文章编号:1004-0609(2007)11-1833-05

近净成形制备SiC/Al复合材料Ⅰ:SiC预成形坯的制备

刘君武,郑治祥,吴玉程,王建民,汤文明,吕 君,徐光青

(合肥工业大学 材料学院,合肥 230009)

摘 要:以微米级的碳化硅粉和石墨粉为原料,采用氧化结合法制备出不同孔隙含量的、适合液态铝无压渗透的SiC预成形坯。研究SiC多孔陶瓷的低温烧结机理和石墨添加量对SiC陶瓷骨架烧结密度和尺寸变化的影响。结果表明:在1 100 ℃烧结时,碳化硅和石墨粉同时发生氧化反应;SiC氧化产生的结晶态SiO2膜将SiC粉体粘结成陶瓷骨架,石墨氧化去除后形成孔隙;SiC粉体间本征孔隙和石墨去除后留下的孔隙构成三维互连通状态;因SiC氧化导致陶瓷骨架产生4%左右的线膨胀,但坯体不发生形状改变;通过调整石墨含量,能获得孔隙率从0.47~0.63的SiC陶瓷骨架。

关键词:SiC预成形坯;氧化结合;孔隙率;造孔剂;线膨胀

中图分类号:TB 331 文献标识码:A

Fabrication of SiC/Al composites with near-net-shape Ⅰ: Preparation of SiC preforms

LIU Jun-wu, ZHENG Zhi-xiang, WU Yu-cheng, WANG Jian-min, TANG Wen-ming, L? Jun, XU Guang-qing

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: SiC preforms with different porosities for Al pressureless infiltrating in were prepared by oxidation bonding process deriving from micron-grade powders of SiC and graphite. The low temperature sintering mechanism of SiC preforms and the effect of graphite content on the density and dimension of the porous preforms were studied. The results show that SiC powders and graphite powders oxidize synchronously at 1 100 ℃ in air atmosphere; Crystalloid SiO2 film transformed from SiC by oxidation bonds SiC powders to each other to form a ceramic skeleton, and the sites occupied by graphite powders turn into pores when graphite powders burned out. Three dimensional co-continuous net-work of pores is achieved by original clearance among SiC powders and pores formed by graphite powders. The linear expansion of SiC preforms without any deformation is about 4% due to oxidation of SiC powders. SiC preforms with porosity ranging from 0.47 to 0.63 can be obtained by modulating graphite content.

Key words: SiC preforms; oxidation bonding; porosity; pore-forming agent; linear expansion

高增强体含量的SiC/Al复合材料具有优异的综合性能(高比强度、高比模量、高导热、低膨胀),在航空航天、汽车工业,以及作为电子热封装材料都有巨大的发展潜力[1?3],其性能可通过控制两相体积配比进行任意调整。采用液态铝及其合金熔渗SiC多孔预成形坯制备高增强体含量的SiC/Al复合材料能够实现材料制备与成型加工一体化,极大地降低加工成本[4?5]。渗透工艺由两个主要环节构成:SiC预成形坯的制备和液态铝合金渗入到SiC坯体颗粒间隙形成接近全致密的复合材料[6?8]。为降低复合材料的热膨胀系数就要尽可能地提高SiC含量[9?10],一般采用粗SiC粉[5]或不同粒径SiC粉混合的办法[11]提高复合材料中SiC的体积含量。已有的研究表明[10, 12],细颗粒SiC粉在不降低复合材料热膨胀系数的前提下能减少SiC含量,而且细颗粒的SiC粉在制备超薄壳体制品方面更具有优势。因而研究超细SiC粉体增强铝基合金具有重要意义。

本文作者以名义粒径为7 μm的微米级SiC粉体为原料制备SiC/Al复合材料,研究超细SiC粉体及其含量对铝基合金结构和性能的影响。由于细颗粒的SiC具有更好的烧结活性,其坯体不必用添加有机高分子粘结剂,经溶剂脱脂、真空脱脂的工艺来制备

