铝合金热挤压过程中界面摩擦的研究进展

来源期刊:中国有色金属学报2017年第7期

论文作者:刘志文 李落星 张明 李世康

文章页码:1311 - 1323

关键词:铝合金;热挤压;界面摩擦;摩擦学行为;摩擦模型;表征方法

Key words:aluminium alloy; hot extrusion; interface friction; tribological behavior; friction model; equivalent characterization

摘 要:在铝合金热挤压过程中,工件与模具界面的摩擦对模具磨损、挤压载荷、产品表面质量等具有重要的影响。摩擦也是挤压数值仿真中一个重要的边界条件,影响因素多,难以定量确定。为得到精确的仿真结果,需采用合理的摩擦模型。揭示铝合金热挤压过程中不同接触界面的摩擦学行为。分析工作带位置的摩擦磨损对型材表面质量的影响机理。综述模具材料的表面强化技术,并对各工艺作出评价。归纳总结铝合金热挤压过程中采用的摩擦理论模型及等效表征方法。最后指出热挤压过程中界面摩擦研究存在的主要问题。

Abstract: In the hot extrusion of aluminium alloys, friction at the workpiece/tools interface has great influence on the die wear, profile surface quality and extrusion load. The friction coefficient is also an important thermal boundary condition in the FE simulation of aluminium extrusion, which is affected by many factors and hard to be quantified. To obtain accurate simulation results, reasonable friction models and friction coefficient should be adopted. The tribological behaviors of contact interfaces in the hot extrusion of aluminum alloy were revealed. The effect of friction and wear on the surface quality of the profile in the bearing was analyzed. The research status and development of surface treatment techniques were comprehensively reviewed and evaluated. The friction models and equivalent characterizations being used for the FE simulation of aluminium extrusion at different contact interfaces were summarized. The main problems of friction in the hot extrusion of aluminium alloys were put forward.

DOI:10.19476/j.ysxb.1004.0609.2017.07.01

刘志文1, 2,李落星1, 2,张 明1, 2,李世康1, 2

(1. 湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082;

2. 湖南大学 机械与运载工程学院,长沙 410082)

摘 要:在铝合金热挤压过程中,工件与模具界面的摩擦对模具磨损、挤压载荷、产品表面质量等具有重要的影响。摩擦也是挤压数值仿真中一个重要的边界条件,影响因素多,难以定量确定。为得到精确的仿真结果,需采用合理的摩擦模型。揭示铝合金热挤压过程中不同接触界面的摩擦学行为。分析工作带位置的摩擦磨损对型材表面质量的影响机理。综述模具材料的表面强化技术,并对各工艺作出评价。归纳总结铝合金热挤压过程中采用的摩擦理论模型及等效表征方法。最后指出热挤压过程中界面摩擦研究存在的主要问题。

关键字:铝合金;热挤压;界面摩擦;摩擦学行为;摩擦模型;表征方法

文章编号:1004-0609(2017)-07-1311-12 中图分类号:TH117.1 文献标志码:A

铝型材由于具有比强度、比刚度高,吸能性能好,回收容易等一系列优点,是汽车轻量化理想的构件[1]。挤压作为一种高效率、低能耗的少无切屑加工工艺,是铝型材加工的主要方法[2]。摩擦是一种复杂的力学现象,而热挤压过程中工件和模具之间涉及复杂的形变、热力学及化学反应,使摩擦问题更为复杂[3]。在铝合金热挤压过程中,工模具主要包括挤压垫、挤压筒和挤压模具,工件与工模具不同接触部位由于产生的变形温升、接触压力和界面滑移速度等具有显著差异,使接触界面的摩擦学行为显而不同。特别是模具工作带位置在高温高压条件下,产生严重的粘着或滑移摩擦,使表面材料易发生磨损失效,严重影响模具的使用寿命、挤压出口的材料流动行为、产品的表面质量和报废率等[4]。因此,理解挤压过程不同接触界面的摩擦学行为特征对于模具材料的表面强化、提高型材的表面质量以及根据接触界面的摩擦学特征为挤压数值仿真选择合适的摩擦模型和摩擦因数具有重要意义。

数值仿真是铝合金热挤压工艺优化与成本控制的重要手段[5]。摩擦是影响仿真精度一个重要的边界条件,难以测量和确定。目前,在挤压数值仿真中,摩擦模型一般采用库伦或剪切摩擦模型[6-8],摩擦因数也通过查表或经验获取,仿真模拟精度较低。因此,为得到精确的仿真结果,仿真中采用的摩擦边界条件应能尽可能的接近实际情况,建立的摩擦模型需能反映工件/模具界面的摩擦学物理本质。影响挤压过程的工艺参数和边界条件多且相互耦合,直接采用挤压试验方法来确定摩擦因数具有较大的局限性。如何选择和设定合适的等效摩擦试验方法来表征不同接触界面的摩擦因数至关重要。

本文作者首先揭示了铝合金热挤压过程不同接触界面的摩擦学行为。分析了工作带位置摩擦磨损对型材表面质量的影响机理。综述了模具材料的表面强化技术,并进行了评述。归纳总结了铝合金热挤压过程中采用的摩擦模型及等效表征方法。最后指出了热挤压过程中界面摩擦研究存在的主要问题。

1 热挤压过程中界面的摩擦、磨损 行为

1.1 不同接触界面的摩擦学行为

在铝合金热挤压过程中,工模具界面的工作条件十分恶劣,在高温、高压、反复循环应力等作用下产生高摩擦和热磨损(熔损)行为。对于空心和半空心型材热挤压模具,摩擦磨损是工作带位置最常发生的失效方式,严重影响了工模具的使用寿命和挤压产品的最终形状和表面质量。在铝合金挤压过程中,挤压材料与工模具的接触界面包含铝锭与挤压垫、铝锭与挤压筒和挤压模具以及挤出型材与模具工作带等3个接触界面。

1.1.1 铝锭与挤压垫接触界面

在挤压杆的作用下,铝锭与挤压垫接触界面产生非常大的静水压力。在连续挤压生产过程中,在大的压应力下挤压垫前端面与铝合金产生完全粘着,挤压终了时,导致挤压垫与残铝分离困难。实际挤压生产中挤压垫通常需要加石墨或玻璃润滑剂进行润滑[9]。在开始挤压阶段,由于挤压筒与铝锭间存在间隙,根据最小阻力定律,金属在挤压力作用下,首先向此间隙流动填充挤压筒,导致铝锭与挤压垫接触界面产生滑动摩擦。随着挤压过程的进行,到了紊流挤压阶段,在挤压筒界面摩擦的影响下,铝锭中心部位金属流动速度远大于外层金属,进一步增大铝锭与挤压垫接触界面的滑动摩擦力。

1.1.2 铝锭与挤压筒、模具接触界面

在铝挤压过程中,热铝与工模具接触界面的静水压力从挤压筒沿挤压模具出口方向逐渐减少。挤压筒、挤压模具与铝合金界面之间的接触压力达上百至数百兆帕[10],在高温高压下由于化学扩散、压力粘结发生严重的铝粘模现象,摩擦类型为完全粘着摩擦。铝锭与挤压筒由于发生粘结而不能正常流动,从而在铝锭的次表层发生剪切变形。接触面上铝与挤压筒之间的摩擦逐渐转变为锭坯表面层金属的内摩擦,使得接触面上摩擦的性质和行为发生变化。同时接触面由微观结构上的不相称(晶体尺度和取向不同,铝与铁性质不同)自发地趋于相称,从而导致更大的摩擦[11]。SCHIKORRA等[12]通过追踪金属材料流动来研究热铝挤压过程中铝锭与挤压筒内壁的摩擦问题。在6060铝锭中嵌入19根带有标记的4043铝合金棒材进行挤压试验,通过观察不同挤压行程下带有标记的4043铝合金棒材在铝锭中的流动状态就可研究挤压筒内壁界面的摩擦行为。结果发现在挤压温度达到430 ℃时,铝锭与挤压筒内壁的接触表面几乎产生完全粘着摩擦,导致铝粘模发生。

