 7 Three possible positions of thermocouple after Gleeble tensile test

图8 材料最大工程应力与工程应变随温度变化情况

Fig. 8 Variation of maximum engineering stress and engineering strain with temperature

由此可知,Gleeble热模拟实验能够部分替代炉中高温拉伸实验,能较为准确的获得材料在高温下的屈服强度和抗拉强度的数值。但其最大变形量的测量误差较大,主要是由热电偶安装位置与试样发生颈缩破坏位置的不一致所带来的。

2.4 金相组织特点

图9 800与1000 ℃下试样拉伸后断口微观组织(0.001 s-1)

Fig. 9 Microstructures of fracture positions after deformation (0.001 s-1) at 800 ℃ and 1000 ℃

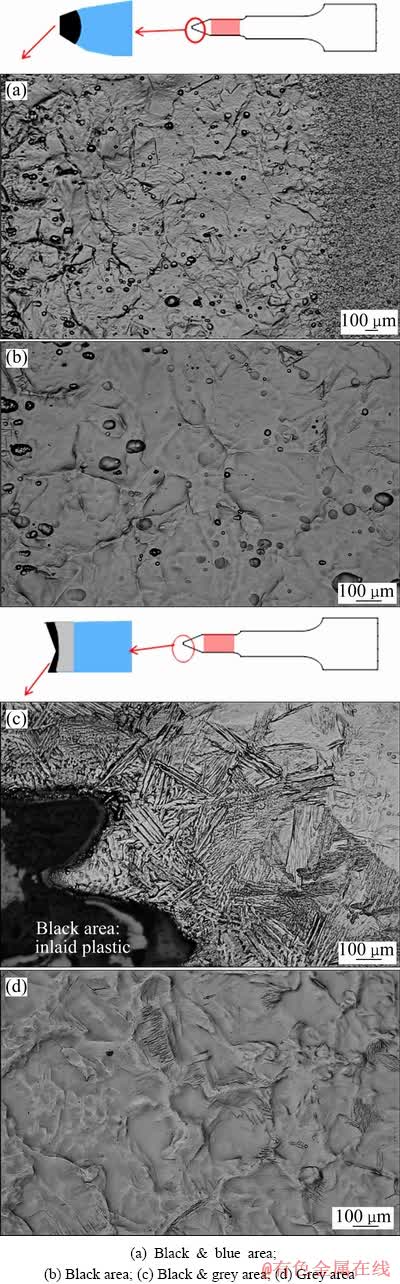

观察应变速率0.001 s-1,拉伸温度分别800 ℃和1000 ℃下试样拉伸断口与邻近区域的金相组织图,如图9所示。由图9可知,800℃试样在拉伸断口和其邻近区域出现两种组织的过渡:邻近区域处如图9(a)示意图中的蓝色区域,细小的α相晶粒保持良好的等轴性,类似母材组织;而在断口处黑色区域的组织则出现了大量晶粒尺寸粗大的α相晶粒,在此区域还可以观察到动态再结晶现象,有细小点状的初生α相生成和破碎的晶粒分布,如图9(b)所示。这说明TA7钛合金已经发生了部分区域的动态再结晶软化。

当理想温度为1000 ℃时,试样中出现三种组织的过渡分布,除了图9(c)示意图蓝色区域中类似母材的组织,离断口较近的灰色区域可以观察到长大变形的α相晶粒,如图9(d)所示;在沿断口的黑色区域处观察有层片状α组织,主要源于高温拉伸时形成的β相在空冷时发生马氏体相变,形成了集束针状魏氏组织,如图9(c)所示。此时再结晶后的晶粒长大已经成为TA7钛合金的主要软化机制。

由此可见,温度的升高对TA7钛合金微观组织形貌具有一定的影响。在800 ℃和应变速率为0.001 s-1时,TA7钛合金的断口显微组织中可以观察到明显的动态再结晶和晶粒长大的现象。在1000 ℃,相同应变速率下,断口显微组织中有伴随β相变和大变形量而出现的片状α组织,软化作用较强。

