文章编号:1004-0609(2015)06-1465-06

超高频感应连续钎焊立方氮化硼磨粒的界面反应机理

李奇林1,苏宏华2,徐九华2,雷卫宁1

(1. 江苏理工学院 机械工程学院,常州 213001;

2. 南京航空航天大学 机电学院,南京 210016)

摘 要:采用超高频感应连续钎焊工艺,在不同扫描速度条件下实现了立方氮化硼(CBN)磨粒、Ag-Tu-Ti合金以及基体三者之间的钎焊连接。采用扫描电子显微镜(SEM)和X射线能谱仪(EDX)观察钎焊后的CBN磨粒界面新生化合物形貌。结果表明:随着扫描速度的变化,在CBN磨粒表面生成颗粒状TiN化合物以及针状和六棱柱状的TiB2化合物。其中,TiN尺寸为100 nm左右,而TiB2尺寸小于200 nm。在超高频感应连续钎焊CBN磨粒表面首先生成颗粒状TiN层,然后在TiN层外围形成柱状TiB2层,最终形成CBN/TiN/TiB2/钎料结构。当扫描速度为0.5 mm/s时,可以获得较好的界面新生化合物层结构。

关键词:Ag-Cu-Ti合金;超高频感应加热;钎焊;立方氮化硼;界面反应

中图分类号:TG454;TG401 文献标志码:A

Interfacial reaction mechanism of CBN grain continuous brazed by ultra-high frequency induction

LI Qi-lin1, SU Hong-hua2, XU Jiu-hua2, LEI Wei-ning1

(1. School of Mechanical Engineering, Jiangsu University of Technology, Changzhou 213001, China;

2. College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics,

Nanjing 210016, China)

Abstract: Continuous brazing with ultra-high frequency induction was proposed to braze the cubic born nitride (CBN) grits and steel substrate based on Ag-Cu-Ti filler alloy. The new compounds morphologies were observed and analogized by scanning electron microscopy (SEM) and energy diffraction X-ray (EDX). The results show that, with the variation of scanning speed, granular compounds TiN about 100 nm in size, the needle-like and prismatic compounds TiB2 less than 200 nm in size are observed, respectively. The theoretical analysis results reveal that, during continuous brazing by ultra-high frequency induction, granular TiN layer forms on the surface of CBN firstly, and then, prismatic TiB2 layer forms on the outside of the new TiN layer. The joint is CBN/TiN/TiB2/filler structure, finally. A satisfactory interfacial structure can be obtained when scanning speed is 0.5 mm/s.

Key words: Ag-Cu-Ti alloy; ultra-high frequency induction heating; brazing; cubic born nitride (CBN); interfacial reaction

立方氮化硼(CBN)是硬度仅次于金刚石的超硬磨料[1]。近几十年的研究成果表明:采用钎焊方法制作的CBN砂轮具有结合力强、磨粒出露高、砂轮寿命长等诸多优势,在钛合金、高温合金等难加工材料的高效磨削中具有广阔的应用前景[2-3]。

通过界面反应生成的化合物,是单层钎焊砂轮对CBN磨料实现牢固把持的关键。目前,主要采用真空炉中钎焊的方法制备单层钎焊CBN砂轮。其特点是钎焊过程在真空炉内进行,温度变化比较缓慢,界面反应处于近似平衡过程,耗时较长。国内外迄今对炉中钎焊的界面反应热力学和动力学过程有了较为广泛的研究[4-5],深入研究了界面新生化合物的形貌、显微组织和形成机理,为提高钎焊CBN砂轮的性能提供了依据[6]。

采用超高频感应加热对砂轮基体进行连续钎焊的方法是近几年提出的新型钎焊工艺[7]。该工艺利用局部微区加热结合扫描实现连续钎焊,因而不受砂轮尺寸限制,并且还有利于减小砂轮基体在钎焊后的热变形,是一种极具应用前景的钎焊工艺。由于超高频感应连续钎焊的温度变化速度可达100 ℃/s以上[8],是典型的非平衡过程。因此,其界面反应机理以及化合物形态与平衡条件下的炉中钎焊存在较明显的差异。然而,目前对于超高频感应连续钎焊的界面反应机理缺乏认识,这种非平衡条件下钎焊界面反应过程的相关研究较少。

