DOI: 10.11817/j.ysxb.1004.0609.2020-37664

超高强Al-Zn-Mg-Cu合金挤压型材粗晶环的热处理调控工艺

韩宝帅,曾元松,徐严谨,刘雅菲,马晓光

(中国航空制造技术研究院,北京 100024)

摘 要:粗晶环是铝合金挤压型材内常见的组织结构,降低了组织与性能的均匀性。本文设计了一系列阶梯式热处理工艺,利用不同温度阶段的回复作用消除变形过程累积的畸变能,控制固溶后超高强Al-Zn-Mg-Cu合金挤压型材内粗晶环的尺寸。结果表明:经(250 ℃, 24 h)、(300 ℃, 24 h)、(350 ℃, 24 h)、(400 ℃, 24 h)热处理后,粗晶环平均宽度降至未经处理的1/10~1/7,同时沿厚度方向拉伸性能均匀性显著提高。本研究为优化超高强Al-Zn-Mg-Cu合金型材的组织与性能提供了可参考办法。

关键词:超高强铝合金;Al-Zn-Mg-Cu;粗晶环;热处理;晶粒组织;力学性能

文章编号:1004-0609(2020)-09-2022-10 中图分类号:TG379 文献标志码:A

超高强铝合金是指高合金化的Al-Zn-Mg-Cu合金,Zn含量通常在10%(质量分数)以上,抗拉强度在750 MPa以上[1],相比目前广泛使用的7075[2]、7050[3]、7055[4]等材料具有显著的优势,对实现结构轻量化具有重要意义。挤压型材是超高强Al-Zn-Mg-Cu合金的一种重要使用形式,但经热处理后在挤压型材边缘区域易形成粗大的环状晶粒区域[5],即粗晶环。受粗晶环影响,铝合金挤压型材的力学性能、耐腐蚀性能均显著降低,加工与使用过程中表层易开裂或脱落。而如果采用切削加工的方式去除掉粗晶环,则会造成材料的严重浪费,并且构件尺寸精度不易保证,增加了使用成本[6]。

通常认为,粗晶环的产生与变形过程中挤压坯料和挤压筒壁之间的摩擦有关[5]:受到挤压筒内壁的约束作用,挤压坯料外层材料流动滞后于芯部;在挤压力和摩擦力复合作用下,外层材料发生的变形程度显著的高于芯部材料,晶粒内积累了高密度的位错与较高的畸变能,再结晶温度降低,在固溶过程中极易发生再结晶,且晶粒长大程度不易控制,形成粗晶环。目前,控制粗晶环的办法主要有以下几种:1) 优化挤压工艺过程,如高挤压温度,降低挤压速度,或选用多孔挤压模具、降低变形抗力,采用反向挤压技术、减小坯锭与挤压筒间的摩擦力,以及使用润滑剂等[7];2) 缩短固溶时间,抑制晶粒长大[8];3) 在淬火前进行足够的冷变形,使边缘区域晶粒破碎,高再结晶形核率,减少粗晶[5, 9];4) 优化化学成分,利用Cr[10]、Mn[11]等元素形成的第二相粒子,钉扎晶界、抑制晶粒长大。但由于超高强Al-Zn-Mg-Cu合金的变形抗力大,挤压变形工艺区间窄、优化范围有限[12];并且由于合金元素含量高,缩短固溶时间不利于合金元素充分回溶,影响了后续时效析出过程,降低了超高强Al-Zn-Mg- Cu合金的力学性能。因此,前文控制粗晶环的方法不适用于超高强Al-Zn-Mg-Cu合金挤压型材,亟需开发合理的工艺。

研究发现,热处理具有释放变形能[13]、抑制铝合金的再结晶[14-16]的作用。基于此,本文探索热处理工艺对粗晶环尺寸的影响,寻找调控超高强Al-Zn-Mg- Cu合金挤压型材粗晶环的办法,并分析其对组织与性能的影响。

1 实验

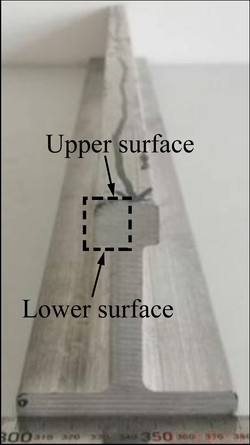

采用的超高强Al-Zn-Mg-Cu合金锭坯由江苏豪然喷射成形合金有限公司提供,成分经ICP法测定为 Al-11.88Zn-2.85Mg-1.1.Cu-0.13Zr(质量分数,%)。初始铸锭直径为600 mm,经挤压成形“工”字型材,如图1所示。选定“工”字型材的上部窄横梁作为研究对象,考虑型材结构的对称性,利用型材上部窄横梁一半区域的微观组织代替整体微观组织,如图1中所示。本文制定的热处理过程工艺参数如表1所列。

