文章编号:1004-0609(2008)05-0834-06

镍基合金/不锈钢钨极惰性气体钎焊接头的特性

宋建岭,林三宝,杨春利,范成磊

(哈尔滨工业大学 现代焊接生产技术国家重点实验室,哈尔滨 150001)

摘 要:选用CuSi3焊丝对镍基合金/不锈钢进行钨极惰性气体(TIG)钎焊实验,运用OM、SEM和EDS分析接头微观组织,通过拉伸实验和硬度实验评定接头的力学性能。结果表明:TIG钎焊接头具有熔焊和钎焊的双重性质,不锈钢母材局部熔化,生成Fe基熔合区;在接头搭接区及镍基合金母材与焊缝金属之间存在界面反应层,反应层可分为熔化未混合区、Ni基树枝晶和晶间Cu基区;焊缝区为Cu基体上分布着颗粒状Fe基固溶体;CuSi3接头剪切强度达到195 MPa,接头断裂于焊缝与不锈钢界面处,断口为微孔聚合机制引起的塑性断裂;在界面处硬度值发生突变,Ni基树枝晶硬度值达到HV433.3,不锈钢熔合区中的Fe基体硬度值达到HV453.4,近界面处焊缝区Cu基体硬度值为HV150。

关键词:钨极惰性气体钎焊;界面反应层;显微组织;力学性能

中图分类号:TG 457.1 文献标识码:A

Characteristics of tungsten inert gas brazing joints of

nickel-based alloy and stainless steel

SONG Jian-ling, LIN San-bao, YANG Chun-li, FAN Cheng-lei

(State Key Laboratory of Advanced Welding Production Technology, Harbin Institute of Technology, Harbin 150001, China)

Abstract: The tungsten inert gas(TIG) brazing of nickel-based alloy and stainless steel using CuSi3 wire was carried out. The microstructures and mechanical properties of the joint were studied using OM, SEM, EDS, instron-testing machine and hardness measurement device. The results show that the joint has dual characteristic and is divided into a welding part on the stainless steel and a brazing part on the nickel-based alloy. The stainless steel fusion zone is made of Fe-based solid solution, the interface reaction layer is made of molten unmixed zone, Ni-based fir-tree crystal microstructure and Cu-based solid solution in the intergranular. The weld is made of α-copper matrix and Fe-based solid solution in the matrix. The shear strength reaches 195 MPa and the shear fracture occurs at the interface between brazing alloy and stainless steel. The microhardness in the Ni-based fir-tree crystal, the Fe-based solid solution of the fusion zone and Cu-based solid solution of the weld near the interface reach HV433.3, HV453.4 and HV150, respectively.

Key words: tungsten inert gas brazing; interface reaction layer; microstructure; mechanical properties

某型号发动机束式喷管延伸段由镍基合金方管拼焊制造而成,在实际制作过程中需要焊接不锈钢加强环进行约束,如何连接该镍基合金方管拼焊板和不锈钢加强环是生产过程中面临的一个难题。如果采用普通电弧熔焊的方法,其热输入量高,热影响区过热度大,焊后工件变形量大,对于薄板容易产生焊穿现象,焊接过程中易产生熔滴飞溅,影响其焊缝表面成形

[1]。如果采用炉中钎焊或真空钎焊,其要求整体加热,且加热时间长;焊后工件变形量大,对间隙配合要求高,且消耗大、成本高;火焰钎焊加热区宽,热量输入不易控制,焊后也会导致大的残余变形,尤其是薄壁工件变形更大,且产生合金元素氧化烧蚀现象

[1-2]。

钨极惰性气体(TIG)钎焊是在氩气保护下,采用非熔化的钨合金作为电极,在钨极与工件间形成电弧,焊接过程中母材不熔或微熔,采用特制的钎焊丝连续送进并熔化形成填充金属,将母材连接起来的一种复合焊接工艺。TIG钎焊热输入量小,加热速度快,接头在高温停留时间短,热影响区过热度低,母材金属不易产生晶粒长大,不易产生热裂纹,具有焊缝成形美观,工件变形量小,接头强度高,可以实现焊接过程自动化等优点,在异种材料连接、薄壁器件连接等领域具有广阔的应用前景[3-10]。PATON WI焊接工作者等对TIG钎焊工艺和特种焊丝方面做了大量的工 作[11-14],姜晓飞等[3]和于治水等[5]对镀锌钢板TIG钎焊工艺做了探索性的研究,但对于镍基合金与不锈钢异种材料的TIG钎焊连接的研究至今未见报道。本文作者采用CuSi3焊丝对Inconel 600/1Cr18Ni9Ti进行了TIG钎焊实验,研究了接头微观组织和力学性能。

