DOI:10.19476/j.ysxb.1004.0609.2019.03.06

挤压铸造对重熔原位α-Al2O3p/ZL109复合材料组织与性能的影响

徐进康1,陈 刚1, 2,张振亚1, 2,赵玉涛1, 2,周 祥1,刘 新1,严 庆1

(1. 江苏大学 材料科学与工程学院,镇江 212013;

2. 江苏大学 江苏省高端结构材料重点实验室,镇江 212013)

摘 要:以Al-SiO2为反应体系,借助半固态机械搅拌法,结合电磁搅拌分散工艺,制备5% α-Al2O3p/ZL109(体积分数)复合材料,并对重熔后的复合材料进行挤压铸造成型研究。结果表明:挤压铸造显著消除了复合材料因半固态机械搅拌卷气而引起的严重气孔缺陷,并细化基体α(Al)相晶粒;当压射比压达到80 MPa时,气孔缺陷完全消失,粗大的α(Al)树枝晶转变为细小的等轴晶,针状共晶Si细化成短棒状;分布在晶界的α-Al2O3颗粒也在一定程度上细化α(Al)晶粒。经80 MPa挤压铸造的重熔复合材料的T6热处理态抗拉强度和布氏硬度分别达到347 MPa和136 HB,与ZL109基体相比,提高5.8%和5.4%;与未挤压复合材料相比,提高20.9%和18.3%。

关键词:Al-SiO2体系;α-Al2O3p/ZL109复合材料;挤压铸造;显微组织;力学性能

文章编号:1004-0609(2019)-03-0474-10 中图分类号:TB331 文献标志码:A

原位颗粒增强铝基复合材料具有高比强度、高比模量、耐磨、耐高温、低线膨胀系数等优点,且因增强颗粒为原位化学反应生成,故有效地避免了外加颗粒所产生的界面污染、结合性不佳和有害脆性相等缺 点[1-2]。目前,原位颗粒增强铝基复合材料已广泛应用于航空航天、汽车及电子器件领域。半固态机械搅拌是通过熔体直接反应法制备原位颗粒增强铝基复合材料的主要添加反应物的技术手段。同液态机械搅拌相比,半固态存在的部分固态结晶相促使熔体黏度增大,呈现粘流态。因此,在半固态下,即使添加的反应物粉末与熔体的润湿性不佳,在强烈的机械搅拌作用下,反应物粉末也可通过搅拌涡流形成与破碎细小结晶相的机械混合,并在其裹挟作用下顺利进入熔体中,并实现较为均匀的分布[3]。然而,半固态机械搅拌过程极易卷气,且因颗粒增强铝基复合材料的黏度较大,通过精炼除气难以达到理想效果。此外,精炼过程容易带出部分增强颗粒,从而影响增强效果。因此,在精炼除气无法实现理想效果的条件下,采用传统的重力铸造往往出现较为严重的气孔问题,大大制约了原位颗粒增强铝基复合材料强度的提高。

挤压铸造,是对进入型腔内的液态(或半固态)金属施加较高的机械压力,使其在压力下成形和凝固,从而获得铸件的成型技术。作为结合铸造和锻造特点的工艺,挤压铸造的优势可概括如下[4-7]:1) 消除气孔、缩松、缩孔、偏析等铸造缺陷,提高组织致密性;2) 提高形核率,细化晶粒;3) 近净成形,表面成形质量高,适用范围广。目前,颗粒增强铝基复合材料采用挤压铸造成型的报道主要集中在外加法[8-11],而针对原位反应法的相关研究较少。XUE等[12],LI等[13]分别选用K2TiF6/KBF4/Al2014和Zr(CO3)2/A356反应体系,采用挤压铸造制备TiB2p/2014和(Al3Zr+ Al2O3)p/ A356复合材料。结果表明:挤压铸造可明显细化显微组织,提高组织致密性,并在一定程度上改善了颗粒增强相的分布,复合材料的力学性能得到显著提高。

