文章编号: 1004-0609(2006)06-0945-06

骨架结构对SiC/Al双连续相复合材料的影响

赵龙志, 方志刚, 曹小明, 田 冲, 胡宛平, 张劲松

(中国科学院 金属研究所, 沈阳 110016 )

摘 要: 用挤压铸造法制备了不同结构的SiC泡沫增强ZL109双连续相复合材料, 研究了增强体骨架结构(筋的结构、 泡沫孔和体积分数)对复合材料压缩性能和弯曲性能的影响。 结果表明: SiC泡沫增强体的筋的结构影响了界面的结合, 影响了材料的压缩性能; 当筋具有三明治结构时, 复合材料的强度最大; 当筋具有双层结构时, 复合材料的强度最低; 随着SiC泡沫孔径的增大, 复合材料的压缩强度、 弹性模量和屈服强度都有所提高, 材料的屈服应变减小, 弯曲强度先升高后降低, 弯曲强度在泡沫孔径为1.5mm时达到最大值; 复合材料的压缩强度随着增强体体积分数的增大而提高, 屈服应变随着体积分数的增大而减小。

关键词: 双连续相复合材料; 骨架结构; 压缩性能; 弯曲强度 中图分类号: TG113.25

文献标识码: A

Effect of preform structure on SiC/Al co-continuous composites

ZHAO Long-zhi, FANG Zhi-gang, CAO Xiao-ming,

TIAN Chong, HU Wan-ping, ZHANG Jin-song

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The SiC/Al co-continuous composites reinforced by different structure SiC foam were fabricated, and the effects of preform structure on the mechanical properties were investigated. The results show that the structures of SiC foam strut play an important role to the compressive property of composites for changing the interface bond. The compressive strength of the composite reinforced by SiC foam with sandwich-structure strut is the highest, and that of the composite reinforced by SiC foam with double-layer strut is the lowest. With the increase of SiC foam aperture, the compressive strength, elastic modul and yield strength of the composites increase, but the ratio of compress decreases. The flexural strength gets the peak value when the aperture is 1.5mm.With the increase of the volume fraction of SiC foam reinforcement, the compressive strength increases, but the ratio of compress decreases.

Key words: co-continuous composites; preform structure; compressive properties; flexural strength

SiCp/Al复合材料具有优异的物理性能和力学性能, 是航空航天、 汽车工业以及其他许多应用的理想材料[1-4], 而陶瓷增强体的不连续性和陶瓷与金属的不润湿使陶瓷颗粒很难均匀地分布在金属基体中, 影响了其性能的提高[5], 陶瓷相的不连续性也使颗粒增强金属基复合材料很难应用于多功能材料。 双连续相复合材料由于其特有的拓扑结构填补了这项空白[6]。 双连续相增强体通常包括微孔陶瓷和泡沫陶瓷, 微孔陶瓷的制备成本较高[6, 7], 而使用泡沫陶瓷作为增强体将会大大降低双连续相复合材料的制备成本, 简化材料的制备工艺[8, 9]。 目前人们对以泡沫陶瓷为增强体增强的双连续相复合材料的研究, 主要集中在复合材料的界面改性和复合工艺[8-12], 对泡沫增强体结构特性的研究还未见报道。 复合材料的增强体的结构特征对复合材料有重大的影响, 因此本文作者研究SiC泡沫增强体的结构特性对复合材料力学性能的影响。

1 实验

实验所用的SiC泡沫陶瓷增强体采用反应烧结法制备, 复合材料的基体为ZL109铝合金, 成分为: 85.1%Al, 1%Cu, 1.1%Mg, 1%Ni, 11.8%Si。 复合材料的坯料尺寸为d100mm×15mm。 材料复合的主要步骤见文献[8], 主要工艺参数: 骨架预热温度800℃, 保压时间15s, 自然卸压时间30s, 复合压力120MPa, 浇注温度750℃, 模具预热温度250℃。

将复合材料用线切割机切成13mm×13mm×27mm的压缩试样, 在DCS-10万能实验机作试验, 加载速度为2N/s。 弯曲样品的尺寸为6mm×8mm×70mm, 弯曲实验在DCS-10万能实验机上进行, 载荷为2000N, 加载速率为0.5mm/min, 跨距为50mm。 材料的形貌在S360扫描电子显微镜和德国产的MEF4A金相显微镜下进行观察。

