DOI: 10.11817/j.issn.1672-7207.2015.11.007

双辊甩带制备Au-20%Sn焊料及其均匀化退火工艺

刘锐,王日初,韦小凤,彭健

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:采用双辊甩带技术制备Au-20%Sn焊料薄带材,观察和分析快速凝固Au-20%Sn焊料薄带的显微组织以及熔融特性,并研究合金的均匀化退火工艺。研究结果表明:双辊甩带合金由ζ′(An5Sn)和δ(AuSn)两相组成,显微组织细小。合金的熔化温度接近共晶点,满足焊料的熔点要求。均匀化退火过程中,δ(AuSn)相逐渐长大,合金的硬度降低。根据薄带的组织和硬度,确定均匀化退火工艺为260 ℃下退火4 h。

关键词:双辊法;金锡焊料;均匀化退火

中图分类号:TG162.83 文献标志码:A 文章编号:1672-7207(2015)11-4021-07

Au-20%Sn solder prepared by twin-roll method and its homogenized annealing

LIU Rui, WANG Richu, WEI Xiaofeng, PENG Jian

(School of Materials, Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Au-20%Sn solder strips were prepared by twin-roll method. The microstructure of the solders was observed and melting behaviors were analyzed, homogenized annealing technology was also studied. The results show that the strips prepared by twin-roll method are composed of two phases, which are siginificantly refined ζ(An5Sn) and δ(AuSn) phases. The melting temperature of the alloy is close to the eutectic temperature, which can meet the requirements of Au-20%Sn solders. During the homogenized annealing, δ(AuSn) phase grows gradually and the hardness of the alloy decreases. According to the microstructure and the hardness of strips, the optimal treatment is annealed at 260 ℃ for 4 h.

Key words: twin-roll; AuSn solder; homogenized annealing

Au-20%Sn焊料是近年来发展起来的中低温焊料,具有优良的耐蚀性、抗氧化性、流动性和润湿性,且蒸气压低、高温稳定性良好以及钎焊接头强度高,是目前梯度封装中焊接温度为300~330 ℃时的最佳焊料[1]。Au-20%Sn焊料可焊接铜、镍、可伐合金和不锈钢等,适用于电真空器件以及航空发动机等重要零件的焊接,在高可靠性封装方面有广泛应用[2-3]。Au-20%Sn合金钎料由ζ′(Au5Sn)和δ(AuSn) 2种脆性金属间化合物组成,塑性加工困难,不能采用常规的轧制成形方法获得适合于焊接的箔材。目前,Au-20%Sn合金带材主要是采用叠层冷轧法制造[4-5]。99.99%的纯Au和纯Sn薄片交替排列,经冷压铆合后多道次、小变形量冷轧,轧制到一定厚度后再退火合金化得到均匀的共晶组织。但由于Au与Sn力学性能的差异,轧制后的合金带材中成分会存在偏差,从而影响合金的焊接性能。朱志君[6]采用压铸法制备Au-20%Sn合金,压铸水淬得到厚度为0.4 mm的合金焊片,并研究了合金的增韧。在260 ℃下退火1 h能使合金韧性提高,可以冲压成型。但制备过程中包含真空吸铸、热压延展和分条熨平等,制备工艺复杂且对设备的要求较高。双辊甩带法是一种新型的制备薄带材的方法,在钢铁、电子以及航空航天方面有广泛应用[7-8]。熔融金属液在一定压力作用下喷射入2个反向转动的辊轮之间,与辊面接触后迅速冷却形成稳定的凝固层。随着辊面转动,两凝固层厚度逐渐增大并在间距最小处形成薄带,最后沿辊面切线方向高速甩出。崔大田[9]采用双辊快速凝固法制备出表面质量较好、显微组织细小的Au-19.25Ag-12.80Ge焊料合金。本文作者采用双辊甩带法制备Au-20%Sn合金带材,研究快速凝固合金的显微组织和熔融特性以及均匀化退火工艺。