3 讨论

3.1 应变硬化指数n

应变硬化指数n表示板材在塑性变形中变形抗力对应变的变化强度[20]。根据Hollomon经验公式,采用下式拟合硬化区域:

(1)

(1)

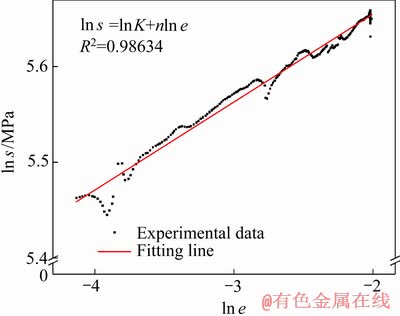

式中:K为强度系数,对无明显屈服点的真应力-真应变曲线,应变硬化区域应取弹性变形结束至峰值应力之间区域,通过线性拟合ln s-ln e得到的斜率即为n的值,拟合曲线示意图如图10所示。

图10 Gleeble试验拉伸硬化区域ln s-ln e曲线拟合

Fig. 10 Curve fitting of ln s-ln e at tension stiffening area after Gleeble tensile test (800 ℃, 0.01 s-1)

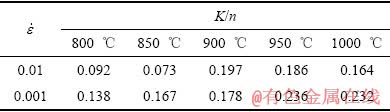

由此可以获得TA7 ELI钛合金在不同温度和应变速率下的应变硬化指数,如表2所列。由表2可知,n值大的材料,应变硬化效应高,发生缩颈前依靠硬化使材料均匀变形能力强,不会在变形量较小的时候过早发生局部塑性变形而出现颈缩,从而可实现较大和均匀的变形量。

表2 不同温度下两种应变速率的K/n值

Table 2 K/n values at two strain rates at different temperatures

分析n值的拟合结果,发现在0.001 s-1的应变速率下其应变硬化现象随着温度升高而加强。n值在950 ℃最高为0.236,在该条件下,适当的硬化能够有效的抑制颈缩,有望进一步发生超塑性变形。随着应变速率的降低,n值增大,材料更易在较高温度下进行均匀变形。

3.2 应变速率敏感性指数m

应变速率敏感性指数m表征金属材料抵抗颈缩的能力,其大小体现了流变应力随应变速率的变化而变化的剧烈程度。m值越高则材料抵抗颈缩发展能力强,有利于在软化阶段获得较大的伸长率。因此根据实验结果,获取m值较大的温度区间,可作为材料发生高温大变形的加工温度区间。

m的定义式为:

(2)

(2)

由于材料在高温下变形的本构方程为:

(3)

(3)

式中:A为常量; 为应力;p为晶粒指数;n是应力指数,其值为1/m;D0为扩散因子;Q为激活能。当只有温度发生微小变化时,可以将

为应力;p为晶粒指数;n是应力指数,其值为1/m;D0为扩散因子;Q为激活能。当只有温度发生微小变化时,可以将 、应变速率和应力的对数等视为常量,由此可得到:

、应变速率和应力的对数等视为常量,由此可得到:

(4)

(4)

两边取对数,化简得 。

。

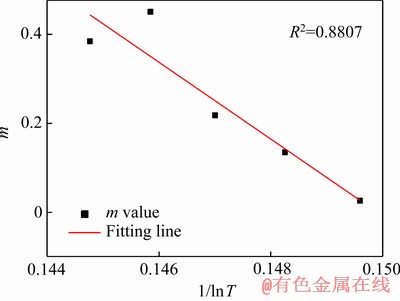

在真应力-应变曲线的稳定变形阶段选择同一应变e=0.4,取各应变速率0.01、0.001和0.0005 s-1下此点对应的应力数据,绘制ln s-ln e曲线,其斜率即为m值。在温度由900 ℃升到950 ℃过程中,m值明显增大,在900 ℃以下m值小于0.3,而在950 ℃出现最大的m值0.45;1000 ℃时,m值出现小的回落。分析认为较大的应变速率会使试样高温软化更不充分,造成应力升高。结合之前推导出的1/m与ln T所具有的线性关系,拟合数据发现m与1/ln T的变化较符合线性规律。得出m值的计算公式为:

