文章编号: 1004-0609(2005)03-0368-06

锰结合预先热处理对铝硅合金中

富铁相组织和力学性能的影响

张 磊, 焦万丽, 尉海军, 姚广春

(东北大学 材料与冶金学院, 沈阳 110004)

摘 要: 探索了通过加入金属Mn并结合熔体热处理工艺来控制铝硅合金中富铁相的形态。 结果表明: 熔体经过预先热处理后, 加入Mn可以使绝大多数针状铁相转变成块状铁相, 且粒径均一; 预先热处理可以减少Mn的加入量而取得较好的效果, 适宜的加入量为x(Mn)/x(Fe)=0.5~1.1(摩尔比), 并可以通过控制Mn的加入量来控制块状富铁相杂质的粒径大小; 经过联合处理的含铁铝硅合金的抗拉强度提高40~80MPa, 伸长率提高6%~7%。

关键词: 富铁相; 预先热处理; 杂质; 粒径; 力学性能

中图分类号: TF777 文献标识码: A

Influence of manganese and pre-heat treatment on microstructure and mechanical properties of Al-Si alloy

ZHANG Lei, JIAO Wan-li, YU Hai-jun, YAO Guang-chun

(School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: The control of the shape of iron-rich phase were realized by adding manganese in melt of Al-Si alloy and pre-heat treatment. The results show that the needle-like iron phase can mostly be transformed into lumpish by adding manganese after pre-heat treatment, and the grain sizes are symmetrical. The better effect can be gained by adding less manganese after heat-treatment, and the grain size can be controlled by controlling the amount of manganese basically. The suitable amount of Mn is x(Mn)/x(Fe)=0.5~1.1(molar ratio). After the combined treatment, the tensile strength and elongation of Al-Si alloy are improved by 40~80MPa and 6%~7%, respectively.

Key words: iron-rich phase; pre-heat treatment; impurity; grain size; mechanical property

铁可以作为基体增强相提高铝合金高温短时抗拉强度、 蠕变强度、 室温、 高温硬度和耐磨性。 但铁在Al-Si合金中经常以β铁相的形式存在, 既硬又脆, 呈粗大片状割裂基体, 大大影响铝合金的力学性能。 消除其有害影响的途径有两个: 一是设法降低铁在铝合金中的含量; 二是改变铁在铝合金中的存在形态。 现今工业上有多种净化方法可以降低铁含量, 其净化效果都与富铁相的形态密切相关[1]。 可见, 改变富铁相的形态成为降低其危害性的关键。

改变富铁相的方法主要有: 冷速的改变[2, 3]; 熔体过热处理[4]; 中和元素的加入[5, 6]。 但前两种方法都缺乏可操作性, 在很大程度上依赖于其他因素。 对于加入中和元素的研究较多, 常用的有Mn、 Cr、 Co、 Be、 S等, 这些元素在抑制β铁相析出方面都有不俗的表现。 但是这些元素的最佳加入量目前尚无定论[7], 而且中和元素并不能完全消除富Fe相的有害作用[8, 9]。 目前, 联合使用多种添加剂也有报道, 也取得了一定的效果[10, 11], 但是加入多种元素会大大增加材料的回收局限性。 针对以上情况, 本文作者提出一种简单、 流程短、 影响因素少的工艺来控制铝硅合金中的富Fe相, 主要是采用单一的中和元素(金属Mn), 结合预先(特指在加入中和元素之前)热处理工艺来达到控制富铁相形态和粒径大小的目的, 以改善其力学性能。

1 实验

实验采用成分为Al-10%Si-1%Fe和Al-10%Si-5%Mn的两种铝合金。 实验分两个阶段进行: 一是将两种铝合金在650℃下熔化, Mn和Fe的含量按x(Mn)/x(Fe)(摩尔比)=0.5~1.5加入, 熔体搅拌保温2h后浇铸; 二是将含Fe的Al-Si合金在850℃下熔化, 搅拌, 再将熔体降至650℃下保温2h, 然后加入含Mn的Al-Si合金, Mn和Fe的含量以x(Mn)/x(Fe)(摩尔比)=0.3~1.3加入, 熔体经搅拌保温2h后浇铸。 所有样品均经过打磨、 抛光, 在金相显微镜下观察、 拍照。 将以上各成分合金按GB6397-1986标准加工成拉伸试样, 检测其力学性能。