本文作者采用Ag-Cu-Ti合金作为钎料,在不同超高频感应连续钎焊工艺条件下研究CBN磨粒界面新生化合物显微组织特征及其界面反应机理,从而通过控制超高频感应连续钎焊工艺过程来调控结合界面的显微组织。

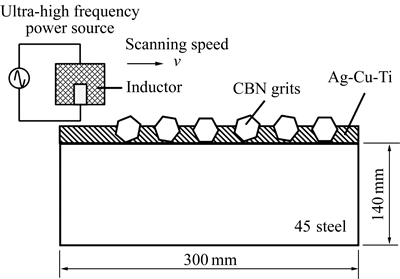

1 实验

实验采用无镀膜CBN磨粒,牌号为CBN-230,直径为300~425 μm。钎料采用Ag-Cu-Ti合金粉末,其主要组分为96(72Ag-28Cu)-4Ti(质量分数,%)。基体材料为45号钢,尺寸为300 mm×20 mm×140 mm。钎焊前,将CBN放入丙酮溶液中超声清洗10 min,并对45钢基体表面进行除锈、去油污处理。图1所示为超高频连续钎焊示意图,采用Ar气做为保护气氛。采用单回线加热结合感应器连续移动的方式进行连续钎焊,扫描速度为0.25~2 mm/s。感应加热电流频率为1 MHz,功率为4~6 kW,钎焊温度为940 ℃。

将钎焊后的试样沿垂直于磨粒与钎料的方向用线切割的方法分割,抛光后采用Hitch S3400型扫描电镜观察显微组织。为了观察磨粒表面生成物的形貌,用10%(质量分数)的稀HNO3溶液作为电解液,将磨粒从基体上电解下来,这样可以完整保留磨粒表面新生化合物。通过Hitch S4800型场发射扫描电镜(SEM)和Bruker XFlash Detector 5010 型X射线能谱仪(EDX)对试样进行观察和分析。

图1 超高频连续感应钎焊示意图

Fig. 1 Schematic diagram of continuous brazing with ultra- high frequency

2 结果与讨论

2.1 界面结构特征

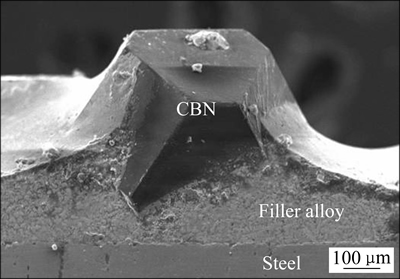

图2所示为抛光之后的钎焊接头的SEM像。CBN出露高度达到50%以上,且磨粒晶型完整,表面无裂纹和破碎。钎料沿磨粒根部向顶部爬升,可以增强钎料合金对金刚石磨粒的把持力。

图2 抛光后钎焊接头的SEM像

Fig. 2 SEM image of brazed joint after buffing

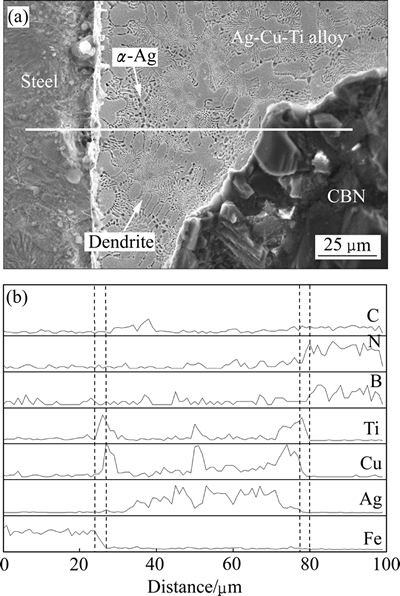

图3所示为扫描速度0.5 mm/s条件下CBN/钎料/45号钢基体结合界面的SEM像。从图3(a)可以看出,三者在接头处结合较为致密,无明显空洞和缺陷存在。钎料层组织内部含有黑色花纹状的α相富Ag固溶体以及枝晶状的β相富Cu固溶体。超高频感应连续钎焊工艺能够细化Ag-Cu-Ti钎料晶粒的组织,有利于增强钎料层的强度,提高钎料对金刚石磨粒的把持力。由于钎料层在钎焊过程中快速冷却,内部原子的扩散过程落后于结晶过程[4],钎料合金的均匀化不够充分,从而形成了枝晶状的非平衡组织。