(5)

(5)

总之,在TA7超塑性变形中,位错塞积和晶粒长大导致的硬化和动态回复与再结晶导致的软化是同时进行、相互竞争的,在最佳变形温度下试样的硬化和软化达到较好的平衡才获得较大的伸长率。

图11 m值与1/ln T倒数的关系

Fig. 11 Relationship between m value and 1/ln T

4 结论

1) 950~1000 ℃范围内,应变速率低于0.001 s-1时,TA7 ELI钛合金高温拉伸会出现超塑性变形。采用高温炉中拉伸实验对结果进行了验证,伸长率最高可达260%。

2) Gleeble高温拉伸实验能够部分替代炉中高温拉伸实验,获得材料的高温屈服极限和抗拉强度。其变形量测量误差较大是由于试样发生颈缩破坏时的颈缩位置具有随机性,与热电偶的安装位置有可能不一致。

3) 变形温度对TA7钛合金微观组织形貌有较大的影响。800 ℃时,TA7钛合金的显微组织中可以观察到明显的动态再结晶现象。温度为1000 ℃时,TA7钛合金微观组织中出现了粗大的层片状α体,有相变现象,晶粒长大的软化作用较强。

4) TA7钛合金应变硬化指数和应变速率敏感性指数都有随着温度升高而增大的变化趋势,在温度为950 ℃时,到达峰值分别为0.236和0.45,此时,材料的伸长率也最大。应变速率敏感性指数m与温度T的拟合关系为: 。

。

REFERENCES

[1] EL-TAYEB N S M, YAP T C, BREVERN P V. Wear characteristics of titanium alloy Ti54 for cryogenic sliding applications[J]. Tribology International. 2010, 43(12): 2345-2354.

[2] 王 松, 廖振华, 刘伟强. 医用钛合金热氧化处理工艺及其耐磨损、耐腐蚀性能和生物活性的研究进展[J]. 中国有色金属学报, 2014, 24(6): 1466-1473.

WANG Song, LIAO Zhen-hua, LIU Wei-qiang. Advances in thermal oxidation treatment of medical titanium alloys and their wear resistance, corrosion resistance and biological activity[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1466-1473.

[3] WANG H, SUNQ Y, XIAO L, SUN J. Effect of grain size on twinning behavior in Ti-2Al-2.5Zr alloy fatigued at 77 K[J]. Materials Science and Engineering A, 2012, 542: 1-7.

[4] 刘延辉, 姚泽坤, 宁永权, 郭鸿镇. 生物医用TC20钛合金高温变形行为及本构关系[J]. 材料工程, 2014(7): 16-21.

LIU Yan-hui, YAO Ze-kun, NING Yong-quan, GUO Hong-zhen. High temperature deformation behavior and constitutive relationship of biomedical TC20 titanium alloy[J]. Material Engineering, 2014(7): 16-21.

[5] 林 翠, 赵 晴, 文庆杰. TC1钛合金的腐蚀加工及其对基体性能影响[J]. 材料工程, 2015, 43(7): 48-55.

LIN Cui, ZHAO Qing, WEN Qing-jie. Corrosion processing of TC1 titanium alloy and its effect on matrix properties[J]. Material Engineering, 2015, 43(7): 48-55.

[6] 赵永庆, 洪 权, 葛 鹏. 钛及钛合金金相图谱[M]. 长沙: 中南大学出版社, 2011: 143.

ZHAO Yong-qing, HONG Quan, GE Peng. Metallographic atlas of titanium and titanium alloys[M]. Changsha: Central South University Press, 2011: 143.