2 结果与分析

2.1 阶段一的结果与分析

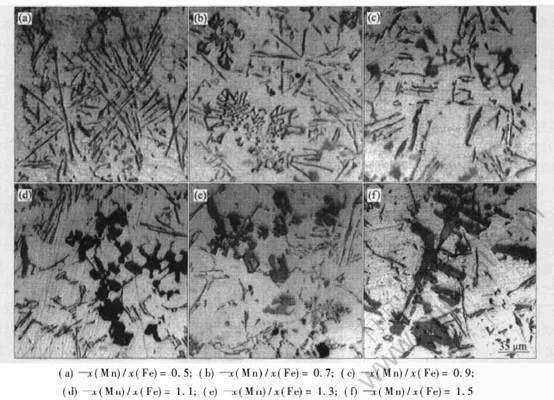

图1(a)~(f)所示是x(Mn)/x(Fe)分别为0.5, 0.7, 0.9, 1.1, 1.3和1.5合金样品的金相组织照片。 由图1可以清楚地看出, 随着金属Mn的加入, 富铁相的析出形态有了明显的变化。 当x(Mn)/x(Fe)=0.5时, 针状铁相没有明显的变化, 只是出现了少量的汉字状铁相, 表明少量Mn的加入不能对全局铁相形态的改变起到作用, 绝大部分针状铁相依然存在。 当Mn含量增加时(x(Mn)/x(Fe)=0.7, 0.9, 1.1), α铁相的数量明显增加, 并且分布很广, 针状铁相的数量大大减少。 但当Mn量再增加时(x(Mn)/x(Fe)=1.3), α铁相的形态开始变得不规则, 并且邻近的铁相出现明显的连接现象, 间接增加了铁相的体积和不规则程度。 当x(Mn)/x(Fe)=1.5时, Mn出现偏析现象, 富铁相变得异常粗大。 在整个过程中, 颜色较浅的针状铁相仍有一定数量存在。

Al-Si合金中的富铁相实际上是固溶体, 它有相当的晶格空位去溶解其它元素。 锰作为中和元素加入到铝硅合金中去, 能有效促进α-AlFeMnSi相生成, 此时, α-AlFeMnSi是稳定相。 对三元AlFeSi合金来说, Al8SiFe2是准稳定相, 对AlFeMnSi四元化合物而言, 稳定相与非稳定相的相互转化同铁锰的相对含量有关。 从微观组织来看, 当Mn含量较低时, Mn元素固溶到针状铁相当中, 而针状铁相晶体在单一的方向上有特殊的生长优势, Mn主要也是依附于此进行生长, 但还未等到针状铁相起到变化, 就消耗完毕。 当Mn含量增加时, 富铁相晶体开始在其他方向生长, 尺寸较小的针状铁相形成汉字状的四元化合物[12-14], 而且在局部Mn含量相对高的区域, 某些汉字状晶体内部开始生长, 形成块状晶体, 但仍有尺寸较大的针状铁相保持原有状态。 Mn含量继续提高, 不但不能使剩余的针状铁相发生变化, 反而出现Mn的偏析现象, 使得块状铁相长得更加粗大, 形成不规则的形态。 在本阶段实验条件下, Mn的加入不能从根本上抑制针状铁相的出现, 一味地提高Mn的加入量, 会使铁相变得异常粗大和极不规则, 富铁相形态变化复杂, 规律性不强。

