DOI: 10.11817/j.issn.1672-7207.2015.12.013

D型光纤传感器的飞秒激光加工方法

邓旺,周剑英,孙小燕,银恺,罗志,谭超,周江夏子,段吉安

(中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083)

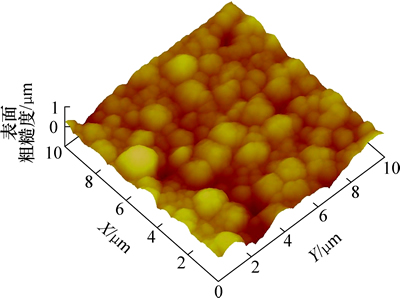

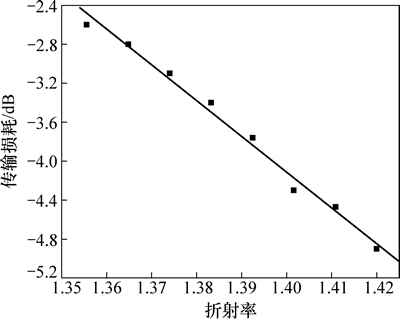

摘要:基于飞秒激光加工系统中二维CCD观测定位的轮廓线方法加工D型光纤,研究离焦量对飞秒激光轮廓线加工质量的影响。研究结果表明:随着聚焦光斑焦平面从光纤的近物镜端逐渐深入光纤,D型光纤加工面沿光传播方向的轮廓倾斜度会变得越来越大。飞秒激光加工方法能够保证加工的一致性。加工的D型光纤有效长度为200 μm,从包层顶端到加工面的加工深度为56.4 μm,原子力显微镜测得纤芯附近加工表面粗糙度为129 nm。将加工好的D型光纤用于折射率为1.36~1.42的液体传感,测得其传输损耗随折射率线性增大,此D型光纤传感器的单位折射率的传感灵敏度为37 dB。本文的加工方法在提高效率的同时,能够保证D型光纤的加工精度及传感灵敏度。

关键词:飞秒激光;D型光纤;轮廓线加工;离焦量;折射率传感

中图分类号:TN249 文献标志码:A 文章编号:1672-7207(2015)12-4476-05

Femtosecond laser micromachining of D-shape optical fiber sensor

DENG Wang, ZHOU Jianying, SUN Xiaoyan, YIN Kai, LUO Zhi,

TAN Chao, ZHOU Jiangxiazi, DUAN Ji’an

(State Key Laboratory of High Performance Complex Manufacturing,

Central South University, Changsha 410083, China)

Abstract: A D-shape optical fiber sensor fabricated by profile-line method based on two-dimensional CCD observation in femtosecond laser micromachining system was proposed. Experiments were carried out to research the effect of defocus on the profile-line machining results. The results show that with the focus plane going deep into the fiber from the side close to objective, the profile-line slope of the machined surface of D-shape optical fiber gets larger in the direction of laser propagation. This method can guarantee the machining repeatability. The dimensions of the D-shape zone are 56.4 μm in depth measured from the surface of the cladding, and 200 μm in effective length. The mean roughness of the surface around the fiber core is 129 nm as determined by AFM. The transmission loss of the D-shape optical fiber sensor immersed in liquid increases linearly with its refractive index in the range of 1.36 to 1.42. The calculated sensitivity of the sensor for unit of refractive index is 37 dB. The profile-line method can not only improve the efficiency, but also guarantee the high machining precision and sensing sensitivity.

Key words: femtosecond laser; D-shape optical fiber; profile-line machining; defocus; refractive index sensing