1.1.3 挤出型材与工作带接触界面

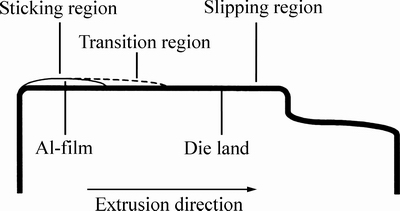

靠近挤压出口的模具工作带位置,由于接触压力从入口的较高值逐渐减少到0,接触界面的摩擦磨损行为完全发生改变。WELO等[13]等认为模具工作带位置的摩擦类型分为3种:粘着区域、过渡区域和滑移区域(见图1)。靠近工作带入口,在高温和高压下,模具表面粘附一层铝合金,发生严重的化学扩散和粘着摩擦。而靠近工作带出口压力下降为0,为滑移区域。在粘着和滑移区域之间,形成一个过渡区域。这是因为在连续挤压加工中,由于需要更换铸锭,金属在模具停留过程中与模具表面发生严重的化学粘结。模具工作带入口位置,在高的接触压力下界面粘结强度增加,使金属与模具表面的流动的滑移受阻,导致粘着区域的产生。ABTAHI[14]发现挤压模具磨损一般发生在工作带位置的过渡区域。在粘着区域和滑移区域,接触界面形成的混合层和氧化物起扩散障碍作用,会阻碍模具表面的化学磨损。而过渡区域的化学磨损速率条件是最优的,金属流动速度足够低且没有扩散障碍。化学反应主要引起两种磨损机制,一是模具表面材料的连续溶解;二是模具表面材料的间断剥落。在连续挤压过程中,表面材料的剥落会加剧。模具工作带位置3个区域的长度,取决于工作带表面和工件之间的摩擦,材料的流动,表面压力的分布、及型材出口的牵引力大小及模具表面混合层等,要精确确定目前尚未有明确的方法。

图1 挤压模具工作带位置摩擦从粘着摩擦转变至滑移摩擦[13]

Fig. 1 Friction transition from sticking to slipping in die bearing[13]

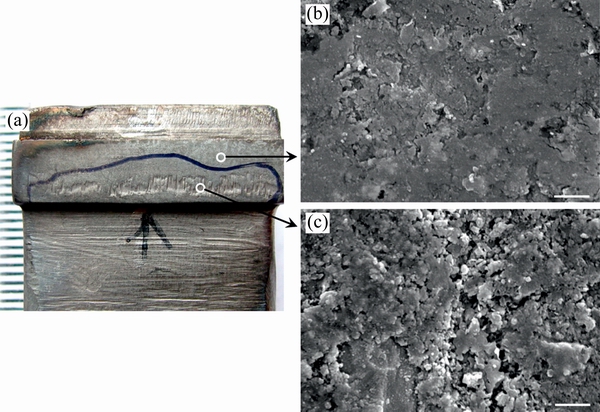

BIROL[15]研究了气体氮化H13钢挤压模工作带位置的磨损失效机制。靠近模具工作带入口3 mm处的表面混合层发生严重的摩擦磨损,大部分剥落,最大磨损深度达到50 μm,而其他部分没有发生磨损(见图2)。热挤压过程中靠近工作带入口位置受高温、高压和高剪应力作用形成大量表面裂纹。当裂纹达到一定尺寸时,剪应力会超过模具钢的开裂强度,出现磨损碎片。多元渗氮导致次表面扩散层的脆化和网状氮化物沿晶界的分布进一步加剧裂纹的形成。磨损坑中游离铝的诱导促进表面层的剥落。剥落形成的硬的氮化物沿挤压方向起犁沟作用导致工作带表面的磨损。GUTOVSKAYA等[16]研究了Inconel718模具钢工作带位置在挤压过程中的磨损行为。实验结果证明离模具工作带入口8~10 mm位置出现严重磨损,而模芯和靠近出口位置基本没有发生磨损。同时对比发现Inconel718模具钢的挤压使用寿命相比H13钢的更好,达到40次以上,而H13钢热挤压30次左右模具工作带位置出现严重磨损。Inconel718模具钢磨损机制与H13钢相似,主要为粘着磨损和磨粒磨损。强烈的铝粘模化学现象导致Ni-Al-Si-Mo-Ti-Cr-Fe-Zn-O金属间混合物的形成。在工作带位置高拉应力的作用下该混合物会发生剥落。同时剥落的混合物和界面形成的铝合金氧化层共同起磨粒作用使模具钢表面层出现剥落。 等[17]调查了气体渗氮和CVD沉积TiC+TiN涂层两种挤压模具的磨损失效行为。挤压模具表面首先发生化学磨损,然后出现剥层和蚀损。渗氮处理的模具离工作带入口0.5~2 mm的过渡处基体被化学磨损成20~100 μm的火山坑,而CVD沉积TiC+TiN涂层的模具在工作带入口附近处发生磨粒磨损。

等[17]调查了气体渗氮和CVD沉积TiC+TiN涂层两种挤压模具的磨损失效行为。挤压模具表面首先发生化学磨损,然后出现剥层和蚀损。渗氮处理的模具离工作带入口0.5~2 mm的过渡处基体被化学磨损成20~100 μm的火山坑,而CVD沉积TiC+TiN涂层的模具在工作带入口附近处发生磨粒磨损。

图2 热挤压模具工作带位置的磨损示意图[15]

Fig. 2 Stereo microscope macrograph of sketch of wear in die bearing surface (a), SEM micrographs of die bearing surface near outlet (b) and inside heavy wear band, i.e. near inlet (c)[15]

1.2 工作带界面的摩擦磨损对挤出型材表面质量的影响

模具工作带的几何形态和表面质量直接影响挤出型材的表面质量。型材表面挤压条纹的产生或挤压碎屑,与模具工作带附近的金属流动行为、工作带表面的磨损状况密切相关。模具工作带位置不同部位的损伤或磨损,对型材表面质量的影响机理作用不同[18-19]。模孔入口附近的工作带损伤对型材表面的影响相对很小,轻微损伤、磨损虽然会使铝合金表面暂时出现划痕,但由于金属流过模具入口尚未最终成形,在高温下通过后部光滑平整的工作带时,表面缺陷问题可以得到修复。因此,只要工作带长度适当,一般不会在型材表面留下明显痕迹;而靠近模孔出口的工作带损伤对型材表面的影响较大,即使该部位工作带没有损伤,由于模具维护或其他原因导致工作带靠近出口部位出现大的负角或圆弧状时,也会导致型材表面产生明显的模纹。一方面,型材通过该位置逐渐与工作带表面分离,有效工作带长度大为缩短,不能保证最小必要的工作带长度,导致模纹缺陷;另一方面,大的负角或圆弧状容易产生粘铝现象。凹凸不平的粘铝层与型材表面发生摩擦或滑出工作带,形成粗糙的表面模纹和挤压磨屑。

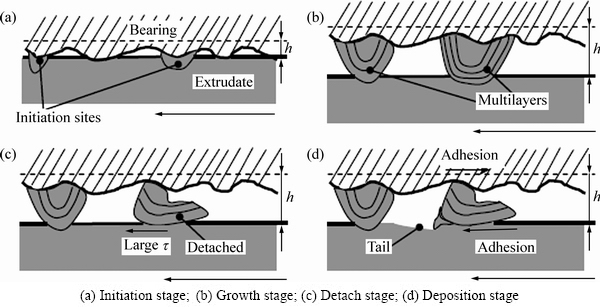

MA[20]从机理上揭示了挤压型材表面质量主要跟磨屑有关。磨屑的形成有4个阶段(见图3):1) 初始阶段:在模具工作带滑移区域表面上的粗糙凸峰位置,在高温条件下,钢铝在粘着摩擦磨损条件下发生材料转移,形成磨屑生长点;2) 生长阶段:随着挤压过程的继续,材料不断转移,初始生长点开始长大,同时粘结点的表面氧化很快,形成一个多层混合结构。为了维持工作带表面压力不变,型材与工作带接触间隙深度h增加,几乎达到粘结点的高度(约30 μm);3) 分离阶段:胶粘点不断长大,达到一个很大的高宽比。在剪切摩擦的作用下,粘结点与挤压型材发生分离,与模具工作带仍然保持粘着;4) 沉积阶段:由于工作带位置的阻力阻碍粘结点移出工作带,粘结点在工作带处沉积,并磨损挤压金属,在型材表面上留下划痕,使型材表面粗糙度增加。同时某些粘着点可能滚动移出工作带,残留在挤压型材表面,形成挤压磨屑。

