Trans. Nonferrous Met. Soc. China 23(2013) 1275-1280

Influence of addition of Grp/Al2O3p with SiCp on wear properties of aluminum alloy 6061-T6 hybrid composites via friction stir processing

A. DEVARAJU, A. KUMAR, B. KOTIVEERACHARI

Department of Mechanical Engineering, National Institute of Technology, Warangal, A.P., 506004, India

Received 2 July 2012; accepted 23 January 2013

Abstract: Aluminum alloy base surface hybrid composites were fabricated by incorporating with mixture of (SiC+Gr) and (SiC+Al2O3) particles of 20 μm in average size on an aluminum alloy 6061-T6 plate using friction stir processing (FSP). Microstructures of both the surface hybrid composites revealed that SiC, Gr and Al2O3 are uniformly dispersed in the nugget zone (NZ). It was observed that the addition of Gr particles rather than Al2O3 particles with SiC particles, decreases the microhardness but immensely increases the dry sliding wear resistance of aluminum alloy 6061-T6 surface hybrid composite. The observed microhardness and wear properties are correlated with microstructures and worn micrographs.

Key words: aluminum alloy; hybrid composite; friction stir processing; wear; solid lubricant; microstructure

1 Introduction

Aluminum alloy 6061-T6 is well known for wide utilization in aircraft, defence, automobiles and marine areas due to its good strength, low density and good corrosion properties. But, it exhibits inferior tribological properties in extensive usage [1,2]. In addition, the composites become brittle by the addition of reinforcements such as SiC and alumina ceramic particles [3]. A proper technique can be employed to refine the microstructure and homogeneously disperse reinforcements only on the metallic surface ever since wear is surface deprivation property [4]. Dispersion of reinforcement particles on the metal surface and control are more difficult to attain by conventional surface modification techniques [5]. Earlier researches [6,7] reported that thermal spraying and laser beam techniques were utilized to prepare surface composites, by which the properties were degraded due to creation of unfavourable phases. These techniques were operated at higher temperatures and impossible to avoid the reaction between the reinforcements and the matrix, which forms detrimental phase. In this concern, a process can be employed which is operated below melting temperature of matrix for the fabrication of surface composites. It could avoid the above mentioned complications.

Considering these problems, friction stir processing (FSP) is a successful technique intended for the preparation of surface composites and modification [8,9]. In FSP a rotating tool with shoulder and pin is plunged onto the surface of material, which creates frictional heat and dynamic mixing of metal underneath the tool and also to incorporate and/or disperse the reinforcement particles into the matrix such as aluminum alloys, magnesium alloys and copper [10,11].

The current authors [12] achieved homogeneous dispersion of SiC particles on a surface of aluminum alloy 6061-T6 via FSP. Hybrid composites were reinforced with a mixture of two or more different types of particles to obtain the individual properties of each. ESSAM [13] reported that Al-1050-H24/(20%Al2O3+ 80%SiC) hybrid composite had high hardness and superior wear resistance than the matrix material. The previous investigations [13,14] showed that Al2O3 and BN particles acted as solid lubricant similar to Gr during wear due to producing a tinny layer between the deformed surfaces, which decreased the coefficient of friction and enhanced the wear resistance.

The objective of the present work is to achieve the surface hybrid composites with better wear characteristics via FSP and also study the influence of the addition of Gr/Al2O3 with SiC particles on the wear properties and microhardness of aluminum alloy 6061-T6 surface hybrid composites.

2 Experimental

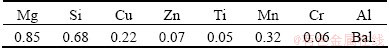

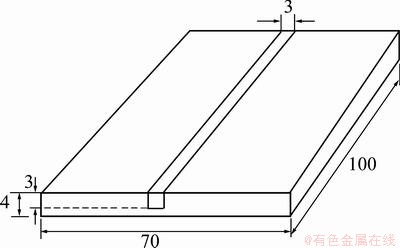

Aluminum alloy 6061-T6 rolled plate of 4 mm thickness was utilized as the matrix metal for making the surface hybrid composites. The nominal composition of aluminum alloy 6061-T6 is shown in Table 1. SiC, Gr and Al2O3 particles with various ratios were used as reinforcements. The reinforcement particles have the similar average particle size of 20 μm. The groove was made in dimensions of 3 mm width and 3 mm depth, which is tangential to the pin in the advancing side and 2 mm far away from the centre line of the tool rotation on the aluminum alloy 6061-T6 plate as shown in Fig. 1.