图1 超高强Al-Zn-Mg-Cu合金挤压型材结构

Fig. 1 Structure of ultrahigh strength Al-Zn-Mg-Cu alloy extrusion profile

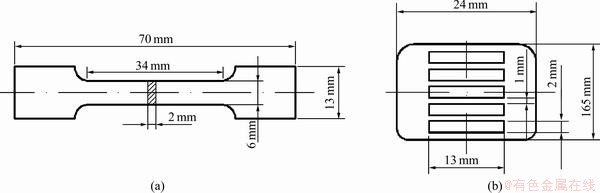

金相试样的制备过程如下:试样经240、600、1000、1500和2000号砂纸打磨后,在抛光机上进行机械抛光,抛光剂为粒径0.5 μm的金刚石悬浮液。利用金相显微镜(OM,DM6000M,Leica)观察金相组织;利用扫描电镜(S-4300,Hitachi,Japan)观察断口形貌。拉伸实验在电子万能试验机(Instron5569)上进行,拉伸速率为2 mm/min;选用板状拉伸试样,试样厚度2 mm,详细尺寸与取样位置见图2。为控制实验误差,相同位置沿挤压方向取5根试样,计算平均值。

2 结果与分析

2.1 粗晶环对超高强Al-Zn-Mg-Cu合金的组织与性能的影响

2.1.1 微观组织

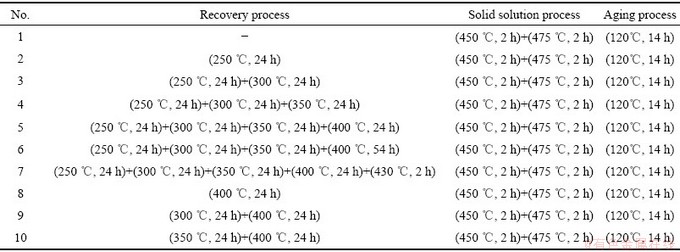

表1 热处理工艺

Table 1 Heat treatment process

图2 拉伸试样尺寸和分布位置

Fig. 2 Dimension of specimen sin tensile test(a) and sampling location(b)

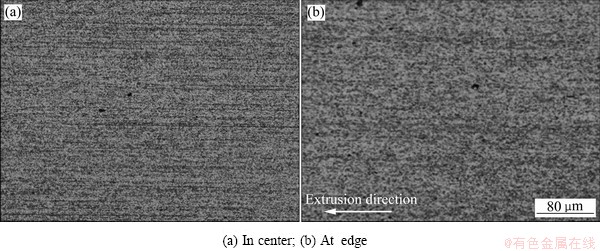

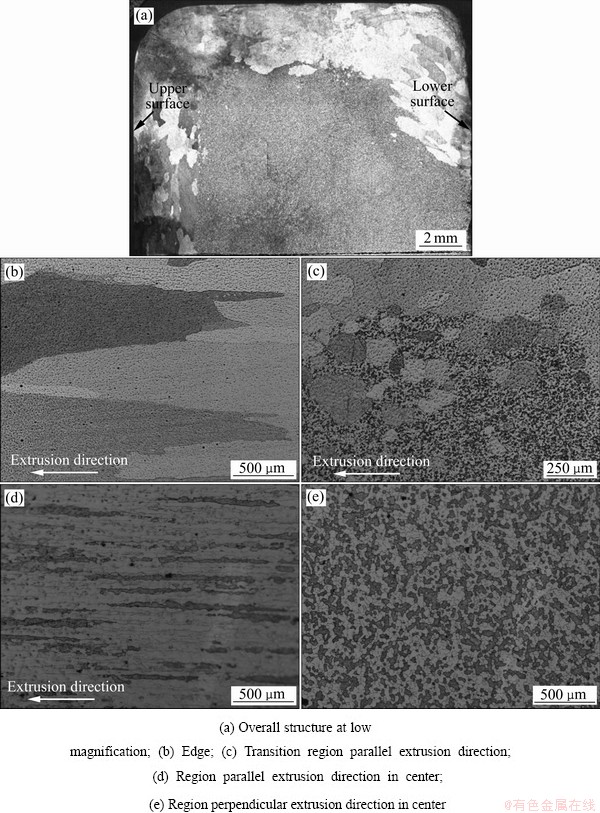

挤压态型材芯部及边缘的微观组织如图3所示。可以看出,型材芯部位置保持着完整的挤压流线,流线方向平行挤压方向;而边缘区域也保持着平行挤压方向的流线,但流线分布不如芯部清晰完整。分析认为,由于表层区域受到推杆挤压力与模具的摩擦力的作用,晶内畸变能较高,挤压过程发生了动态再结晶,挤压流线结构被部分破坏,而芯部位置的主要受挤压力作用,晶内畸变能低,再结晶作用微弱,流线结构未受到影响。