图3 挤出型材表面缺陷形成机制[20]

Fig. 3 Formation mechanism for surface defects (Arrows at bottom right corner indicate extrusion direction)[20]

2 模具表面材料的强化技术

为了提高挤压模具工作带的寿命和挤出型材的表面质量,需采用适当的热处理和表面强化技术,使工作带表面具有高硬度、耐磨和耐疲劳等性能。热处理工艺主要用于提高模具基体的强度和韧性,而表面强化主要用于弥补模具基体材料的性能缺陷,改善模具表面的耐磨损和耐腐蚀性能,强化效果和成本更低。从处理方式上表面强化技术可分为化学处理、离子注入、沉积涂层、激光表面改性等。其中化学处理又包括渗氮、渗碳、碳氮共渗、多元共渗等。

林高用等[21]在500 ℃左右排气2 h后,温度为550~570 ℃时进行气体渗氮 12~14 h,得到H13挤压模具钢表面渗氮层深度达0.24 mm,其中白亮层约10 μm,表面硬度达950 HV。同时发现预喷丸处理对气体渗氮有明显的催渗作用。渗氮温度升高,催渗效果显著提高。预喷丸催渗条件下形成的渗氮层硬度高于普通气体渗氮。余春燕等[22]在520 ℃左右对H13挤压模具钢进行1.5 h的离子渗氮,获得最佳的渗氮层组成,化合物层厚度可达6 μm,渗氮层厚度0.3 μm左右,渗氮层的硬度高达1100 HV,耐磨性能最佳。 等[23]利用块盘试验研究了对模具表面进行等离子体渗氮和气体渗氮两种渗氮方法的耐磨性能。结果表明铁氮化合物层比模具材料的化学稳定性更强,磨损首先从化合物层开裂,使其从表面剥落。化合层越厚表示氮化程度越低,更容易从表面剥落,反之亦然。剥落区域的凹坑加速了热铝的化学腐蚀磨损。

等[23]利用块盘试验研究了对模具表面进行等离子体渗氮和气体渗氮两种渗氮方法的耐磨性能。结果表明铁氮化合物层比模具材料的化学稳定性更强,磨损首先从化合物层开裂,使其从表面剥落。化合层越厚表示氮化程度越低,更容易从表面剥落,反之亦然。剥落区域的凹坑加速了热铝的化学腐蚀磨损。 等[24]采用气体渗氮和复合涂层两种技术对H13挤压模进行表面渗氮。其中复合涂层技术H13钢先离子氮化处理再进行PVD沉积CrN涂层。结果表明模具钢采用复合涂层后使用寿命是气体渗氮的5倍以上。大量细小的CrN晶粒提高了模具钢的耐磨和耐腐蚀性。龚刚等[25]对H13挤压模具钢在540~560 ℃离子渗氮8 h后再在550 ℃下低温盐浴复合渗铬6 h,复合渗铬层主要是由CrN、Cr2N 组成,CrN化合物层平均深度为5 μm,硬度可达1450~1550 HV,耐腐蚀性也比离子渗氮好。张春华等[26]采用高能束激光熔凝处理,在H13模具钢表面获得激光熔凝层,在不改变模具钢表面成分的条件下,实现钢基表面的“自强化”,使模具的耐腐蚀性提高,自腐蚀电位正移,维钝电流明显减小。同时还在H13钢表面制备Si3N4改性NiFeBSi 合金熔覆层,熔覆层与基体H13钢呈良好的冶金结合,组织细密、无孔隙。陈慧敏等[27]采用真空粉末烧结法在H13模具钢表面获得了深度为1~3 mm的三元硼化物(Mo2FeB2)基金属陶瓷覆层,覆层和钢基体通过 Fe、B、Cr、Ni等相互扩散渗透牢固结合,硬度达到1200 HV,使钢表面耐磨性能大幅度提高。

等[24]采用气体渗氮和复合涂层两种技术对H13挤压模进行表面渗氮。其中复合涂层技术H13钢先离子氮化处理再进行PVD沉积CrN涂层。结果表明模具钢采用复合涂层后使用寿命是气体渗氮的5倍以上。大量细小的CrN晶粒提高了模具钢的耐磨和耐腐蚀性。龚刚等[25]对H13挤压模具钢在540~560 ℃离子渗氮8 h后再在550 ℃下低温盐浴复合渗铬6 h,复合渗铬层主要是由CrN、Cr2N 组成,CrN化合物层平均深度为5 μm,硬度可达1450~1550 HV,耐腐蚀性也比离子渗氮好。张春华等[26]采用高能束激光熔凝处理,在H13模具钢表面获得激光熔凝层,在不改变模具钢表面成分的条件下,实现钢基表面的“自强化”,使模具的耐腐蚀性提高,自腐蚀电位正移,维钝电流明显减小。同时还在H13钢表面制备Si3N4改性NiFeBSi 合金熔覆层,熔覆层与基体H13钢呈良好的冶金结合,组织细密、无孔隙。陈慧敏等[27]采用真空粉末烧结法在H13模具钢表面获得了深度为1~3 mm的三元硼化物(Mo2FeB2)基金属陶瓷覆层,覆层和钢基体通过 Fe、B、Cr、Ni等相互扩散渗透牢固结合,硬度达到1200 HV,使钢表面耐磨性能大幅度提高。

表面化学热处理工艺中,普通渗氮应用最为广泛,成本低,可靠性高;与普通渗氮相比,多元共渗和复合处理的效果最好,渗层比较深;离子注入可提高表面硬度又不会降低结合力,可注入多种元素,使模具钢的耐磨性、抗腐蚀性大幅度提高;激光表面改性技术快速,变形极小,且显著细化晶粒,但该工艺影响因素较多,生产设备昂贵,成本高;另外,粉末烧结、涂层等技术也可应用于模具钢的表面强化,但工业应用较少。

3 热挤压过程中界面摩擦边界条件的定量表征

数值仿真已成为挤压工艺优化的重要手段。而摩擦是影响挤压数值仿真精准度一个重要的边界条件。国内外学者对摩擦的另一个研究热点主要集中于如何表征挤压接触界面的摩擦边界条件。在实际挤压过程中,摩擦是与材料热变形条件密切相关的一个变量,接触界面存在相对滑移,且在高温、高压和高应变速率下还伴随严重的表面扩张和温升效应。因此,为得到更精确的仿真结果,选择合理的摩擦模型和摩擦测试方法来等效表征挤压过程不同接触界面的摩擦边界条件和行为是十分重要的。

3.1 摩擦模型

在铝合金热挤压过程中,存在3种不同的接触界面:铝锭与挤压垫、铝锭与挤压筒和挤压模具以及挤出型材与模具工作带。在整个挤压过程中,不同接触界面的摩擦学行为完全不同,需采用不同的摩擦模型。为了在仿真中准确地模拟铝合金热挤压过程中不同接触界面的摩擦学行为,许多学者为此提出了多种摩擦模型,主要可以概括为三类:经典理论摩擦模型、经验摩擦模型和基于物理本质的摩擦模型。

3.1.1 经典理论摩擦模型

经典摩擦模型包括库伦摩擦模型和剪切摩擦模型。在库伦定律中,摩擦力与正压力成正比,即

(1)

(1)

式中:f是摩擦力;μ是摩擦因数;N为正压力。库伦摩擦模型在在铝合金热挤压仿真中应用较少。HE等[28]对6063铝合金的挤压虚拟试模仿真分析中,挤压筒和模具界面μ取值为0.3,工作带界面μ取值为0.4;然而在热挤压过程中,工件/模具界面上的接触压力很大,由库伦模型计算所得的摩擦应力会比工件材料的剪切流动应力大。因此,库伦模型会高估摩擦应力,很少用于铝合金热挤压的有限元仿真摩擦边界条件。

为了避免高估摩擦应力,剪切摩擦模型被用于热挤压有限元仿真中。剪切摩擦模型假设摩擦应力与材料的剪切流动应力成正比,即

(2)

(2)