Table 1 Chemical composition of aluminum 6061-T6 alloy (mass fraction, %)

Fig. 1 Schematic diagram of aluminum alloy plate for FSP (unit: mm)

The tool was made of H13 tool steel with a shoulder diameter of 24 mm, screwed taper profile probe diameter of 8 mm and height of 3.5 mm. The reinforcement mixtures of (SiC+Gr) and (SiC+Al2O3) at volume ratio of 8%:4% respectively were packed in the groove. The groove was initially covered by means of the tool having only shoulder without pin to avoid the escape of reinforcement particles while processing. The rotational speed of 900 r/min, traveling speed of 40 mm/min, tool vertical force of 5 kN and tool onward tilt angle of 2.5° along the centre line were used. FSP was carried out on a vertical milling machine (Make: HMT FM-2, 7.35 kW, 3000 r/min). For hardness, microstructure analysis and wear tests, the specimens were cut from the stir zone using wire-cut EDM. Microstructural observations were carried out at the cross section of nugget zone (NZ) of surface hybrid composites normal to the FSP direction by optical microscope (OM). The specimens were mechanically polished and etched with Keller’s reagent (2 mL HF, 3 mL HCl, 20 mL HNO3 and 175 mL H2O). The microstructures of the surface hybrid composites were captured and presented. Microhardness test was carried out using Vickers digital microhardness tester (Make: Shimatzu, Model: HMV-2000) with a 15 g load and 15 s duration. Wear test was carried out on a pin-on-disc tribo meter (Make: Ducom, Model: TL-20ER) as per ASTM standard G99-05 under dry sliding conditions with a constant load of 40 N, rotational speed of 650 r/min and sliding speed of 3.4 m/s. Prismatic pins of 8 mm diameter were cut from the stir zone, with the axis of the pin normal to the FSP direction. The disc was made of EN31 steel with hardness of HRC 62. The diameter of the sliding track on the disc surface was 100 mm.

3 Results and discussion

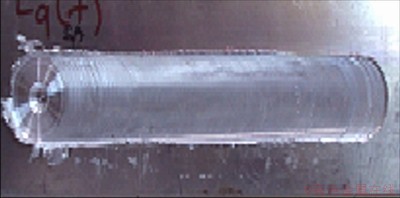

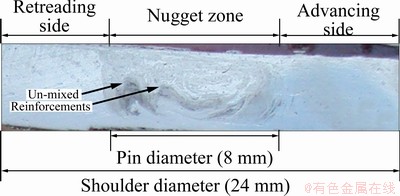

The surface hybrid composites were successfully fabricated via FSP as shown in Fig. 2. There were no imperfections such as cracks, voids on the surface. It also revealed that the top surface appears to be smooth and fine quality with almost no depressions. The cross sectional micrograph of the aluminum surface hybrid composite is shown in Fig. 3. It revealed clearly different regions on the surface hybrid composite after FSP.

