铝电解生产过程的多目标优化

郭俊,桂卫华,文新海

(中南大学 信息科学与工程学院,湖南 长沙,410083)

摘要:针对某铝厂铝电解生产过程中的摩尔比、电解温度和极距难以根据不同工况进行实时调整,无法达到期望综合生产目标的问题,提出以电流效率最高、槽电压最低为优化目标,以氧化铝浓度指标和生产工艺要求为约束条件的基本优化思想。首先采用多元线性回归与改进BP神经网络方法,建立铝电解生产过程非线性不等式约束的多目标优化模型;然后,采用比例加权系数法与广义简约梯度组合算法求解多目标优化问题,获得摩尔比、电解温度和极距的优化设定值。研究结果表明,在工况正常时,模型优化结果的相对误差在5%左右;工况异常时,模型优化结果的相对误差在10%以内;本文所用方法的优化精度较高,基于实际生产数据的仿真结果的有效率都在90%以上,在工况正常情况下可以达到97%,此结果能很好地满足企业的要求。

关键词:铝电解;BP神经网络;多目标优化;比例加权系数法

中图分类号:TP273 文献标志码:A 文章编号:1672-7207(2012)02-0548-06

Multi-objective optimization for aluminum electrolysis production process

GUO Jun, GUI Wei-hua, WEN Xin-hai

(School of Information Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Based on the fact that in aluminum electrolysis production process, it’s difficult to adjust molecular ratio, electrolytic temperature and polar distance timely according to different conditions, the anticipant integrated production target can’t be reached, a basic optimization idea was proposed using the maximum of current efficiency and minimum of aluminum cell voltage as the optimization objective and using concentration of alumina and technological requirements as the constraint conditions. Firstly, the multiple linear regression and improved BP neural network methods were used to build a multi-objective optimization model with nonlinear inequality constraints for aluminum electrolysis production process.Then, the proportion weighted coefficient method and GRG (Generalized reduced gradient) combinatorial algorithm were applied to resolve the multi-objective optimization problem. Finally, the optimized target values of molecular ratio, electrolytic temperature and polar distance were obtained. The results show that the relative error of the proposed model is about 5% under normal producing condition and is less than 10% during abnormal production, which indicates the approach owns high precision. What’s more, the efficiency of the optimization results based the producing data is higher than 90%, and can reach 97% during normal production so the approach can meet the enterprise needs well.

Key words: aluminum electrolysis; BP neural networks; multi-objective optimization; proportion weighted coefficient method

铝电解过程是一个非线性、多变量耦合、时变和大时滞的工业过程体系[1-3],其自身内部复杂的物理化学变化、各种外界条件以及作业的干扰决定了电解槽在运行过程中存在众多参数和变量的不确定性以及不可连续测定性[4-6]。铝电解生产过程作为复杂工业过程,受到国内外学者的高度重视,一些研究成果已初步应用于生产实践,使铝电解生产过程的自动化水平得到一定程度提高。目前国内外研究出一些针对铝电解生产的控制优化方法[7-9],国内很多铝厂的电解铝生产过程也已经建立一些控制系统,包括自动下料控制系统、阳极自动提升控制系统等。这些方法和系统的建立提高了工厂的自动化水平,取得了一定的经济效益,但同时也存在一些问题,如摩尔比、电解温度、极距难以根据工况变化进行实时调整。铝厂为了提高其竞争力,要求在铝电解生产过程中达到其期望的综合生产目标,即在氧化铝浓度满足要求的前提下,电流效率最高,槽电压最低。为了能达到企业要求,需要从满足综合生产目标的角度出发,研究铝电解生产过程的优化问题。在此,本文作者结合某铝厂的实际铝电解生产过程,从满足企业期望的综合生产目标的角度出发,集成多元线性回归与改进BP神经网络方法建立铝电解生产过程的多目标优化模型,然后,利用比例加权系数法与广义简约梯度组合优化算法求解多目标优化问题。