1 实验

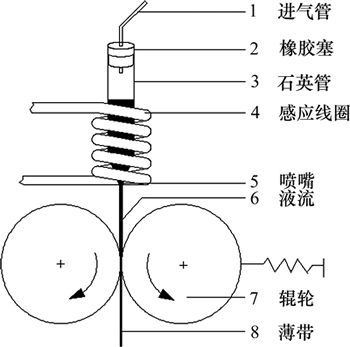

纯度为99.99%的Au与Sn用GP-30E型超音频感应加热炉熔化制备Au-20%Sn合金锭坯,将制备好的合金锭坯用双辊甩带法制备带材。双辊甩带设备示意图如图1所示。合金锭坯置于石英管3中,石英管底端是直径为0.5 mm的喷嘴。进气管1连通氩气,在氩气保护下加热合金至450,550和650 ℃后加压力0.1 MPa将熔融合金从喷嘴喷出,在辊轮的作用下形成带材。喷嘴距辊缝高度为15 mm,辊速为10 m/s。采用超音频感应加热法加热锭坯,采用红外测温仪测量合金的温度。

采用X线衍射(XRD)、扫描电镜(SEM)和差热分析(DSC)等检测方法表征甩带后合金带材与铸态合金的相组成和熔融性能。将甩带后的合金带材置入电阻炉中,在220,240和260 ℃下分别退火1,4,16和64 h后空冷。试样经磨样抛光后,采用FEI QUANTA-200扫描电子显微镜观察其微观组织形貌。采用Image Pro-Plus图像分析系统对金相组织进行定量分析,并采用等效面积圆直径表征AuSn相粒径。

图1 实验装置示意图

Fig. 1 Schematic diagram of experimental apparatus

2 实验结果与讨论

2.1 浇注温度对带材厚度的影响

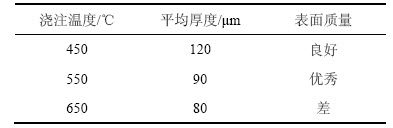

带材厚度的控制是双辊甩带技术的关键。陈明安等[10-11]对影响带材厚度的工艺参数进行了研究,结果表明:薄带的厚度与喷嘴距辊缝的距离、喷射压力成正比,与辊轮的线速度成反比。目前,研究者针对浇注温度与带材厚度之间关系的研究较少。本实验在喷辊距、喷射压力和辊速3个参数不变的情况下,通过调节超音频感应加热设备的功率来设定合金熔体的温度。在不同浇注温度下,钎料薄带的厚度和表面质量如表1所示。从表1可知:随着浇注温度的升高,薄带的厚度降低,当浇注温度为650 ℃时,薄带的厚度可达到80 μm。

表1 不同浇注温度下Au-20%Sn带材的厚度和表面质量

Table 1 Thickness and quality of Au-20%Sn foils at different pouring temperatures

双辊甩带中轧辊的材料为Cu,导热性能很好,甩出的合金带材很薄,合金的冷却速率很快,因此,材料的冷却方式可认为牛顿冷却方式。对于牛顿冷却方式冷却的合金熔体,界面热阻大,当熔体层厚度较小时,熔体内部的温度只与时间有关而和位置无关,熔体冷却过程中的温度场的变化及冷却规律可由一维传热条件下的热传输平衡方程求得[12]。则在熔体冷却时间△t内,通过衬底的热量等于合金熔体冷却到室温所释放的热量。

式中: 为熔体密度;A为熔体与衬底的接触面积;CT为熔体比热容;h为热流密度;l为带材厚度。由式(1)可得合金带材的厚度为

为熔体密度;A为熔体与衬底的接触面积;CT为熔体比热容;h为热流密度;l为带材厚度。由式(1)可得合金带材的厚度为

本实验只改变熔体温度,不改变甩带工艺,假设热流密度h、熔体与轧辊接触的时间△t及熔体密度 都不变。从式(2)可以看出:甩带过程中,浇注温度越高,带材的厚度越小。从表1还可知:当浇注温度为650 ℃时,带材的表面会出现马蹄形裂纹,外观质量差。这主要是因为随着温度的升高,金属液的表面张力会增大,与辊轮的润湿性增强,在甩带的过程中金属液不能及时脱离辊面。