[7] 金和喜, 魏克湘, 李建明, 周建宇, 彭文静. 航空用钛合金研究进展[J]. 中国有色金属学报, 2015, 25(2): 280-292.

JIN He-xi, WEI Ke-xiang, LI Jian-ming, ZHOU Jian-yu, PENG Wen-jing. Research progress of titanium alloys for aeronautics[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 280-292.

[8] 房卫萍, 陈 沦, 史耀武, 虞文军, 毛智勇, 唐振云. 损伤容限钛合金的研究进展及应用现状[J]. 材料工程, 2010(9): 95-98.

FANG Wei-ping, CHEN Lun, SHI Yao-wu, YU Wen-jun, MAO Zhi-yong, TANG Zhen-yun. Research progress and application status of damage tolerance titanium alloys[J]. Material Engineering, 2010(9): 95-98.

[9] 黄朝文, 葛 鹏, 赵永庆, 辛社伟, 周 伟, 李 倩, 曾卫东. 低温钛合金的研究进展[J]. 稀有金属材料与工程, 2016, 45(1): 254-260.

HUANG Chao-wen, GE Peng, ZHAO Yong-qing, XIN She-wei, ZHOU Wei, LI Qian, ZENG Wei-dong. Research progress of low temperature titanium alloys[J]. Rare Metal Materials and Engineering, 2016, 45(1): 254-260.

[10] 李煜佳, 轩福贞, 涂善东. 应力比和残余应力对Ti-6Al-4V高周疲劳断裂模式的影响[J]. 机械工程学报, 2015, 51(6): 45-50.

LI Yu-jia, XUAN Fu-zhen, TU Shan-dong. Effects of stress ratio and residual stress on high cycle fatigue fracture mode of Ti-6Al-4V[J]. Journal of Mechanical Engineering, 2015, 51(6): 45-50.

[11] 朱延松, 卢文壮. 齿轮用TC21-DT钛合金表面稀土-硼共渗强化及其磨削加工研究[J]. 机械工程学报, 2017, 53(8): 81.

ZHU Yan-song, LU Wen-zhuang. Study on rare earth boronizing strengthening and grinding of TC21-DT titanium alloy for gear[J]. Journal of Mechanical Engineering, 2017, 53(8): 81.

[12] 孙玉晶, 孙 杰, 李剑峰. 钛合金铣削加工刀具磨损有限元预测分析[J]. 机械工程学报, 2016, 52(5): 193-201.

SUN Yu-jing, SUN Jie, LI Jian-feng. Finite element prediction analysis of tool wear in titanium alloy milling[J]. Journal of Mechanical Engineering, 2016, 52(5): 193-201.

[13] 苏娟华, 邵 鹏, 任凤章. TA10钛合金高温流变行为及拉伸性能[J]. 材料热处理学报, 2018, 39(6): 14-20.

SU Juan-hua, SHAO Peng, REN Feng-zhang. Rheological behavior and tensile properties of TA10 titanium alloy at high temperature[J]. Journal of Material Heat Treatment, 2018, 39(6): 14-20.

[14] 徐 凯, 韩维群, 赛 音, 李保永. TA12A高温钛合金超塑性工艺参数实验研究[J]. 锻压技术, 2016, 41(7): 51-56.

XU Kai, HAN Wei-qun, SAI Yin, LI Bao-yong. Experimental study on superplastic process parameters of TA12A high temperature titanium alloy[J]. Forging Technology, 2016, 41(7): 51-56.

[15] GHASEMI E, ZAREI-HANZAKI A, MOEMENI S, GHAMBARI M, REZAEE M. An investigation into the warm deformation behavior of Ti-6Al-1.5Cr-2.5Mo-0.5Fe-0.3Si alloy[J]. Materials Science and Engineering A, 2016, 654: 264-270.