1 机理分析与基本优化思想

铝电解生产是一个复杂的工业过程,影响电流效率和槽电压的因素众多。本文首先通过机理分析确定其主要的影响因素,然后,根据主要影响因素以及生产工艺要求确定铝电解生产过程多目标优化模型的优化目标、决策变量以及约束条件,最后给出求解多目标优化问题的优化算法。

1.1 机理分析

在铝电解生产过程中,摩尔比定义为铝电解质体系中NaF的物质的量和AlF3的物质的量之比,它是衡量铝电解工业运行状况的一个重要工艺指标,其值过高,说明电解质过热度过高,电流效率随之降低;其值过低,会导致电解质电导率降低和炉底易产生沉淀结壳,这2方面都会使电解质压降升高[10-11]。电解温度是热平衡的表现,合理保持电解温度,不但有利于电流效率的提高,而且有利于槽况稳定和槽电压控 制[11-12]。极距控制是槽控机控制电解槽热平衡的主要手段,极距过高,槽电压大幅度增加,在提高能耗的同时也破坏了铝电解的热平衡;极距过低,铝的二次反应加剧,电流效率明显下降,严重时铝液的波动可能导致两极短路,造成严重的生产事故[13]。

基于以上分析可知:摩尔比、电解温度以及极距直接影响到铝电解的电流效率和槽电压。由于铝电解生产过程是一个复杂工业过程,电流效率和槽电压的影响因素众多,不仅包括摩尔比、电解温度以及极距,同时也包括了一些关键操作参数,如铝液高度、保温料厚度、阳极侵入电解质的深度等。若将这些参数忽略,则优化结果不理想,因此,在建立优化模型时需要予以考虑。

1.2 基本优化思想

在铝电解生产过程中,期望的综合生产目标是:在氧化铝浓度满足要求的前提下,使电流效率最高、槽电压最低。而摩尔比、电解温度以及极距直接影响电流效率和槽电压,因此,本文提出以电流效率最高、槽电压最低为优化目标,以摩尔比、电解温度以及极距为决策变量,以氧化铝浓度满足要求与铝电解生产工艺要求为约束条件的基本优化思想。满足企业期望的综合生产目标是一个多目标优化问题,建立多目标优化模型是铝电解生产过程优化的关键环节。

由于现有的检测设备和检测水平条件难以对氧化铝浓度进行实时、客观评价,因此,首先需要建立氧化铝浓度预测模型:其次,要使电流效率最高、槽电压最低,需要建立电流效率模型与槽电压模型。通过将电流效率模型、槽电压模型以及氧化铝浓度预测模型进行集成,从而建立铝电解生产过程的多目标优化模型:最后,提出采用比例加权系数法与广义简约梯度组合算法求解多目标优化问题,即采用比例加权系数法将多目标非线性不等式约束优化转换为单目标非线性不等式约束优化问题,再通过广义简约梯度法求解非线性不等式约束的单目标优化问题。优化结果作为铝电解生产过程控制系统的目标值和调度系统的决策参数。

2 多目标优化模型

对复杂的多输入多输出铝电解生产过程,采用多元线性回归以及改进BP神经网络方法建立多目标优化模型:首先采用改进BP神经网络方法建立氧化铝浓度预测模型;其次,利用专家规则,集成多元线性同归以及BP神经网络建立电流效率模型与槽电压模型;最后,给出铝电解生产过程的多目标优化模型,以便为实现过程优化打下基础。

2.1 氧化铝浓度预测模型

铝电解生产过程氧化铝浓度每24 h检测1次,相对某些需要实时调整的操作参数存在严重滞后,因此,需要建立氧化铝浓度预测模型。基本BP神经网络尽管有效,但在目标点附近收敛速度很慢,效率低,因而,本文采用基于变学习率和样本批处理相结合的改进BP神经网络建立氧化铝浓度预测模型。

由机理分析以及关联性分析可知,影响氧化铝质量分数w(Al2O3)的主要因素有摩尔比x1、电解温度x2、极距x3、氟化盐下料量L4、槽电阻L5。采用单隐层BP神经网络建立预测模型,其中:模型的输入变量5个,隐层神经元10个,输出变量1个,学习率选为0.005,从历史数据中选择出60组,其中学习样本50组,预测样本10组。用 来表示神经网络预测模型的结构,则