图3 超高强Al-Zn-Mg-Cu合金挤压型材平行挤压方向微观组织

Fig. 3 Microstructures of ultrahigh strength Al-Zn-Mg-Cu alloy extrusion profile parallel extrusion direction

图4 经工艺1处理超高强Al-Zn-Mg-Cu合金挤压型材微观组织

Fig. 4 Microstructures of ultrahigh strength Al-Zn-Mg-Cu alloy extrusion profile treated by process 1

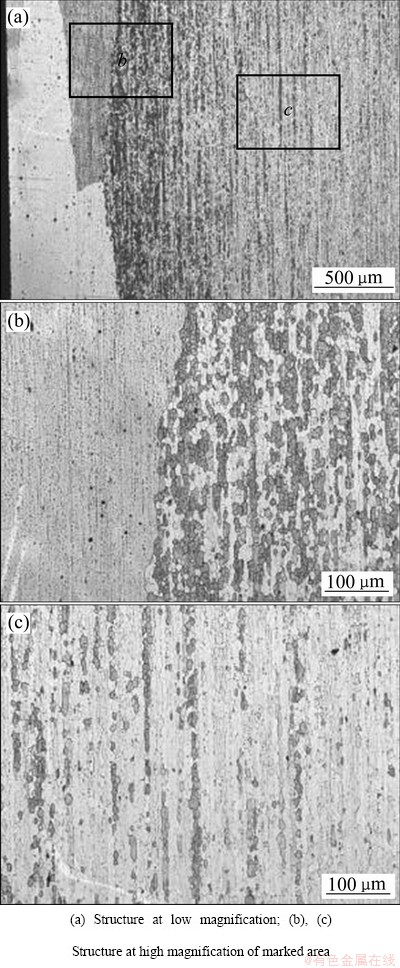

经工艺1处理后,挤压型材横截面上出现了粗晶结构,厚度为2.0~3.5 mm,如图4(a)所示。在型材的边缘区域,晶粒最大宽度超过0.6 mm,长度超过2 mm。在边缘粗晶层与芯部细晶层之间的过渡区域,存在着尺寸较大的等轴晶粒,尺寸分布在50~100 μm之间,如图4(c)所示。而在型材芯部的区域,晶粒保持着挤压态的结构,如图4(d)和(e)所示。整体上看,经工艺1处理后,挤压型材内部形成了典型的粗晶环。

2.1.2 力学性能

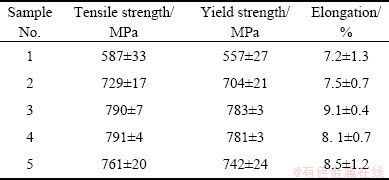

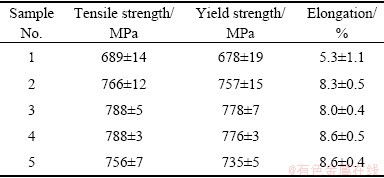

沿“工”字型材的上部窄横梁由上向下取样的拉伸力学性能如表2所示。受粗晶环的影响,表层部位(试样1#)的抗拉强度仅仅为(587±33) MPa,接近7075铝合金的水平[9, 17],远远低于常规超高强Al-Zn-Mg-Cu合金的强度。随着取样位置的下移,粗晶环的影响逐渐降低,强度迅速升高,试样3#与4#的抗拉强度最高接近800 MPa,屈服强度在780 MPa以上,同时伸长率也显著提高到8%以上。相比较于成分相近的合金,如果不考虑粗晶环的影响,本文中挤压型材的抗拉强度、屈服强度以及伸长率与现阶段的研究结果[8, 18-20]相比具一定的优势。取样位置继续下移,受下表面的粗晶环的影响,试样5#抗拉强度与屈服强度降低、伸长率的波动范围明显增加。