2.2 阶段二的结果与分析

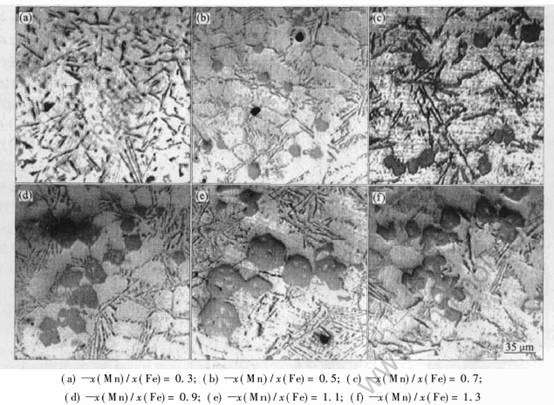

图2(a)~(f)所示是x(Mn)/x(Fe)分别为0.3, 0.5, 0.7, 0.9, 1.1和1.3合金样品的金相组织照片。 可见, 富铁相的析出形态为多边形, 其中以六边形为主, 随着Mn加入量的增加, 富铁相的变化主要体现在颗粒粒径的逐渐增大。 当x(Mn)/x(Fe)=0.3时, 晶体形态细碎, 浅色的富铁相主要以短杆状的形态出现, 表明Mn的加入量明显不足。 继续提高Mn的加入量, 富铁相杂质的析出形态有了根本的变化, 主要为多边形。 当x(Mn)/x(Fe)=0.5时, 富铁相的颗粒粒径分布在10~15μm之间; 当x(Mn)/x(Fe)=0.7时, 富铁相的颗粒粒径多在20μm左右; 当x(Mn)/x(Fe)=0.9时, 富铁相的颗粒粒径可以达到30μm左右; 当x(Mn)/x(Fe)=1.1时, 富铁相的颗粒粒径可以达到40μm。 当x(Mn)/x(Fe)增大到1.3时, 六边形富铁相开始出现明显的缺陷, 形态变得不规则, 而且出现了明显的颗粒连接现象。 利用扫描电镜在针状析出相存在区域进行随机的元素扫描, 结果显示Fe、 Mn两种元素都没有峰值出现, 这表明几乎所有的针状铁相都转变成了块状。 Si元素仍然多以长

图1 阶段一中Mn的加入量对富铁相组织的影响

Fig.1 Effect of addition of manganese on iron-rich phase in state one

图2 阶段二中Mn的加入量对富铁相组织的影响

Fig.2 Effect of addition of manganese on iron-rich phase in state two

针形态析出。

从热力学的角度来说, 相的形成总是趋向于能量最低状态。 针状铁相具有比较大的比表面积, 能量状态比较高, 只要动力学条件满足, 就会发生针状铁相的断裂, 转向能量更低的状态。 文献[15]表明了在高于常规热处理的温度下可发生针状铁相的断裂。 本阶段中, Al-Si合金在850℃下熔化, 同时加以剧烈搅拌。 利用搅拌可以加速针状铁相的断裂, 缩短高温处理的时间。 预先热处理后的铁相多以短杆状或细小的块状出现, 成为新形态铁相生长的核心。 在随后的保温阶段针状铁相的断裂可以继续进行, 而断裂后的短杆状铁相在立体的方向上发育, 成为形态更加规则的核心。 金属Mn加入后会依附于此种核心和富铁相一起生成AlSiFeMn四元化合物, 晶体的生长在各个方向上实力平均, 容易形成多边形, 在成分均匀的前提下, 所生成的富铁相颗粒粒径比较均一。 随Mn的加入量继续提高, 富铁相持续生长, 有些邻近的铁相结合在一起。 当Mn过量时, Mn的偏析现象随之出现, 富铁相停止有规律的生长, 邻近铁相互相连接成为铁相变化的主要方式, 间接形成了大尺寸、 不规则的富铁相。 可见, 规则的核心是形成形态规则富铁相的基础, 熔体的高温处理是形成规则核心的根本原因。 Mn的加入量的多少可以影响富铁相颗粒的大小, 适宜的加入量为x(Mn)/x(Fe)=0.5~1.1。

2.3 力学性能

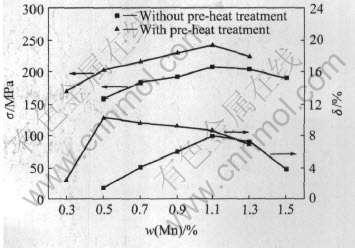

为了考察富铁相杂质颗粒形态对合金力学性能的影响, 避免其它因素的干扰, 合金不经过固溶处理和时效处理。 每种成分的合金做成3个拉伸试件, 拉伸实验结果取平均值, 结果如图3所示。 Al-Si合金中的针状富铁相引起的微观缩松往往是产生裂纹和缺陷的源头, 它的大量存在极大地影响了合金的力学性能, 随着富铁相尺寸的增大, 恶性影响愈加严重。 锰的加入使富铁相的形态有所改善, 抗拉强度和伸长率都有所提高, 在x(Mn)/x(Fe)=1.1时达到最大值。 此时富铁相的形态比较规则。 规则化的富铁相形态可以作为基体的增强相, 改善合金的力学性能。 随着锰的继续加入, 富铁相形态开始趋于不规则, 合金的抗拉强度和伸长率又有所下降。 在阶段一实验条件下, x(Mn)/x(Fe)=1.1的合金样品比x(Mn)/x(Fe)=0.5的合金样品抗拉强度提高50MPa, 伸长率提高6%。