来表示神经网络预测模型的结构,则

(1)

(1)

具体的神经网络结构形式为:

(2)

(2)

其中: 为对应第i个输入变量到第j个隐层神经元的权值;

为对应第i个输入变量到第j个隐层神经元的权值; 为对应第i个隐层神经元的阈值;

为对应第i个隐层神经元的阈值; 为对应第i个隐层神经元到输出层的权值;b0为输出神经元的阈值;

为对应第i个隐层神经元到输出层的权值;b0为输出神经元的阈值; 表示3层BP神经网络描述的输入输出的非线性关系。

表示3层BP神经网络描述的输入输出的非线性关系。

2.2 电流效率与槽电压模型

在某铝厂的铝电解实际生产过程中,槽电压实时检测,槽电压数据每天以平均值保存1次,因此,槽电压以每天的平均槽电压来衡量。在电流效率计算中,理论铝产量是固定的,实际铝产量决定了电流效率。因此,采用电解槽每天的实际产铝量来衡量电流效率。

由机理分析以及关联性分析可知,影响电流效率的主要因素有摩尔比x1、电解温度x2、极距x3、铝液高度M4、阳极效应系数M5、槽龄M6等。采集50组铝电解生产过程历史数据,经过数据预处理后,采用多元线性回归方法获得电流效率的多元线性回归模型:

S1=fLR(x1, x2, x3, M4, M5, M6)=6.95x1+350.98x2+14.73x3-576.94M4-2.14M5-526.55M6+5 970.06 (3)

由电流效率的主要影响因素可以确定电流效率神经网络模型的输入变量为6个,隐层神经元为10个,输出变量为1个,则电流效率神经网络预测模型的结构为:

S2=fNN(x1, x2, x3, M4, M5, M6) (4)

试验结果表明:当电解槽正常工作时,采用BP神经网络方法建立电流效率模型具有较高的精度,但由于在铝电解生产过程中经常会出现一些异常状况,如阳极效应、“冷槽”、“热槽”等,为了保证模型在异常情况下的高精度,这里采用专家规则,集成多元线性回归与BP神经网络方法建立电流效率模型:

S=αS1=βS2=αfLR(x1, x2, x3, M4, M5, M6)+βfNN(x1, x2, x3, M4, M5, M6) (5)

式中:α+β=1;0≤α,β≤1。根据工况变化,改变专家规则实时调整α和β,从而提高模型的精度。

由机理分析以及关联性分析可知:影响槽电压的主要因素有摩尔比x1、电解温度x2、极距x3、保温料厚度N4、炉底压降N5、阳极深入电解质中的深度N6、电压摆动N7。采用与上述同样的方法可以得到如下槽电压集成模型:

Q=αfLR(x1, x2, x3, N4, N5, N6, N7)+βfNN(x1, x2, x3, N4, N5, N6, N7) (6)

2.3 多目标优化模型

根据铝厂综合生产目标要求以及氧化铝浓度预测模型、电流效率与槽电压模型,可以确定铝电解生产过程的多目标优化模型。在实际的铝电解生产过程中,(1)~(6)中的L4,L5,M4,M5,N4,N5和N6均取当前检测值,不参与过程优化环节,决策变量确定为摩尔比x1、电解温度x2、极距x3。

则式(5)和(6)可分别转换为:

S=F1(x1, x2, x3) (7)

Q=F2(x1, x2, x3) (8)

式(1)也可以转换为:

(9)

(9)

根据铝电解生产工艺要求确定:2.2≤x1≤2.55,930≤x2≤960,3.5≤x3≤4.8。

根据企业期望的氧化铝浓度满足要求,即1.5%≤w(Al2O3)≤3%。同时,为了有效地解决强非线性、多约束条件下的目标函数优化问题,这里将极大化问题转换为极小化问题,即令:

(10)

(10)

其中:E为给定正数,满足E-F1(x1, x2, x3)非负。则铝电解生产过程多目标优化模型可描述为:

(11)

(11)

