硫铵法制取等级氧化锌

来源期刊:中国有色金属学报1998年第1期

论文作者:唐谟堂 欧阳民

文章页码:118 - 121

关键词:锌 氧化锌 氨化

Key words:zinc , zinc oxide , ammonium sulfate , ammonia leaching process

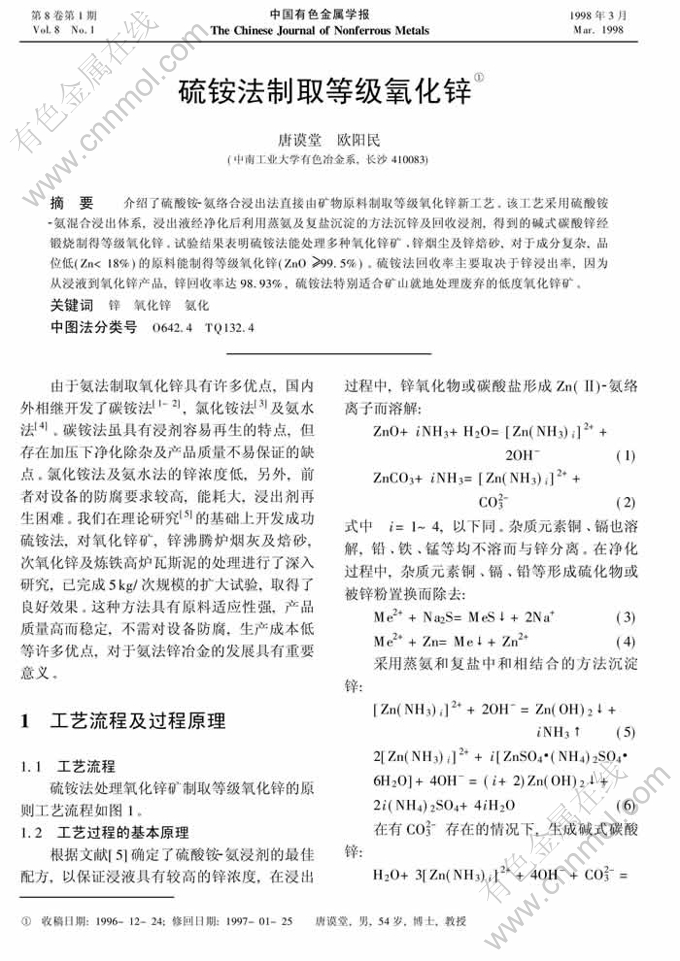

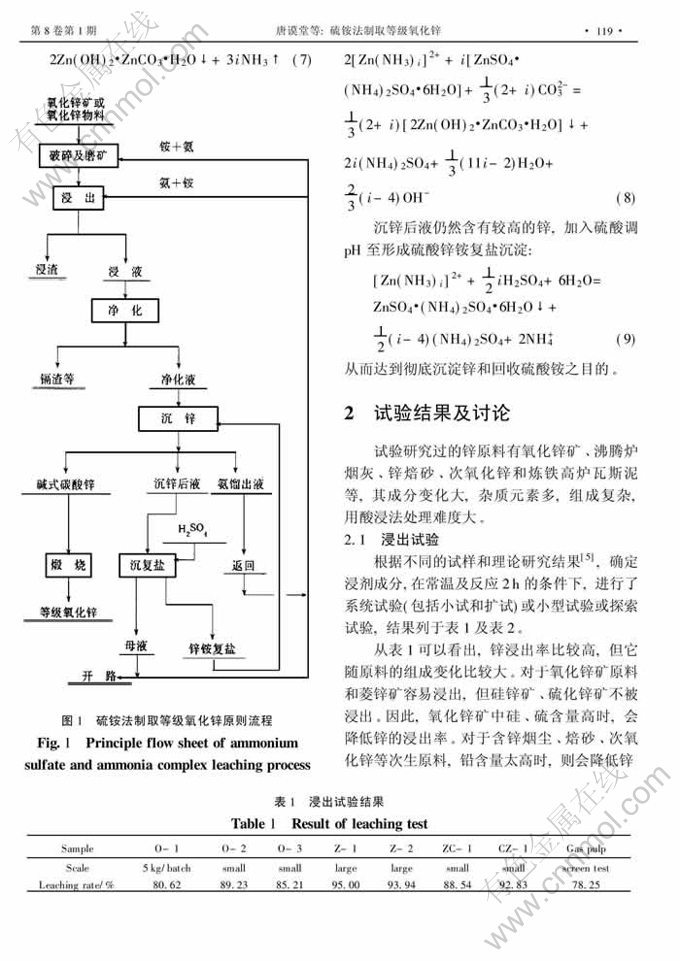

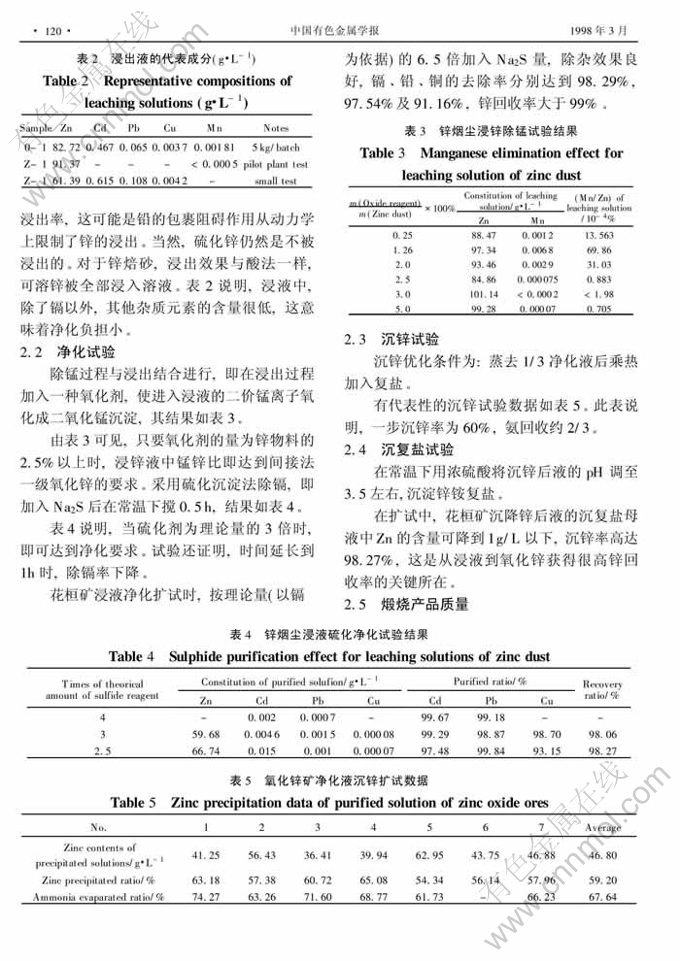

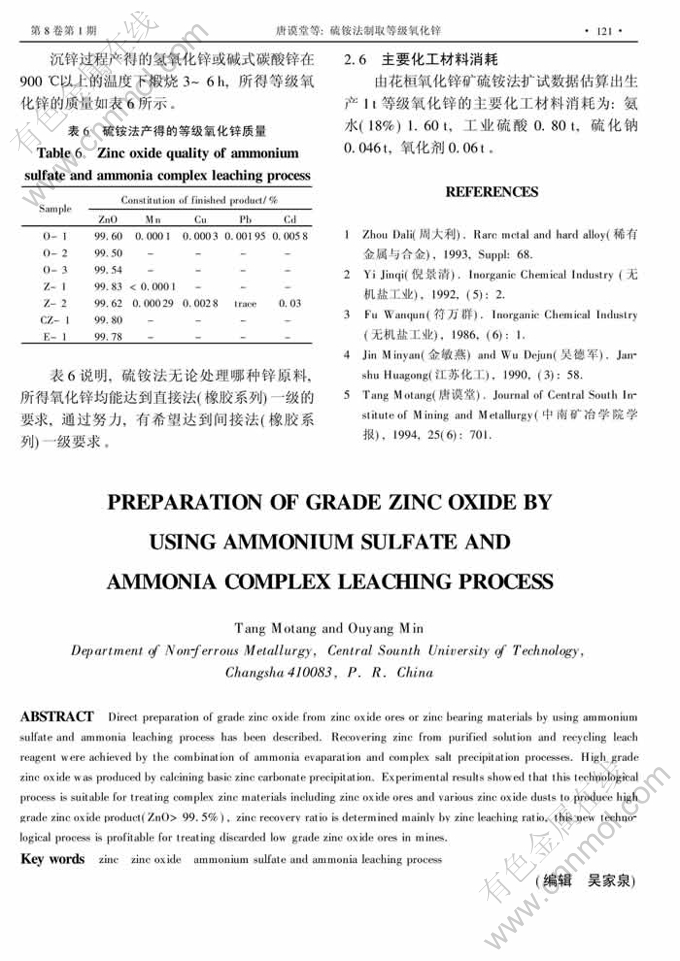

摘 要:介绍了硫酸铵-氨络合浸出法直接由矿物原料制取等级氧化锌新工艺。该工艺采用硫酸铵-氨混合浸出体系, 浸出液经净化后利用蒸氨及复盐沉淀的方法沉锌及回收浸剂, 得到的碱式碳酸锌经锻烧制得等级氧化锌。试验结果表明硫铵法能处理多种氧化锌矿、 锌烟尘及锌焙砂, 对于成分复杂,品位低(Zn<18%)的原料 能制得等级氧化锌(ZnO≥99.5%)。 硫铵法回收率主要取决于锌浸出率,因为从浸液到氧化 锌产品,锌回收率达98.93%,硫铵法特别适合矿山就地处理废弃的低度氧化锌矿。

Abstract: Direct preparation of grade zinc oxide from zinc oxide ores or zinc bearing materials by using ammonium sulfate and ammonia leaching process has been described. Recovering zinc from purified solution and recycling leach reagent were achieved by the combination of ammonia evaparation and complex salt precipitation processes. High grade zinc oxide was produced by calcining basic zinc carbonate precipitation. Experimental results showed that this technological process is suitable for treating complex zinc materials including zinc oxide ores and various zinc oxide dusts to produce high grade zinc oxide product(ZnO>99.5%), zinc recovery ratio is determined mainly by zinc leaching ratio, this new technological process is profitable for treating discarded low grade zinc oxide ores in mines.