Fig. 2 Macrograph of FSP zone of surface hybrid composite

Fig. 3 Cross-sectional micrograph of surface hybrid composite

3.1 Microstructures

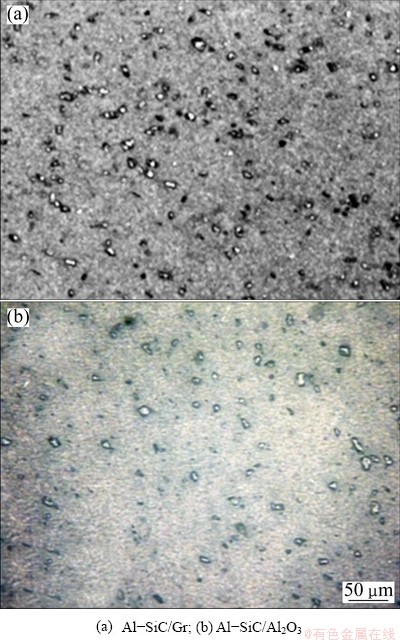

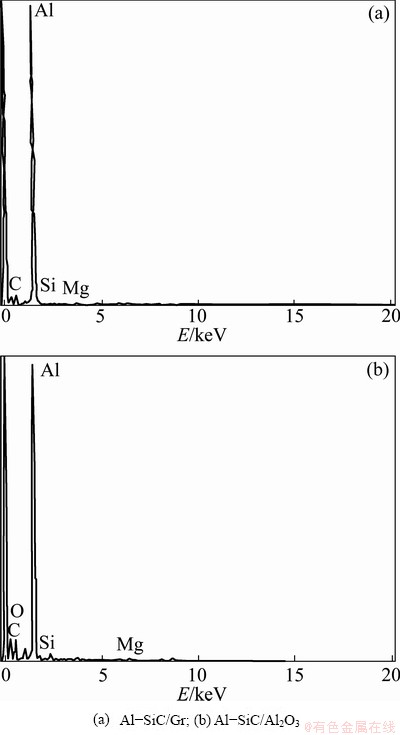

The size of nugget zone (NZ) was normally almost equal to the size of the rotating tool pin, width and depth of 8 mm and 3.5 mm, respectively. The particles of SiC, Gr and Al2O3 were observed to be dispersed uniformly within the NZ due to the existence of dynamic stirring of the rotating tool during the FSP, as shown in Fig. 4. It was observed that some reinforcement particles (SiC, Gr and Al2O3) are smaller in size than the as-received particles. This is because the tool provides a shear and circumferential force to break the reinforcement particles in the NZ. The similar observations were found in the previous work [15-17]. The chemical composition of the surface hybrid composites was analyzed by EDX and presented in Fig. 5, which shows that the surface hybrid composites are rich in Al and there are loss of Mg and Si contents during FSP.

Fig. 4 Microstructure of surface hybrid composites

3.2 Microhardness

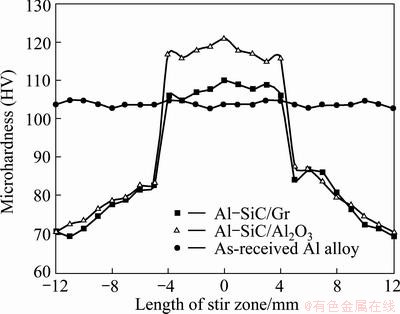

The microhardness was measured and presented in Fig. 6. As compared with the average hardness of about HV 104 of matrix material, the hardness value of both Al-SiC/Gr (about HV 108) and Al-SiC/Al2O3 (about HV120) surface hybrid composites were increased due to the presence of hard reinforcement particles. FSPed aluminum alloy 6061-T6/SiCp composite had higher microhardness due to the presence and pinning effect of SiC particles [12]. In the current investigation, Al-SiC/Gr hybrid composite showed lower hardness value due to the presence of soft Gr phase. While the Al-SiC/Al2O3 showed higher hardness value due to the presence of two hard particles of SiC and Al2O3. The higher hardness of the surface hybrid composites is mainly due to the presence and pinning effect of reinforcement particles and the Orowan strengthening [9].