3 组合优化算法

在铝电解生产过程中,优化目标函数的求解问题属于多目标非线性不等式约束的优化问题,虽然目前出现了许多智能优化算法如多目标进化算法、粒子群算法、遗传算法等用于求解多目标优化问题[14-15],但这些算法大多停留在理论研究水平[15]。在此,本文提出采用比例加权系数法与广义简约梯度组合优化算法来解决多目标优化问题。

3.1 比例加权系数法

由于多目标优化问题的目标函数不是单一的,同时被优化的多个目标之间可能存在冲突,因此,需要根据问题的特点以及决策者的意图来求解多目标优化问题的Pareto最优解。本文采用比例加权系数法将多个分量目标函数转换为一个数值目标函数,这样就可根据决策者意图来获得最优解。

针对式(11),将E-F(x1, x2, x3)和F2(x1, x2, x3)分别赋予不同的加权系数 和

和 ,则式(11)的多目标优化问题转化为如下所示的单目标优化问题:

,则式(11)的多目标优化问题转化为如下所示的单目标优化问题:

(12)

(12)

其中: ≥0;

≥0; ≥0。

≥0。

3.2 广义简约梯度算法

式(12)是一个非线性不等式约束的单目标优化问题。目前,针对这类问题,最有效的算法为广义简约梯度算法,因此,本文采用此算法求解如式(12)所示的单目标优化问题。但在求解之前需要对式(12)中的不等式约束进行处理,即通过松弛变量将不等式约束变为等式约束,处理后的结果为:

min F′= (13)

(13)

具体算法步骤如下。

Step 1:给定控制误差ε1,ε2与正整数K(ε1>0,ε2>0)。选取基本变量为XB和非基本向量XN,其中非基本向量的个数为总变量个数与等式约束的差值。选取初始可行解 ,令h(x)=(h1(X),h2(X))。

,令h(x)=(h1(X),h2(X))。

Step 2:由r(XN)= NZ(X)-

NZ(X)- h(X)(

h(X)( h(X))-1)

h(X))-1)  Z(X))计算简约梯度

Z(X))计算简约梯度 ,通过

,通过

确定方向 。若||

。若|| ||<ε1,则X0为最优解,停止;否则,转到Step 3。

||<ε1,则X0为最优解,停止;否则,转到Step 3。

Step 3: 取θ>0,令 , 若

, 若 ≤

≤ ≤

≤ ,则转Step 4;否则,以

,则转Step 4;否则,以 代替θ,再求

代替θ,再求 ,直至满足

,直至满足 ≤

≤ ≤

≤ ,转Step 4。

,转Step 4。

Step 4:求解非线性方程组 ,即求Y使得

,即求Y使得 ,若

,若 ,则可获得新迭代点

,则可获得新迭代点 。令

。令 ,k=1,有:

,k=1,有:

(1)  ,若

,若 ≤

≤ ≤

≤ ,且

,且 ,则转至Step 5;否则转(2)。

,则转至Step 5;否则转(2)。

(2)若k=K,则以 代替θ,令

代替θ,令 ,

, ,k=1,转至(1);否则令k=k+1,转至(1)。

,k=1,转至(1);否则令k=k+1,转至(1)。

Step 5:令 。若yk+1的某个分量等于下界αj或上界βj,则将其换出基本向量,得到新基本向量和非基本向量

。若yk+1的某个分量等于下界αj或上界βj,则将其换出基本向量,得到新基本向量和非基本向量 ,然后转至Step 1。

,然后转至Step 1。

4 结果与分析

采用某铝厂2010-09的实际生产数据进行分析。电流效率模型、槽电压模型以及氧化铝浓度预测模型均具有较高精度,能较好地满足铝电解生产工艺的要求。采用比例加权系数法与广义简约梯度组合优化算法能在工况正常与异常情况下进行过程优化,有效保证了摩尔比、电解温度以及极距的合理性,为铝电解生产过程提供了最优操作指导。