近年来,疾病、食品和环境等方面的检测对传感器提出了越来越高的要求。光纤传感器由于其结构简单、不受电磁干扰、灵敏度高、易于复用、可远距离遥测、能埋入工程结构等特点越来越受到人们的关注。其中,由于D型光纤特殊的几何结构,使得其既能够保持对外界环境变化的敏感,又拥有较好的机械强度。基于D型光纤的传感器被广泛应用于温度传感[1]、弯曲传感[2]、折射率传感[3]等。传统的制作D型光纤的方法主要有2种。一种是光纤侧边弧形槽基块抛磨法[4],此法要求先在玻璃基块上开弧形槽,然后将光纤用胶固定在此弧形槽中,并放到光学抛磨机上研磨,过程繁琐。另一种是光纤侧边轮式抛磨法[5],此方法是将光纤置于一个旋转轮上,在轮上加研磨剂后,可将光纤的侧边抛磨去一部分。其缺点是光纤的定位较困难,且抛磨定位装置复杂。近年来,随着超短脉冲激光微纳加工技术的发展,利用飞秒激光能够在透明、坚硬以及易碎的材料上进行高精度的烧蚀而不引起微裂纹以及热影响区域,其已被用于加工D型光纤[6-7]、Mach-Zehnder干涉仪[8]、法布里-珀罗干涉仪[9-10]等光纤器件。鉴于其他学者的飞秒激光微细加工多是逐点近阈值烧蚀[6, 8, 11],加工效率低。本文作者基于加工系统中二维CCD观测定位,提出较高能量下基于飞秒激光的轮廓线方法加工D型光纤,并以多组重复实验研究离焦量对轮廓线加工的影响。最后,将较优参数下加工的D型光纤传感器用于折射率为1.36~1.42的液体传感测试。

1 实验

1.1 飞秒激光微加工系统

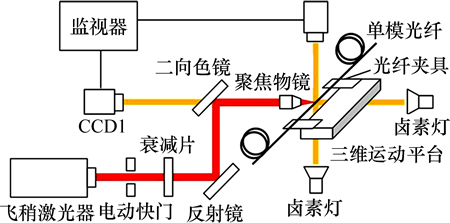

制作D型光纤的飞秒激光微加工系统如图1所示。所用飞秒激光器为钛宝石激光放大器(光谱物理),其波长为800 nm,脉冲宽度为120 fs,重复频率为1 kHz,单脉冲最大能量为4 mJ。激光器前用电动快门控制打到样品上的脉冲数。通过圆形渐变中性密度滤光片调节激光能量。激光经过二向色镜改变方向后,由一个10倍物镜(数值孔径为0.25)聚焦到光纤的适当位置。加工时,夹持光纤的两端并固定在三维运动平台上,运动平台的精度为5 nm。加工系统由两维CCD观测系统辅助定位,与常用的一维观测系统相比[6, 11],本加工系统增加垂直于光传输方向的CCD观测,可以准确标定样品加工时的离焦量,从而提高了加工的可控性及可重复性。

图1 飞秒激光加工系统示意图

Fig. 1 Schematic diagram of femtosecond laser micromachining system

1.2 传感实验装置

用于D型光纤传感实验的装置如下。把D型光纤的一端连接到稳定激光光源,另一端则连接光功率计。实验时,设定光源的波长(λ=1 550 nm)及输出功率,依次将D型光纤浸入不同的折射率溶液中,并分别记录光功率计稳定时的传输损耗。通过分析不同折射率溶液对应的不同传输损耗,可以得出此D型光纤的传感特性。

2 实验结果和讨论

2.1 飞秒激光轮廓线法加工D型光纤

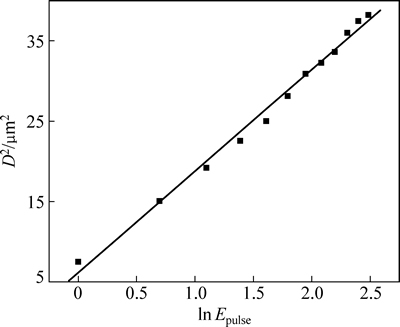

在飞秒激光加工应用中,焦斑处的束腰半径是非常重要的一个参数。为了求得这个参数,本文分别用不同能量在熔融石英片表面进行单脉冲打孔实验,并测得不同能量下单脉冲烧蚀孔的直径。束腰半径r0可根据以下公式得出[12]:

(1)

(1)

(2)

(2)

式中: 为激光的平均能量密度;

为激光的平均能量密度; 为激光单脉冲能量;r0为聚焦光斑的束腰半径;D为孔径;