1 实验

1.1 实验材料

实验母材为镍基合金Inconel 600和不锈钢1Cr18Ni9Ti,镍基合金为5 mm×4 mm方管,壁厚为0.33 mm,不锈钢为2 mm厚的板材,两种材料的化学成分列于表1中。实验用钎焊丝为d1.2 mm的CuSi3焊丝,焊丝成分(质量分数,%)为:Si3.00,Mn1.00,Zn0.50,Cu余量;焊丝熔化温度为950~1 027 ℃。

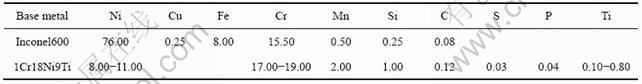

表1 实验材料的化学成分

Table 1 Chemical composition of experimental materials (mass fraction, %)

1.2 实验过程

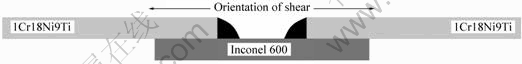

将镍基合金方管TIG拼焊板切成40 mm×40 mm规格,不锈钢板切成80 mm×40 mm×2 mm规格,在镍基合金拼焊板上搭接不锈钢板,如图1所示。焊前用打磨机、砂纸除去试件表面氧化膜、油污等,然后用丙酮擦洗干净。焊接工艺参数为:焊接电流35 A,电弧长度3.0 mm,焊接速度120 mm/min,送丝速度300 mm/min,氩气流量5.0 L/min。

焊后对接头进行垂直切割,将切割后的试样用树脂塑封,采用水磨砂纸按500#、800#、1 000#顺序打磨,然后用粒度为1 μm的金刚石抛光剂抛光,抛光后的样品采用5 g FeCl3 粉末+15 mL盐酸+85 mL水的腐蚀剂腐蚀5~8 s制成试样。使用金相显微镜(OM) OLYMPUS GX71分析接头宏观特征,用扫描电镜(SEM)S-3400N和能谱仪(EDS)分析接头微观组织特征。制作剪切试件,在万能电子拉伸机INSTRON5500R上测试焊缝剪切强度,并对断口进行扫描分析,确定接头断裂状态,在韦氏硬度仪上测量接头不同部位的硬度值。

图1 镍基合金拼焊板与不锈钢搭接装配图

Fig.1 Assembly diagram of nickel-based alloy and stainless steel

2 结果与分析

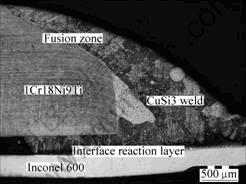

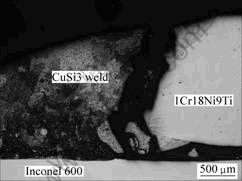

2.1 接头宏观特征

镍基合金/不锈钢TIG钎焊接头横截面如图2所示。接头具有熔焊与钎焊双重性质:在电弧热作用下,CuSi3焊丝熔化铺展填充搭接焊缝,钎料与镍基合金和不锈钢两种母材均发生了界面反应,少量熔化母材与熔化焊丝混合后凝固形成焊缝。不锈钢边受电弧加热多,产生熔化现象,熔化的不锈钢在电弧力的作用下进入焊缝中与液态钎料混合,凝固形成焊缝组织。