图3(b)所示为沿图3(a)中白线的元素含量能谱线扫描分析。图3(b)中虚线标识的两个区域Ⅰ和Ⅱ分别对应45号钢基体/钎料和钎料/CBN的结合界面。可以明显看到,钎料层中的Ti元素在靠近45号钢基体和CBN的界面附近均出现了富集现象。在界面Ⅰ和界面Ⅱ附近,分别可以观察到Ti元素和其他元素的共存区域,在该区域内,各种元素的含量均呈现一定的变化梯度。活性元素Ti在界面附近富集和扩散的现象预示着钎料层与45号钢基体以及CBN磨粒实现了良好的结合,且在CBN磨粒界面处可能形成化合物[6]。

图3 CBN磨粒钎焊界面SEM像和元素线扫描谱

Fig. 3 Interfacial SEM image(a) and element line scanning spectrum(b) of CBN grain

2.2 CBN磨粒表面生成物形貌

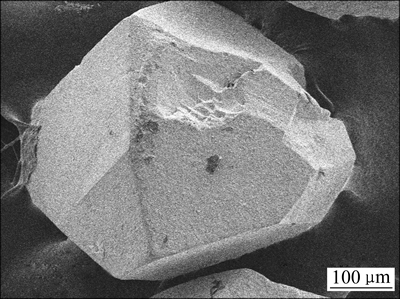

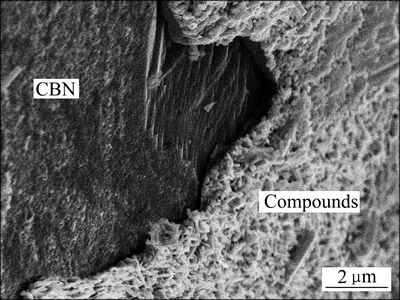

采用扫描电镜和能谱仪对电解腐蚀的CBN磨粒表面形貌进行观察。图4所示为扫描速度为0.5 mm/s条件下钎焊后CBN磨粒的SEM像。由图4可见,钎焊CBN磨粒表面已被一层新生化合物覆盖。图5所示为CBN磨粒表面化合物的SEM像。由图5可见,该新生化合物层厚度不超过1 μm。