表2 带有粗晶结构的挤压型材力学性能

Table 2 Mechanical properties of extrusion profile with coarse crystal structure

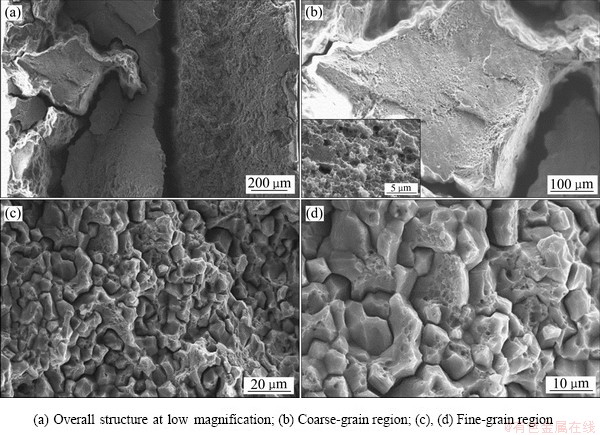

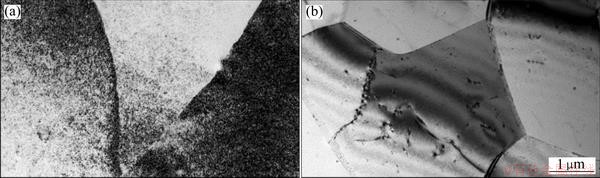

试样1#的断口形貌如图5所示。可以看出,粗晶区域与细晶区域发生了明显的分层,如图5(a)所示。通常情况下,再结晶形成的大角晶界的结合力较弱,粗晶区域与细晶区域的结合不牢固,在外力作用下极易开裂,晶间的开裂十分严重。粗晶区域的断裂方式为穿晶断裂,晶粒横截面上分布着大量极浅的韧窝,如图5(b)所示。在细晶区域,晶粒的断裂方式为沿晶断裂与穿晶断裂的组合形式,晶内的韧窝深度显著高于粗晶区域,如图5(c)和(d)所示,这表明在细晶区域经历了较大的塑性变形过程。

显然,粗晶结构降低了超高强Al-Zn-Mg-Cu合金的拉伸力学性能。通常情况下,晶粒尺寸越大,单个位错从晶内位错源运动到晶界的行进距离越大,晶内的位错塞积数目显著高于细小晶粒,单个晶粒内产生的应力集中严重,在较小的载荷下裂纹开始萌生并随着进一步的扩展导致断裂,力学性能较差[21]。随着晶粒尺寸减小,上述应力集中情况降低,塑性变形过程得以有效进行,裂纹产生与扩展过程推迟,强度提高。

图5 含有粗晶结构超高强Al-Zn-Mg-Cu合金断口形貌

Fig. 5 Fracture morphologies of ultra-high strength Al-Zn-Mg-Cu alloy with coarse-grain structures

2.2 热处理对粗晶环尺寸的影响

2.2.1 微观组织

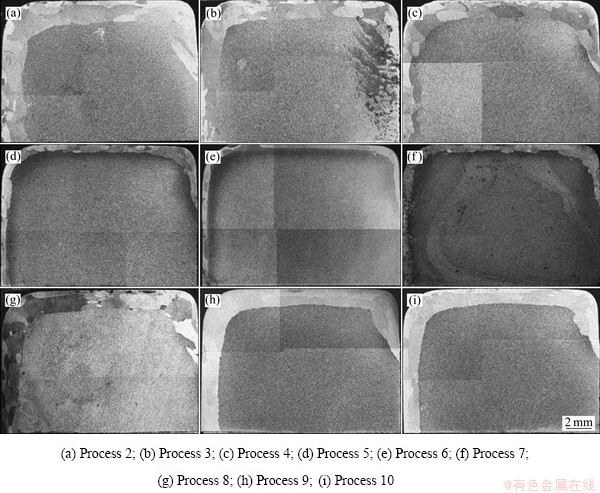

经工艺2~10处理后的挤压型材粗晶环结构如图6所示。可以看出,工艺2处理产生的粗晶结构区域的面积小于直接固溶处理合金材料的,如图6(a)所示;随着热处理温度的阶梯式升高,粗晶结构的区域面积显著降低(见图6(b)~(d)),表明在每一级的热处理过程中,都有一定量的变形畸变能被消除[14]。温度增加到400 ℃处理24 h(工艺5)后,粗晶环的尺寸显著降低,厚度降低到0.3~0.5 mm。进一步延长400 ℃保温时间至54 h(见图6(e)),粗晶环的厚度降低到0.2~0.4 mm。如果继续延长400 ℃保温时间,粗晶环的尺寸会进一步缩小,但考虑到经济效益,回复时间应不宜过长。而升高温度至430 ℃(工艺7),粗晶环则有粗化的趋势,如图6(f)所示,因此回复阶段的温度不宜超过400 ℃。

尽管400 ℃保温阶段对粗晶环的尺寸有着重要的影响,但并不代表只在该温度下保温就可以消除粗晶环。工艺8(400 ℃处理24 h)的微观组织如图6(g)所示,粗晶环宽度为1.2~1.7 mm,低于直接固溶处理的合金,但显著高于工艺5、6处理的合金。另外,在工艺8的基础上增加了300 ℃(工艺9)和350 ℃(工艺10)热处理后,粗晶环的尺寸较工艺7略有降低,但效果仍然远不如工艺5和6。上述实验结果表明,阶梯热处理过程中每阶段的保温对粗晶环尺寸的降低均起到了积极作用,是不可或缺的。