式中:k为变形材料的剪切强度;m是摩擦因数。不同接触界面的m取值范围为0到1之间。

目前,采用剪切摩擦模型在铝合金热挤压有限元仿真中使用最为广泛。然而,摩擦因数m通常采用定值,并通过查表或经验取值。国内外大量学者的研究普遍认为当挤压温度大于450 ℃时,挤压垫、挤压筒、模具界面为全粘着摩擦,在有限元仿真中摩擦因数m取值为0.9~1[29-34];工作带位置可以简化为剪切摩擦,但国内外学者在摩擦因数的取值尚未达成一致,大多选取摩擦因数为0.3~0.1之间的一定值,LI等[29]和YU等[30]在铝合金型材挤压模具结构优化和焊合性能等仿真分析时摩擦因数取值为0.3,侯文荣等[31]采用数值仿真在预测铝合金挤压过程横断面的温度分布时摩擦系因取值为0.4,而Den BAKKER等[32]、MAHMOODKHANI等[33]和DONATI等[34]在铝合金型材挤压的材料流动行为仿真分析和模具结构优化时摩擦因数取值为1。

3.1.2 经验摩擦模型

FLITTA等[35]定量研究了AA2024铝合金实心圆棒热挤压过程中铸锭温度与摩擦因数的关系。所建立的挤压有限元仿真模型中采用剪切摩擦模型。在挤压载荷的两个特定区域内,通过调整摩擦因数m使有限元仿真得到的挤压载荷与实际试验测量的挤压载荷一致。第一个区域是挤压载荷达到峰值时,用来表征挤压初始阶段的摩擦;第二个区域是挤压稳态阶段,挤压载荷缓慢下降,用来研究挤压温升对摩擦的影响。研究结果表明,在所有挤压温度中,假设摩擦因数m的取值不变是不正确的。当铸锭初始温度从300 ℃升高到450 ℃时,挤压力达到峰值时刻的界面摩擦因数从0.654增加到0.92,摩擦类型从滑移摩擦转变为粘着摩擦。摩擦因数和温度之间符合线性关系,即:

(3)

(3)

式中: 指平均摩擦因数;T指的是温度;A和B是常数,拟合值分别为0.1327和0.0018。

指平均摩擦因数;T指的是温度;A和B是常数,拟合值分别为0.1327和0.0018。

同时,FLITTA进一步提出了一个摩擦模型的推广形式,使之适合于所有的挤压工艺条件及挤压全过程。

(4)

(4)

式中: 是平均摩擦因数,它随挤压行程的变化而变化;Zd是Zener-Hollomon参数的平均值;α,n和A是与工件材料性能有关的常数;a和b是与摩擦模型有关的常数。在一个完整挤压过程中,铝锭与挤压筒界面的摩擦是不断变化的,摩擦因数主要取决于材料的流动应力,其中温度是最为重要的影响因素。FLITTA最后获得了挤压峰值时刻和稳态时刻a和b的取值分别为-0.6011,1.1261和-0.4973,1.1056。

是平均摩擦因数,它随挤压行程的变化而变化;Zd是Zener-Hollomon参数的平均值;α,n和A是与工件材料性能有关的常数;a和b是与摩擦模型有关的常数。在一个完整挤压过程中,铝锭与挤压筒界面的摩擦是不断变化的,摩擦因数主要取决于材料的流动应力,其中温度是最为重要的影响因素。FLITTA最后获得了挤压峰值时刻和稳态时刻a和b的取值分别为-0.6011,1.1261和-0.4973,1.1056。

在模具工作带位置的摩擦,从入口到出口可以简划分为粘着摩擦和剪切摩擦两种类型。SAHA[36]提出了一种简化的摩擦模型。该模型摩擦力为由粘着区域和滑移区域产生的摩擦力的总和。在粘着区域,假定为全粘摩擦;在滑移区域,假定摩擦力是摩擦因数为常数的剪切类型。

(5)

(5)

式中:Ff为模具工作带的总摩擦力;m1和m2是粘着和滑动区域的摩擦因数;A1和A2为分别为粘着和滑移区域内的真实接触面积;K是材料的剪切强度,与温度、应变速率等密切相关。对于完全粘着摩擦,m1和m2取值都为1。如果考虑滑移摩擦区域,摩擦因数m2通常取值小于0.7。该模型能灵活地表征模具工作带位置内不同区域的摩擦行为。同时由于摩擦因数被简化成两个常数,用于有限元仿真时计算时间大为减少。

ABTAHI等[37]提出了一种复杂的经验摩擦模型,认为工作带界面的剪切摩擦应力取决于挤压速度和工作带长度。在粘着区域,摩擦为粘着摩擦模型。随着离挤压工作带入口距离的增加,摩擦应力缓慢减少。而在滑移区域,摩擦应力随离工作带入口距离的增加迅速减少。

(6)

(6)

(7)

(7)

式中:τst是粘着区域的摩擦应力;τ0是模具入口处的摩擦应力;x为距离模具入口的距离;k是出口速度的函数;τsl是滑移区域的摩擦应力;α是模具入口处的倾斜角;v是模具工作带位置的工件速度;L是工作带长度;τe是模具出口处的摩擦应力;m和n为常数。该模型表明,滑移区域内的摩擦应力与模具的几何结构和滑移速度等有关。

3.1.3 物理摩擦模型

MA等[38-40]建立了未润滑条件下铝合金热挤压模具工作带界面的物理摩擦模型。该模型能够预测工作带位置粘着和滑移区域的长度及对应的摩擦因数。在低的接触压力下,摩擦力被认为是各粗糙峰产生犁沟力的总和,当总摩擦应力达到材料剪切强度的时候,发生完全粘着摩擦。由于局部摩擦力的计算是基于粗糙峰的犁沟效应,模具表面几何形态会严重影响摩擦。假定挤出材料为光滑的理想塑性表面,工作带为粗糙的刚性表面,由一系列粗糙峰按幂律母线组成:

(8)

(8)

(9)

(9)

式中:h和w是压入深度和母线宽度;S是形状系数;ω是一个粗糙的尖端曲率;χ和λ是表征凹凸形状的常数。采用Challen and Oxley摩擦模型计算接触界面上所有粗糙峰产生的接触正压力和摩擦力总和:

(10)

(10)

(11)

(11)

(12)

(12)

式中:δi是给定的高度h上,粗糙峰的有效压入深度;H是材料的硬度;fhk是单个粗糙峰与工件界面的摩擦因数,假定为常数。当工件/模具接触界面的摩擦应力达到铝合金的剪切强度时,为完全粘着摩擦。该模型适用于低接触压力条件下,而且可以预测粘着区域和滑移区域的工作带长度;然而在高接触压力条件下该模型会高估摩擦因数。因为在高接触压力下,单个粗糙峰聚集在一起形成一个大的接触集块,使接触点数量明显减少。

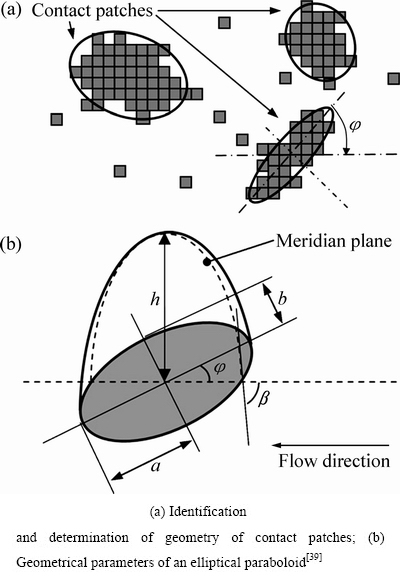

图4 接触集块模型定义[39]

Fig. 4 Definition of contact patched model

在高接触压力条件下,粗糙峰聚集形成接触集块,接触集块的数量远远少于粗糙峰点。MA等[38-40]定义接触集块为一群高度大于或等于分界面的粗糙峰点的集合,形状近似为椭圆抛物状,如图4所示。a,b,h和 β等为接触集块的参数。总摩擦力Ff是由每个接触集块产生的摩擦力的总和,Fn为所有接触集块承受的总正压力:

(13)

(13)

(14)

(14)

该物理模型能完全表征工作带位置摩擦的复杂特性,预测粘着与滑移区域的长度。然而该模型计算时间过长,而且粘着和滑移边界条件的分配在数值上不稳定,并不推荐其用于有限元仿真的摩擦边界条件。