Fig. 5 EDX analysis of surface hybrid composites

Fig. 6 Microhardness of Al-SiC/Gr and Al-SiC/Al2O3 surface hybrid composites

3.3 Wear characteristics

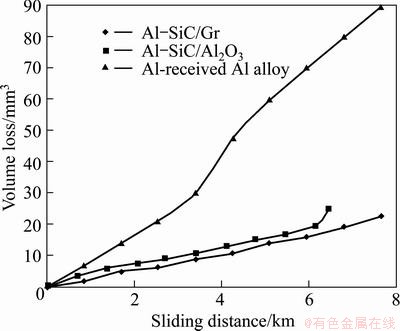

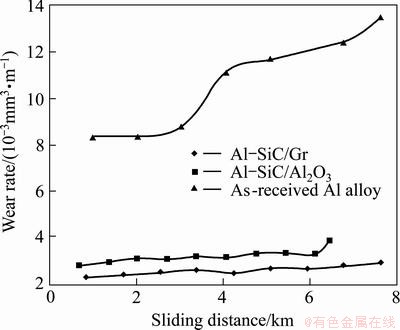

Figure 7 shows the comparison of wear in terms of volume loss as a function of sliding distance. It revealed that the wear increased with increasing the sliding distance for both the surface hybrid composites. Figure 8 shows the wear rate with respect to the sliding distance. It is observed that the wear rate (volume loss/ sliding distance) increased with sliding distance increasing. However, the presence of tribo-mechanically mixed layer acted as solid lubricant which resulted in less wear rates, and led to smaller coefficient of friction [12,16]. From Figs. 7 and 8, both the wear and wear rate were significantly lower for the Al-SiC/Gr composite as compared with the Al-SiC/Al2O3 composite. The improved wear resistance is due to the mechanically mixed layer generated between the composite pin and steel disc surfaces which contained fractured SiC and Gr, where the presence of Gr performed as a solid lubricant which decreased the wear [12,18]. Whereas in the Al-SiC/Al2O3 surface hybrid composite, during the wear process, the hard SiC and Al2O3 particles were pulled out of steel disc, which acted as barrier. Hence, it converted the adhesive wear mode to abrasive wear mode [17]. This phenomenon may not occur in the Al-SiC/Gr surface hybrid composite even though it contains hard SiC, because the presence of soft Gr phase exhibits solid lubricant effect, which reduces the wear.

Fig. 7 Change in volume loss with sliding distance of Al-SiC/Gr and Al-SiC/Al2O3 surface hybrid composites

Fig. 8 Change in wear rate with sliding distance of Al-SiC/Gr and Al-SiC/Al2O3 surface hybrid composites

Furthermore, TJONG et al [14] described that using SiC and BN particles as reinforcement in 6061Al alloy by PM, the addition of 5% (volume fraction) BN to 15% SiCp/Al metal matrix composites improved the wear resistance, and proved that BN particles exhibited a solid lubricant effect like graphite during sliding by forming a thin layer on the deformed surface, which reduced the coefficient of friction and improved the wear resistance. ESSAM [13] also proved that Al2O3 particles exhibited a solid lubricant effect like BN particles during sliding by forming a thin layer on the deformed surface, which reduced the coefficient of friction and improved the wear resistance. This is because Al2O3 particles may play the same role as BN particles, since they have similar hexagonal crystal structure [19].

In the present investigation, Al-SiC/Gr and Al-SiC/Al2O3 surface hybrid composites exhibited lower wear rate compared with the as-received Al alloy, due to the hybrid reinforcements which give the combined effect of individual reinforcement. The improved wear resistance in the case of Al-SiC/Gr surface hybrid composite is due to the presence of SiC acting as load bearing elements and Gr acting as solid lubricant, whereas in the case of Al-SiC/Al2O3 surface hybrid composite, the presence of SiC acts as load bearing elements and Al2O3 acts as solid lubricant. Al-SiC/Gr surface composite exhibited more wear resistance than Al-SiC/Al2O3 surface hybrid composite. This is because Gr exhibits more solid lubricant effect than the Al2O3 particles.

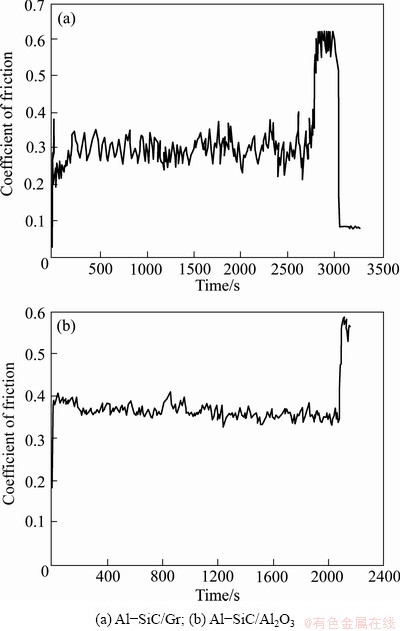

Fig. 9 Change in coefficient of friction with sliding time of surface hybrid composites

Figure 9 shows the variations of coefficient of friction of surface hybrid composites as a function of sliding time. It is seen that the coefficient of friction of the Al-SiC/Gr surface hybrid composite was fairly low (average of 0.30) as compared with the Al-SiC/Al2O3 surface hybrid composite (average of 0.36). This can be attributed to the presence of Gr which may reduce the shear stress at the subsurface. From the results, it is concluded that the Al-SiC/Gr surface hybrid composite exhibited superior wear resistance as compared to the Al-SiC/Al2O3.