根据文献[7, 21]可知,在温度大于0.3Tm(Tm为熔点)时铝合金已经开始发生回复,如纯铝材料的回复起始温度为240 ℃[16]左右。此阶段合金内部的点缺陷(如空位)开始发生运动,位错也被激活,在内应力作用下开始滑移,部分异号位错相遇后抵消,以及位错扩散到晶界后发生湮灭,位错密度降低。随着温度升高,位错运动速度加快,回复作用效果更加显著,越来越多的变形储能被逐渐释放,后续固溶过程中晶粒发生再结晶的动力越来越低,形成粗晶环的尺寸则越来越小。透射电镜结果显示,相较于挤压态,经工艺5回复热处理后的铝合金内部的位错密度大幅度降低,如图7所示。在文献[22]中,邓运来等通过透射电镜观察了200~490 ℃间7050铝合金晶粒内部的位错密度变化,讨论了不同热处理温度下组织变化,发现较高的热处理温度有助于降低晶内位错密度,支持了本文的结果。另外,温度升高有利于合金内析出相的溶解,减少对位错的钉扎作用[17],降低位错运动阻力,促进变形储能释放。

图6 不同热处理工艺处理后超高强Al-Zn-Mg-Cu合金型材截面晶粒结构

Fig. 6 Grain structures at cross section of ultra-high strength Al-Zn-Mg-Cu alloy extrusion profile treated by different heat treatment processes

图7 不同超高强Al-Zn-Mg-Cu合金型材边缘区域微观组织

Fig. 7 Microstructures at edge region of different ultra-high strength Al-Zn-Mg-Cu alloy extrusion profiles treated by solid solution(a) and treated by process 5(b)

经工艺5热处理后超高强Al-Zn-Mg-Cu的平行挤压方向的微观组织如图8所示。同图4(c)相似,边缘粗晶环区域与芯部细小晶粒区域间存在一个过渡的区域,在这个区域内晶粒包括条状晶粒和等轴状晶粒,在一定程度上保留着挤压态的流线结构,如图8(a)、(b)所示。显然等轴晶粒是挤压态组织发生再结晶产生的[23-24],不同于图4(c)的结果,由于变形能大部分被消除,这部分晶粒没有发生异常长大。而在芯部区域,则完整的保留了挤压流线结构,如图8(c)所示。

2.2.2 力学性能

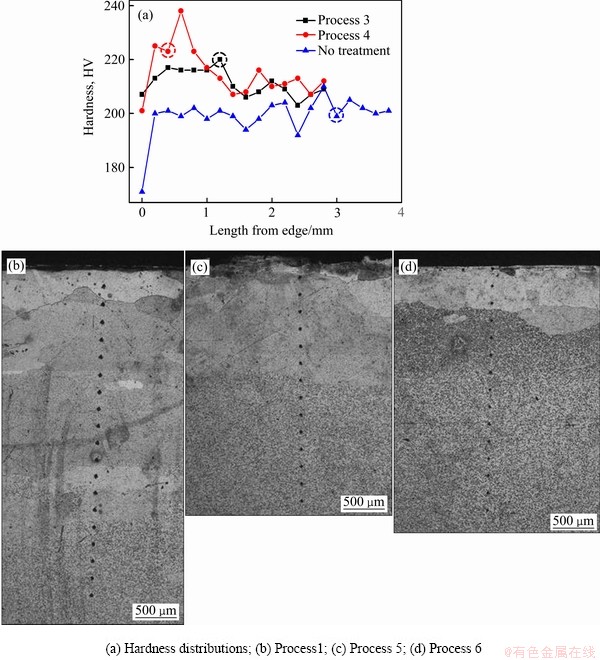

不同粗晶环宽度型材的典型硬度分布如图9(a)所示,图9(a)中标注圆圈的数据为紧邻细晶区域的粗晶环区域的硬度值。结合压痕的位置发现:除试样边缘处位置的硬度普遍较低外,粗晶环区域的硬度均不低于细晶区域的硬度,这在工艺5、6处理的超高强Al-Zn- Mg-Cu合金中表现得比较明显。由于粗晶环区域的晶粒较大,测试得到的硬度值可以认为是晶内力学性能反应,而细晶区域硬度则是晶内与晶间力学性能的综合反应。考虑到晶内的析出相是细小弥散的η’相[1, 20],而晶界上是粗大的η相[25],晶内的强度显著高于晶间的强度,因此粗晶区域的硬度高于细晶区域的硬度。

热处理后不同位置取样的拉伸性能如表3所列,经热处理后,沿厚度方向力学性能的均匀性显著升高。尽管表层材料的性能仍然较低,但性能受粗晶区域的影响显著降低,抗拉强度接近700 MPa;其余位置的抗拉强度均在750 MPa以上,伸长率也在8%以上,相比7050、7055等高强铝合金[17, 26-28]具有明显的优势。

图8 经工艺5热处理后超高强Al-Zn-Mg-Cu合金型材平行挤压方向的微观组织

Fig. 8 Microstructure parallel extrusion direction of ultra-high strength Al-Zn-Mg-Cu alloy extrusion profile treated by process 5

图9 不同热处理工艺下超高强Al-Zn-Mg-Cu合金型材沿厚度方向硬度和压痕分布

Fig. 9 Hardness(a) and indentation((b), (c), (d)) distributions along thickness of ultra-high strength Al-Zn-Mg-Cu alloy extrusion profiles under different heat treatment processes