4.1 多目标优化模型运行结果与分析

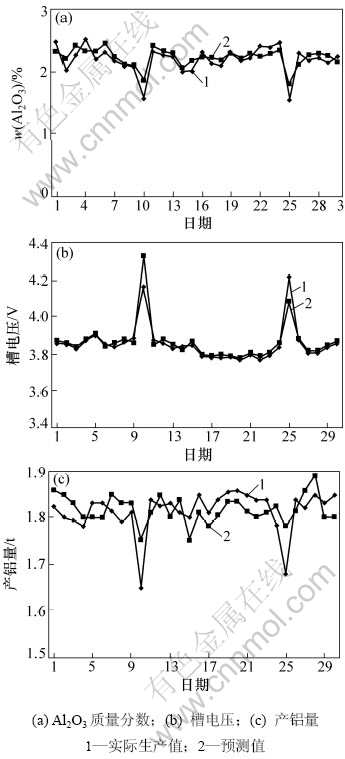

多目标优化模型作为过程优化的基础,其精度直接影响到过程优化的效果。通过对实际生产数据分析,多目标优化模型的运行结果如图1所示。从图1可见:模型的优化结果精度较高。相关的仿真结果显示:当工况正常时,电流效率模型相对误差为3.3%,槽电压模型相对误差为4.5%,氧化铝浓度的神经网络预测模型相对误差为5.3%;当工况异常时,电流效率模型相对误差为6.2%,槽电压模型相对误差为6.9%,氧化铝浓度的神经网络预测模型相对误差为9.2%。可见:多目标优化模型在工况正常与异常情况下都具有较高的模型精度,为铝电解生产的过程优化奠定了基础。

图1 2010-09铝电解多目标优化模型运行结果

Fig.1 Results of multi-objective optimization model for aluminum electrolysis in September, 2010

4.2 过程优化结果与分析

取2010-09实际生产数据1 000组过程优化结果进行分析,发现:当工况正常时,本文采用的比例加权系数法与广义简约梯度的组合优化算法的有效率达到97.6%,即可以97.6%的有效率搜索到一组最优解;当工况异常时,优化算法的有效率达到92.5%。可见,优化算法在实际生产过程中具有较高的有效率。其过程优化结果如表1所示。

表1 铝电解生产过程优化结果

Table 1 Results of optimization of aluminum electrolysis production process

从表1可以看出:对不同的初始值,其过程优化结果均能获得一组非常接近的最优解。这说明本文采用的比例加权系数法与广义简约梯度的组合优化算法具有全局收敛性。

5 结论

(1) 采用多元线性回归与改进BP神经网络方法建立了铝电解生产过程的多目标优化模型,提出了利用比例加权系数法与广义简约梯度的组合优化算法解决具有时变、大时滞的多输入多输出铝电解生产过程的多目标优化问题。

(2) 本文建立的多目标优化模型具有较高的精度,组合优化算法具有全局收敛性以及较高的效率,有利于铝厂的铝电解生产过程优化。

参考文献:

[1] 殷恩生. 160 kA中心下料预焙铝电解槽生产工艺及管理[M]. 长沙: 中南工业大学出版社, 2003: 47-51.

YIN En-sheng. Production technology and management of 160 kA electrolyte for centre-worked prebake cell[M]. Changsha: Central South University of Technology Press, 2003: 47-51.

[2] 邱竹贤. 铝电解原理与应用[M]. 徐州: 中国矿业大学出版社, 1998: 23-31.

QIU Zhu-xian. Principles and applications of aluminum electrolysis[M]. Xuzhou: China University of Mining Press, 1998: 23-31.

[3] 李界家, 郭宏伟, 文达. 神经网络预测器在铝电解过程控制中的应用[J]. 沈阳建筑大学学报: 自然科学版, 2006, 22(6): 1023-1026.

Li Jie-jia, GUO Hong-wei, WEN Da. The research and application of neural network predictor in aluminum electrolysis process control[J]. Journal of Shenyang Jianzhu University: Natural Science, 2006, 22(6): 1023-1026.

[4] 张伟, 袁艳, 张泰山. 铝电解槽智能模糊控制算法的研究[J]. 控制理论与应用, 2005, 24(1): 11-13.

