文章编号:1004-0609(2010)01-0062-05

热轧生产工艺对C70250合金力学性能和导电性能的影响

李华清1, 2,汤玉琼1,汪明朴2

(1. 苏州有色金属研究院,苏州 215026;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:在模拟工业化生产条件下研究C70250合金的热轧、固溶及时效处理工艺,对比C70250合金板坯的热轧、热轧+时效、热轧+冷轧+时效后合金的力学性能与导电性能,同时研究空冷与水冷对材料力学性能的影响。结果表明:时效析出为C70250合金的主要强化手段,时效前的塑性加工能使合金强度提高4%~5%。XRD分析表明:C70250合金铸锭经热轧开坯,在575~725 ℃之间保温1 h,析出相以Ni2Si为主;合金开轧与终轧温度应控制在(900±50)~725 ℃之间,热轧板冷却速度不小于2.5 ℃/s;固溶处理制度为(900±50) ℃、1~3 h;时效工艺为400~ 450 ℃、4~6 h,该工艺制备的C70250合金抗拉强度不小于644 MPa,电导率IACS为40%,伸长率为8%。

关键词:C70250合金;热轧;时效

中图分类号:TG 146.1 文献标识码:A

Effects of hot rolling process on mechanical and

electrical properties of C70250 alloy

LI Hua-qing1, 2, TANG Yu-qiong1, WANG Ming-pu2

(1. Suzhou Institute for Nonferrous Metals, Suzhou 215026, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Hot rolling, solid solution and ageing treatment of C70250 alloy were investigated by mimicking the commercial process. The mechanical and electrical properties of C70250 alloy were analyzed under hot rolling state, aging after hot rolling and aging after cold rolling following hot rolling. The effects of quenching and cooling by radiation on the mechanical properties were also investigated. The results show that aging precipitation is the primary strengthening method for the C70250 alloy. The plastic working prior to the aging process improves the tensile strength by 4%?5%. The hot working temperature should be controlled between (900±50) ℃ and 725 ℃ and followed with on-line quenching. The cooling velocity of hot rolling plate is equal to or higher than 2.5 ℃/s. XRD analysis results show that the main precipitation phase is Ni2Si after C70250 alloy is hot rolled and kept at 575?725 ℃ for 1 h. The preferable off-line treatment process is heated at (900±50) ℃ for 1?3 h. The suitable aging process is 400?450 ℃ for about 4?6 h. The tensile strength, electrical conductivity (IACS) and elongation of the treated alloy are larger than 644 MPa, 40% and 8%, respectively.

Key words: C70250 alloy; hot rolling; aging

电子工业的发展对铜合金板带材料的性能要求不断提高。Cu-Ni-Si系列合金作为一种性能优异的引线框架材料引起人们的极大关注,Cu-Ni-Si合金具有较高的强度[1]、抗应力松弛性能,被认为是理想的第二代铜合金引线框架材料。国外企业已经开发出引线框架用Cu-Ni-Si铜合金系列产品[2?4],并形成产业化生产能力,成为目前世界高档引线框架板带材料的主要供应商。对Cu-Ni-Si合金的研究报导多数集中在力学性能和显微组织方面[5?10],我国对Cu-Ni-Si合金的研究主要集中在基础理论研究方面以及加工工艺调整阶段[11?16]。国内一些铜加工企业已经开始着手进行中试试验,并尝试进行Cu-Ni-Si合金板带产品的生产,并获得很多经验数据,但尚未贯通产业化生产工艺,因此,目前国内尚未形成该合金的产业化供货能力。

本文作者模拟产业化工艺流程,研究了C70250合金板带的热轧、热轧+时效、热轧+冷轧+时效等工艺状态下的力学与导电性能,分析并确定该合金的热轧与时效关键工艺参数,为产业化生产提供参考依据。