表3 热处理后型材的力学性能

Table 3 Mechanical properties of extrusion profile after heat treatment

结合组织与性能分析,本文提出的热处理工艺对消除超高强铝合金挤压型材的粗晶环起到了一定的作用。但仍存在一定的问题:1) 经热处理后,超高强铝合金的表面仍存在一定厚度的粗晶环,对组织和力学性能仍产生一定不良的影响;2) 本文中的工艺4和工艺5的效果最明显,但整个工艺过程需要96 h以上,较长的耗时降低了这种工艺的可应用性。因此,在后续的研究中,研究团队将继续相关研究,优化工艺。

3 结论

1) 采用了热处理技术来控制超高强Al-Zn-Mg- Cu合金挤压型材粗晶环的尺寸,最终确定最佳的热处理工艺为(250 ℃, 24 h)+(300 ℃, 24 h)+(350 ℃, 24 h) + (400 ℃, 24~54 h)。

2) 经过上述工艺处理后,粗晶环的宽度降至0.5 mm以下;得益于粗晶环尺寸的缩小,力学性能分布的不均匀性显著降低,沿厚度方向的抗拉强度均接近或超过700 MPa。

REFERENCES

[1] DITTA A, WEI L, XU Y, WU S. Effect of hot extrusion and optimal solution treatment on microstructure and properties of spray-formed Al-11.3Zn-2.65Mg-1Cu alloy[J]. Journal of Alloys & Compounds, 2019, 797: 558-565.

[2] ZOU X, YAN H, CHEN X. Evolution of second phases and mechanical properties of 7075 Al alloy processed by solution heat treatment[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(10): 2146-2155.

[3] 侯陇刚, 刘明荔, 王新东, 庄林忠, 张济山. 高强7050铝合金超低温大变形加工与组织、性能调控[J]. 金属学报, 2017, 53(9): 1075-1090.

HOU Long-gang, LIU Ming-li, WANG Xin-dong, ZHUANG Lin-zhong, ZHANG Ji-shan. Cryogenic processing high-strength 7050 aluminum alloy and controlling of the microstructures and mechanical properties[J]. Acta Metallurgica Sinica, 2017, 53(9): 1075-1090.

[4] 冯 迪, 刘胜胆, 韩念梅, 陈洪美, 曹文奎, 韩仲杰. 7A55铝合金-RRA态厚板组织和性能及其不均匀性的多因素影响[J]. 中国有色金属学报, 2019, 29(6): 1150-1160.

FENG Di, LIU Sheng-dan, HAN Nian-mei, CHEN Hong-mei, CAO Wen-kui, HAN Zhong-jie. Multi factorial effects on microstructure, properties and through-thickness in homogeneity of 7A55-RRA treated aluminum alloy thick plate[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(6): 1150-1160.

[5] 张胜华, 胡泽豪, 朱旭霞, 林高用, 刘静安, 任小灵, 王岩松. LY12CZ挤压棒材粗晶环微观分析[J]. 中国有色金属学报, 1996, 6(3): 123-126.

ZHANG Sheng-hua, HU Ze-hao, ZHU Xu-xia, LIN Gao-yong, LIU Jing-an, REN Xiao-lin, WANG Yan-song. Microstructure analysis of coarse-grain recrystallization annulus of extruded bar of LY12 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 1996,6 (3): 123-126.

[6] 刘静安, 谢水生. 铝合金材料应用与开发[M]. 北京: 冶金工业出版社, 2011: 43-47.

LIU Jing-an, XIE Shui-sheng. Application and development of aluminum alloy materials[M]. Beijing: Metallurgical industry press, 2011: 43-47.

[7] 王祝堂. 变形铝合金热处理工艺[M]. 长沙: 中南大学出版社, 2011: 4-8.

WANG Zhu-tang. Heat treatment process of deformed aluminum alloy[M]. Changsha: Central South University Press, 2011: 4-8.

[8] 曾苏民. 影响铝合金固溶保温时间的多因素相关规律[J]. 中国有色金属学报, 1999, 9(1): 79-86.

ZENG Su-min. Multi factor correlation law of influencing the holding time of aluminum alloy solid solution[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(1): 79-86.

[9] 文 方, 李 铁. 2A02铝合金挤压棒材粗晶环的消除方 法[J]. 轻合金加工技术, 2003, 31(3): 33-35.

WEN Fang, LI Tie. Method of eliminating coarse grain ring of 2A02 aluminum alloy extruding bar[J]. Light Alloy Fabrication Technology, 2003, 31(3): 33-35.

[10] 陈丁文, 李飞庆, 李飞龙, 黄相博. 化学成分和均匀化处理对6061铝合金棒材粗晶环的影响[J]. 轻合金加工技术, 2014, 42(2): 47-50.