图4 钎焊后的CBN磨粒的SEM像

Fig. 4 SEM image of CBN grain after brazing

图5 CBN磨粒表面新生化合物SEM像

Fig. 5 SEM image of compounds on surface of CBN grain

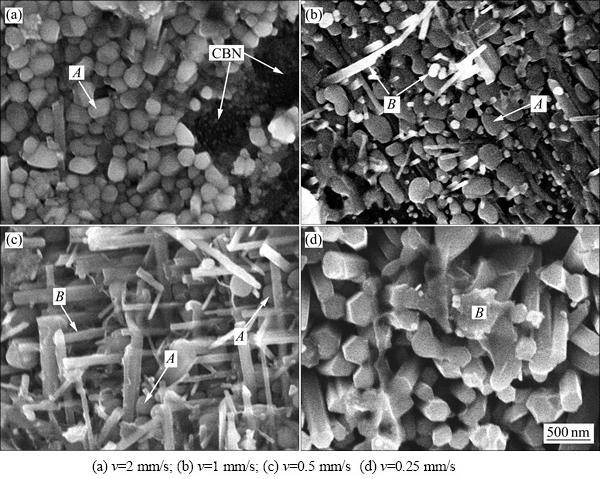

超高频感应连续钎焊的界面反应时间取决于扫描速度,即扫描速度越慢,界面反应时间就越长,反之,亦然。图6所示为不同扫描速度条件下钎焊CBN磨粒表面的新生化合物形貌。当扫描速度为2 mm/s时,可见尺寸为100 nm左右的不规则颗粒状灰色化合物A分布在CBN磨粒表面(见图6(a))。此时化合物层较薄,未完全将CBN磨粒覆盖;当扫描速度为1 mm/s时,颗粒状化合物的数量逐渐增多,而且在颗粒状化合物的间隙处可观察到亮白色的细针状化合物(见图6(b)中化合物B),此化合物沿CBN磨粒表面垂直方向生长;当扫描速度进一步减小到0.5 mm/s时,针状化合物的数量明显增多,几乎将颗粒状化合物完全覆盖(见图6(c));当扫描速度为0.25 mm/s时,化合物B紧密排列,可明显分辨其形状为比较规则的六棱柱状,直径为200 nm以下。需要指出的是,扫描电镜下观察到化合物B的颜色发亮,意味着其具有优异的导电性能。

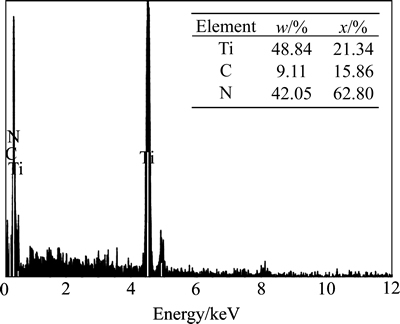

为了确定CBN磨粒表面新生化合物的成分,对图6中的化合物层进行元素能谱(EDX)分析,其结果如图7所示,由图7可以看出,新生化合物的主要成分为Ti、N、C元素。需要特别指出的是,新生化合物层较薄,而X射线具有较强的穿透能力,导致其结果具有一定误差。此外,轻元素B在能谱分析中不容易被检测到。从图7结果可知,钎料中的活性元素Ti已经在CBN磨粒表面发生化合反应。

图6 不同扫描速度条件下CBN磨粒表面的生成物的SEM像

Fig. 6 SEM images of compounds on CBN grain surface at different scanning speeds

图7 CBN表面化合物的EDX谱

Fig. 7 EDX spectrum of compounds on CBN surface

2.3 界面反应及化合物生长机理分析

图 8 Ti-B-N三元简化相图

Fig. 8 Simplified phase diagram of Ti-B-N system

一般认为,Ag-Cu-Ti钎料能够与和CBN磨粒实现润湿,是因为液态钎料中Cu和Ag元素的存在使金属Ti处于β相[5]。而β-Ti与B、N等非金属元素有较强的亲和力,使得活性金属Ti被CBN磨粒表面选择性吸附,Ti从靠近磨粒表面的液态Ag-Cu-Ti钎料合金中分离出来,在磨粒与液态钎料的接触面上富集,进而与CBN表面的B、N元素发生相互扩散和化合,最终生成化合物层[6]。DTA测试结果表明:Ti与CBN磨粒在605 ℃生成TiN,从807 ℃开始反应生成Ti-B化合物[9]。由于实验中的钎焊温度为940 ℃,高于807 ℃,因此,上述两个化学反应均可以发生。根据图8所示的Ti-B-N三元简化相图[10],由于CBN中B、N两种元素的摩尔比相同,因此,从相图可以初步判断其生成物可能是TiB2和TiN,即位于相图中的①区,其化学反应方程式如下所示[11]:

3Ti+2BN=TiB2+2TiN (1)

经计算上述反应的Gibbs生成自由能△G为-495 kJ/mol,该反应在本实验条件下可正向进行。

TiN的晶体构造为面心立方晶系,属于NaCl型结构,晶格常数a为0.4235 nm。化合生成的TiN晶体通常呈不规则颗粒状[12-13]。TiB2是B-Ti之间最稳定的化合物,属于六方晶系C32型结构的准金属化合物。其完整晶体的结构参数a为0.3026 nm,c为0.3228 nm。TiB2具有优良的导电性和金属光泽,其常温电阻率约为8.2×10-8 Ω·m,和一般金属相当[14]。由于TiB2晶体各向异性,极容易沿[0001]和 晶向择优生长,因此TiB2晶体通常呈棒状或须状[15]。从形态上可以判断图5中的颗粒状化合物A为TiN,亮白色的针状以及六棱柱状化合物B为TiB2。随着界面反应时间的增加,超高频感应连续钎焊CBN磨粒表面首先生成颗粒状TiN层,然后在TiN层外围形成柱状TiB2层,最终形成CBN/TiN/TiB2/钎料结构。柱状的TiB2进入钎料层内部,对CBN磨粒与钎料间的连接起到纤维增强效果,从而有利于提高界面的结合强度。