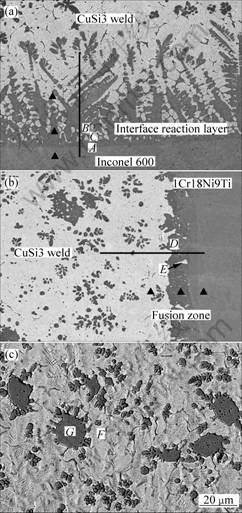

2.2 接头微观组织特征

图3所示为接头的微观组织和EDS分析测试点位置。各点EDS测试元素的化学成分如表2所列。结合图2和3及EDS分析可知,不锈钢界面处形成较宽的熔合区,同时熔化母材在电弧力作用下沿不锈钢边流动在下部凝固成大块Fe基固溶体,由于钎焊温度低,冷却速度快,熔合区中只有少量的液态钎料元素扩散进来形成颗粒状Cu基固溶体。搭接处及镍基合金母材受电弧加热少,焊缝金属与母材为钎焊结合,镍基合金表面与液态铜基钎料发生界面反应,以树枝晶形式向焊缝区生长,界面反应层的存在保证了钎料与镍基合金具有较高的结合强度。在电弧吹力不均匀的搅拌作用下,焊缝中存在大量尺寸不等的高温Fe基颗粒,分析认为在TIG钎焊过程中液态钎料凝固速度快,过冷度大,Cu-Fe系随过冷度的增大,液态不可混性的热力学倾向增大,引起液态分离,产生Fe基球状颗粒。

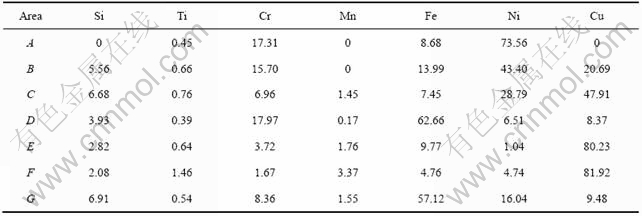

表2 CuSi3接头微观组织不同区域的EDS分析

Table 2 EDS analysis at different areas in CuSi3 joint (mass fraction, %)

图2 TIG钎焊搭接接头横截面形貌

Fig.2 Morphology of cross section of TIG brazing lap joint

图3 CuSi3接头的微观组织

Fig.3 Microstructures of CuSi3 joint: (a) Interface reaction layer of nickel-based alloy; (b) Fusion zone of stainless steel; (c) CuSi3 weld

由图3可看出,镍基合金界面反应层分为3个不同区域:熔化未混合区(A)、镍基树枝晶区(B)和晶界铜基区(C)。在A区,母材表面在液态钎料的作用下出现了溶蚀现象,由于热输入量小,钎料凝固速度快,液态钎料元素没有获得足够的热量向母材中扩散,形成熔化未混合区;在B区,熔化母材中Fe、Ni和Cr等元素与液态钎料中Cu和Si等元素在高温下互溶,以树枝晶形式向焊缝区生长,由表3能谱定量分析及相关二元相图[15]可知,Fe-Ni和Cu-Ni元素间可以无限固溶,Fe-Cu间虽为有限固溶,但不形成化合物,Fe-Si间的Si含量超过10%时才有可能形成化合物,因此生成成分复杂的Ni基固溶体组织,组织中存在较多的Si元素,Si原子尺寸较小,可以形成间隙固溶体,起到固溶强化的作用;在枝晶间C区形成Cu基固溶体组织。不锈钢熔合区组织是以Fe基固溶体为基体,在其上分布着颗粒状Cu基固溶体(见D区和E区)。焊缝区组织是以Cu基固溶体为基体,在其上分布着尺寸大小不等的颗粒状Fe基固溶体(见F区和G区),在Cu基体中固溶了少量的Si和Mn等元素提高了接头强度。同时,在大块Fe基固熔体颗粒内部存在液态分离过程中形成的许多细小Cu基颗粒,这在图3(b)中更清楚,在进行能谱分析过程中,点有时打在Cu基颗粒边界上,因此G区显示含有较高的Cu含量。