CHEN Ding-wen, LI Fei-qing, LI Fei-long, HUANG Xiang-bo. Effect of chemical compositions and homogenization treatment on the coarse grain ring of 6061 aluminum alloy bars[J]. Light Alloy Fabrication Technology, 2014, 42(2): 47-50.

[11] 刘俊生, 蒋秋妹, 何克准, 杨 文, 唐露华, 周文标. 化学成分对2024铝合金挤压圆棒粗晶环的影响[J]. 轻合金加工技术, 2015, 43(6): 39-44.

LIU Jun-sheng, JIANG Qiu-mei, HE Ke-zhun, YANG Wen, TANG Lu-hua, ZHOU Wen-biao. The influence of chemical compositions on peripheral coarse grains of the extruded, round bar of 2024 aluminum alloy[J]. Light Alloy Fabrication Technology, 2015, 43(6): 39-44.

[12] ZHANG Xin-ming, LU Yan-hong, LIU Sheng-dan, LIU Wen-jun, LI Hong-ping. Effect of step-homogenization on microstructures and mechanical properties of 7055 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 2154-2162.

[13] 王 岗, 刘 坚, 程仁寨, 宋明浩. 控制2024铝合金挤压棒材粗晶环的工艺研究[J]. 轻合金加工技术, 2013, 41(4): 36-40.

WANG Gang, LIU Jian, CHENG Ren-zhai, SONG Mning-hao. Technology study of coarse grain ring of 2024 aluminum alloy extrusion bar[J]. Light Alloy Fabrication Technology, 2013, 41(4): 36-40.

[14] 潘复生, 张丁非. 铝合金及应用[M]. 北京: 化学工业出版社, 2006: 141-148.

PAN Fu-sheng, ZHANG Ding-fei. Aluminum alloy and application[M]. Beijing: Chemical Industry Press, 2006: 141-148.

[15] 许晓静, 蒋 伟, 邓平安, 张香丽, 谈 成, 孙良省, 范亚洲. 预回复对Al-11.5Zn-3.5Mg-2.3Cu-0.24Zr挤压材固 溶-T652组织与性能的影响[J]. 稀有金属材料与工程, 2017, 46(3): 796-801.

XU Xiao-jing, JIANG Wei, DENG Ping-an, ZHANG Xiang-li, TAN Cheng, SUN Liang-sheng, FAN Ya-zhou. Effect of pre-recovery on microstructure and properties of Al-11.5Zn-3.5Mg-2.3Cu-0.24Zr-0.0025Sr aluminum alloy extrusion[J]. Rare Metal Materials and Engineering, 2017, 46(3): 796-801.

[16] 谈 成, 许晓静, 蒋 伟, 孙良省, 张香丽, 范亚洲, 赵建吉. 预回复对固溶-T652处理超高强铝合金挤压材组织与性能的影响[J]. 中国有色金属学报, 2015, 25(11): 3019-3025.

TAN Cheng, XU Xiao-jing, JIANG Wei, SUN Liang-sheng, ZHANG Xiang-li, FAN Ya-zhou, ZHAO Jian-ji. Effect of pre-recovery treatment on microstructure and properties of ultra high strength aluminum alloy extrusion treated by solid solution-T652 treatment[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(11): 3019-3025.

[17] MARSHALL G J. 控制工业纯铝板材的低温回复和再结晶[J]. 铝加工技术, 1992(2): 214-221.

MARSHALL G J. Control of low temperature recovery and recrystallization of industrial pure aluminum sheet[J]. Aluminum Processing Technology, 1992(2): 214-221.

[18] HUO W, SHI J, HOU L, ZHANG J. An improved thermo-mechanical treatment of high-strength Al-Zn-Mg-Cu alloy for effective grain refinement and ductility modification[J]. Journal of Materials Processing Technology, 2017, 239: 303-314.

[19] SENKOV O N, SHAGIEV M R, SENKOVA S V, MIRACLE D B. Precipitation of Al(Sc,Zr) particles in an Al-Zn-Mg-Cu-Sc-Zr alloy during conventional solution heat treatment and its effect on tensile properties[J]. Acta Materialia, 2008, 56(15): 3723-3738.

[20] LI H, CAO F, GUO S, JIA Y, D. ZHANG, LIU Z, WANG P, SCUDINO S, J. SUN. Effects of Mg and Cu on microstructures and properties of spray-deposited Al-Zn-Mg-Cu alloys[J]. Journal of Alloys & Compounds, 2017, 719: 89-96.

[21] WEN K, FAN Y, WANG G, JIN L, LI X, Li Z, Y. ZHANG, XIONG B. Aging behavior and precipitate characterization of a high Zn-containing Al-Zn-Mg-Cu alloy with various tempers[J]. Materials & Design, 2016, 101: 16-23.

[22] 侯增寿, 卢光熙. 金属学原理[M]. 上海: 上海科学技术出版社, 1990: 197-213.