综上可知,经典的库伦摩擦模型适合于接触压力小,少数凸峰发生接触的界面,而对于高静水压力的挤压变形接触界面不合适;经典剪切摩擦模型应用最为广泛,计算简便,但摩擦因数取定值。挤压垫、挤压筒和模具界面位置摩擦因数可以取值为0.9~1.0,而对于模具工作带界面的摩擦因数目前国内外学者尚未达到一致,且差异较大,取值范围为0.3~1.0;现有的经验摩擦模型具有一定的物理意义,但与材料、挤压工艺参数、滑移速度和模具入口结构等参数密切相关,要在数值仿真软件中普遍应用具有一定局限性,还需要积累和建立更多数据库;已有物理摩擦模型从模具工作带微观摩擦表面形态出发,建立了不同界面接触压力条件下的摩擦模型,虽能完全反映工作带界面摩擦的物理本质,但难以在实际应用中,需要解决模型计算时间长,数值计算求解不稳定,且在商业化仿真软件中对接触界面粗糙峰形状和压力很难达到精确模拟的问题。

3.2 摩擦等效表征方法

3.2.1 圆环压缩试验

圆环压缩试验是研究金属成形过程摩擦边界条件最为常用的方法[41],常被用于定量表征锻压成形中的摩擦因数及评价润滑对变形的影响。圆环压缩变形后,在任何摩擦条件下,试样外径总是增大的,而内径则随摩擦条件不同,可以增大、减小和不变。在低摩擦条件下,材料向外侧流动,圆环的内外侧半径都增大;在高摩擦条件下,靠近内侧的材料向内移动,外侧内侧向外移动,使内侧半径减小,外侧半径增大。通过测定试样内径与高度的变化可以定量确定模具与试样接触界面的摩擦因数。采用圆环压缩试验获取摩擦因数应用在热挤压仿真中未见相关报道。

3.2.2 挤压试验

挤压试验是研究摩擦对材料流动和挤压力影响最直接的方法。挤压过程的挤压力由克服金属内部变形阻力和各种界面的摩擦力组成。通过挤压力可以反求出各接触界面的摩擦。另一方面,工件与模具之间摩擦力的大小将严重影响挤压材料在工模具中的流动,摩擦力较小的区域材料流动速度明显要比摩擦力较大的区域大。

BAKHSHI-JOOYBARI等[42]从挤压力的角度研究摩擦问题。挤压过程的挤压力由3个部分组成:工件与挤压筒的摩擦力、工件与模具工作带的摩擦力以及工件材料发生塑性变形需要的力。工件与挤压筒界面之间的摩擦力与材料的剪切强度、挤压筒的内径及挤压筒内铝锭的长度等均有关系。因此,工件与挤压筒接触表面的总摩擦力可以通过改变锭子的原始长度来获取。FLITTA等[43]采用正向热挤压与有限元模拟相结合的方法来研究挤压筒界面的摩擦问题。通过调整与实验获得的挤压力相符合的有限元模拟边界条件来确定摩擦因数。BUSCHHAUSEN等[44]利用摩擦对材料流动的影响开展了反挤压试验。将下挤压杆和模具固定,上挤压杆以固定速度挤压铝锭。由于挤压杆、铝锭和模具之间的相对速度差异构成了不同的摩擦环境,两端挤出材料的长度会出现差异,尤其是在挤压比较小的情况下。通过有限元模拟建立校准曲线,摩擦则可以用挤出物的长度以及冲头的倾斜角进行定量表征。NAKAMURA等[45-46]利用与BUSCHHAUSEN相似的方法,提出了两种新的反向挤压试验方法:一种是反向挤压锥形模具;另一种是固定的下挤压杆设计成锥形或小的直径。这两种试验方法的挤出材料长度均对摩擦条件十分敏感,因此摩擦的状况可以从有限元模拟中获得的校准曲线中判断出来。

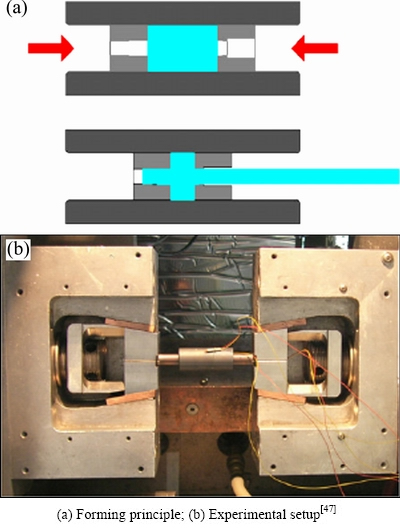

近年来,WANG等[47]提出一种新型的双动挤压方法(DAE)来研究7475铝合金挤压模具工作带界面的摩擦。试验使用两个不同工作带长度的模具,两端同时施加一定速度挤压铝棒。该试验可在Gleeble热模拟试验机实现。结果发现挤出型材的长度与工作带位置的摩擦是密切相关的。因此,模具工作带区域的摩擦可通过挤出型材长度来进行表征。双动挤压试验的原理、装置如图5所示。

3.2.3 块盘试验

块盘试验是将挤出物做成盘状或是圆筒状,并试图模拟挤压环境来反映真实挤压过程中摩擦的技术手段。随着磨损过程的进行,界面的接触压力会很快下降到较低值。PELLIZZARI等[48]采用块盘试验等效研究了6082铝合金热挤压H13模具钢的摩擦磨损机制。由于挤压过程中铝合金逐渐粘附在模具表面上,磨损过程由两种不同的机制组成,从开始的铝-钢接触磨损转变为完全塑性变形的铝-铝接触磨损。实验发现,经过不同硬涂层处理的钢球表面层与铝的化学相容性以及表面层的机械稳定性决定了两种磨损机制之间过渡时间的长短。 等[49]采用筒块法和理论分析等效研究6063铝合金挤压模具工作带表面的摩擦行为。实验先将铝筒和块样加热至550 ℃来模拟工作带区域的温度环境并在氩气的环境下进行,在1 min内通过弹簧施加铝筒和块样间的正压力从20 N增加到60 N。结果发现铝筒和块样之间存在着密集的粘着摩擦,导致严重的模具磨损和大的摩擦因数。通过挤压试验发现工作带区域从入口到出口的摩擦类型为从全粘摩擦逐渐转变至滑移摩擦。TVERLID等[50]通过测量全粘摩擦区域和滑移摩擦区域的长度来描述摩擦的特性。

等[49]采用筒块法和理论分析等效研究6063铝合金挤压模具工作带表面的摩擦行为。实验先将铝筒和块样加热至550 ℃来模拟工作带区域的温度环境并在氩气的环境下进行,在1 min内通过弹簧施加铝筒和块样间的正压力从20 N增加到60 N。结果发现铝筒和块样之间存在着密集的粘着摩擦,导致严重的模具磨损和大的摩擦因数。通过挤压试验发现工作带区域从入口到出口的摩擦类型为从全粘摩擦逐渐转变至滑移摩擦。TVERLID等[50]通过测量全粘摩擦区域和滑移摩擦区域的长度来描述摩擦的特性。

图5 双动挤压方法示意图[47]

Fig. 5 Schematic diagram of double action extrusion (DAE)

3.2.4 球盘试验

球盘试验也是一种广泛用于定量研究接触材料间的摩擦学行为及确定摩擦因数的有效方法[51]。典型的球盘试验是将固定的钢球压在旋转的铝盘上,在钢球上施加一定载荷并沿特定轨迹反复磨损旋转铝盘。球盘试验可以精确控制温度、正压力及滑移速度等实验条件。球盘试验钢球和旋转盘界面产生较高的接触应力且随着磨损距离的增加而减小,这与模具工作带位置的接触压力变化是非常吻合的。此外,软铝在钢球滑移的过程中产生严重的塑性变形,引起表面氧化层的破损,导致纯金属之间的接触,这与挤压工作带的接触环境是一致的。因此,球盘试验可有效描述挤压工作带的摩擦学行为。