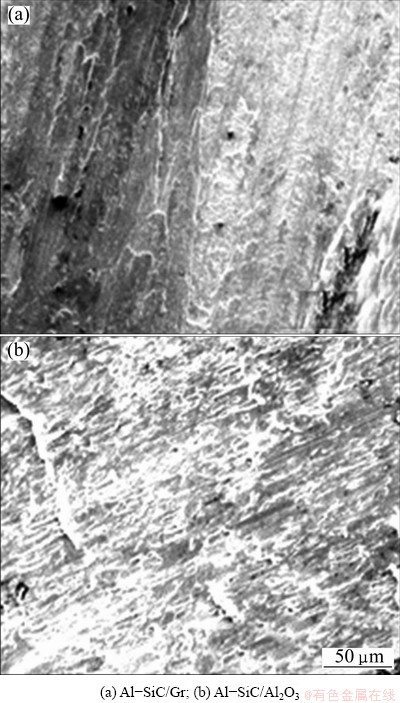

Figure 10 shows the SEM microstructures of worn tracks of the Al-SiC/Gr and Al-SiC/Al2O3 surface hybrid composites against a steel disk. It is seen that the scratches are less in Al-SiC/Gr composite than in the Al-SiC/Al2O3 composite. This is because the presence of Gr in the Al-SiC/Gr composite performs wear in adhesive manner, and in the Al-SiC/Al2O3 composite, the presence of Al2O3 performs wear in the abrasive manner. There seems to be less abrasive wear on the Al-SiC/Gr composite than on the Al-SiC/Al2O3 composite, caused by Gr on the worn surface which is much softer than Al2O3.

Fig. 10 SEM micrographs of worn track of surface hybrid composites

4 Conclusions

1) The reinforcement particles of mixture of (SiC+Gr) and (SiC+Al2O3) were distributed uniformly inside the nugget zone with devoid of imperfections.

2) The hardness values of both Al-SiC/Gr (about HV 108) and Al-SiC/Al2O3 (about HV 120) surface hybrid composites were increased as compared with the average hardness of about HV 104 of the aluminum matrix due to the presence of hard reinforcement particles.

3) The Al-SiC/Gr hybrid composite showed lower hardness value due to the soft Gr phase, whereas the Al-SiC/Al2O3 showed higher hardness value due to the presence of both harder phase particles.

4) The Al-SiC/Gr surface hybrid composite showed less coefficient of friction than the Al-SiC/Al2O3 surface hybrid composite.

5) The Al-SiC/Gr surface hybrid composite exhibited superior wear resistance than the Al-SiC/Al2O3 surface hybrid composite, due to the formation of thin and hard mechanically mixed layer containing Gr which exhibited more solid lubricant effect than Al2O3.

Acknowledgements

The authors like to thank the authorities of National Institute of Technology (NIT), Warangal, India for providing the facilities to carry out this work.

References

[1] BAKES H, BENJAMIN D, KIRKPATRICK C W. Metals handbook [M]. Metals Park, OH: ASM, 1979, 2: 3-23.

[2] RAVI N, SASTIKUMAR D, SUBRAMANIAN N, NATH A K, MASILAMANI V. Microhardness and microstructure studies on laser surface alloyed aluminium alloy with Ni-Cr [J]. Materials and Manufacturing Processes, 2000, 15: 395-404.

[3] CLYNE T W, WITHERS P J. An introduction to metal matrix composites [M]. Cambridge: Cambridge University Press, 1993.

[4] RABINOWICZ E. Friction and wear of materials [M]. New York: John Wiley & Sons, 1965.

[5] BUDINSKI K G. Surface engineering for wear resistance [M]. New Jersey: Prentice-Hall, 1988.

[6] GUPTA M,MOHAMED F A, LAVERNIA E J. Solidification behavior of Al-Li-SiCpMMCs processed using variable co-deposition of multi-phase materials [J]. Materials and Manufacturing Processes, 1990, 5(2): 165-196.