[13],本研究尝试采用SiC粉体直接氧化结合

[14]的简洁工艺来制备用于无压渗透液态铝合金的SiC预成形坯。采用添加造孔剂的方法来调节SiC预成形坯的孔隙率,研究造孔剂的成孔机制、造孔剂含量对SiC坯体尺寸和孔隙率的影响。

1 实验

以牌号为W7的工业磨料用SiC和牌号为W5的高纯石墨(造孔剂)为主要原料,石墨和SiC的质量比分别为0?1、10?90、25?75。采用硬脂酸锌作为润滑剂,添加量(质量分数)为1%。以10%的聚乙烯醇水溶液作为粘接剂。将上述原料按设计比例分组在滚筒式混料机上混合4 h,然后在手动陶瓷压片机上以80 MPa的压力压制成形。素坯经80 ℃干燥处理后在箱式空气电阻炉中烧结。

用TGA?50H型热重分析仪分别测定SiC和造孔剂石墨的氧化温度特性以确定烧结工艺。用Mastersizer?2000型激光粒度仪分析粉末原料的粒度组成。用游标卡尺测量试样三维尺寸。用Poremastr GT?60型自动压汞仪测量SiC陶瓷骨架的孔径分布。用D/max-rB型X衍射仪分析物相组成。用X?650型扫描电子显微镜观察SiC坯体的组织形貌。

2 结果与讨论

2.1 SiC陶瓷骨架烧结温度的确定

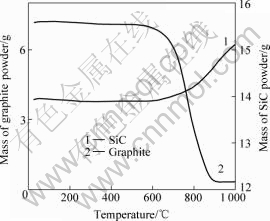

SiC陶瓷骨架的烧成温度主要由SiC和石墨的氧化特性决定。SiC粉体借助其表面氧化生成的SiO2将素坯点焊成具有一定强度的多孔骨架,而石墨氧化后变成气体去除而在相应位置留下孔隙。由SiC、石墨样品的热重分析(如图1所示)可知,SiC和石墨在 600 ℃以下基本不氧化,在700 ℃以上表现出快速氧化,两者的氧化过程在700~900 ℃范围内重叠,SiC增量相对较慢;石墨烧损极为迅速,温度升至900 ℃时已烧损殆尽。烧结温度在900 ℃以上时,在造孔剂石墨氧化去除过程中,SiC粉体能通过氧化生成的SiO2膜粘结到一起并具备一定的强度,从而有效防止SiC多孔陶瓷坍塌。氧化温度过高时,SiC表层的氧化膜过厚,会严重影响SiC/Al复合材料的性能,特别是导热性能,同时还会导致烧结膨胀过大、坯体易变形,对精确控制坯体尺寸不利。综合各种因素,素坯的烧结温度确定在1 100 ℃,保温时间为3 h。

图1 石墨和SiC粉体的热重曲线

Fig.1 TG curves of SiC and graphite powders

2.2 SiC预成形坯的物相组成、组织形貌及孔隙特征

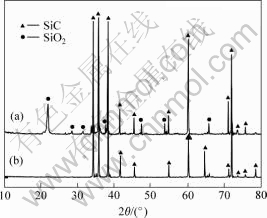

烧结SiC坯体及其原料SiC粉体的X射线衍射分析结果如图2所示。可见,在1 100 ℃烧结时,SiC粉体表面氧化生成的SiO2结晶较好,为低温α-方英石,密度为3.515 g/cm3。一般认为SiC在1 200 ℃以下氧化所形成的氧化膜以非晶态为主,高于该温度(包括1 200 ℃)所得的氧化膜主要是晶态的β-方石英[15],该结论显然与本实验结果不一致。这主要由于本实验采用的是磨料用SiC,包括有多种SiC晶型,而且杂质含量也高,导致其更易氧化、更易结晶。在干燥且不含腐蚀性介质的气氛中,单晶或多晶SiC的氧化因气氛中氧分压的不同分为活化氧化和钝化氧化两种类型。高氧分压下的钝化氧化可在SiC表面形成均匀、致密的氧化膜[16]:

SiC(s)+3/2O2(g)=SiO2(s)+CO(g)

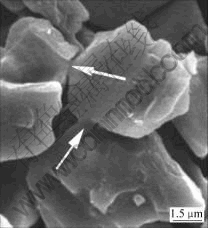

在本实验温度下,SiC氧化速度慢,供氧充分,能获得致密的氧化膜。SiO2氧化膜在自发熔渗制备SiC/Al复合材料过程中起着至关重要的作用。在预成形坯制备阶段,SiO2氧化膜起到粘结SiC粉体的作用(如图3中箭头所指的SiO2烧结颈),使之形成具备一定强度的陶瓷骨架。在随后工序中,SiO2氧化膜能通过液?固界面反应[17],有效改善SiC与Al液间的润湿性,促使Al液自发向SiC多孔陶瓷中渗入。同时由于SiO2氧化膜,可保护其内部的SiC不与铝液直接接触,避免了有害物Al4C3的形成。

图2 SiC样品的XRD谱

Fig.2 XRD patterns of SiC samples: (a) Sintered SiC perform; (b) SiC powders as received

图3 SiC粉体间的SiO2烧结颈

Fig.3 Sintered SiO2 bridges among SiC particles

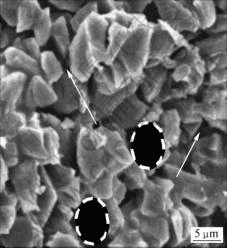

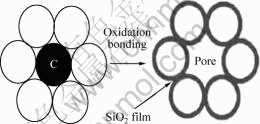

SiC陶瓷骨架的断口形貌如图4所示。可以看到,SiC颗粒棱角分明,很好地维持最初始的外形,彼此紧密地堆积在一起。粘结剂和润滑剂全部清除干净,没有观察到片状石墨的存在,这就为液态铝的自发渗入提供良好的固相反应界面。在SiC颗粒之间有两种类型的孔隙:一是紧密堆积SiC颗粒间隙形成的孔隙(如图4箭头所示);另一类则是SiC颗粒包围的石墨颗粒氧化去除后留下的孔隙(如图4虚线圆环所示),这类孔隙在烧结过程中形成过程如图5所示。由于石墨与SiC的密度相差不大,颗粒尺寸也相近,石墨粉体在混合粉中分布均匀,导致第二类孔隙分布也很均匀,从而保证最终SiC与Al两相的均匀性。

图4 SiC预成形坯的端口形貌

Fig.4 SEM image of SiC preform

图5 石墨造孔示意图

Fig.5 Schematic illustration of pore formed by Graphite particles

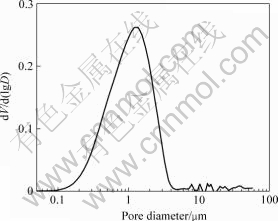

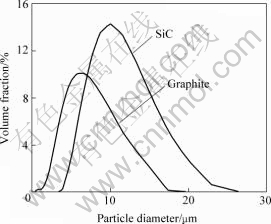

SiC具有很高的弹性模量和耐高温性能,在压制成形和低温烧结过程中基本不发生变形,能很好地保证粉体间形成孔隙的连通性,最终构成三维空间互通的开放间隙网络。汞压入法的测定结果(如图6所示) 证实了这些孔隙的三维连通性。 将SiC陶瓷骨架的孔径分布(图6)与原料粉粒度分布(图7)进行对比,SiC骨架中的孔隙大小在0.1~4 μm之间,以1~2 μm居多,显然是粒度为7 μm左右SiC颗粒间的本征间隙。石墨去除后留下的孔隙在材料断口能明显观察到(图4),但未能在汞压仪测试中很好地显示出来,只是在对应粒径处(图6)有少许凸起,这是由于测试仪器本身的局限所至。