1 实验

实验用材料为C70250合金半连续铸锭,铸锭尺寸为:180 mm×75 mm×1000 mm。主要合金成分为Ni 2.2%~4.2%,Si 0.25%~1.2%(质量分数)。铸锭经 (900±50) ℃保温1~3 h后,热轧得到厚6 mm的板坯,热轧板材分别采用空冷和喷水冷却。将两种冷却方式得到的热轧板进行冷轧,变形量80%,随后进行时效处理,时效温度300~600 ℃,保温时间为4~6 h,测量其力学性能与导电性能,以研究不同时效工艺参数对合金性能的影响。为了确定终轧温度范围,将C70250合金在(900±50)℃保温1~3 h后淬水,进行固溶处理,然后将经过淬火处理的试样在500~850 ℃下退火(加热时间30 min~1 h),研究析出相随退火温度的变化规律。

冷变形在500 mm四辊可逆式冷轧机上进行,轧辊尺寸为d 200 mm×550 mm。时效在罩式炉内进行,控温精度±5 ℃。时效时采用氮气进行保护。采用D/max 2200 PC型X射线衍射仪对合金的物相进行分析。电阻(电导率)使用ZY9987型数字微欧计测量,测量误差不大于20 μ?,电导率试样尺寸为3 mm×200 mm。合金的力学性能采用CSS?44100型万能试验机测量。金相观察采用NIKON Epiphot 200倒置式金相显微镜,金相试样经粗磨、细磨、抛光后用盐酸三氯化铁溶液腐蚀。

2 结果与分析

2.1 C70250合金热轧工艺试验

铜合金板带工业化生产中,半连铸坯料热轧开坯通常需要经过9~13道次,坯料厚度由170~300 mm减薄至(17±2) mm。轧制过程中坯料通过传导与辐射损失的热量远大于变形热导致的坯料温升,因此轧制过程坯料温度迅速下降,为避免终轧温度过低,需合理安排轧制道次、道次压下量以及轧制速度。

实际生产过程中为了提高终轧温度而过度提高开轧温度容易造成过量氧化以及过烧等缺陷另外,增加金属损耗,终轧温度较高时容易导致晶粒过度长大,因而开轧温度不宜过高。试验结果表明,C70250合金适宜的开轧温度为(900±50) ℃,实际操作过程需要根据坯料截面尺寸和工作环境温度等条件做适当调整;若终轧温度太低,容易导致板坯内部裂纹缺 陷,对于析出强化型合金,则会降低时效析出强化效果。C70250合金在(900±50) ℃保温1~3 h后水淬,然后在500~850 ℃下退火,采用X射线衍射仪检测析出相。

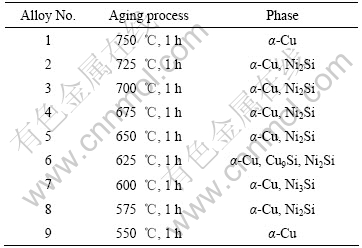

表1所列为合金的XRD物相分析结果。750 ℃与725 ℃时效处理试样的XRD谱如图1所示。 当温度不小于750 ℃和不大于550 ℃时,未检测出金属间化合物相。

表1 合金的XRD物相分析结果

Table 1 XRD phase results of alloys

经XRD物相检测发现,C70250合金热轧板坯在750 ℃处于饱和固溶态(见表1和图1(a)),合金元素完全固溶于铸坯基体中;当温度下降至725 ℃时,合金中出现金属间化合物,析出相为Ni2Si(见表1和图1(b));在575~725 ℃温度范围内保温30 min~1 h,检测到Ni2Si以及微弱量Ni3Si和Cu9Si等相析出;当温度低于550 ℃时,合金中未发现Ni2Si等析出相,分析认为这是由于析出动力不足,析出相数量很少,因而未能检出。

图1 经750和725 ℃时效处理后C70250合金的XRD谱

Fig.1 XRD patterns of C70250 alloy after aged at 750 ℃ and 725 ℃

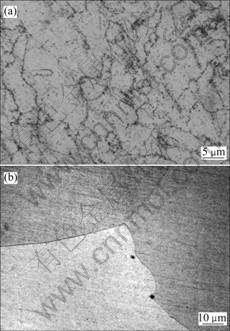

图2所示为C70250合金铸态、固溶态和热轧淬火态的微观组织。由图2可知,可以观察到非均匀分布的一次析出相(见图2(a));经过(900±50) ℃、1~3 h固溶处理后,一次析出相固溶进入合金基体(见图2(b))。金相组织观察表明,此时C70250合金为完全固溶状态,因而(900±50) ℃可以作为开轧温度。中试试验表明,该温度范围开轧,合金板坯无裂纹等缺陷,成材率较高,是理想的开轧温度。