为激光单脉冲能量;r0为聚焦光斑的束腰半径;D为孔径; 为熔融石英的单脉冲烧蚀阈值。D2与

为熔融石英的单脉冲烧蚀阈值。D2与 的关系如图2所示。由图2可知:焦斑的束腰半径为2.51 μm。同时,还可以得到熔融石英的单脉冲烧蚀阈值

的关系如图2所示。由图2可知:焦斑的束腰半径为2.51 μm。同时,还可以得到熔融石英的单脉冲烧蚀阈值 为3.11 J/cm2。以上实验得到的结果与文献[6]中的结果相差很小。由于裸光纤的主要成分也是熔融石英,所以可将光纤的烧蚀阈值近似看作3.11 J/cm2。本文采用单脉冲能量为100 μJ,即束腰处平均能量密度为505.24 J/cm2的飞秒激光加工光纤,属于远超阈值加工。

为3.11 J/cm2。以上实验得到的结果与文献[6]中的结果相差很小。由于裸光纤的主要成分也是熔融石英,所以可将光纤的烧蚀阈值近似看作3.11 J/cm2。本文采用单脉冲能量为100 μJ,即束腰处平均能量密度为505.24 J/cm2的飞秒激光加工光纤,属于远超阈值加工。

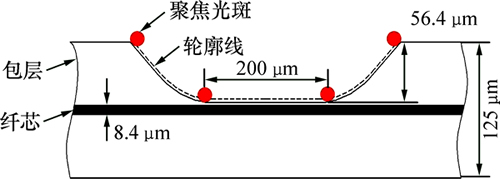

飞秒激光轮廓线法加工D型光纤的示意图如图3所示(光纤在加工前已去掉涂覆层)。光束沿着垂直于纸面方向传播,被物镜聚焦到光纤上,聚焦光斑相对光纤沿着图中的轮廓线从左往右移动(实际加工过程中是光斑不动,光纤作相对运动)。当加工完成时,光斑停在轮廓线的最右端。此时,轮廓线以上的部分会自动脱落,剩下的部分即为所要得到的D型光纤。所加工的D型区域有效长度为200 μm(不含过渡区域),平均加工深度为56.4 μm,即加工处的剩余包层厚度仅约2 μm。

图2 熔融石英片上D2与 的关系

的关系

Fig. 2 Relationship between D2 on flat fused silica plate and

图3 轮廓线法加工D型光纤的示意图

Fig. 3 Schematic diagram of profile-line method for fabrication of D-shape optical fibers

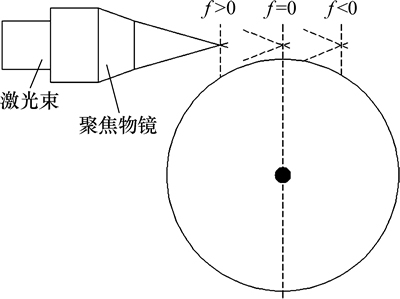

飞秒激光加工时,加工面的形貌与激光在该处的能量分布密切相关[13]。轮廓线法加工D型光纤,与样品加工面作用的是聚焦光斑的侧面,而聚焦光斑侧面的能量随着离焦量的不同存在很大的差异[14],所以离焦量是轮廓线法加工D型光纤中一个非常重要的参数。为了便于讨论离焦量与加工面形貌的关系,实验中将激光单脉冲能量定为100 μJ,扫描速度设定为0.05 mm/s。由于轮廓线法加工D型光纤时,与聚焦光斑最先接触的是光纤圆柱面的顶端,所以文中把离焦量的零点位置(焦平面f=0)定为焦点位于穿过光纤圆柱轴心且与光束垂直的面上。离焦量示意图如图4所示,当焦平面位于离焦量零点左边时,称为正离焦;当焦平面位于离焦量零点右边时,称为负离焦。实验中,分别取离焦量为-60,-40,-20,0,20,40和60 μm。