图6 SiC陶瓷骨架中的孔径分布

Fig.6 Pore diameter dirtribution in SiC preform

图7 SiC和石墨的粒度分布

Fig.7 particle size distributions for SiC and graphite powders

2.3 石墨含量对SiC多孔陶瓷的孔隙率和烧结尺寸变化的影响

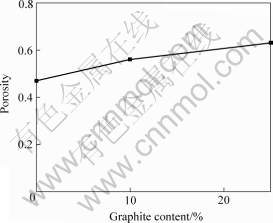

由于SiC粉体在压制成形的过程中不能发生塑性变形,主要通过粉体间的移动、转动来实现的,因而压制密度普遍较低,素坯的相对密度随陶瓷粉末粒度变细而降低。本实验得到的烧结SiC坯体的相对密度最大值在0.53左右。石墨含量对SiC烧结坯体孔隙率的影响如图8所示。氧化结合SiC陶瓷的孔隙率变化并不与石墨含量呈正比,而是略低于石墨的增量,这是由于比SiC粉体细的石墨粉在压制成形时会进入SiC粉体间隙所致。通过添加不同量的石墨,能获得0.47~0.63的孔隙率,过高的石墨含量易导致SiC坯体烧结时坍塌。

图8 石墨含量对SiC预成形坯孔隙率的影响

Fig.8 Effect of graphite content on porosity of SiC preform

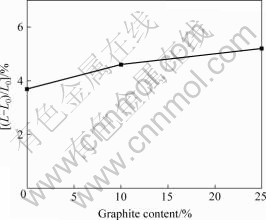

由于SiC氧化生成SiO2氧化膜的体积大于消耗掉的SiC体积,从而导致SiC素坯烧结后体积普遍增大。由图9可知,SiC粉体氧化结合时产生4%左右的线膨胀,但不足以使坯体产生变形。由于石墨在烧结时产生的二氧化碳气体快速通过SiC颗粒间隙排时产生的向外张力导致坯体膨胀略有增大。随石墨含量的增大,坯体的线膨胀缓慢增加。

图9 石墨含量对SiC预成形坯尺寸变化的影响

Fig.9 Effect of graphite content on dimension variation of SiC preform

3 结论

1) 在1 100 ℃烧结SiC?石墨复合坯体,碳化硅和石墨同时发生氧化反应,SiC粉体因氧化产生致密的结晶态SiO2膜而相互粘结形成陶瓷骨架有效避免坯体坍塌,石墨粉氧化去除后形成孔隙。

2) SiC粉体间本征孔隙和石墨去除后留下的孔隙一起构成三维互连通的、开放的孔隙网络;由石墨氧化形成的孔隙在SiC骨架内分布均匀,没有偏聚现象。

3) 因SiC氧化导致陶瓷骨架产生4%左右的线膨胀,但坯体不发生形状改变,通过调整石墨含量,能获得孔隙率从0.47~0.63的SiC预成形坯。

REFERENCES

[1] Zweben C. Advances in composite materials for thermal management in electreonic packaging[J]. JOM, 1998, 50(6): 47?51.

[2] Rawal S. Metal-matrix composites for space applications[J]. JOM, 2001, 53(4): 14?17.

[3] 张 韧, 王子良, 崔 岩. 无压浸渗SiC/Al的电镀和应用[J]. 电子与封装, 2004, 4(5): 26?30.

ZHANG Ren, WANG Zi-liang, CUI Yan. Plating and application of pressure-free infiltrated SiC/Al[J]. Electronics and Packaging, 2004, 4(5): 26?30.

[4] 黄 强, 金燕萍, 顾明元. 电子封装用金属基复合材料的制备[J]. 材料导报, 2002, 16(9): 18?19.

HUANG Qiang, JIN Yan-ping, GU Ming-yuan. Processing routes of metal matrix composites for electronic packing[J]. Material Review, 2002, 16(9): 18?19.

[5] 张 强, 陈国钦, 武高辉, 姜龙涛, 栾伯峰. 含高体积分数SiCp的铝基复合材料制备与性能[J]. 中国有色金属学报, 2003, 13(5): 1180?1183.

ZHANG Qiang, CHEN Guo-qin, WU Gao-hui, JIANG Long-tao, LUAN Bo-feng. Fabrication and property of SiCp/Al composites with high content of SiC[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1180?1183.