本文作者选用Al-SiO2反应体系,通过半固态机械搅拌结合电磁搅拌辅助颗粒分散的工艺制备了5%α-Al2O3p/ ZL109(体积分数)复合材料,并对该复合材料进行了挤压铸造成型,研究了压射比压对重熔复合材料显微组织及力学性能的影响。

1 实验

1.1 实验材料

所用到的主要实验材料为:A356铝合金(即ZL101A, ZAlSi7MgA)、球状SiO2粉(尺寸约2 mm)、Al粉(尺寸约100 mm)、结晶Si、Cu片、Ni片、Mg块、六氯乙烷(C2Cl6)精炼剂、Al-10Sr变质剂、Al箔。

1.2 复合材料的制备

制备复合材料前,首先对Al-SiO2混合粉进行24 h球磨处理。球磨的作用是促使SiO2粉嵌入Al粉内部或粘附在Al粉表面,起到预分散作用并利于半固态过程添加。球磨中,Al-SiO2粉中Al和SiO2质量比为1:1,球料比为10:1,转速为300 r/min。

复合材料的制备过程概述如下:将A356合金锭置于石墨坩埚,在电阻炉内加热至750 ℃熔化并采用0.3% C2Cl6(质量分数)精炼。待A356合金熔体温度降至半固态区间(574~615 ℃)后对熔体进行机械搅拌,搅拌速度为500 r/min。将烘干的Al-SiO2球磨粉缓慢加至熔体中,并视半固态状态调整加粉速度,球磨粉加入量按生成5% α-Al2O3(体积分数)颗粒计算。球磨粉添加完毕后,升温至1050 ℃并保温0.5 h,保证铝熔体和SiO2粉末完全反应,生成α-Al2O3颗粒。反应结束后,降温至750 ℃,将按比例配好的结晶Si、Cu、Ni、Mg加至熔体中,保温30 min,以完成ZL109基体的配制。最后将复合材料浆料在750 ℃下保温,在电流为250 A、频率为7.5 Hz、磁感应强度为0.039 T的旋转磁场下进行10 min的电磁搅拌处理,最后浇注到预热至300 ℃、尺寸为100 mm×40 mm×15 mm的长方形铁模中。ZL109基体合金用同样的A356合金配制,用作对比材料。

1.3 复合材料的重熔挤压铸造成型

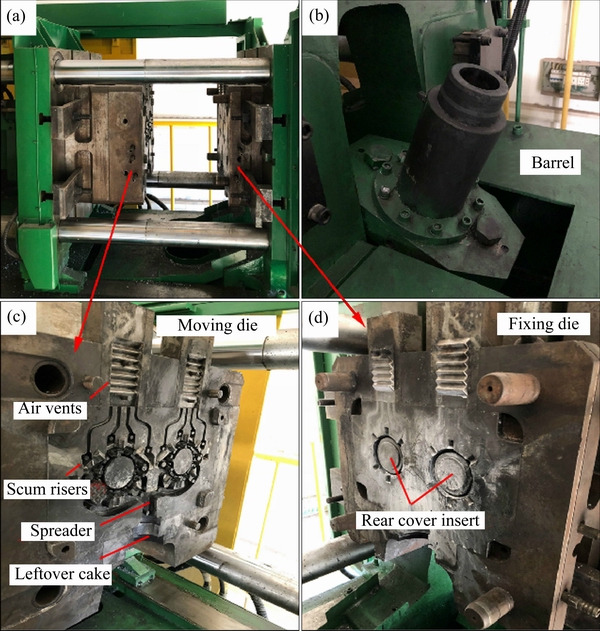

使用高频炉重熔采用1.2节制备的足量5% α- Al2O3p/ZL109(体积分数)复合材料及ZL109基体合金,分别采用0.5% Al-10Sr(质量分数)进行变质处理,用作挤压铸造材料。设备为三基SCH180型精密卧式冷室挤压铸造机,模具为汽车用后盖插件。该模具由动模和定模组成,包括排气槽、集渣包、后盖插件、分流锥和料饼等部分组成。具体的实物图如图1所示。