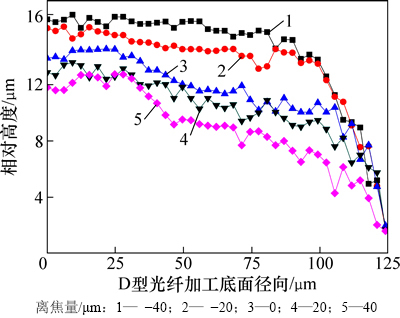

当离焦量为-60 μm和60 μm时,光纤不能1次扫描加工,未能加工成D型光纤;其他离焦量下,均能加工D型光纤。在共聚焦显微镜下,分别测得不同离焦量时D型光纤加工表面沿光传播方向的轮廓(径向轮廓),如图5所示。从图5可以看出:随着离焦量由-40 μm渐变到40 μm,加工表面的径向轮廓倾斜度变得越来越小。为了定量给出加工表面径向轮廓倾斜度随离焦量的变化关系,本文用2个量来表征径向轮廓倾斜度:轮廓最左端与最右端的高度差(两端高度差)、轮廓最高点与最低点的高度差(峰谷高度差)。在相同的实验条件下,一共进行了3组重复实验。

图4 离焦量示意图

Fig. 4 Schematic diagram of defocus

图5 D型光纤加工面径向轮廓随离焦量的变化图

Fig. 5 Radical profile of machined surface of D-shape optical fibers fabricated at different defocus

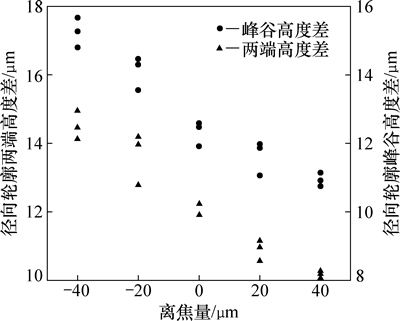

径向轮廓两端高度差、峰谷高度差与离焦量的关系如图6所示。从图6可以看出:随着离焦量由-40 μm渐变到40 μm,径向轮廓两端高度差以及峰谷高度差均变得越来越小。且3组重复实验变化规律一致。由此也可以得出,本文的加工实验具有较高的可重复性。

以上的变化规律与文献[15]中激光金属打孔时孔的锥度随离焦量的变化规律类似。从本质上讲,本文的轮廓线加工可以看作多脉冲打孔的过程,只是打出来的是一排重叠度很高的连续孔。所以,图5中展示的加工面径向轮廓实际就是多脉冲打孔的孔壁轮廓,轮廓的右边(加工时离物镜近的一边)即为孔的上孔壁,轮廓的左边为下孔壁。离焦量由40 μm渐变到-40 μm的过程中,光纤离物镜越来越近,光纤的上孔壁由于受到的激光辐射能量更大且分布更宽,上孔径会迅速增大;而根据高斯光束聚焦光斑能量分布的特点,此时上孔壁附近的锥度也会逐渐变大,对激光的散射就会增强,传到激光下孔壁处的激光能量相应减小,其增大幅度比上孔壁处小。因此,随着光纤离物镜越来越近,上孔径增大的程度要大于下孔径增大的程度,所以加工面的径向轮廓倾斜度也变得越来越大。而离焦量为-60 μm时,光纤没有打穿则是由于过大的负离焦使上孔壁附近出现了较大的锥度,使得孔深由于光线的散射大大减小,因此出现了打不穿的情形;离焦量为60 μm时,光纤没有打穿则是因为激光在空气中散失了太多的能量,以至于不能够打穿光纤。

图6 径向轮廓两端高度差、峰峰高度差与离焦量的关系

Fig. 6 Altitude intercepts of two ends and peak-to-valley of radical profile of surface fabricated at different defocus

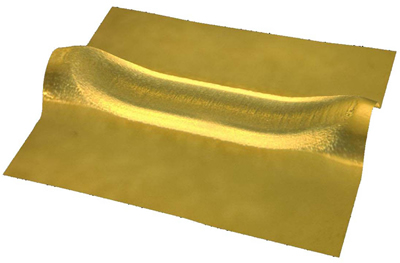

由于在光纤传输中,主要的光通量都是在纤芯附近传输,由图5可知:离焦量为-40 μm时纤芯附近加工效果最好。图7所示为轮廓线方法加工的D型光纤的三维光学形貌图。图8所示为在原子力显微镜下测得的D型光纤纤芯附近表面形貌,所测区域的平均表面粗糙度为129 nm。与文献[6,11]逐点近阈值烧蚀相比,加工精度在同一数量级。且本文的加工方法只需扫描1次,大大提高了加工效率。