[6] Konopka K, Olszowka-Myalska A, Szafran M. Ceramic-metal composites with an interpenetrating network[J]. Mater Chem Phys, 2003, 81(2/3): 329?332.

[7] Arpon R, Molina J M, Saravanan R A, Garcia-Cordovilla C, Louis E, Narciso J. Thermal expansion behaviour of aluminum/SiC composites with bimodal particle distributions[J]. Acta Mater, 2003, 51(11): 3145?3152.

[8] 崔 岩, 陈续东. 低膨胀、超高模量铝基复合材料及其无压浸渗制备加工技术[J]. 中国有色金属学报, 2004, 14(S3): 33?36.

CUI Yan, CHEN Xu-dong. Alnminum matrix composites with low coefficient of thermal expansion and ultra-high modulus and their near net-shape fabrication technology based on pressureless infiltration[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S3): 33?36.

[9] Elomari S, Skibo M D, Sundarrajan A, Richards H. Thermal expansion behaviour of particulate metal matrix composites[J]. Composites Science and Technology, 1998, 58(3/4): 369?373.

[10] Gebel J, Elomari S, Peth? A, Boukhili R, Zimmer H G, San M C, Mortensen A, Lloyd D J. Thermal expansion responses of pressure infiltrated SiC/Al metal matrix composites[J]. Journal of Materials Science, 1997, 32(8): 2131?2140.

[11] 赵国田, 孙素杰, 徐永东, 朱秀荣, 陈照峰. 无压浸渗法制备高体积含量的铝基复合材料[J]. 兵器材料科学与工程, 2006, 29(2): 66?69.

ZHAO Guo-tian, SUN Su-jie, XU Yong-dong, ZHU Xiu-rong, CHEN Zhao-feng. High volume aluminum matrix composites prepared by pressureless infiltration[J]. Ordnance Material Science and Engineering, 2006, 29(2): 66?69.

[12] Shen Y L, Needleman A, Suresh S. Coefficients of thermal expansion of metal matrix composites for electronic packaging[J]. Metallurgical and Materials Transactions A, 1994, 25A(4): 840?847.

[13] 任淑彬, 何新波, 曲选惠, 等. 电子封装用高体积分数SiCp/Al复合材料的制备[J]. 北京科技大学学报, 2006, 28(5): 444?447.

REN Shu-bin, HE Xin-bo, QU Xuan-hui, et al. Preparation of high volume fraction SiCp/Al composites for electronic packaging[J]. Journal of University of Science and Technology of Beijing, 2006, 28(5): 444?447.

[14] She J H, Deng Z Y, Daniel-Doni J, Ohji T. Oxidation bonding of porous silicon carbide ceramics[J]. J Mater Sci, 2002, 37(17): 3615?3622.

[15] Sen S, Dhindaw B K, Stefanesen D M. Evaluation of interface stability and melt-processing techniques of Ni3A1/SiC particulate composites[J]. Mater Sci Eng A, 1994, 174(2): 207?216.

[16] 汤文明, 郑治祥, 丁厚福, 金志浩. O-SiCp/Fe界面化学稳定 性[J]. 航空材料学报, 2001, 21(4): 18?22.

TANG Wen-ming, ZHENG Zhi-xiang, DING Hou-fu, JIN Zhi-hao. Study on the chemical compatibility of O-SiCp/Fe[J]. Journal of Aeronautical Materials, 2001, 21(4): 18?22.

[17] Rantnaparkhi P L, Howe J M. Characterization of a diffusion-bonded Al-Mg alloy/SiC interface by high resolution and analytical electron microscopy[J]. Metall Mater Trans A, 1994, 25(3): 617?627.

基金项目:合肥工业大学科学研究发展基金资助项目(103-037508);合肥工业大学中青年创新群体基金资助项目(103-037016)

收稿日期:2007-05-18;修订日期:2007-09-14

通讯作者:刘君武,副教授;电话:0551-2901372;E-mail: jwliu@hfut.edu.cn

(编辑 陈爱华)