图1 模具及浇注系统实物图

Fig. 1 Physical maps of mold and casting system

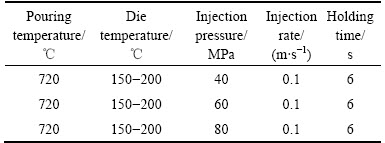

进行挤压铸造前,预先浇注ZL109合金烫模3~5个,预热模具至150~200 ℃,随后ZL109基体合金及复合材料分别进行压射比压为40 MPa、60 MPa和80 MPa的挤压铸造成型。挤压铸造的主要工序:合模→料筒浇料→料筒摆正上升→压射→保压→开模→顶针顶出。挤压铸造件实物图及测试表征的取样位置如图2所示。挤压铸造的工艺参数设置如表1所列。

图2 挤压铸造件实物及取样位置

Fig. 2 Physical maps of squeeze casting part and sampling sites

表1 挤压铸造工艺参数

Table 1 Process parameters of squeeze casting

1.4 测试与表征

1.4.1 显微组织、成分及物相组成

直读光谱仪(SPECTRO MAXx mm06)用于测定1.2节制备的ZL109及复合材料的化学成分;XRD用于鉴定相组成;采用线切割,从复合材料铸锭及重熔挤压铸造ZL109及复合材料件中分别取尺寸为5 mm×5 mm×5 mm的立方金相试样(如图2所示),经磨制、抛光后借助光镜(OM, Zeiss Observer.Zlm)及配备能谱仪的扫描电镜(SEM, JSM-7001F)进行组织观察和成分分析。

1.4.2 拉伸性能测试

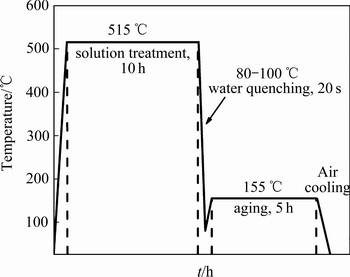

重熔后的铸态及T6热处理态挤压铸造ZL109及复合材料的拉伸性能测试在电子万能拉伸试验机(AGS-X, SHIMADZU)上进行。T6热处理工艺路线如图3所示。拉伸测试采用微型片状拉伸试样,试样尺寸如图4所示。拉伸速度为1 mm/s,每组测定5个拉伸试样,舍去最大值和最小值后取平均值。

图3 T6热处理工艺路线

Fig. 3 Process route of T6 heat treatment

图4 拉伸试样尺寸

Fig. 4 Sizes of tensile specimen (Unit: mm)

1.4.3 布氏硬度测试

采用布氏硬度仪(SCTMC, DHB-3000)对抛光后的T6态重熔挤压铸造金相试样进行硬度测试。硬度仪采用淬火钢球,载荷为2450 N,保压时间为30 s。每组试样测试5次,测量压痕直径后,查表得出硬度值,舍去最大和最小值后取平均值。

2 结果与讨论

2.1 复合材料的成分及物相分析

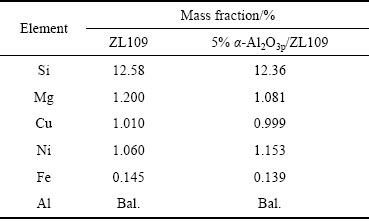

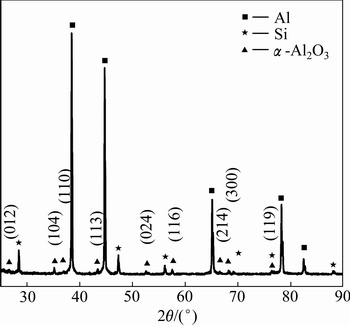

表2列出了1.2节制备的ZL109及复合材料的元素成分,其完全符合ZL109合金的成分要求。图5所示为复合材料的XRD谱,其显示,复合材料的相组成为Al、Si和α-Al2O3,并未检测出SiO2相。此结果表明,Al熔体与SiO2的反应已进行完全,且已全部生成α-Al2O3相。