2 结果与讨论

2.1 SiC泡沫筋的结构对复合材料的影响

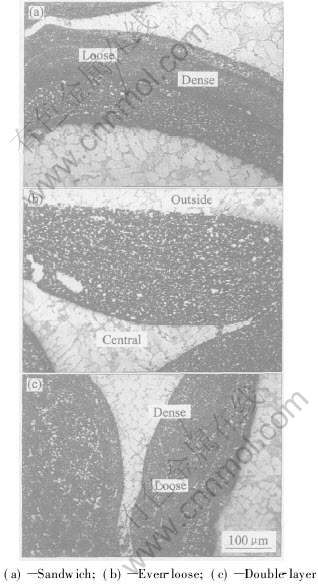

SiC/Al双连续相复合材料由增强相SiC泡沫和金属合金ZL109构成。 增强体具有三维连通网络结构, 由一根根筋连通, 每根筋为空心管, 筋的中心孔呈三角形状, 筋与筋之间的空间为泡沫孔, 如图1所示。 泡沫陶瓷和金属基体复合以后, 基体被压渗到泡沫陶瓷增强体遗留的空间, 主要包括泡沫孔、 筋的中心孔和筋壁的开放式微孔洞三大区域, 如图2所示。 泡沫增强体的筋分为三类: 一类为外疏松内致密的双层式, 另一类为均匀疏松式, 第三类具有内外疏松中间致密的三明治结构。

图1 SiC泡沫增强体的宏观形貌

Fig.1 Macro-morphology of SiC foam reinforcement

图2 SiC/Al双连续相复合材料中

泡沫增强体的筋的形貌

Fig.2 Morphologies of strut of SiC foam

reinforcement of SiC/Al co-continuous composites

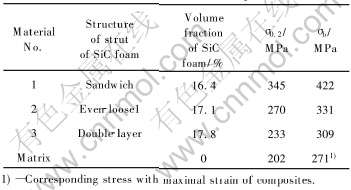

从表1可以看出, SiC/Al双连续相复合材料的屈服强度都比基体高。 SiC泡沫增强体的筋具有三明治结构, 复合材料的屈服强度最高, 比基体提高了70%; 筋具有均匀疏松结构, 屈服强度提高了34%; 筋具有双层结构, 提高了15%。 复合材料的压缩强度也都比相同压缩应变的基体的强度高, 其变化趋势与屈服强度相同。 SiC泡沫的筋具有三明治结构时, 强度最高, 与基体相比提高了56%; 筋具有双层结构, 强度最低, 只提高了14%; 筋具有均匀疏松结构, 强度介于前两者之间, 压缩强度比基体提高了22%。 材料的强度与其微观结构有密切的关系, 对于复合材料, 其强度与材料的界面和增强体的强度有密切的关系。 复合材料中, 增强体与基体之间的界面负责传递加载时复合材料内部的应力。