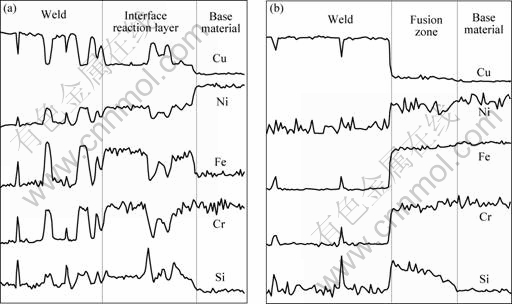

对界面区进行线扫描,扫描位置如图3所示,线扫描结果如图4所示。在镍基合金界面层Ni基树枝晶固溶体成分较为稳定,而树枝间Cu基固溶体组织成分发生很大变化,距离界面处越近,Cu和Si元素含量逐渐减少,Cr和Fe含量逐渐升高,并在界面处发生突变,镍基合金母材中没有发生钎料元素的扩散。在不锈钢熔合区附近的焊缝区,Cu基体成分稳定,在界面发生成分突变,熔合区为Fe基固溶体,含Cu量很少,同时发生了Si元素的扩散,距离母材越近,界面反应区中的Si含量逐渐降低。

图4 接头界面反应区的EDS线扫描结果

Fig.4 EDS line scanning results of interface reaction layer: (a) In interface reaction layer of nickel-based alloy; (b) In fusion zone of stainless steel

2.3 接头力学性能分析

由于TIG拼焊的镍基合金方管不能大力装卡,镍基合金两边分别钎焊不锈钢板,通过装卡不锈钢板进行剪切实验,试件制作如图5所示。实验测得接头剪切强度达到195 MPa,接头断裂于焊缝与不锈钢界面上(见图6)。对界面反应区进行硬度分析,测试点如图3中“▲”所示,实验测得镍基合金母材硬度为HV183.0,界面反应层由于Si和Ti等合金元素的固溶强化作用[16-17],使硬度发生突变,Ni基树枝晶硬度达到HV433.3;不锈钢母材硬度为HV187.2,熔合区Fe基体由于Si元素的固溶强化作用,硬度发生突变,硬度值达到HV453.4;近界面处焊缝区,Cu基体硬度值为HV150。

图5 剪切试件示意图

Fig.5 Sketch diagram of shear sample

图6 CuSi3接头断裂位置的形貌

Fig.6 Morphology of fracture position of CuSi3 joint

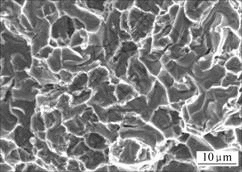

图7所示为CuSi3接头断口形貌。由图7可看出,断口存在许多的韧窝,具有较明显的撕裂棱,韧窝尺寸比较小,断口存在许多微裂纹。分析认为,断口是由微孔聚合机制引起的塑性断裂,在剪切应力作用下,焊缝内部产生微裂纹,在外力的持续作用下,微裂纹逐渐长大,最终微裂纹间相互联系产生断裂。

图7 CuSi3接头断口形貌

Fig.7 Shear fractograph of CuSi3 joint

3 结论

1) TIG钎焊具有熔焊和钎焊的双重性质,不锈钢边受电弧加热多,产生熔化现象,在界面处形成较宽的熔合区;搭接处及镍基合金母材受电弧加热少,焊缝金属与母材为钎焊结合,镍基合金表面与液态铜基钎料发生界面反应,以树枝晶形式向焊缝区生长,界面反应层的存在保证了钎料与镍基合金具有较高的结合强度。

2) 镍基合金界面反应层分为3个不同区域:熔化未混合区、Ni基树枝晶区和晶界Cu基区。不锈钢熔合区组织是以Fe基固溶体为基体,在其上分布着颗粒状Cu基固溶体;焊缝区组织是以Cu基固溶体为基体,在其上分布着尺寸大小不等的颗粒状Fe基固溶体。在界面区存在Si元素的扩散,距离母材越近,Si含量逐渐减少。

3) CuSi3接头剪切强度达到195 MPa,接头断裂于焊缝与不锈钢界面上,断口为微孔聚合机制引起的塑性断裂;在界面处硬度值发生突变,Ni基树枝晶硬度达到HV433.3;不锈钢熔合区的Fe基体硬度值达到HV453.4,近界面处焊缝区的Cu基体硬度值为HV150。

REFERENCES

[1] 李亚江. 特殊及难焊材料的焊接[M]. 北京: 化学工业出版社, 2003.

LI Ya-jiang. Welding & joining of special and difficult welded materials[M]. Beijing: Chemical Industry Press, 2003.

[2] 赵 越. 钎焊技术及应用[M]. 北京: 化学工业出版社, 2004.

ZHAO Yue. Technology and application of brazing & soldering[M]. Beijing: Chemical Industry Press, 2004.