表2 材料的化学成分

Table 2 Chemical composition of materials

图5 复合材料的XRD谱

Fig. 5 XRD pattern of composite

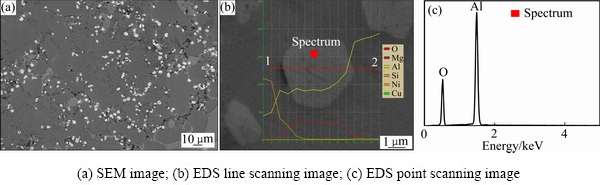

复合材料的扫描电镜组织如图6(a)所示。由图6(a)可知,复合材料组织主要由分布较好的白色颗粒及非常严重的气孔组成,气孔聚集在一起,组成严重的河流状孔洞缺陷。气孔缺陷与半固态机械搅拌过程在大气环境下进行而引起的严重卷气现象直接相关。图6(b)和(c)所示的线扫和点扫均表明,放大的白色颗粒仅有Al和O元素组成,为Al2O3相,结合图5中的XRD谱可知,白色颗粒即为α-Al2O3相。

2.2 挤压铸造对重熔复合材料显微组织的影响

2.2.1 挤压铸造对气孔及α-Al2O3颗粒分散性的影响

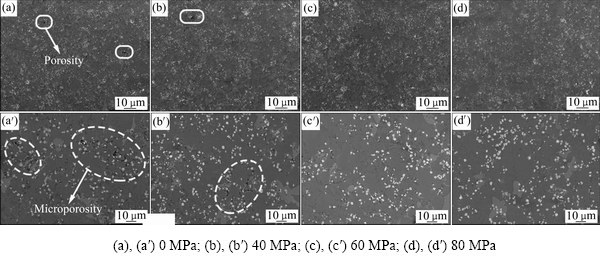

图7(a)~(d)为分别经0、40、60、80 MPa压射比压成型后重熔复合材料的低倍扫描电镜图。低倍条件下,气孔缺陷不易观察,仅未经挤压铸造的图7(a)中可观察到较为明显的孔洞,随压射比压提高,气孔逐渐较少,压射比压为60 MPa时,复合材料低倍组织已无法观察到气孔存在。图7(a′)~(d′)为分别经0、40、60、80 MPa压射比压成型后的重熔复合材料的高倍扫描电镜图。从图7(e)中可清晰地看到,高倍条件下,重熔未挤压的复合材料存在明显的孔洞缺陷,显微气孔大多集中在α-Al2O3颗粒周围。这表明α-Al2O3颗粒容易成为气孔的形核位置。随压射比压提高,显微气孔数量明显减少,压射比压为60 MPa时,已经无法观察到显微气孔。当压射比压达到80 MPa时,复合材料的气孔问题基本得到根除,复合材料组织显著致密化。图7还表明,重熔后经挤压铸造的复合材料中α-Al2O3颗粒依然保持了较好的分散性,仅有极少量、尺寸细微的团聚存在。这表明,重熔及挤压铸造可显著根除复合材料因半固态机械搅拌过程卷气严重而引起的气孔过多问题,对于颗粒的分散性无明显影响。