表1 SiC/Al双连续相复合材料的压缩性能

Table 1 Compressive property of SiC/Al co-continuous composites

在金属基复合材料的界面附近, 材料物理性质和化学性质的不连续性使增强体与基体合金之间产生了热力学不平衡。 因此, 界面的结构对载荷的传递和断裂过程起着决定性的作用。 当复合材料承受外加载荷时, 产生的应力在材料内部分布不均匀, 界面的结构会改变应力的分布。 材料的界面越宏观, 越容易形成应力集中, 界面传递应力的能力就会下降[13]。 SiC与铝合金之间的界面结合属于机械结合, 在增强体与基体之间仅仅依靠单纯的粗糙表面相互嵌入互锁作用进行连接。 因此, 增强体的表面粗糙程度是影响机械结合主要因素[14]。 当筋具有疏松多孔结构时, 基体合金渗入微孔, 在筋的表层形成了金属陶瓷复合层, 为材料的界面提供了缓冲区, 在界面前沿形成了互穿式结构, 减小了由于基体和增强体热膨胀失配造成的热残余应力, 从而提高了材料的强度。 同时, 筋的疏松多孔结构, 使界面处的应力得到分散, 应力的方向随着筋的微孔洞方向的随机变化而改变, 从而增加了界面传递应力的能力, 提高了材料的强度。 当SiC泡沫的筋具有致密结构时, 与疏松多孔结构相比, 致密结构可以提高增强体的强度, 从而提高复合材料的强度。 但是, 具有致密结构的筋表面与基体之间的界面, 不具有互穿式结构, 传递应力的能力比较差, 而且前者对复合材料强度的影响没有后者明显。 SiC泡沫的筋具有三明治结构时, 筋的内外表面为疏松多孔结构, 形成的界面为互穿式结构, 中间部分为致密结构(图2(a))。 这种致密结构既提高了复合材料的强度又不影响界面结构, 而筋具有均匀疏松结构的复合材料只有互穿式界面, 因此筋具有三明治结构的复合材料的强度比筋为均匀疏松的复合材料的强度高。 当SiC泡沫增强体的筋具有双层结构时, 筋的外壁为一层40μm厚的疏松多孔层, 外表面形成的界面为互穿式界面, 具有致密结构的内壁形成的界面为普通界面(图2(c))。 虽然具有致密结构的筋本身能提高复合材料的强度, 但是它与基体之间的界面结构发生了变化, 使材料强度的降低。 双层结构的致密部分总体上降低了材料的强度。 可见, 与筋具有均匀疏松结构的复合材料相比, 筋具有双层结构的复合材料的强度低。

2.2 SiC泡沫孔径对复合材料的影响

图3所示为不同孔径的SiC泡沫增强铝基观连续相复合材料的压缩应力应变关系。 由图3可见, SiC泡沫增强体的孔径对复合材料的压缩力学性能有重大的影响。 随着SiC泡沫孔径的增大, 材料的强度提高, 材料的屈服应变减小。 泡沫孔径为2.0mm的双连续相复合材料的弹性模量、 屈服强度和压缩强度最大, 屈服应变最小, 孔径为1.0mm的复合材料的强度最低, 屈服应变最大。 材料力学性能的变化与复合材料的结构有密切的关系。 首先, SiC泡沫孔径的变化影响基体合金的微观结构。 泡沫的孔径越小, 泡沫孔中的基体越容易形成近似垂直于泡沫筋的柱状枝晶, 形成等轴晶的概率下降, 如图4所示。 泡沫孔径的减小还会降低复合材料凝固时液态合金中的对流, 使枝晶的晶粒变大[15]。 粗大的柱状枝晶会降低基体合金的强度, 进而降低复合材料的强度。 因此, 泡沫的孔径越小, 复合材料的强度越低。 另外, SiC泡沫孔径的减小还影响筋的横向尺寸。 在体积分数相同的情况下, 泡沫的孔径越小, 泡沫孔的单元就越多, 筋的数量越多, 筋就变得越细小, 泡沫筋的强度就越低。 由于SiC泡沫是三维连通网络结构, 复合材料在承载时增强体SiC泡沫即传递载荷又承受载荷[7]。 因此, 泡沫的孔越小, 复合材料的强度就越低。 随着泡沫的孔径变大大, 泡沫筋变粗。 SiC泡沫增强体泡沫的筋越粗, 复合材料载承载过程中泡沫筋中越容易形成微裂纹, 使材料的屈服应变减小。

图3 不同孔径的SiC泡沫增强铝基双连续相复合材料的压缩应力应变关系

Fig.3 Relationship between compressive stress and strain of SiC/Al co-continuous composites reinforced by SiC foams with different apertures

图4 不同孔径SiC泡沫增强铝基双连续相复合材料

Fig.4 SiC/Al co-continuous composites reinforced by SiC foam with different apertures

图5所示为SiC泡沫孔径对复合材料弯曲强度的影响。 从图5可以看出, 在泡沫孔径小于1.5mm时, 弯曲强度随着孔径的增大而提高, 在孔径为1.5mm左右时, 弯曲强度达到最大值。 在孔径大于1.5mm时, 弯曲强度随着孔径的增大而减小。 其原因是, 当泡沫孔小于1.5mm时, 随着泡沫孔径的增大, 泡沫筋变粗, 筋的强度增加, 整个泡沫增强体的强度增大, 因此复合材料的弯曲强度增大。 当泡沫孔径大于1.5mm时, 随着泡沫孔径的增大, 泡沫筋变粗, 泡沫增强体的强度也随之增大[16, 17]。 但是对于用浸渍法制备的泡沫陶瓷, 在筋变粗的同时, 筋内部出现微观缺陷的几率也变大, 筋内部由于SiC料浆不均匀出现局部微孔洞缺陷[18]。 材料在断裂时, 微裂纹将在缺陷周围形成, 然后慢慢扩展, 加速了材料破坏, 使材料的弯曲强度降低。