ZHANG Wei, YUAN Ye, ZHANG Tai-shan. An intelligent fuzzy algorithm for prebaked aluminium electrolytic process[J]. Control Theory and Applications, 2005, 24(1): 11-13.

[5] 李界家, 马驰. 基于铝电解过程的神经网络模型预测控制的应用研究[J]. 轻金属, 2007(3): 25-28.

LI Jie-jia, MA Chi. The research and application of neural network model predictive control based on aluminum electrolysis process[J]. Light Metals, 2007(3): 25-28.

[6] 汪成亮, 庞栩, 陆志坚. 基于神经网络的铝电解混合控制模型研究[J]. 计算机应用研究, 2010, 27(7): 2536-2539.

WANG Cheng-liang, PANG Xu, LU Zhi-jian. Research on hybrid control methods of aluminum reduction on neural network[J]. Application Research of Computers, 2010, 27(7): 2536-2539.

[7] 汪成亮, 陆志坚, 庞栩, 等. 铝电解混合智能优化控制方法研究与应用[J]. 轻金属, 2009(11): 23-27.

WANG Cheng-liang, LU Zhi-jian, PANG Xiang, et al. Research and application of hybrid intelligent optimal control method for operation of aluminum electrolytic processes[J]. Light Metals, 2009(11): 23-27.

[8] 王殿清, 张忠仁. 铝电解三度寻优控制技术应用的可行性[J]. 材料与冶金学报, 2010(9): 140-142.

WANG Dian-qing, ZHANG Zhong-ren. Aluminum three-seeking control of the feasibility of technology[J]. Journal of Materials and Metallurgy, 2010(9): 140-142.

[9] Kolas S, Store T. Bath temperature and AlF3 control of an aluminium electrolysis cell[J]. Control Engineering Practice, 2009(17): 1035-1043.

[10] 刘建新. 浅析中间下料预焙槽电解质摩尔比的控制方法[J]. 广东有色金属学报, 2005, 15(1): 15-18.

LIU Jian-xin. Control of molecular ratio of electrolyte for centre-worked prebake cell[J]. Journal of Guangdong Non-ferrous Metals, 2005, 15(1): 15-18.

[11] 吕怀军. 铝电解技术条件对正常生产期电流效率的影响[J]. 中州煤炭, 2009(5): 34-36.

L? Huai-jun. Technical conditions on the normal production of aluminum on the current efficiency[J]. Zhongzhou Coal, 2009(5): 34-36.

[12] 沈序章. 铝电解槽电压异常波动的机理及其防治[J]. 轻金属, 2008(9): 31-35.

SHEN Xu-zhang. The mechanism of voltage fluctuation in aluminum reduction cell and its precautions[J]. Light Metals, 2008(9): 31-35.

[13] 史志荣, 杨文杰, 张刚. 大型铝电解槽瞬时电流效率测定技术的研究[J]. 轻金属, 2009(7): 23-26.

SHI Zhi-rong, YANG Wen-jie, ZHANG Gang. Study on measuring technique of instant current efficiency on large sized aluminum electrolytic cell[J]. Light Metals, 2009(7): 23-26.

[14] LU H M, YEN G G. Rank-density—based multi-objective genetic algorithm and benchmark test function study[J]. IEEE Transactions on Evolutionary Computation, 2003, 7(4): 325-342.

[15] 刘淳安, 王宇平. 约束多目标优化问题的进化算法及其收敛性研究[J]. 系统工程与电子技术, 2007, 29(2): 277-280.

LIU Chun-an, WANG Yu-ping. Constrained multi-objective optimization problems and its convergence of evolutionary algorithms[J]. Systems Engineering and Electronics, 2007, 29(2): 277-280.

(编辑 陈灿华)

收稿日期:2011-03-11;修回日期:2011-05-28

基金项目:国家“十一五”科技支撑计划项目(2009BAE85B00)

通信作者:郭俊(1982-),男,湖南武冈人, 博士研究生,从事铝电解生产过程优化与控制研究;电话:15116245128;E-mail: gjhr12200221@163.com