[3] 姜晓飞, 何 鹏, 冯吉才, 石常亮. CMT法30CrMnSi钢板表面熔敷CuSi3接头组织结构特征[J]. 焊接学报, 2007, 28(2): 47-50.

JIANG Xiao-fei, HE Peng, FENG Ji-cai, SHI Chang-liang. Microstructure characteristics of CuSi3 cladding on 30CrMnSi steel with cold metal transfer technology[J]. Transactions of The China Welding Institution, 2007, 28(2): 47-50.

[4] MURAKAMI T, NAKATA K, TONG Hong-jun. Dissimilar metal joining of aluminum to steel by MIG arc brazing using flux cored wire[J]. ISIJ International, 2003, 43(10): 1596-1602.

[5] 于治水, 周方明, 祁 凯, 吴铭方. Cu基钎料MIG钎焊接头断裂行为分析[J]. 焊接学报, 2001, 22(6): 29-32.

YU Zhi-shui, ZHOU Fang-ming, QI Kai, WU Ming-fang. Fracture behavior analysis of MIG-brazed joint with Cu-based filler metals[J]. Transactions of The China Welding Institution, 2001, 22(6): 29-32.

[6] GAWRYSIUK W. Technology of the arc-braze welding process[J]. Welding International, 2006, 20(1): 10-16.

[7] CHOVET C, GUIHEUX S. Possibilities offered MIG and TIG brazing of galvanized ultra high strength steels for automotive applications[J]. La Metallurgia Italiana, 2006, 98(7/8): 47-54.

[8] BOUAIFI B, OUAISSA B, HELMICH A. Plasma arc brazing in sheet metal construction[J]. Science and Technology of Welding and Joining, 2002, 7(5): 326-330.

[9] KAZUYOSHI S, KAZUTOSHI N. Recent trends and future development of interfacial joining processes[J]. Journal of Japan Weld Society, 2003, 72(1): 31-39.

[10] NAKAHASHI M, SUENAGA S, SHIROKANE M, TAKEDA H. Transient liquid phase bonding for Ni-base superalloys, Mar-M247 and IN939[J]. Materials Transactions, JIM, 1992, 33(1): 60-65.

[11] FRINGS A, STOCKEL S. Fully mechanized inert-gas metal-arc brazing of aluminized thin steel sheet[J]. Schweien und Schneiden, 1989, 41(11): 577-583.

[12] HACKL H. MIG brazing of galvanized light-gauge sheets[J]. Welding Review International, 1996, 15(6): 122-123.

[13] PREGELJ A, BRECEIL F. TIG-plasma brazed vacuum joints [J]. Vacuum, 1990, 40(1): 65-66.

[14] KEMGF B, JUNG J, BREME J. New brazing solders for the joining of chrome-nickel steels[J]. Schweissen und Schneiden, 2001, 53(1): 26-31.

[15] 黄德彬. 有色金属材料手册[M]. 北京: 化学工业出版社, 2005: 18-35.

HUANG De-bin. Handbook of nonferrous materials[M]. Beijing: Chemical Industry Press, 2005: 18-35.

[16] 倪加明, 李俐群, 陈彦宾, 封小松. 铝/钛异种合金激光熔钎焊接头特性[J]. 中国有色金属学报, 2007, 17(4): 617-622.

NI Jia-ming, LI Li-qun, CHEN Yan-bin, FENG Xiao-song. Characteristics of laser welding-brazing joint of Al/Ti dissimilar alloys[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(4): 617-622.

[17] 潘志勇, 汪明朴, 李 周, 邓楚平, 肖 柱, 陈 畅. 超高强度Cu-5.2Ni-1.2Si合金的形变热处理[J]. 中国有色金属学报, 2007, 17(11): 1821-1826.

PAN Zhi-yong, WANG Ming-pu, LI Zhou, DENG Chu-ping, XIAO Zhu, CHEN Chang. Thermomechanical treatment of super high strength Cu-5.2Ni-1.2Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1821-1826.

收稿日期:2007-11-10;修订日期:2008-03-02

通讯作者:林三宝,副教授,博士;电话:0451-86418844;E-mail: sblin@hit.edu.cn

(编辑 李艳红)