图5 SiC泡沫孔径对复合材料弯曲强度的影响

Fig.5 Influence of aperture of SiC foam on flexural strength of composites

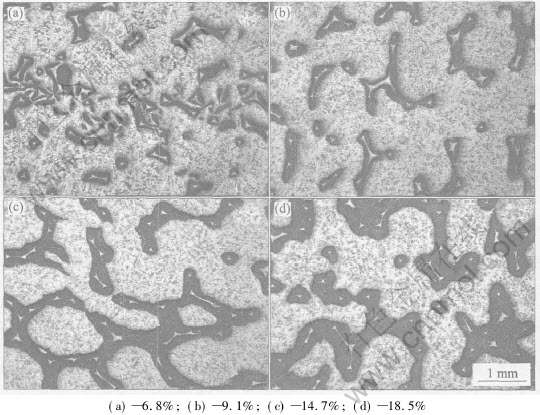

2.3 SiC泡沫增强体体积分数对复合材料的影响

图6所示为不同体积分数SiC增强铝基复合材料的应变应力关系。 由图6可见, 复合材料中SiC泡沫增强体的体积分数越高, 材料的压缩性能越好。 复合材料的弹性模量、 屈服强度和压缩强度均随着增强体体积分数的增加而提高, 而屈服应变却减小。 在SiC泡沫增强铝基复合材料中, 增强体为三维网络连通结构, 当泡沫孔孔径为一定值时, 增强体体积分数的增加是通过增加泡沫筋的横向尺寸来实现的, 如图7所示。 当SiC泡沫筋十分细时, 泡沫的整体结构强度很低, 不能承受材料复合时所需要的压力, 使得材料中存在局部的坍塌现象(图7(a))。 SiC泡沫增强体的体积分数越高, 泡沫筋越粗, 筋的强度越高。 当筋的强度足以承受复合压力时, 泡沫筋可以保持良好的三维连同性, 保证了复合材料双连续性(图7(b)~(d))。 单个筋的强度越高, 整个SiC泡沫的强度越大, 复合材料的强度就越高[16, 17]。 同时, 泡沫筋越粗, 泡沫的刚性越好, 复合材料的弹性模量越高。 对于SiC/Al双连续相复合材料, 在承受压缩载荷时, 复合材料发生压缩变形, 泡沫增强体的筋是最先失效的区域。 在SiC泡沫增强复合材料中, 一旦筋中薄弱部位产生微裂纹, 裂纹迅速扩张, 容易形成近似筋的横向尺寸的宏观裂纹, 因此增强体的筋越粗, 产生的裂纹越大, 复合材料越容易失效。 可见, 复合材料的屈服应变随着增强体体积分数的增大而减小。

图6 不同体积分数SiC增强铝基复合材料的应变与应力关系

Fig.6 Relationship between strain and stress for composites reinforced by SiC foam with different volume fractions

图7 不同体积分数SiC泡沫增强铝基复合材料

Fig.7 Co-continuous SiC/Al composites reinforced by SiC foam with different volume fractions

3 结论

1) SiC泡沫增强体的筋的结构影响了界面的结合, 改变了材料的压缩性能。 当筋具有三明治结构的复合材料强度最大, 具有双层结构的强度最低, 具有均匀疏松结构的强度介于两者之间。

2) 随着SiC泡沫孔径的增大, 复合材料的压缩强度、 弹性模量和屈服强度都提高, 屈服应变减小, 弯曲强度先升高后降低, 弯曲强度在泡沫孔径为1.5mm时达到最大值。

3) 复合材料的压缩强度随着增强体体积分数的增加而提高, 屈服应变随体积分数的增加而降低。

REFERENCES

[1]Ibrahim I A, Mohamed F A, Lavernia E J. Particulate reinforced metal matrix composites—a review[J]. Journal of Material Science, 1991, 26: 1137-1156.