图2 C70250合金的铸态(a)和经(900±50) ℃,1~3 h固溶态(b)的微观组织

Fig.2 Microstructures of C70250 alloy of as cast state(a) and solid solution treated at (900±50) ℃ for 1?3 h(b)

热轧结束时,对合金板坯采取在线淬火处理有利于提高合金元素的固溶效果。当热轧道次较多时,终轧温度通常会偏低。根据XRD试验结果,温度低于725 ℃时,合金中开始出现Ni2Si等金属间化合物,因此终轧温度不宜低于725 ℃。根据实际工况,终轧温度下限应控制在725~750 ℃之间。

2.2 确定C70250合金的时效处理工艺

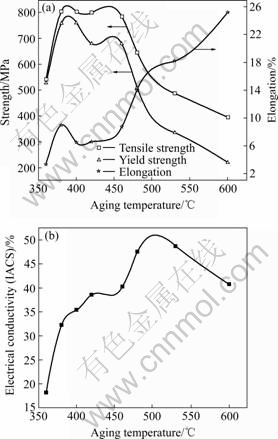

C70250合金时效处理需要较长的保温时间,以促进强化相的充分析出。图3所示为C70250合金冷轧板材力学性能和导电性能随时效温度的变化曲线,其保温时间为4~6 h。

图3 C70250合金冷轧板材的力学性能(a)和导电性能(b)随时效温度的变化曲线

Fig.3 Changing curves of mechanical properties(a) and electrical conductivity(b) of rolled C70250 alloy with aging temperature

由图3可看出,C70250合金峰时效温度为400~450 ℃(见图3(a));合金的伸长率与时效温度成正相关性,并在450~500 ℃区间内快速增加;电导率在(500±25) ℃达到峰值。考虑到合金的综合性能匹配,理想的时效制度是在(450±50) ℃保温4~6 h。此状态下合金的抗拉强度为670~720 MPa,电导率(IACS)为40%,伸长率为8%~10%。

Cu-Ni-Si合金是时效析出强化型铜合金,控制时效析出行为对合金的性能具有重要的影响。试验结果表明:与热轧后缓慢空冷相比,热轧后经在线淬火可以达到较好的固溶效果,有利于时效过程析出相的均匀弥散分布,从而获得更佳的综合性能。

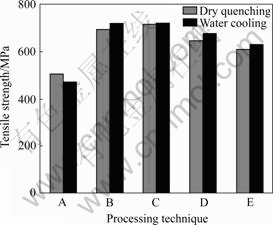

图4所示为不同加工工艺下C70250合金的抗拉强度。由图4可看出,试样分别经过热轧、热轧+时效、热轧+冷轧+时效处理。为了对比冷却速度对轧制板材强度的影响程度,中试试验分别设计空冷与水冷两种冷却方式,其中空冷试样的冷却工艺为热轧板材在空气中自然冷却,板坯试样温度在2 min内从600 ℃下降到300 ℃;水冷试样的冷却工艺为热轧板材,单面喷淋冷却水,初始水温低于20 ℃,板坯试样温度在20 s内由600 ℃下降到300 ℃。

图4 不同加工工艺下C70250合金的拉伸强度

Fig.4 Tensile strengths of C70250 alloy under various processing techniques: A—Hot rolling; B—Hot rolling+450 ℃, 4 h; C—Hot rolling+cold rolling+440℃, 4h; D—Hot rolling+ cold rolling+450 ℃, 4 h; E—Hot rolling+cold rolling+480 ℃, 4 h