对于影响飞秒激光轮廓线方法加工精度的其他参数,如激光能量、扫描速度等,有待进一步研究。待优化这些参数后,该方法的加工精度有望进一步提高。

2.2 D型光纤的传感测试

将加工的D型光纤用于折射率传感测试。不同折射率溶液由不同浓度的蔗糖溶液实现[16]。测试前,先按照实验部分将检测装置与待测D型光纤连接好。测试过程中,将D型光纤依次浸入到不同浓度的蔗糖溶液中,分别记录下光功率计稳定时的值,且每次记录数据后均用温水把D型光纤清洗干净。不同折射率溶液与相应传输损耗的对应关系如图9所示。从图9可知:D型光纤传输损耗与折射率的拟合曲线的相关系数R=0.993 6。由曲线斜率可得D型光纤传感器的单位折射率的传感灵敏度为37 dB。这与文献[17]的光纤传感器灵敏度相当。若在光纤加工面敷上一层金属纳米颗粒,使其成为表面等离子体共振传感器,则传感灵敏度可在更窄的折射率范围内得到很大的提高[18]。

图7 D型光纤三维光学形貌图

Fig. 7 Three-dimensional optical topography of D-shape optical fiber

图8 D型区域纤芯附近表面的AFM图像 (扫描范围10 μm×10 μm)

Fig. 8 AFM image of surface near core of D-shape zone (scanning area 10 μm×10 μm)

图9 传输损耗与折射率的关系

Fig. 9 Relationship between transmission loss and refractive index

3 结论

1) 验证了远超阈值能量下基于飞秒激光的轮廓线方法加工D型光纤的可行性。

2) 随着焦平面从光纤的近物镜端逐渐深入到光纤内部,D型光纤加工面的径向轮廓倾斜度越来越大。且3组重复实验的规律一致。由此可知,本文的加工方法有较高的重复性。

3) 基于本文方法加工的D型光纤,其纤芯附近表面粗糙度为129 nm,在保证加工精度的同时大大提高了加工效率。

4) 将本文的D型光纤用于折射率为1.36~1.42的液体传感测试,单位折射率的传感灵敏度为37 dB,为高灵敏度光纤传感器的制作提供了一种简单有效的方法。

参考文献:

[1] Chandani S M, Jaeger N A. Fiber-optic temperature sensor using evanescent fields in D fibers[J]. IEEE Photonics Technology Letters, 2005, 17(12): 2706-2708.

[2] Allsop T, Gillooly A, Mezentsev V, et al. Bending and orientational characteristics of long period gratings written in D-shaped optical fiber[J]. IEEE Transactions on Instrumentation and Measurement, 2004, 53(1): 130-135.

[3] Chiu M H, Wang S F, Chang R S. D-type fiber biosensor based on surface-plasmon resonance technology and heterodyne interferometry[J]. Optics Letters, 2005, 30(3): 233-235.

[4] 胡永明, 廖延彪, 陈哲, 等. 双偏振结构保偏光纤偏振器的研制[J]. 光学学报, 2001, 21(6): 741-743.

HU Yongming, LIAO Yanbiao, CHEN Zhe, et al. Manufacture of a double polarization structure of polarization maintaining fiber polarizer[J]. Acta Optica Sinica, 2001, 21(6): 741-743.

[5] 江沛凡, 陈哲, 曾应新, 等. 侧边抛磨光纤的光传输特性研究[J]. 半导体光电, 2006, 27(5): 578-581.

JIANG Peifan, CHEN Zhe, ZENG Yingxin, et al. Investigations on optical transmitting characters of side-polished fibers[J]. Semiconductor Optoelectronic, 2006, 27(5): 578-581.

[6] Chen C H, Chao T C, Li W Y, et al. Novel D-type fiber optic localized plasmon resonance sensor realized by femtosecond laser engraving[J]. Journal of Laser Micro/Nanoengineering, 2010, 5(1): 1-5.

[7] 宁超. 基于飞秒激光制备的光纤传感器的研究[D]. 哈尔滨: 哈尔滨工业大学光电科学系, 2011: 1-51.