[2]Challa N, Shen Y L. Mechanical behavior of particle reinforced metal matrix composites[J]. Advanced Engineering Materials, 2001, 3(6): 357-370.

[3]Gnjidic Z, Grbovic J, Mitkov M, et al. Influence of SiC particles on compressive strength of sintered aluminum alloy[J]. Powder Metallurgy, 2003, 46(1): 21-24.

[4]Lloyd D J. Particle reinforced aluminum and magnesium matrix composites[J]. International Materials Reviews, 1994, 39 (1): 1-23.

[5]Tszeng T C. The effects of particle clustering on the mechanical behavior of particle reinforced composites[J]. Composites Part B, 1998, 29: 299-308.

[6]David R C. Interpenetrating phase composites[J]. Journal of American Ceramic Society, 1992, 75(4): 739-59.

[7]Srikanth N, Kurniawan L A, Gupta M. Effect of interconnected reinforcement and its content on the damping capacity of aluminum matrix studied by a new circle-fit approach[J]. Composites Science and Technology, 2003, 63: 839-849.

[8]赵龙志, 曹小明, 田冲, 等. 骨架表面改性对SiC/Al双连续相复合材料性能的影响[J]. 材料研究学报, 2005, 19(5): 512-518.

ZHAO Long-zhi, CAO Xiao-ming, TIAN Chong, et al. Effect of surface treatment of foam perform on the properties of SiC/Al composites[J]. The Chinese Journal of Materials Research, 2005, 19(5): 512-518.

[9]赵龙志, 曹小明, 田冲, 等. 新型复式连通SiC/390Al复合材料的研究[J]. 材料研究学报, 2005, 19(5): 485-491.

ZHAO Long-zhi, CAO Xiao-ming, TIAN Chong, et al. New-model double-interpenetrating SiC/390Al composite[J]. The Chinese Journal of Materials Research, 2005, 19(5): 485-491.

[10]Xing H W, Cao X M, Hu W P, et al. Interfacial reactions in 3D-SiC network reinforced Cu-matrix composites prepared by squeeze casting[J]. Materials Letters, 2005, 59(12): 1563-1566.

[11]邢宏伟, 曹小明, 胡宛平, 等. 三维网络SiC/Cu 金属基复合材料的凝固显微组织[J]. 材料研究学报, 2004, 18(6): 597-605.

XING Hong-wei, CAO Xiao-ming, HU Wan-ping, et al. Solidification microstructure of 3D-meshy SiC/Cu metal matrix composites[J]. The Chinese Journal of Materials Research, 2004, 18(6): 597-605.

[12]Peng H X, Fan Z, Evans J R G. Bi-continuous Metal matrix composites[J]. Mater Sci Eng A, 2001, A303: 37-45.

[13]吴人洁. 复合材料[M]. 天津: 天津大学出版社, 2000.

WU Ren-jie. Composites[M]. Tianjin: Tianjin University Press, 2000.

[14]郝元恺, 肖加余. 高性能复合材料学[M]. 北京: 化学工业出版社, 2004.

HAO Yuan-kai, XIAO Jia-yu. High Performance Composites[M]. Beijing: Chemistry Industry Press, 2004.

[15]Dutta B, Surappa M K. Microstructure evolution during multidirectional solidification of Al-Cu-SiC composites[J]. Composites Part A, 1998, 29: 565-573.

[16]Rasto B, David J G, Chuong Q D. Evaluation of strut strength in open-cell ceramics[J]. Journal of American Ceramic Society, 1989, 72(6): 885-889.

[17]Rasto B, David J G. Fracture behavior of open-cell ceramics[J]. Journal of American Ceramic Society, 1989, 72(7): 1145-1152.

[18]Fitzgerald T J, Michaud V J, Mortensen A. Processing of microcellular SiC foams[J]. Journal of Materials Science, 1995, 30: 1037-1045.

收稿日期: 2005-09-30; 修订日期: 2006-01-20

通讯作者: 张劲松, 研究员; 电话: 024-23971896; 传真: 024-23906640; E-mail: jshzhang@imr.ac.cn

(编辑何学锋)