未经时效处理的热轧水冷板材强度略低于热轧空冷板材的强度,时效处理后,水冷板材的强度略高于空冷板材的(见图4)。这是由于水冷(淬火)冷却速度为15 ℃/s,较空冷(自然冷却)的冷却强度(2.5 ℃/s)更大,第二相在冷却过程中来不及析出,合金的固溶度较高,而空冷板材在冷却过程中部分第二相粒子析出,微弱的析出强化导致空冷板材强度稍高于水冷板材。时效处理后,随着第二相析出,两种板材的强度随时效时间的延长而增大,由于水冷板材的固溶度大,析出动力大,析出相的弥散分布效果优于自然冷却试样,因此强化效果更为显著。另外,空冷板材中的第二相在时效过程中长大,易造成过时效,因此空冷板材的强度略低于水冷板材的。

空冷与水冷状态下合金的抗拉强度结果表明(见图4),冷轧变形加工对时效处理后C70250合金的强度影响不大。经450 ℃时效处理后,空冷与水冷热轧板坯的抗拉强度分别提高37.6%和53.5%,表明时效析出是C70250合金主要的强化手段;热轧板经冷轧+时效处理后较热轧板直接进行效处理的抗拉强度提高6%,表明塑性变形程度对C70250合金的最终力学性能影响有限;对C70250合金板坯采用相同的轧制和时效工艺,冷却速度由2.5℃/s提高到15℃/s时,试样的强度提高4%~5%,即欠时效状态,C70250合金强度由644 MPa提高到678 MPa,峰时效状态合金强度由695 MPa提高到720 MPa。结果表明,终轧温度大于750 ℃、热轧板坯的冷却速度不小于2.5 ℃/s时,可以得到理想的固溶效果。

3 结论

1) C70250合金热轧的开轧温度为(900±50) ℃,终轧温度应不小于750 ℃,热轧板坯冷却速度应不小于2.5 ℃/s。

2) 时效析出为C70250合金主要的强化手段,加工强化其次,预先经过冷塑性变形处理C70250合金时效处理后的抗拉强度比未经冷塑性变形处理合金的提高6%;热轧板坯冷却速度由2.5 ℃/s提高到15 ℃/s时,合金强度提高4%~5%。

3) C70250合金理想的时效工艺是(450±50) ℃保温4~6 h,此状态下合金的抗拉强度不小于644 MPa,电导率(IACS)为40%,伸长率为8%。

REFERENCES

[1] WATANABE C, HIRAIDE H, ZHANG Z, MONZEN R. Microstructure and mechanical properties of Cu-Ni-Si alloys[J]. Journal of the Society of Materials Science Japan, 2005, 54(7): 717?723.

[2] FUJIWARA H. Designing high-strength copper alloys based on the crystallographic structure of precipitates[J]. Furukawa Review, 2004, 26: 37?42.

[3] YAMAMOTO Y, SASAKI G, YAMAKAWA K, OTA M. High-strength and High-electrical-conductivity copper alloy for high-pin-count lead frames[J]. Hitachi Cable Review, 2000, 19: 65?70.

[4] LOCKYER S A, NOBLE F W. Precipitates structure in a Cu-Ni-Si alloy[J]. Journal of Materials Science, 1994, 29: 218?226.

[5] 李银华, 刘 平, 田保红, 贾淑果, 任凤章, 张 毅. 引线框架用Cu-Ni-Si合金的发展[J]. 材料研究与应用, 2007, 1(4): 260?264.

LI Yin-hua, LIU Ping, TIAN Bao-hong, JIA Shu-guo, REN Feng-zhang, ZHANG Yi. Development of Cu-Ni-Si alloy for lead frame[J]. Materials Research and Application, 2007, 1(4): 260?264.

[6] 龙永强, 刘 平, 刘 勇, 张伟民. 高性能Cu-Ni-Si合金材料的研究进展[J]. 材料导报, 2008, 22(3): 48?52.

LONG Yong-qiang, LIU Ping, LIU Yong, ZHANG Wei-min. Progress in research on high performance Cu-Ni-Si alloy[J]. Materials Review, 2008, 22(3): 48?52.

[7] 潘志勇, 汪明朴, 李 周, 黎三华, 陈 畅. 添加微量元素对Cu-Ni-Si合金性能的影响[J]. 材料导报, 2007, 21(5): 86?90.