图3 不同锰含量合金的抗拉强度和伸长率

Fig.3 Tensile strength and elongation of alloy with different content of Mn

合金经过预先热处理后, 当x(Mn)/x(Fe)=0.5时, 富铁相形态有了根本的转变, 此时抗拉强度为194MPa, 伸长率达到最大值9.3%。 富铁相颗粒的粒径增加, 抗拉强度继续增加, 但伸长率有所下降。 直到富铁相形态变得不规则(x(Mn)/x(Fe)=1.3), 抗拉强度开始下降。 规则的块状、 六角形富铁相可以作为合金的基体增强相存在, 不容易产生裂纹和缺陷, 可以在一定程度上阻止合金基体枝晶的滑移, 提高合金的抗拉强度, 但增大的颗粒会影响伸长率。 预先热处理可以增强同样成分合金的力学性能的改善效果, 在富铁相颗粒形态规则的前提下, 提高Mn含量可以提高合金的抗拉强度。

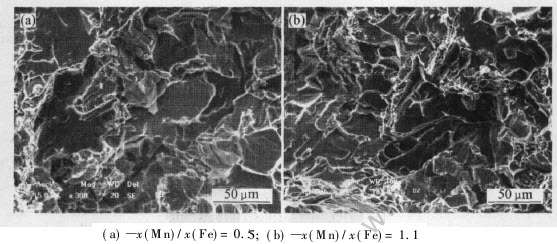

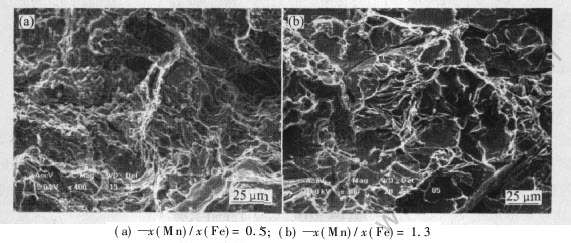

图4所示为未经过热处理的两种合金的断口形貌。 当x(Mn)/x(Fe)=0.5时, 合金的断裂方式是典型的脆性断裂(图4(a)), 其断口上显示出大小分布不均的解理面, 基本上不存在撕裂痕迹和纵向开裂痕迹。 当x(Mn)/x(Fe)=1.1时, 断口形貌有了变化(图4(b)), 解理面的面积明显缩小, 而且还分布着许多准解理小面, 互相交错。 可见一定量的锰的加入可以改变合金的断裂方式, 改善其力学性能。 合金经过联合处理后, 合金的断裂方式又发生了很大变化。 当x(Mn)/x(Fe)=0.5时, 断口上分布着空穴和准解理小面(图5(a)), 基本上不存在解理面, 明显的撕裂棱表明合金经过了较大的塑性变形, 此种合金具有较大的伸长率。 当x(Mn)/x(Fe)=1.3时, 断口形貌是解理面加准解理面(图5(b)), 降低了合金的塑性。 断口形貌的观察结果与前面的力学性能测试结果一致。

图4 阶段一中合金的断口形貌

Fig.4 Fractographs of alloy in state one

图5 阶段二中合金的断口形貌

Fig.5 Fractographs of alloy in state two

3 结论

1) 单纯的加入Mn元素的方法不能从根本上抑制针状铁相的出现, Mn可以从一定程度上改变富铁相的形态, 适宜的加入量为x(Mn)/x(Fe)=1.1左右。

2) 经过预先热处理的Al-Si合金熔体, 加入Mn后富铁相以规则的多边形形态析出, 几乎完全抑制了针状铁相的出现, 适宜的加入量为x(Mn)/x(Fe)=0.5~1.1。

3) 经过联合处理的Al-Si合金熔体, 多边形富铁相粒径的大小和Mn的加入量密切相关, 通过控制Mn(x(Mn)/x(Fe)=0.5~1.1)的加入量, 可以使绝大部分富铁相以一定粒径(10~40μm)析出。

4) 铝硅合金经过预先热处理可以加强锰改善力学性能的效果, 经过联合处理的合金样品的抗拉强度和伸长率比单纯加锰的合金样品分别提高40~80MPa和6%~7%。

REFERENCES

[1]印飞, 杨江波, 孙宝德. 铝硅合金中的六角形铁相[J]. 上海交通大学学报, 2001, 35 (3): 477-480.

YIN Fei, YANG Jiang-bo, SUN Bao-de. Hexagonal iron phase study in aluminum-silicon alloy[J]. Journal of Shanghai Jiaotong University, 2001, 35(3): 477-480.