晶向择优生长,因此TiB2晶体通常呈棒状或须状[15]。从形态上可以判断图5中的颗粒状化合物A为TiN,亮白色的针状以及六棱柱状化合物B为TiB2。随着界面反应时间的增加,超高频感应连续钎焊CBN磨粒表面首先生成颗粒状TiN层,然后在TiN层外围形成柱状TiB2层,最终形成CBN/TiN/TiB2/钎料结构。柱状的TiB2进入钎料层内部,对CBN磨粒与钎料间的连接起到纤维增强效果,从而有利于提高界面的结合强度。

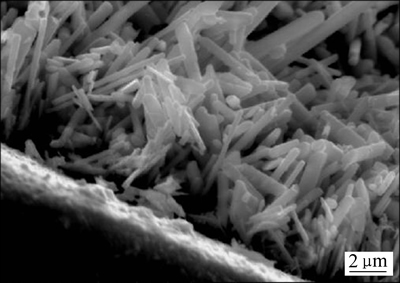

采用真空炉进行钎焊的研究表明:CBN磨粒表面被较厚的新生化合物TiB2、TiN等覆盖,而且CBN磨粒与钎料界面接头形式为CBN/TiB2/TiN/钎料结构[16] (见图9)。而在本实验中观察到的新生化合物层的数量更少,形貌也具有一定差异。因此,在超高频感应连续钎焊条件下,尽管钎料与磨粒在界面处发生了化学反应,但是新生的Ti-N、Ti-B化合物析出和长大过程却与炉中钎焊条件下存在不同。

CBN磨粒与活性元素Ti的界面反应是原子体积较小的N、B原子向Ti晶格内扩散的过程[7]。Ag-Cu-Ti合金在真空炉中钎焊条件下,界面反应在近似平衡条件下进行。当真空炉内温度达到605 ℃时,TiN先在CBN表面析出。由于温度变化缓慢,新生的TiN有足够的时间向钎料层内部生长,从而形成比较厚的TiN层,阻碍了B原子的扩散。随着温度逐渐上升到807 ℃以上,在CBN与新生TiN层界面处积累的B与TiN发生置换反应,形成TiB2层。

图9 Ag-Cu-Ti钎料真空炉中钎焊CBN的生成物SEM像[16]

Fig. 9 SEM image of compounds on CBN surface brazed in vacuum furnace with Ag-Cu-Ti alloy[16]

超高频感应加热产生的交变磁场对熔融的钎料具有强烈的电磁搅拌作用[17],能够加速原子在CBN磨粒与液态钎料界面处的扩散。因此,在温度迅速上升至940 ℃的较短时间内,TiN首先在CBN磨粒表面形核(见图5(a))。然而,B原子在液相Ti层中的溶解度和扩散系数均稍微大于N原子[18-19]。TiN生成之后,B原子在电磁搅拌作用的驱动下,不会在新生的TiN层附近积累,而是透过新生的TiN层迅速扩散出来,与Ti原子化合生成TiB2。由于界面反应在较短的时间内结束,因此界面最终形成CBN/TiN/TiB2/钎料结构,且新生化合物层较图9所示的更薄。

CBN磨粒界面处的新生化合物层是实现钎料对磨粒牢固连接的纽带。然而,新生的Ti-N和Ti-B化合物是脆性相,如果界面新生化合物层较厚,则在磨削过程中当磨粒受到冲击时,容易在界面处产生裂纹,形成断口[6]。因此,根据本实验中观察到的新生化合物层形貌,当扫描速度不高于0.5 mm/s时,界面化合物的数量较合适。相对于真空炉中钎焊获得的较厚新生化合物层,超高频感应连续钎焊工艺在更短的时间内形成了CBN磨粒与Ag-Cu-Ti合金的化学冶金结合,且更利于提高磨粒界面处在磨削过程中的抗冲击 能力。