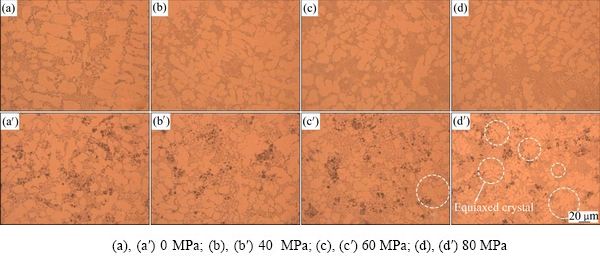

2.2.2 挤压铸造对显微组织的细化作用

图8所示为在光镜下观察到的不同压射比压条件下的重熔ZL109及复合材料的组织。图8(a)~(d)所示为分别经0、40、60、80 MPa压射比压成型后的重熔ZL109的显微组织。图8(a)显示,未进行挤压铸造时,ZL109组织中分布着粗大的树枝晶α(Al)相,二次枝晶臂间距较大,共晶Si为长条、针状组成的珊瑚状形貌。挤压铸造后,随压射比压增大,ZL109组织出现了明显的细化现象。粗大的α(Al)树枝晶破碎成较小的树枝晶,二次枝晶臂间距缩短,且部分较小的树枝晶开始向等轴晶转变。共晶Si细化成更加细小的针状、短棒状,圆整度大为提高。当压射比压达到80 MPa时,ZL109组织基本呈现细小的α(Al)树枝晶和部分等轴晶的形态,共晶Si细化成短棒状。图8(a′)所示为未经挤压铸造的重熔复合材料的显微组织,其呈现较大的α(Al)相树枝晶及较为细小的蠕虫状共晶Si组成的分布较为均匀的珊瑚状结构。光学显微镜下无法清晰地观察到高倍扫描电镜组织中呈现的显微气孔缺陷(图7(a′))。图8(b′)~(d′)所示为分别经40、60、80 MPa压射比压成型后的复合材料显微组织图。比较后可以发现,挤压铸造对于复合材料组织细化的作用同ZL109类似。当压射比压达到80 MPa时,粗大的α(Al)相树枝晶几乎全部转变为细小的等轴晶,共晶Si细化成细小的短棒状。

挤压铸造细化铸件晶粒可归结为两个方面的原因。其一,挤压铸造提高了形核率。首先,依据Clausius-Clapeyron方程[14],压力增加提高了合金的液相线温度,因此,合金的实际过冷度提高,形核率提高。其表达式如下:

(1)

(1)

式中: 为体系的摩尔升华热或摩尔气化热,kJ/mol,温度变化不大时,视为常数;△Vm为摩尔体积变化,dm3/mol;△p为压力变化,kPa;△Tp为压力p下的熔点变化,K;Tm为平衡状态下的熔点,K。另外,在压力作用下,铸件与模具内壁的接触更加紧密,改善了合金与铸型的热交换条件,提高了冷却速度,同样提高了形核率。其二,挤压铸造使部分枝晶得到破碎、细化。挤压铸造过程材料将发生一定塑性变形,部分先结晶的枝晶不但得以破碎、细化,而且提供了更多的形核核心。综上所述可知,挤压铸造能明显细化铸件的晶粒尺寸。

为体系的摩尔升华热或摩尔气化热,kJ/mol,温度变化不大时,视为常数;△Vm为摩尔体积变化,dm3/mol;△p为压力变化,kPa;△Tp为压力p下的熔点变化,K;Tm为平衡状态下的熔点,K。另外,在压力作用下,铸件与模具内壁的接触更加紧密,改善了合金与铸型的热交换条件,提高了冷却速度,同样提高了形核率。其二,挤压铸造使部分枝晶得到破碎、细化。挤压铸造过程材料将发生一定塑性变形,部分先结晶的枝晶不但得以破碎、细化,而且提供了更多的形核核心。综上所述可知,挤压铸造能明显细化铸件的晶粒尺寸。

图6 复合材料的扫描电镜及能谱图

Fig. 6 SEM and EDS images of composite

图7 挤压铸造重熔复合材料的SEM像

Fig. 7 SEM images of squeeze casting remelted composites

图8 光镜下经挤压铸造的重熔ZL109及复合材料组织

Fig. 8 Microstructures of squeeze casting remelted ZL109 and composites under optical microscopy

2.2.3 α-Al2O3颗粒对α(Al)相的细化作用

需要提及的是,单独比较图8(a)和(a′)、(b)和(b′)、(c)和(c′)、(d)和(d′)可知,在同样的压射比压条件下,相比ZL109,复合材料中的α(Al)相细化程度更加明显,该现象显然与α-Al2O3颗粒的细化作用相关。目前,增强颗粒对基体的细化作用主要存在两种机制。