[7] MABHALI L A B, PITYANA S L, SACKS N. Laser surface alloying of aluminum (AA1200) with Ni and SiC powders [J]. Materials and Manufacturing Processes, 2010, 25(12): 1397-1403.

[8] MISHRA R S, MA Z Y, CHARIT I. Friction stir processing—A novel technique for fabrication of surface composites [J]. Mater Sci Eng A, 2003, 341: 307–310.

[9] MA Z Y. Friction stir processing technology: A review [J]. Metall Mater Trans A, 2008, 39: 642-58.

[10] ASADI P, BESHARATI GIVI M K, FARAJI G. Producing ultrafine- grained AZ91 from as-cast AZ91 by FSP [J]. Materials and Manufacturing Processes, 2010, 25(11): 1219-1226.

[11] DEHGHANI K, MAZINANI M. Forming nanocrystalline surface layers in copper using friction stir prpocessing [J]. Materials and Manufacturing Processes, 2011, 26(7): 922-925.

[12] DEVARAJU A, KUMAR A. Dry sliding wear and static immersion corrosion resistance of aluminum alloy 6061-T6/SiCp metal matrix composite prepared via friction stir processing [J]. Int J of Adv Res Mech Engg, 2011, 1(2): 62-68.

[13] ESSAM R I. Wear characteristics of surface-hybrid-MMCs layer fabricated on aluminum plate by friction stir processing [J]. Wear, 2010, 268: 1111-1121.

[14] TJONG S C, LAU K C, WU S Q. Wear of Al-based hybrid composites containing BN and SiC particulates [J]. Metall Mater Trans A, 1999, 30: 2551-2555.

[15] WEI W. A novel way to produce bulk SiCp reinforced aluminum metal matrix composites by friction stir processing [J]. Journal of Materials Processing Technology, 2009, 209: 2099-2103.

[16] MIN Y. Fabrication of AA6061/Al2O3 nano ceramic particle reinforced composite coating by using friction stir processing [J]. J Mater Sci, 2010, 45: 4431-4438.

[17] SHAFIEI Z A. Microstructure and mechanical properties of Al/Al2O3 surface nano-composite layer produced by friction stir processing [J]. Mater Sci Eng A, 2009, 500: 84-91.

[18] TED G M L. Tribological behaviour of self-lubricating aluminium/SiC/graphite hybrid composites synthesized by the semi-solid powder densification method [J]. Comp Science and Technology, 2000, 60: 65-74.

[19] MARINOPOULOS A G, NUFER S,  C. Interfacial structures and energetics of basal twins inα-Al2O3: First-principles density-functional and empirical calculations [J]. Phys Rev B, 2001, 63: 165112.

C. Interfacial structures and energetics of basal twins inα-Al2O3: First-principles density-functional and empirical calculations [J]. Phys Rev B, 2001, 63: 165112.

添加石墨/Al2O3和SiC颗粒对搅拌摩擦加工技术制备6061-T6铝基复合材料磨损性能的影响

A. DEVARAJU, A. KUMAR, B. KOTIVEERACHARI

Department of Mechanical Engineering, National Institute of Technology, Warangal, A.P., 506004, India

摘 要:采用搅拌摩擦加工技术,将平均粒径为20 μm的(SiC+石墨)或(SiC+Al2O3)混合粉末掺入到6061-T6铝合金板中,制备铝基表面混杂复合材料。组织观察结果表明,SiC、石墨和Al2O3颗粒均匀分散于铝基表面复合材料的焊合区中。与添加Al2O3和SiC相比,添加石墨和SiC颗粒虽然使表面复合材料的显微硬度有所降低,但却使其磨损性能得到显著提升。对复合材料的显微组织和磨损表面进行了分析。

关键词:铝合金;混杂复合材料;搅拌摩擦加工;磨损;固体润滑;显微组织

(Edited by Sai-qian YUAN)

Corresponding author: A. DEVARAJU; Tel: +91-9963336460; Fax: + 91-8702462834; E-mail: aruri_devaraj@yahoo.com

DOI: 10.1016/S1003-6326(13)62593-5