HOU Zeng-shou, LU Guang-xi. Metallographyprinciple[M]. Shanghai: Shanghai Scientific & Technical Publishers, 1990: 197-213.

[23] DENG Y, WAN L, ZHANG Y, ZHANG X. Evolution of microstructures and textures of 7050 Al alloy hot-rolled plate during staged solution heat-treatments[J]. Journal of Alloys & Compounds, 2010, 498(1): 88-94.

[24] 左锦荣, 侯陇刚, 史金涛, 崔 华, 庄林忠, 张济山. 两阶段轧制变形过程中高强铝合金析出相与晶粒结构演变及其对性能的影响[J]. 金属学报, 2016, 52(9): 1105-1114.

ZUO Jin-rong, HOU Long-gang, SHI Jin-tao, CUI Hua, ZHUANG Lin-zhong, ZHANG Ji-shan. Precipitates and the evolution of grain structures during double step rolling of high-strength aluminum alloy and related properties[J]. Acta Metallurgica Sinica, 2016, 52(9): 1105-1114.

[25] 郎玉婧, 崔 华, 蔡元华, 张济山. 应变诱导析出对7050合金连续热变形组织的影响[J]. 中国有色金属学报, 2012, 22(10): 2726-2733.

LANG Yu- jing, CUI Hua, CAI Yuan -hua, ZHANG Ji- shan. Effect of strain induced precipitation on subsequent hot deformed microstructure of 7050 alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(10): 2726-2733.

[26] FENG W, XIONG B, ZHANG Y, ZHU B, LIU H, HE X. Effect of heat treatment on the microstructure and mechanical properties of the spray-deposited Al-10.8Zn- 2.8Mg-1.9Cu alloy[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(1): 648-652.

[27] LI L, WEI L, XU Y, MAO L, WU S. Study on the optimizing mechanisms of superior comprehensive properties of a hot spray formed Al-Zn-Mg-Cu alloy[J]. Materials Science and Engineering A, 2019, 742: 102-108.

[28] ZUO J, HOU L, SHI J, CUI H, ZHUANG L, ZHANG J. Enhanced plasticity and corrosion resistance of high strength Al-Zn-Mg-Cu alloy processed by an improved thermomechanical processing[J]. Journal of Alloys & Compounds, 2017, 716: 220-230.

[29] 莫纪平, 程晓农, 邓平安, 许晓静, 吴 瑶, 蒋 伟. 多向压缩对7085铝合金挤压材组织和力学性能的影响[J]. 稀有金属材料与工程, 2015, 44(8): 2003-2006.

MO Ji-ping, CHENG Xiao-nong, DENG Ping-an, XU Xiao-jing, WU Yao, JIANG Wei. Effect of multi-axial compression on microstructure and mechanical properties of 7085 aluminum alloy extrusions[J]. Rare Metal Materials and Engineering, 2015, 44(8): 2003-2006.

Heat treatment control process of coarse-grained rings of ultrahigh strength Al-Zn-Mg-Cu alloy extrusion profiles

HAN Bao-shuai, ZENG Yuan-song, XU Yan-jin, LIU Ya-fei, MA Xiao-guang

(AVIC Manufacturing Technology Institute, Beijing 100024, China)

Abstract: Coarse crystal ring is a common structure in the extruded Al alloy profiles, which reduces the homogeneity of the microstructures and properties. In this work, a series of step heat treatment processes were designed, in which the distortion energy of deformation process was eliminated by using the recovery effect at different temperature stages to control the size of the coarse-grained rings after solution treatment. The results show that the average width of the coarse-grained rings decreases from 1/10 to 1/7 of the untreated one after the heat treatment of (250 ℃, 24 h)+(300 ℃, 24 h)+(350 ℃, 24 h)+(400 ℃, 24 h), and the uniformity of mechanical properties along the thickness direction enhances significantly. This work may provide a reference method for optimizing the microstructure and properties of the ultra-high strength Al-Zn-Mg-Cu alloy profiles.

Key words: ultra-high strength alloy; Al-Zn-Mg-Cu; coarse-grained rings; heat treatment; grain structure; mechanical properties

Foundation item: Project(JCKY2017205B032) supported by the Defense Industrial Technology Development Program, China; Project supported by the National Defense Science and Technology Innovation Special Zone Program, China; Project(51971206) supported by the National Natural Science Foundation of China

Received date: 2019-11-20; Accepted date: 2020-06-23

Corresponding author: XU Yan-jin; Tel: +86-10-85701427; E-mail: xuyj_avic@aliyun.com

(编辑 王 超)

基金项目:国防基础科研计划资助项目(JCKY2017205B032);国防科技创新特区项目;国家自然科学基金资助项目(51971206)

收稿日期:2019-11-20;修订日期:2020-06-23

通信作者:徐严谨,高级工程师,博士;电话:010-85701427;E-mail:xuyj_avic@aliyun.com