都不变。从式(2)可以看出:甩带过程中,浇注温度越高,带材的厚度越小。从表1还可知:当浇注温度为650 ℃时,带材的表面会出现马蹄形裂纹,外观质量差。这主要是因为随着温度的升高,金属液的表面张力会增大,与辊轮的润湿性增强,在甩带的过程中金属液不能及时脱离辊面。

2.2 快速凝固的组织和熔融特性

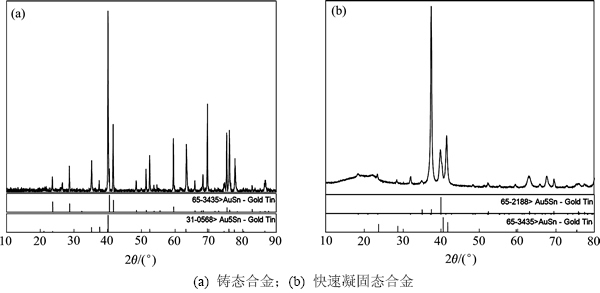

图2所示为不同制备方法Au-20%Sn合金的XRD衍射图谱。从图2(a)可见:铸态合金的XRD衍射图谱的特征峰明显,与标准PDF卡片的匹配度高。而从图2(b)可见:快速凝固态Au-20%Sn合金的衍射峰明显宽化,部分峰不明显,最高峰的位置有所偏差。但物相检索表明铸态和凝固态合金均是由ζ′(Au5Sn)和δ(AuSn)两相组成。Jean等[13]发现Au-20%Sn合金在急冷作用下可形成亚稳态的γ相,但需要的过冷度较大,一般是将熔体液滴在-190 ℃的基板上急冷才能得到亚稳态的γ相。在双辊甩带实验中,AuSn合金没有达到这样的急冷条件,并不会有亚稳态的γ相生成,相组成仍为ζ′(Au5Sn)和δ(AuSn)。

双辊甩带后的合金具有快速凝固的特点,合金的组织与铸态合金有显著差异。图3所示为不同制备方法Au-20%Sn合金的显微组织图。图3(a)中,浅灰色的区域为ζ′(Au5Sn)相,深灰色区域为δ(AuSn)相。从图3(a)可知:可以观察到典型两相交替排列的共晶组织。从图3(b)可知:与铸态组织相比,快速凝态合金后并不能观察到明显的共晶组织,在SEM下放大2万倍仍不能看到两相衬度。根据结晶理论,随着过冷度的增大,晶粒形核速率的增长大于生长速度的增长,单位体积的晶粒数增加,晶粒的尺寸减小。双辊甩带法可以使金属熔体达到较大的过冷度,因此快速凝固AnSn合金的晶粒非常细小,在高倍放大倍数下也观察不到两相衬度。

图2 不同制备方法Au-20%Sn合金的XRD衍射图谱

Fig. 2 XRD spectra of Au-20%Sn by different preparation methods

图3 不同制备方法Au-20%Sn合金的显微组织图

Fig. 3 Microstructure of Au-20%Sn by different preparation methods

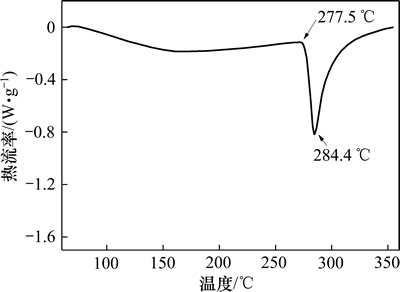

双辊甩带法制备Au-20%Sn合金的DSC曲线如图4所示。从图4可见:只在284.8 ℃时有1个明显的吸热峰,与Au-20%Sn共晶合金的熔化温度280 ℃时的吸热峰相差不大,满足焊料的熔点要求。甩带后合金仍由ζ′(Au5Sn)和δ(AuSn)两相组成,晶粒粒度小。而合金在190 ℃的共析转变并不明显,因为快速冷却作用会使合金中产生“溶质截留”现象,即凝固相中会固溶大量溶质原子,相的成分与平衡态有一定的偏差[14],过饱和的相在加热过程中会析出,从而造成共析转变吸热峰不明显。