[2]Narayanan L A, Samuel F H, Gruzleski J E. Crystallization behavior of iron-containing inter-metallic compound in 319 aluminum alloy[J]. Metallurgy and Materials Transactions A, 1992, 25A: 1761.

[3]Sigworth G K, Shivkuman S, Apelian D. The influence of molten metal processing on mechanical properties of cast Al-Si-Mg alloy[J]. AFS Transactions, 1989, 139: 811-824.

[4]Awano Y, Shimizu Y. Non-equilibrium crystallization of AlSiFe compound in melt-superheated Al-Si alloy casting[J]. AFS Transactions, 1990, 176: 889-896.

[5]Couture A. Iron in aluminum casting alloys—A literature survey[J]. AFS Transactions, 1981, 11: 9-17.

[6]Muali S, Raman K S, Murthy K S S. Morphological studies on β-FeSiAl5 phase in Al-7Si-0.3Mg alloy with trace addition of Be, Mn, Cr and Co[J]. Materials Characterization, 1994, 33: 99-112.

[7]孙业赞, 于敞, 厉松春, 等. 铁在铝硅合金中存在的形态及其作用分析[J]. 铸造, 1998(7): 42-46.

SUN Ye-zan, YU Chang, LI Song-chun, et al. The analysis of action and shape of iron in Al-Si alloy[J]. Foundry, 1998(7): 42-46.

[8]杨江波, 印飞. 改善铝硅合金中铁相形态的措施[J]. 铸造, 2000, 49(8): 454-459.

YANG Jiang-bo, YIN Fei. Improvement of the morphology of iron phase in Al-Si alloy[J]. Foundry, 2000, 49(8): 454-459.

[9]林小征, 印飞, 孙宝德. 铁对铝硅合金的性能的影响及抵消其有害作用的措施[J]. 铸造技术, 1999(5): 29-32.

LIN Xiao-zheng, YIN Fei, SUN Bao-de. Influence of Fe on the properties of Al-Si alloy and methods of neutralizing the effect of Fe[J]. Foundry Technology, 1999(5): 29-32.

[10]陈冰泉, 彭军波, 缪鄂. 稀土镍锰对铝硅合金熔敷金属中铁相形态的影响[J]. 机械工程材料, 2003, 27(4): 14-17.

CHEN Bing-quan, PENG Jun-bo, LIAO E. Influence of RE, Ni, Mn on Fe-phase aspect in Al-Si alloy[J]. Meterials for Mechanical Engineering, 2003, 27(4): 14-17.

[11]廖恒成, 夏锦宏, 孙国雄. Sr+B联合熔体处理对Al-Si-Mg合金组织和力学性能的影响[J]. 中国有色金属学报, 2003, 13(1): 27-34.

LIAO Heng-chang, XIA Jin-hong, SUN Guo-xiong. Influence of combined melt treatment of Sr+B on microstructure and mechanical properties of Al-Si-Mg casting alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 27-34.

[12]贾雨, 赵平. 过共晶铝硅合金中Al-Si-Mn-Fe相的形态影响因素[J]. 成都理工学院学报, 2001, 28 (2): 214-216.

JIA Yu, ZHAO Ping. Effects of Al-Si-Mn-Fe phase in hypereutectic Al-Si alloy[J]. Journal of Chengdu University of Technology, 2001, 28 (2): 214-216.

[13]Li Y J, Lars A. Evolution of primary particles in DC cast AA3003 alloy during heating and homogenization[J]. Light Metals, 2002: 765-770.

[14]Samuel F H, Ouellet P, Samuel A M, et al. Effect of Mg and Sr additions on the formation of intermetallics in Al-6wt pct Si-3.5wt pct Cu-(0.45) to (0.8)wt pct Fe 319-type alloys[J]. Metallurgy and Materials Transactions A, 1998, 29A(12): 2871-2884.

[15]印飞, 杨江波, 王亦新, 等. 铝硅合金中针状铁相的断裂现象[J]. 特种铸造及有色合金, 2001(1): 1-3.

YIN Fei, YANG Jiang-bo, WANG Yi-xin, et al. Ruptured phenomenon of needle iron phase in Al-Si alloy[J]. Special Foundry and Nonferrous Alloy, 2001(1): 1-3.

(编辑袁赛前)

基金项目: 国家重点基础研究发展规划项目(G199906490-4)

收稿日期: 2004-06-18; 修订日期: 2004-12-21

作者简介: 张 磊(1977-), 男, 博士研究生.

通讯作者: 张 磊; 电话: 024-83686462; E-mail: jwlz177@163.com