[16] 东赟鹏, 于秋颖, 方 爽, 王淑云, 王超渊, 宋晓俊. TA7钛合金高温流变行为研究[J]. 航空材料学报, 2015, 35(1): 13-19.

DONG Yun-peng, YU Qiu-ying, FANG Shuang, WANG Shu-yun, WANG Chao-yuan, SONG Xiao-jun. Study on high temperature rheological behavior of TA7 titanium alloy[J]. Journal of Aeronautical Materials, 2015, 35(1): 13-19.

[17] 庞 洪, 张海龙, 王希哲, 吴 凯, 陈 东. 包覆叠轧TA7钛合金薄板的组织与力学性能[J]. 中国有色金属学报, 2010, 20(S1): 66-69.

PANG Hong, ZHANG Hai-long, WANG Xi-zhe, WU Kai, CHEN Dong. Microstructure and mechanical properties of coated and rolled TA7 titanium alloy sheet[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): 66-69.

[18] ZHU Shen-liang, DONG Hong-bo, ZHANG Gui-hua CHENG Liu, YU Xin-ping. Superplastic tensile deformation behavior of TC21 titanium alloy[J]. Special Casting & Nonferrous Alloys, 2014, 134(11): 1217-1221.

[19] WANG M, DONG H, ZOU Z, WANG X. Superplastic tensile deformation behavior and constitutive equation of TB8 titanium alloy[J]. Special Casting & Nonferrous Alloys, 2016, 36(1): 103-106.

[20] 徐雪峰, 王高潮, 童国权, 董洪波. 基于温度变化的AA5083合金拉伸变形行为描述[J]. 塑性工程学报, 2011, 18(1): 96-100.

XU Xue-feng, WANG Gao-chao, TONG Guo-quan, DONG Hong-bo. Description on tensile deformation behavior of AA5083 alloy based on temperature changing[J]. Journal of Plasticity Engineering, 2011, 18(1): 96-100.

Tensile deformation of TA7 alloy at high temperature

ZHANG Jing-qi1, LIN Jian1, HU Xiao2, WEI Rui-gang2, YUAN Shao-qian2

(1. College of Materials Science and Engineering, Beijing University of Technology, Beijing 100124, China;

2. Capital Aerospace Machinery Corporation Limited, Beijing 100076, China)

Abstract: The tensile tests of TA7 ELI alloy sheet with 4 mm thickness were performed by Gleeble-1500D machine at high temperatures and various strain rates. The temperature and strain rate ranges of superplastic deformation were obtained, which were verified by tensile test in furnace. In the range of 950-1000 ℃, the superplastic deformation of TA7 occurs when the strain rate is lower than 0.001 s-1. The elongation reaches 260%. At the strain rate of 0.001 s-1, dynamic recrystallization occurs at 800 ℃ while a lamellar-type coarse α phase and grain growth appear in the fracture at 1000 ℃. With the increase of temperature, the strain rate sensitivity exponent (m) and strain hardening exponent (n) both increase. The maximum values of m and n are obtained at 950 ℃ when the tension stiffening and high temperature softening behaviors of the material reach balance.

Key words: TA7 titanium alloy; superplastic; high temperature tension; strain hardening exponent; strain rate sensitivity exponent

Foundation item: Project(2017YFB1104803) supported by the National Basic Research Development Program of China; Project(51005004) supported by the National Natural Science Foundation of China; Project(3132006) supported by the Natural Science Foundation of Beijing, China

Received date: 2019-04-26; Accepted date: 2020-01-02

Corresponding author: LIN Jian; Tel: +86-13810667902; E-mail: linjian@bjut.edu.cn

(编辑 王 超)

基金项目:国家重点研发计划资助项目(2017YFB1104803);国家自然科学基金资助项目(51005004);北京市自然科学基金资助项目(3132006)

收稿日期:2019-04-26;修订日期:2020-01-02

通信作者:林 健,副教授,博士;电话:13810667902;E-mail:linjian@bjut.edu.cn