图4 双辊甩带Au-20%Sn合金的DSC曲线

Fig. 4 DSC curve of Au-20%Sn by twin-roll method

2.3 均匀化退火工艺

双辊甩带后的合金具有快速凝固的特点,金属具有硬脆性,硬度大的材料微裂纹不容易钝化,微裂纹很容易扩展而导致脆断,不利于后续的加工,因此,快速凝固后的合金都需要通过退火处理以降低其硬度,增大材料韧性,改善其加工性能。美国专利[15]表明金锡合金焊片在200~270 ℃下退火一定时间后,硬度降低,韧性有所提高。

本实验将双辊甩带后的Au-20%Sn合金在不同温度下退火的显微组织如图5所示。图5中深色相为δ(AuSn)相,白色相为ζ′(Au5Sn)相。从图5可见:在220 ℃下退火,随着退火时间的延长,δ相逐渐长大。退火1 h后,合金出现典型的共晶组织,细小的δ相均匀分布在ζ′相之间;退火时间达到64 h时,δ相晶粒明显长大并呈现无规则多边形,但仍以岛屿状均匀分布在ζ′相之间。图5(e)和图5(f)所示分别为在240 ℃下退火16 h和260 ℃下退火4 h后的显微组织,发现不同尺寸的AuSn相分布在ζ′相之间,与在220 ℃下退火64 h的组织相似。

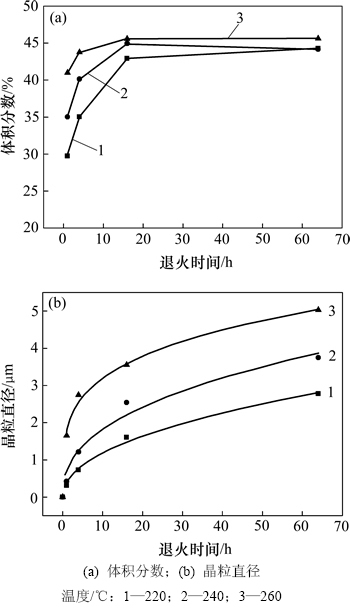

采用定量金相方法分析不同退火温度下AuSn相的体积分数和平均颗粒直径随保温时间延长的变化。不同退火温度下AuSn相的体积分数随保温时间的变化曲线如图6(a)所示。从图6(a)可知:在同一温度下退火时,保温1~4 h,AuSn相的体积分数迅速增大;当保温时间延长至4~16 h时,AuSn相的体积分数增长缓慢;当退火时间达到16 h时,AuSn相的体积分数已经接近稳定值(43%~45%),再增加退火时间体积分数变化不大。因此,退火时间应小于16 h。当退火时间相同时,温度越高,AuSn相的体积分数越大。从金锡平衡相图[16]可知,共晶成分中Sn的原子分数为29%,根据杠杆原理可知平衡时AuSn相的体积分数约为44.5%。双辊甩带An-20%Sn合金快速凝固形成过饱和固溶体,在均匀化退火过程中,组织向平衡态转化。随着时间的延长,AuSn相体积分数不断增大,最终达到稳定值。过饱和固溶体的析出受扩散速率的影响,温度越高,扩散速率越快,组织均匀化越快。在260 ℃下退火,保温1 h时AuSn相体积分数已达到41.0%,而在220 ℃时,退火16 h后AuSn相的体积分数才达到42.9%。可见,退火温度对AuSn相析出的影响更为显著。

不同退火温度下AuSn相的尺寸随保温时间的变化曲线如图6(b)所示。从图6(b)可知:AuSn相的尺寸随着保温时间的延长而增大,温度越高,AuSn相的尺寸越大。由于快速凝固组织中的AuSn相非常细小,可以假设其初始粒径为0 μm。球状析出粒子在扩散控制长大时的半径r可描述为

其中:K为粒子粗化速率;n为时间指数。按照式(3),粒子会无限制长大,但是实际上粒子必须吸取周围的溶质原子才能长大,所以,在每个粒子周围都会形成一个溶质浓度下降的区域,当这些区域相互重叠时,粒子的生长会受到限制。