3 结论

1) 随着扫描速度的变化,可见到颗粒状、针状和六棱柱状的化合物在CBN磨粒表面生成。颗粒状化合物尺寸为100 nm左右,针状和六棱柱状化合物直径小于200 nm。

2) 超高频感应连续钎焊CBN磨粒表面首先生成颗粒状TiN层,然后在TiN层外围生成柱状TiB2层,形成CBN/TiN/TiB2/钎料结构。

3) 当扫描速度为0.5 mm/s时,同时兼顾了界面结合强度和抗冲击能力,可以获得较合适的界面新生化合物层结构。

REFERENCES

[1] WEBSTER J, TRICARD M. Innovations in abrasive products for precision grinding[J]. CIRP Annals-Manufacturing Technology, 2004, 53(2): 597-617.

[2] CHATTOPADHYAY A K, HINTERMANN H E. On brazing of cubic boron nitride abrasive crystals to steel substrate with alloys containing Cr or Ti[J]. Journal of Materials Science, 1993, 28(21): 5887-5893.

[3] MIAO Q, DING W F, XU J H, YANG C Y, FU Y C. Fractal analysis of wear topography of brazed polycrystalline CBN abrasive grains during grinding nickel super alloy[J]. International Journal of Advanced Manufacturing Technology, 2013, 68(9/12): 2229-2236.

[4] JOHARI M R, HADIAN A M. Effect of brazing time on microstructure and mechanical properties of cubic boron nitride/steel joints[J]. Ceramics International, 2014, 40(6): 8519-8524.

[5] 卢金斌, 穆云超, 孟 普. 钛基钎料真空钎焊立方氮化硼的分析[J]. 焊接学报, 2010, 31(5): 57-60.

LU Jin-bin, MU Yun-chao, MENG Pu. Analysis on vacuum brazing of CBN grits with Ti-base filler[J]. Transaction of the China Welding Institution, 2010, 31(5): 57-60.

[6] PAL B, CHATTOPADHYAY A K, CHATTOPADHYAY A B. Development and performance evaluation of monolayer brazed cBN grinding wheel on bearing steel[J]. International Journal of Advanced Manufacturing Technology, 2010, 48(9/12): 935-944.

[7] 李奇林, 徐九华, 苏宏华, 谭 敏, 茅暑杰. 超高频连续感应钎焊金刚石界面特征[J]. 人工晶体学报, 2013, 42(1): 7-12.

LI Qi-lin, XU Jiu-hua, SU Hong-hua, TAN Min, MAO Shu-jie. Interfacial characteristics of diamond brazed by ultra-high frequency induction[J]. Journal of Synthetic Crystals, 2013, 42(1): 7-12.

[8] LI Q L, XU J H, SU H H. Simulation of temperature field in ultra-high frequency induction heating and verification[J]. Transactions of Nanjing University of Aeronautics and Astronautics, 2013, 30(2): 155-161.

[9] 王明智, 臧建兵, 王艳辉. 立方氮化硼表面镀Ti及其与金属粘结剂的作用[J]. 中国有色金属学报, 1997, 7(2): 107-109.

WANG Ming-zhi, ZANG Jian-bing, WANG Yan-hui. Interface between Ti-cladding CBN and metal alloy bond[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(2): 107-109.

[10] SHIN J H, CHOI K S, WANG T, KIM K H, NOWAK R. Microstructure evolution and mechanical properties of Ti-B-N coatings deposited by plasma-enhanced chemical vapor deposition[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S3): s722-s728.

[11] 李建林, 胡克鳌, 周 勇. 高能球磨过程中Ti与BN的反应[J]. 金属学报, 2001, 37(5): 547-550.

LI Jian-lin, HU Ke-ao, ZHOU Yong. Reaction of Ti with BN during high energy ball milling process[J]. Acta Metallurgica Sinica, 2001, 37(5): 547-550.