RANGANATHA等[52]率先尝试通过球盘试验来描述铝合金挤出型材与模具工作带之间的摩擦。实验用铝制圆球磨损钢制旋转盘。实验发现当温度超过300 ℃时,摩擦因数随着温度的增加而增大,而摩擦因数的值也会由于材料间强烈的化学相互作用而变得很高。WANG等[53-55]通过短距离球盘试验等效研究了7005铝合金挤出材料与H13模具钢工作带之间界面的摩擦。且与RANGANATHA不同的是,WANG等采用钢制圆球磨损旋转铝盘。实验得到与RANGANATHA相反的结果,发现摩擦因数随着温度的增加而减小。这是由于随着温度的升高,钢球磨损铝盘的磨损机制从磨粒磨损逐渐变化为氧化磨损、剥层磨损以及严重的塑性变形磨损。磨损机制的改变使得摩擦因数随着温度的升高呈现出先增大后减小的趋势。刘志文等[56]通过短距离球盘试验研究了温度对铝合金热挤压模具工作带位置摩擦因数的影响,也得出随温度升高,摩擦因数呈先增大后减小的趋势。

虽然采用球盘试验方便控制且实验结果较为精确,但由于缺乏对磨损过程中接触条件演变的理解,只能定性评价实验条件对挤压摩擦的影响,不能用于挤压数值仿真中的摩擦边界条件。球盘试验中的摩擦包含剪切和犁沟摩擦。实际铝挤压犁沟摩擦的影响较小,而球盘试验中大的犁沟变形可能使犁沟摩擦效应偏大,试验结果不能直接用于描述工作带区域的摩擦边界条件。为了能利用球盘试验结果来表征工作带区域的摩擦,需定量区分犁沟和剪切摩擦所占总摩擦的比例。GODDARD等[57]率先建立了球盘试验的接触力学模型,后来TAYEBI等[58]对该模型进行了修正并实验验证。WANG等[59]把TAYEBI模型推广应用到高温球盘试验中。结果发现不同温度下,犁沟和剪切摩擦因数都随滑移距离增加而增大,而剪切摩擦应力在磨损过程中趋于稳定,认为由剪切摩擦应力来表征工作带区域的摩擦相比摩擦因数可能是一个更合适的方法。湖南大学李落星课题组采用球盘摩擦试验表征铝合金热挤压模具工作带位置的摩擦特征也得出了类似的规律,并采用逆多项式峰值函数拟合剪切摩擦应力与温度之间的关系[60]。

采用摩擦测试方法等效表征挤压过程的摩擦需满足几个基本条件:1) 接触条件需与挤压界面基本相吻合。如挤压筒、模具界面位置的接触压力非常高,模具工作带位置的接触压力从入口的较高值到出口逐渐减少为0;2) 温度、速度和接触压力等对摩擦因数的影响十分显著。为了能便于研究各参数对界面摩擦的定量影响,测试方法能改变各参数变量且在试验过程中能精确控制。由上述可知,圆环压缩试验是研究金属体积成形中摩擦最常用的方法。然而该方法不适合用来表征挤压过程界面的摩擦行为。在铝挤压过程中,铝材料与模具接触界面的压力从挤压筒到工作带位置逐渐减少,界面上发生严重粘着摩擦且存在相对滑移。圆环压缩试验并不能真实地反映挤压过程不同接触界面的摩擦学行为及特征;采用挤压试验根据挤压力或挤出型材长度可以反求出整个挤压过程中挤压筒或工作带位置的摩擦因数。由于摩擦与温度、滑移速度、界面接触压力、新表面生成等密切相关。在挤压过程中,铝锭在挤压筒中的变形温升较小,接触压力基本一致,且界面不存在滑移。但是在模具特别是工作带位置的变形温升非常大,界面滑移速度大,不同出口位置可能不一致。因此,采用挤压试验只可以用来研究挤压筒位置不同变形温度和接触压力等单一因素下的摩擦,对于模具工作带位置则很难研究单一因素对摩擦的影响;块盘试验虽能研究单一因素对接触界面的摩擦行为。但块盘摩擦在磨损过程中,界面产生的接触压力是非常低的,特别是在铝块温度过高情况下,这一现象与挤压过程界面高的接触压力不符合;球盘试验可以精确控制单一因素的变化。钢球和旋转盘界面产生较高的接触应力且随着磨损距离的增加而减小。铝盘在磨损过程中表面氧化层破损,导致纯金属之间的接触。虽然采用球盘试验可有效表征模具工作带位置的摩擦学行为,但是球盘摩擦测试出的摩擦因数包括剪切摩擦和犁沟摩擦因数两部分,不能直接用于数值仿真的摩擦边界条件。已有研究成果表明剪切摩擦应力在磨损过程中保持一致,可以代替摩擦因数作为工作带位置的摩擦边界条件,但该模型如何引入到商业有限元软件里并能较好模拟材料出口材料流动行为等还需进一步研究。

4 结论

1) 不加润滑条件下,铝垫与挤压垫、挤压筒、挤压模具接触界面的摩擦在高接触压力条件为完全粘着摩擦;模具工作带位置的接触压力从入口的较高值到出口逐渐减少为0,摩擦类型从粘着摩擦逐渐过渡为滑移摩擦。界面摩擦存在3个区域,但如何定量确定3个区域的长度需要进一步探索。

2) 模具工作带位置产生的高摩擦和严重的化学扩散,使工作带的过渡区域容易出现磨损和疲劳,严重制约模具使用寿命和挤出型材表面质量。开发具有高性能低成本和适合工业化应用的表面强化技术提升模具材料的耐磨性和耐腐蚀具有重要前景。

3) 库伦摩擦模型不适合于挤压摩擦边界条件;剪切摩擦模型在挤压仿真摩擦边界条件应用最为广泛。挤压垫、挤压筒和模具界面位置摩擦因数可以取值为0.9~1。模具工作带位置的摩擦因数取值国内外学者尚未达到一致,差异较大,需要进一步的研究;现有的经验摩擦模型与物理摩擦模型虽能一定或完全反映接触界面的物理本质,但目前在仿真软件中应用都具有一定局限性。

4) 挤压试验方法适合于研究挤压筒位置的接触摩擦学行为;短距离球盘摩擦试验适合于表征模具工作带位置的接触摩擦学行为,磨损过程中的剪切摩擦应力可以代替摩擦因数作为工作带位置的摩擦边界条件,但如何引入到商业有限元软件里并是否能准确模拟材料流动行为需进一步研究。

REFERENCES

[1] 刘志文, 李落星. 轻量化构件弯曲短流程工艺研究现状与进展[J]. 中国有色金属学报, 2014, 24(8): 2003-2012.

LIU Zhi-wen, LI Luo-xing. Review of bending short process for lightweight component[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(8): 2003-2012.

[2] 侯文荣, 张志豪, 谢建新, 陈蕴博. 铝合金空心型材分流模挤压成形全过程温度场的数值模拟[J]. 中国有色金属学报, 2013, 23(10): 2769-2778.

HOU Wen-rong, ZHANG Zhi-hao, XIE Jian-xin, CHEN Yun-bo.Numerical simulation of temperature field during whole extrusion process of aluminum hollow profile with porthole die extrusion forming[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 2769-2778.

[3] WANG L, ZHOU J, DUSZCZYK J, KATGERMAN L. Friction in aluminium extrusion—Part 1: A review of friction testing techniques for aluminium extrusion[J]. Tribology International, 2012, 56: 89-98.

[4] SCHRADER T, SHIRGAOKAR M, ALTAN T. A critical evaluation of the double cup extrusion test for selection of cold forging lubricants[J]. Journal of Materials Processing Technology, 2007, 189(1): 36-44.

[5] WANG L, YANG H. Friction in aluminium extrusion—part 2: A review of friction models for aluminium extrusion[J]. Tribology International, 2012, 56: 99-106.

[6] ZHANG C, ZHAO G, CHEN H, GUAN Y, CAI H, GAO B. Investigation on effects of die orifice layout on three-hole porthole extrusion of aluminum alloy 6063 tubes[J]. Journal of Materials Engineering and Performance, 2013, 22(5): 1223-1232.

[7] ZHOU J, LI L, DUSZCZYK J. Computer simulated and experimentally verified isothermal extrusion of 7075 aluminium through continuous ram speed variation[J]. Journal of Materials Processing Technology, 2004, 146(2): 203-212.

[8] LI L, ZHANG H, ZHOU J, DUSZCZYKJ, LI G Y, ZHONG Z H. Numerical and experimental study on the extrusion through a porthole die to produce a hollow magnesium profile with longitudinal weld seams[J]. Materials & Design, 2008, 29(6): 1190-1198.