NING Chao. Investigation on optical fiber sensor fabricated by femtosecond laser[D]. Harbin: Harbin Institute of Technology. Department of Optoelectronics Science, 2011: 26-27.

[8] ZHAO Longjiang, JIANG Lan, WANG Sumei, et al. A high-quality Mach-Zehnder interferometer fiber sensor by femtosecond laser one-step processing[J]. Sensors, 2010, 11(1): 54-61.

[9] 王文辕, 文建湘, 庞拂飞, 等. 飞秒激光制备的全单模光纤法布里-珀罗干涉高温传感器[J]. 中国激光, 2012, 39(10): 85-89.

WANG Wenyuan, WEN Jianxiang, PANG Fufei, et al. All single-mode fiber Fabry-Perot interferometric high temperature sensor fabricated with femtosecond laser[J]. Chinese Journal of Lasers, 2012, 39(10): 85-89.

[10] TAO Wei, HAN Yukun, LI Yanjun, et al. Temperature- insensitive miniaturized fiber inline Fabry-Perot interferometer for highly sensitive refractive index measurement[J]. Optics Express, 2008, 16(8): 5764-5769.

[11] Chen C H, Tsao T C, Li W Y, et al. Novel U-shape gold nanoparticles-modified optical fiber for localized plasmon resonance chemical sensing[J]. Microsyst Technol, 2010, 16(7): 1207-1214.

[12] Ben-Yakar A, Byer R L. Femtosecond laser ablation properties of borosilicate glass[J]. Journal of Applied Physics, 2004, 96(3): 5316-5323.

[13] Farson D F, Choi H W, Zimmerman B, et al. Femtosecond laser micromachining of dielectric materials for biomedical applications[J]. Journal of Micromechanics and Microengineering, 2008, 18(3): 1-9.

[14] 吕百达. 激光光学[M]. 北京: 高等教育出版社, 2003: 98-102.

L Baida. Laser optics[M]. Beijing: Higher Education Press, 2003: 98-102.

Baida. Laser optics[M]. Beijing: Higher Education Press, 2003: 98-102.

[15] 谭险峰, 杨俊华, 耿艳青. 激光打孔中离焦量与小孔尺寸关系的实验研究[J]. 应用激光, 2011, 31(3): 244-247.

TAN Xianfeng, YANG Junhua, GENG Yanqing. Experimental research on the relationship of the defocus and size of holes in laser drilling[J]. Applied Laser, 2011, 31(3): 244-247.

[16] 白泽生, 刘竹琴, 徐红. 几种液体的折射率与其浓度关系的经验公式[J]. 延安大学学报(自然科学版), 2004, 23(1): 33-34, 36.

BAI Zesheng, LIU Zhuqin, XU Hong. The experienced formula about the connection of refraction index and consistence of several liquid[J]. Journal of Yanan University (Natural Science Edition), 2004, 23(1): 33-34, 36.

[17] 龚元, 郭宇, 饶云江, 等. 光纤法布里-珀罗复合结构折射率传感器的灵敏度分析[J]. 物理学报, 2011, 60(6): 064202.

GONG Yuan, GUO Yu, RAO Yunjiang, et al. Sensitivity analysis of hybrid fiber Fabry-Pérot refractive-index sensor[J]. Acta Physica Sinica, 2011, 60(6): 064202.

[18]  J. Miniaturization of fiber optic surface plasmon resonance sensor[J]. Sensors and Actuators B: Chemical, 1998, 51(1/2/3): 311-315.

J. Miniaturization of fiber optic surface plasmon resonance sensor[J]. Sensors and Actuators B: Chemical, 1998, 51(1/2/3): 311-315.

(编辑 赵俊)

收稿日期:2014-12-09;修回日期:2015-03-14

基金项目(Foundation item):国家自然科学基金资助项目(91123035,51005250);国家重点基础研究发展计划(973计划)项目(2011CB013000)(Projects (91123035, 51005250) supported by the National Natural Science Foundation of China; Project (2011CB013000) supported by the National Basic Research Development Program (973 Program) of China)

通信作者:周剑英,博士,从事激光加工与光通信、传感器件研究;E-mail:zhoujy@csu.edu.cn