PAN Zhi-yong, WANG Ming-pu, LI Zhou, LI San-hua, CHEN Chang. Effect of trace elements on properties of Cu-Ni-Si alloy[J]. Materials Review, 2007, 21(5): 86?90.

[8] 齐 亮, 柳瑞卿, 蔡 薇. C70250铜合金抗拉性能和导电性能研究[J]. 南方金属, 2006, 4: 25?27.

QI Liang, LIU Rui-qing, CAI Wei. A study of the tensile properties and conductivity of C70250 copper alloy[J]. Southern Metals, 2006, 4: 25?27.

[9] 张旦闻, 赵冬梅, 董企铭, 刘 平, 刘宏昭. 组合时效对 Cu-Ni-Si 合金性能的影响[J]. 功能材料, 2004, 35: 2160?2163.

ZHANG Dan-wen, ZHAO Dong-mei, DONG Qi-ming, LIU Ping, LIU Hong-zhao. Effect of complex-aging in Cu-Ni-Si alloy[J]. Journal of Functional Materials, 2004, 35: 2160?2163.

[10] LONG Yong-qiang, LIU Ping, LIU Yong, ZHANG Wei-min, PAN Jian-sheng. Simulation of recrystallization grain growth during re-aging process in the Cu-Ni-Si alloy based on phase field model[J]. Materials Letters, 2008, 62(7/8): 3039?3042.

[11] PAN Zhi-yong, WANG Ming-pu, LI Zhou, XIAO Zhu, CHEN Chang. Thermomechanical treatment of super high strength Cu-8.0Ni-1.8Si alloy[J]. Trans Nonferrous Met Soc China, 2007, 17: s1076?s1080.

[12] 鲍俊娟, 王海龙. CuNiSiCr合金热处理工艺研究[J]. 热加工工艺, 2005, 7: 14?16.

BAO Jun-juan, WANG Hai-long. Study on heat treatment process of CuNiSiCr alloy[J]. Hot Working Technology, 2005, 7: 14?16.

[13] LU De-ping, WANG Jun, ATRENS A, ZOU Xing-quan, LU Lei, SUN Bao-de. Calculation of Cu-rich part of Cu-Ni-Si phase diagram[J]. Trans Nonferrous Met Soc China, 2007, 17: s12?s15.

[14] 赵冬梅, 董企铭, 刘 平, 康布熙, 黄金亮, 田保红, 金志浩. Cu-3.2Ni-0.75Si合金时效早期相变规律及强化机理[J]. 中国有色金属学报, 2002, 12(6): 1167 ?1171.

ZHAO Dong-mei, DONG Qi-ming, LIU Ping, KANG Bu-xi, HUANG Jin-liang, TIAN Bao-hong, JIN Zhi-hao. Transformation and strengthening of early stage of aging in Cu-3.2Ni-0.75Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1167?1171.

[15] 张旦闻, 赵冬梅, 董企铭, 刘 平, 刘宏昭. Cu-Ni-Si合金二次时效时的再结晶行为[J]. 中国有色金属学报, 2004, 14(7): 1241?1245.

ZHANG Dan-wen, ZHAO Dong-mei, DONG Qi-ming, LIU Ping, LIU Hong-zhao. Recrystallization behaviour of Cu-Ni-Si alloy during two-step aging[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1241?1245.

[16] 汪 黎, 孙扬善, 付小琴, 薛 烽, 陈 曦. Cu-Ni-Si基引线框架合金的组织和性能[J]. 东南大学学报: 自然科学版, 2005, 35(5): 729?732.

WANG Li, SUN Yang-shan, FU Xiao-qin, XUE Feng, CHEN Xi. Microstructure and properties of Cu-Ni-Si based alloys for lead lame[J]. Journal of Southeast University: Natural Science Edition, 2005, 35(5): 729?732.

基金项目:中国铝业公司科技发展基金资助项目(2007KJA10)

收稿日期:2009-02-16;修订日期:2009-06-30

通信作者:李华清,高级工程师,博士;电话:0512-88856526;E-mail: lihuaqing2008@163.com

(编辑 李艳红)