[9] 赵云路, 邢再兴, 薛荣敬, 曹兴颐. 国内外固定挤压垫装置评述[J]. 轻合金加工技术, 2007, 35(3): 6-15.

ZHAO Yun-lu, XING Zai-xing, XUE Yun-jin, CAO Xing-xun. Review about foreign and domestic fixed dummy block[J]. Light Alloy Fabrication Technology, 2007, 35(3): 6-15.

[10] LOF J. Elasto-viscoplastic FEM simulations of the aluminium flow in the bearing area for extrusion of thin-walled sections[J]. Journal of Materials Processing Technology, 2001, 114(2): 174-183.

[11] 邓小民, 孙中建, 李胜祗, 方木云, 曹 杰. 铝合金挤压时的摩擦与摩擦因数[J]. 中国有色金属学报, 2003, 13(3): 599-605.

DENG Xiao-min, SUN Zhong-jian, LI Sheng-zhi, FANG Mu-yun, CAO Jie. Friction and friction coefficient for aluminium alloy extrusion[J]. The Chinese Journal of Nonferrous Metal, 2003, 13(3): 605-609.

[12] SCHIKORRA M, DONATII L, TOMESANI L, KLEINER M. The role of friction in the extrusion of AA6060 aluminum alloy, process analysis and monitoring[J]. Journal of Materials Processing Technology, 2007, 191(1): 288-292.

[13] WELO T, ABTAHI S, SKAUVIK I, ST REN S, MELANDER M, TJ

REN S, MELANDER M, TJ TTA S. Friction in the bearing channel of aluminium extrusion dies[C]//Proceedings of the15th Riso international symposium on materials science. Roskilde: Ris

TTA S. Friction in the bearing channel of aluminium extrusion dies[C]//Proceedings of the15th Riso international symposium on materials science. Roskilde: Ris National Laboratory, 1994: 615-620.

National Laboratory, 1994: 615-620.

[14] ABTAHI S. Friction and interface reactions on the die land in thin-walled extrusion[R]. Trondheim: The University of Trondheim, 1995.

[15] BIROL Y. Analysis of wear of a gas nitrided H13 tool steel die in aluminium extrusion[J]. Engineering Failure Analysis, 2012, 26: 203-210.

[16] GUTOVSKAYA J, SOLBERG J K, LANGE H I, ANDERSEN L H. Wear of Inconel 718 die during aluminium extrusion—A case study[J]. Wear, 2004, 256(1): 126-132.

[17]  J,HEDENQVISTC P. Physical vapour deposition duplex coatings for aluminium extrusion dies[J]. Wear, 1999, 225: 1123-1130.

J,HEDENQVISTC P. Physical vapour deposition duplex coatings for aluminium extrusion dies[J]. Wear, 1999, 225: 1123-1130.

[18] CLODE M P, SHEPPARDT. Formation of die lines during extrusion of AA6063[J]. Materials Science and Technology, 1990, 6(8): 755-763.

[19] 姚立群, 张洪舸, 南磊层. 模具工作带状况对铝合金挤压型材表面模纹的影响[J]. 塑性工程学报, 2013, 20(4): 99-103.

YAO Li-qun, ZHANG Hong-ge, NAN Lei-ceng. Influences of die bearing belt conditions on the die-lines of Al-alloy extrusion profiles[J]. Journal of Plasticity Engineering, 2013, 20(4): 99-103.

[20] MA X. Surface quality of aluminium extrusion products[D]. Enschede: University of Twente, 2011.

[21] 林高用, 郑小燕, 冯 迪, 杨 伟, 张胜华. 热处理状态对 H13 模具钢渗氮层的影响[J]. 钢铁, 2009, 43(12): 63-66.

LIN Gao-yong, ZHEN Xiao-yan, FENG Di, YANG Wei, ZHANG Sheng-hua. Effects of heat treatment on nitrided layer of H13 tool steel[J]. Iron & Steel, 2009, 43(12): 63-66.

[22] 余春燕, 王社斌, 侯文义, 许并社. 氮在 H13 钢中的扩散行为[J]. 机械工程材料, 2007, 31(6): 73-75.

YU Chun-yan, WANG Shen-bin, HOU Wen-yi, XU Bing-she. The diffusion behavior of nitrogen in H13 steel[J]. Materials for Mechanical Engineering, 2007, 31(6): 73-75.

[23]  M, SMOLEJ A, FAJFAR P, TURK R. Laboratory assessment of wear on nitrided surfaces of dies for hot extrusion of aluminium[J]. Tribology International, 2007, 40(2): 374-384.

M, SMOLEJ A, FAJFAR P, TURK R. Laboratory assessment of wear on nitrided surfaces of dies for hot extrusion of aluminium[J]. Tribology International, 2007, 40(2): 374-384.

[24]  R, HOGMARK S. Wear of surface treated dies for aluminium extrusion—a case study[J]. Wear, 2001, 249(3): 316-323.

R, HOGMARK S. Wear of surface treated dies for aluminium extrusion—a case study[J]. Wear, 2001, 249(3): 316-323.

[25] 龚 刚, 曹辉亮, 刘江文, 焦东玲, 罗承萍. H13钢550 ℃复合渗铬工艺研究[J]. 热加工工艺, 2008, 37(4): 63-66.

GONG Gang, CAO Hui-liang, LIU Jiang-wen, JIAO Dong-ling, LUO Cheng-ping. Study on complex chromizing at 550 ℃ for H13 steel[J]. Hot Working Technology, 2008, 37(4): 63-66.

[26] 张春华, 李春彦, 张 松, 康煜平, 陈 江, 才庆魁. H13模具钢激光熔凝层的组织及性能[J]. 金属热处理, 2004, 29(10): 14-17.

ZHANG Chun-hua, LI Chun-yan, ZHANG Song, KANG Yi-ping, CHEN Jiang, CAI Qing-kui. Microstructure and property of laser surface melt-solidifying for H13 die steel[J]. Heat Treatment of Metals, 2004, 29(10): 14-17.

[27] 陈慧敏, 周小平, 潘永清,周细枝. H13钢表面粉末烧结金属陶瓷覆层的组织及性能[J]. 特种铸造及有色合金, 2005, 25(9): 526-527.

CHEN Hui-min, ZHOU Xiao-ping, PAN Yong-qing, ZHOU Xi-zhi. Microstructure and properties of cermet coating on surface of H13 steel by vacuum powder sintering[J]. Special Casting & Nonferrous Alloys, 2005, 25(9): 526-527.

[28] HE Zhao, WANG He-nan, WANG Meng-jun, LI Guang-yao. Simulation of extrusion process of complicated aluminium profile and die trial[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1732-1737.

[29] LI L, ZHOU J, DUSZCZYK J. Prediction of temperature evolution during the extrusion of 7075 aluminium alloy at various ram speeds by means of 3D FEM simulation[J]. Journal of Materials Processing Technology, 2004, 145(3): 360-370.

[30] YU J, ZHAO G, CHEN L. Analysis of longitudinal weld seam defects and investigation of solid-state bonding criteria in porthole die extrusion process of aluminum alloy profiles[J]. Journal of Materials Processing Technology, 2016, 237: 31-47.

[31] 侯文荣, 张志豪, 谢建新, 马青梅, 盖洪涛. 基于质点逆向追踪的铝合金空心型材横断面温度的不均匀性[J]. 中国有色金属学报, 2015, 25(7): 1798-1807.

HOU Wen-rong, ZHANG Zhi-hao, XIE Jian-xin, MA Qing-mei, GAI Hong-tao. Temperature inhomogeneity on cross section of Al alloy hollow profile based on reverse point tracking method[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1798-1807.

[32] den BAKKER A J, WERKHOVEN R J, SILLEKENS W H, KATGERMAN L. The origin of weld seam defects related to metal flow in the hot extrusion of aluminium alloys EN AW-6060 and EN AW-6082[J]. Journal of Materials Processing Technology, 2014, 214(11): 2349-2358.

[33] MAHMOODKHANI Y, WELLS M A, PARSON N,POOLE W J. Numerical modelling of the material flow during extrusion of aluminium alloys and transverse weld formation[J]. Journal of Materials Processing Technology, 2014, 214(3): 688-700.

[34] DONATI L, TOMESANI L, SCHIKORRA M, BEN KHALIFA N,TEKKAYA A E. Friction model selection in FEM simulations of aluminium extrusion[J]. International Journal of Surface Science and Engineering, 2009, 4(1): 27-41.