将220,240和260 ℃下AuSn相粒子平均晶粒直径随保温时间的变化曲线按照式(3)拟合。在不同温度下退火时,AuSn相晶粒尺寸随着退火时间的延长逐渐增大,与图3中显微组织的观察结果一致。退火温度越高,粒子的粗化速率越大。这是因为析出相的长大过程受热激活控制。粗化速率可描述为

图5 Au-20%Sn合金在分别在不同温度下退火后的显微组织

Fig. 5 Microstructure of Au-20%Sn alloy after annealing at different temperatures

其中 :Q为AnSn相的长大激活能;K0为生长比例系数;R为气体常数;T为热力学温度。AuSn相的长大主要依靠原子的扩散进行,温度越高,原子的扩散越快。在220 ℃退火16 h时,AuSn相的平均粒径为1.60 μm;而在260 ℃下退火1 h,平均粒径就达到1.63 μm。因此,在260 ℃进行退火处理可以提高热处理效率。

朱志君[6]研究表明,压铸水淬的Au-20%Sn在 260 ℃保温1 h后,维氏硬度能从180降低到125,而在240 ℃下保温,退火3 h后硬度仍有141。图7所示为Au-20%Sn合金的硬度随退火时间和退火温度变化的曲线。从图7可知:在同一温度下退火,合金的硬度随着退火时间的延长而下降,且1~4 h内硬度的下降速率较快,在16~64 h下降缓慢。而退火时间相同时,温度的升高可以显著降低合金的硬度。在220 ℃下退火16 h,合金的维氏硬度达到150,而在260 ℃下退火1 h合金的维氏硬度就能达到150,保温4 h时维氏硬度为133。因此,提高退火温度可以有效地提高热处理的效率。

图6 不同温度下AuSn相的体积分数和晶粒直径随时间的变化曲线

Fig. 6 Volume fraction and particle size of AnSn phase with time at different temperatures

图7 不同温度下Au-20%Sn合金硬度随时间变化曲线

Fig. 7 Hardness of Au-20%Sn alloy with time at different temperatures

随着退火时间的延长,双辊甩带Au-20%Sn合金的组织逐渐均匀化,AuSn相尺寸快速增大,随后由于固溶原子减少,AuSn相粒子的长大速率减小。在260 ℃下保温4 h,组织基本均匀化,合金的维氏硬度降到133,利于冲压成型。因此,双辊甩带Au-20%Sn合金的退火工艺为260 ℃退火4 h。

3 结论

1) 双辊甩带Au-20%Sn合金显微组织由ζ′(Au5Sn)和δ(AuSn)两相组成,与铸态组织相比,凝固态合金组织更加细小。合金的DSC曲线只有1个熔化吸热峰,熔化温度为284.8 ℃,满足An-20%Sn焊料的熔点要求。

2) 双辊甩带Au-20%Sn合金均匀化退火时,δ(AuSn)相析出并长大。δ(AuSn)相的体积分数随着保温时间延长或退火温度升高而增大最终达到稳定值(43%~45%),接近平衡态的体积分数。δ相的粒径也随着时间的延长或温度升高而增大,并且退火温度的影响更加显著。

3) Au-20%Sn合金在260 ℃退火4 h后,合金基本均匀化,合金的维氏硬度由最初的190降到了129,改善了合金的韧性,有利于后续冲压加工。因此,双辊甩带Au-20%Sn合金的退火工艺为260 ℃下退火4 h。

参考文献:

[1] WANG Yikai, LIU Wensheng, MA Yunzhu, et al. Indentation size effect and micromechanics characterization of intermetallic compounds in the Au-Sn system[J]. Materials Science & Engineering A, 2014, 610(29):161-170.

[2] WEI Xiaofeng, ZHANG Yukun, WANG Richu, et al. Microstructural evolution and shear strength of AuSn20/Ni single lap solder joints[J]. Microelectronics Reliability, 2013, 5(5):748-754.

[3] Rodriguez R I, Ibitayo D, Quintero P O. Thermal stability characterization of the Au-Sn bonding for high-temperature applications[J]. IEEE Trans on Components, Packaging and Manufacturing Technology, 2013, 3(4): 549-556.