[12] WANG W, QIAN S Q, ZHOU X Y. Microstructure and properties of TiN/Ni composite coating prepared by plasma transferred arc scanning process[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1180-1184.

[13] 章 林, 路 新, 赵玉强, 曲选辉, 何新波, 秦明礼, 朱鸿民. 醇盐水解法制备TiN包覆SiC复合粉末[J]. 中国有色金属学报, 2012, 22(10): 2825-2832.

ZHANG Lin, LU Xin, ZHAO Yu-qiang, QU Xuan-hui, HE Xin-bo, QIN Ming-li, ZHU Hong-min. TiN coated SiC composite powders produced by controlled hydrolysis[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2825-2832.

[14] 黎军军, 赵学坪, 陶 强, 黄晓庆, 朱品文, 崔 田, 王 欣. 二硼化钛的高温高压制备及其物性[J]. 物理学报, 2013, 62(2): 491-497.

LI Jun-jun, ZHAO Xue-ping, TAO Qiang, HUANG Xiao-qin, ZHU Pin-wen, CUI Tian, WANG Xin. Characterization of TiB2 synthesized at high pressure and high temperature[J]. Acta Phys Sin, 2013, 62(2): 491-497.

[15] 周立娟, 郑永挺, 杜善义. AlN-TiN-TiB2复相陶瓷的显微结构和力学性能[J]. 稀有金属材料与工程, 2009, 38(S2): 502-505.

ZHOU Li-juan, ZHENG Yong-ting, DU Shan-yi. Microstructure and mechanical properties of AlN-TiN-TiB2 composite conductive ceramics[J]. Rare Metal Materials and Engineering, 2009, 38(S2): 502-505.

[16] 丁文锋, 徐九华, 傅玉灿, 苏宏华, 肖 冰, 徐鸿钧. 银铜钛合金与立方氮化硼磨粒钎焊界面显微分层结构及形成机理[J]. 机械工程学报, 2008, 44(6): 61-65.

DING Weng-feng, XU Jiu-hua, FU Yu-can, SU Hong-hua, XIAO Bing, XU Hong-jun. Delamination behavior and formation mechanism of the interfacial microstructure in the brazed joint of silver-copper-titanium alloy and cubic boron nitride grain[J]. Chinese Journal of Mechanical Engineering. 2008, 44(6): 61-65.

[17] 邓安元, 王恩刚, 徐永义, 张兴武, 赫冀成. 复合磁场作用下金属液面行为的实验研究[J]. 金属学报, 2010, 46(8): 1018-1024.

DENG An-yuan, WANG En-gang, XU Yong-yi, ZHANG Xing-wu, HE Ji-cheng. Experimental research on melting surface behavior in mold under compound magnetic field[J]. Acta Metall Sinica, 2010, 46(8): 1018-1024.

[18] 张群莉, 曾 启, 姚建华, 潘 颐. 激光复合溶胶-凝胶法制备TiN-TiB2强化涂层的组织与性能[J]. 应用激光, 2012, 32(6): 469-473.

ZHANG Qun-li, ZENG Qi, YAO Jian-hua, PAN Yi. Microstructure and property of TiN-TiB2 hardened coating prepared by hybrid method combined sol-gel with laser hardening[J]. Applied Laser, 2012, 32(6): 469-473.

[19] 丁元柱, 梁 刚. 钛合金表面氩弧熔覆原位合成TiB2-TiN显微组织与形成机理[J]. 材料开发与应用, 2012(4): 69-72.

DING Yuan-zhu, LIANG Gang. Microstructure and formation mechanism of in-situ TiB2-TiN in titanium alloy surface by argon arc cladding[J]. Materials Science and Technology, 2012(4): 69-72.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51275231);江苏省普通高校自然科学研究计划(14KJB460011);江苏省大学生创新创业训练计划(201411463003Z)

收稿日期:2014-10-14;修订日期:2015-03-05

通信作者:李奇林,讲师,博士:电话:0519-86953212;E-mail: liqilin@jsut.edu.cn