[35] FLITTA I, SHEPPARD T. Nature of friction in extrusion process and its effect on material flow[J]. Materials Science and Technology, 2003, 19(7): 837-846.

[36] SAHA P K. Thermodynamics and tribology in aluminum extrusion[J]. Wear, 1998, 218(2): 179-190.

[37] ABTAHI S, STOREN S, WELO T. Interface mechanisms on the bearing surface in extrusion[C]//Proceedings from Extrusion Technology Seminar. Chicago: Aluminium Association Inc, & Aluminium Extrudes Council, 1996: 125-132.

[38] MA X, de ROOIJ M B, SCHIPPER D J. Modelling of contact and friction in aluminium extrusion[J]. Tribology International, 2010, 43(5): 1138-1144.

[39] MA X, de ROOIJ M B, SCHIPPER D J. A load dependent friction model for fully plastic contact conditions[J]. Wear, 2010, 269(11): 790-796.

[40] MA X, de ROOIJ M B, SCHIPPER D J. Friction conditions in the bearing area of an aluminium extrusion process[J]. Wear, 2012, 278: 1-8.

[41] 李落星, 彭大署, 刘振球. 玻璃或石墨润滑剂在 TC4 合金高温变形过程中的行为研究[J]. 稀有金属材料与工程, 2000, 29(4): 239-241.

LI Luo-xing, PENG Da-shu, LIU Zhen-qiu. Study on the lubricities of glass and graphite in the deformation processing of the alloy TC4 at high temperatures[J]. Rare Metal Materails and Engineering, 2000, 29(4): 239-241.

[42] BAKHSHI-JOOYBARI M. A theoretical and experimental study of friction in metal forming by the use of the forward extrusion process[J]. Journal of Materials Processing Technology, 2002, 125: 369-374.

[43] FLITTA I, SHEPPARD T. On the mechanics of friction during the extrusion process[C]//Proceedingsof the 7th International AluminumExtrusionTechnologySeminar. Chicago: Aluminium Association Inc, & Aluminium Extrudes Council, 2000: 197-204.

[44] BUSCHHAUSEN A, WEINMANN K, LEE J Y, ALTAN T. Evaluation of lubrication and friction in cold forging using a double backward-extrusion process[J]. Journal of Materials Processing Technology, 1992, 33(1): 95-108.

[45] NAKAMURA T, BAY N, ZHANG Z L. FEM simulation of friction testing method based on combined forward rod-backward can extrusion[J]. Journal of Tribology, 1997, 119(3): 501-506.

[46] NAKAMURA T, BAY N, ZHANG Z L. FEM simulation of a friction testing metliod based on combined forward conical can-backward straight can extrusion[J]. Journal of Tribology, 1998, 120(4): 716-723.

[47] WANG L, HE Y, ZHANG Y, CAI J, ZHOU J, DUSZCZYK J, KATGERMAN L. Modeling of double action extrusion—A novel extrusion process for friction characterization at the billet–die bearing interface[J]. Tribology International, 2010, 43(11): 2084-2091.

[48] PELLIZZARI M, ZADRA M, MOLINARI A. Tribological properties of surface engineered hot work tool steel for aluminium extrusion dies[J]. Surface Engineering, 2007, 23(3): 165-168.

[49]  J, HOGMARK S. Tribological simulation of aluminium hot extrusion[J]. Wear, 1999, 224(2): 216-225.

J, HOGMARK S. Tribological simulation of aluminium hot extrusion[J]. Wear, 1999, 224(2): 216-225.

[50] TVERLID S. Modelling of friction in the bearing channel of dies for the extrusion of aluminium sections[D]. Norway: Norwegian University of Science and Technology, 1997.

[51] VALIORGUE F, RECH J, HAMDI H, BONNETA C,GILLESB P,BERGHEAUA J M. Modelling of friction phenomena in material removal processes[J]. Journal of Materials Processing Technology, 2008, 201(1): 450-453.

[52] RANGANATHA S, KAILAS S V, ST REN S, SRIVATSAN T S. Role of temperature on sliding response of aluminum on steel of a hot extrusion[J]. Materials and Manufacturing Processes, 2007, 23(1): 29-36.

REN S, SRIVATSAN T S. Role of temperature on sliding response of aluminum on steel of a hot extrusion[J]. Materials and Manufacturing Processes, 2007, 23(1): 29-36.

[53] WANG L, HE Y, ZHOU J, DUSZCZYK J. Effect of temperature on the frictional behaviour of an aluminium alloy sliding against steel during ball-on-disc tests[J]. Tribology International, 2010, 43(1): 299-306.

[54] WANG L, HE Y, ZHOU J, DUSZCZYK J. Modelling of plowing and shear friction coefficients during high-temperature ball-on-disc tests[J]. Tribology International, 2009, 42(1): 15-22.

[55] WANG L, CAI J, ZHOU J, DUSZCZYK J. Characteristics of the friction between aluminium and steel at elevated temperatures during ball-on-disc tests[J]. Tribology Letters, 2009, 36(2): 183-190.

[56] 李斯旭, 刘志文. 温度对 6061 铝合金摩擦磨损行为的影响[J]. 机械工程材料, 2016, 40(1): 20-24.

LI Si-xu, LIU Zhi-wen. Influence of temperature on friction and wear behavior of 6061 aluminum alloy[J]. Materials for Mechanical Engineering, 2016, 40(1): 20-24.

[57] GODDARD J, WILMAN H. A theory of friction and wear during the abrasion of metals[J]. Wear, 1962, 5(2): 114-135.

[58] TAYEBI N, CONRY T F, POLYCARPOU A A. Determination of hardness from nanoscratch experiments: Corrections for interfacial shear stress and elastic recovery[J]. Journal of Materials Research, 2003, 18(9): 2150-2162.

[59] WANG L, ZHOU J, DUSZCZYK J, KATGERMAN L. Identification of a friction model for the bearing channel of hot aluminium extrusion dies by using ball-on-disc tests[J]. Tribology International, 2012, 50: 66-75.

[60] 张 明. 6061铝合金热挤压过程中摩擦磨损行为等效表征研究[D].长沙: 湖南大学, 2014.

ZHANG Ming. Equivalent characterization of the friction and wear behavior during hot extrusion of 6061 aluminum[D]. Changsha: Hunan University, 2014.

LIU Zhi-wen1, 2, LI Luo-xing1, 2, ZHANG Ming1, 2, LI Shi-kang1, 2

(1. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University, Changsha 410082, China;

2. College of Mechanical and Vehicle Engineering, Hunan University, Changsha 410082, China)

Abstract: In the hot extrusion of aluminium alloys, friction at the workpiece/tools interface has great influence on the die wear, profile surface quality and extrusion load. The friction coefficient is also an important thermal boundary condition in the FE simulation of aluminium extrusion, which is affected by many factors and hard to be quantified. To obtain accurate simulation results, reasonable friction models and friction coefficient should be adopted. The tribological behaviors of contact interfaces in the hot extrusion of aluminum alloy were revealed. The effect of friction and wear on the surface quality of the profile in the bearing was analyzed. The research status and development of surface treatment techniques were comprehensively reviewed and evaluated. The friction models and equivalent characterizations being used for the FE simulation of aluminium extrusion at different contact interfaces were summarized. The main problems of friction in the hot extrusion of aluminium alloys were put forward.

Key words: aluminium alloy; hot extrusion; interface friction; tribological behavior; friction model; equivalent characterization

Foundation items: Project (2014ZX04002071) supported by the National Key Project of Science and Technology of China; Project (51475156) supported by the National Natural Science Foundation of China; Project (2016YFB0101704) supported by the National Key Research and Development Program of China

Received date: 2016-05-17; Accepted date: 2016-12-14

Corresponding author: LI Luo-xing; Tel: +86-731-88821571; E-mail: llxly2000@163.com

(编辑 王 超)

基金项目:国家科技重大专项(2014ZX04002071);国家自然科学基金面上资助项目(51475156);国家重点研发计划资助项目(2016YFB0101704)

收稿日期:2016-05-17;修订日期:2016-12-14

通信作者:李落星,教授,博士;电话:0731-88821571;E-mail:llxly2000@163.com