[4] 刘泽光, 罗锡明, 陈登权, 等. 金锡共晶合金箔带材制造方法: 中国, 03105811. 6[P], 2003-07-25.

LIU Zeguang, LUO Ximing, CHEN Dengquan, et al. Manufacturingmethod of eutectic Au-Sn strips: China, 03105811. 6[P], 2003-07-25.

[5] 韦小凤, 王日初, 彭超群, 等. AuSn20/Ni 焊点的界面反应及剪切强度[J]. 中国有色金属学报, 2013, 23(7): 1907-1913.

WEI Xiaofeng, WANG Richu, PENG Chaoqun, et al. Interfacial reaction and shear strength of AuSn20/Ni solder joints[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1907-1913.

[6] 朱志君. 金锡预成型焊片制备工艺与应用研究[D]. 武汉: 华中科技大学材料科学与工程学院, 2009: 29-54.

ZHU Zhijun. Research on manufacture and applications of AuSn20 solder perform[D]. Wuhan: Huazhong University of Science and Technology. School of Materials Science and Engineering, 2009: 29-54.

[7] Haga T, Sakaguchi H, Watari H, et al. High-speed twin-roll casting of Al-Mg-Si alloys[J]. International Journal of Microstructure and Materials Properties, 2007, 2(2): 178-187.

[8] Oh Y S, Lee H, Lee J G, et al. Twin-roll strip casting of iron-base amorphous alloys[J]. Materials Transactions, 2007, 48(7): 1584-1588.

[9] 崔大田. 中温共晶焊料薄带制备及其相关基础研究[D]. 长沙: 中南大学材料科学与工程学院, 2008: 65-85.

CUI Datian. Preparation and related fundamental research on mid-temperature eutectic solder ribbon[D]. Changsha: Central South University. School of Materials Science and Engineering, 2009: 65-85.

[10] 陈明安, 卓利, 张新明. Al-12.6%Si薄带双辊快速凝固成形试验研究[J]. 材料工程, 1999, 4(4): 1-7.

CHEN Mingan, ZHUO Li, ZHANG Xinming. Preparation of rapidly solidified Al-12.6%Si alloy strips by double-roller method[J]. Journal of Materials Engineering, 1999, 4(4): 1-7.

[11] 崔大田, 王志法. 快速凝固新型Au-Ag-Ge合金薄带的制备[J]. 材料热处理学报, 2010, 31(1): 40-42.

CUI Datian, WANG Zhifa. Preparation of rapidly solidified new-type Au-Ag-Ge alloy ribbon[J]. Transactions of Materials and Heat Treatment, 2013, 31(1): 40-42.

[12] 沈宁福, 汤亚力, 关绍康. 凝固理论进展与快速凝固[J]. 金属学报, 1996, 32(7): 673-684.

SHEN Ningfu, TANG Yali, GUAN Shaokang. Solidification theory and rapid solidification[J]. Acta Metallurgica Sinica, 1996, 32(7): 673-684.

[13] Jena A K,Giessen B C,Bever M B. On the metastability of an Au-Sn phase prepared by splat cooling[J]. Metallurgical Transactions, 1973, 4(1): 279-281.

[14] 赵素, 李金富, 刘礼, 等. 溶质截留对过冷共晶生长过程的影响[J]. 金属学报, 2008, 44(11): 1335-1339

ZHAO Su, LI Jinfu, LIU Li, et al. Effect of solute trapping on the growth process in undercooled eutectic melts[J]. Acta Metallurgica Sinica, 2008, 44(11): 1335-1339.

[15] Miyazaki K, Hiratsuka. Foil-form soldering metal and method for processing the same: USA, 7048813 B2[P]. 2006-05-23.

[16] Ciulik J, Notis M R. The Au-Sn phase diagram[J]. Journal of Alloys and Compounds, 1993, 191(1): 71-78.

(编辑 罗金花)

收稿日期:2014-12-04;修回日期:2015-03-10

基金项目(Foundation item):国家军品配套项目(JPPT-125-GH-039) (Project(JPPT-125-GH-039) supported by the National Military Facilities)

通信作者:王日初,教授,博士生导师,从事电子封装材料研究;E-mail: wrc910103@163.com