1) 增强颗粒作为异质形核核心。增强颗粒与基体间良好的晶体学匹配关系是异质形核机制的基础和保证。经典形核理论认为,异质形核所需的临界形核功如式(2)所示[15]。

(2)

(2)

式中: 为固/液界面能,kJ/(mol·m2);ΔGv为凝固所需自由能,kJ/mol;θ为接触角,(°)。由于α-Al2O3是密排六角形结构,而Al为面心立方结构。基于两者晶体结构的显著差异,取得低错配度以减小接触角θ和固液界面能

为固/液界面能,kJ/(mol·m2);ΔGv为凝固所需自由能,kJ/mol;θ为接触角,(°)。由于α-Al2O3是密排六角形结构,而Al为面心立方结构。基于两者晶体结构的显著差异,取得低错配度以减小接触角θ和固液界面能 ,从而减小临界形核功并不现实。相关研究结果也表明[16-17],Al2O3和Al之间并无固定的取向关系。此外,LI等[18]与本文的研究结果均表明,Al2O3颗粒主要分布在Si/Al界面或α(Al)晶界位置。因此,可以推断,α-Al2O3颗粒并不能作为基体的有效异质形核核心。

,从而减小临界形核功并不现实。相关研究结果也表明[16-17],Al2O3和Al之间并无固定的取向关系。此外,LI等[18]与本文的研究结果均表明,Al2O3颗粒主要分布在Si/Al界面或α(Al)晶界位置。因此,可以推断,α-Al2O3颗粒并不能作为基体的有效异质形核核心。

2) 晶界限制生长机制。该理论认为α-Al2O3颗粒在基体凝固过程中将被推移至凝固界面前沿并限制α(Al)晶粒的生长。STEFANESCU等[19-20]和KAPTAY等[21]认为增强颗粒在复合材料凝固过程中可能被吞噬而处在晶粒内部或者被排斥到晶界,这主要取决于液固界面前沿的临界移动速率vc与实际移动速率vSL间的关系,vc的表达式如式(3)所示[21]。

(3)

(3)

式中: 为颗粒与固相表面能与颗粒与液相表面能的差值,J/m2;

为颗粒与固相表面能与颗粒与液相表面能的差值,J/m2; 为原子间距,m;η为液相黏度,Pa·s;K*为颗粒与液相热导率的比值;R为颗粒半径,m。当vSL>vc时,颗粒被液固界面吞噬;反之,颗粒将被推移至最后凝固区域。由于Al液和α-Al2O3颗粒的润湿性较差,故α-Al2O3与固相Al和液相Al的表面能差值均较高。此外,ZL109基体合金流动性好,黏度η较低。因此,复合材料熔体凝固界面前沿的临界冷却速率vc要高于实际移动速率vSL,α-Al2O3颗粒将被推移至最后凝固区域,最终分布在α(Al)晶界、枝晶臂及共晶Si位置。这与图8的实验结果相符。

为原子间距,m;η为液相黏度,Pa·s;K*为颗粒与液相热导率的比值;R为颗粒半径,m。当vSL>vc时,颗粒被液固界面吞噬;反之,颗粒将被推移至最后凝固区域。由于Al液和α-Al2O3颗粒的润湿性较差,故α-Al2O3与固相Al和液相Al的表面能差值均较高。此外,ZL109基体合金流动性好,黏度η较低。因此,复合材料熔体凝固界面前沿的临界冷却速率vc要高于实际移动速率vSL,α-Al2O3颗粒将被推移至最后凝固区域,最终分布在α(Al)晶界、枝晶臂及共晶Si位置。这与图8的实验结果相符。

基于以上分析,本文认为α-Al2O3颗粒对于α(Al)相的细化作用主要由晶界限制生长机制决定。分布在晶界的α-Al2O3颗粒限制了α(Al)相的持续长大。此外,α-Al2O3颗粒在晶界的偏聚还将引起成分过冷,将界面的生长方式由直接界面生长转变为胞状生长[22],最终细化了α(Al)相。

2.3 挤压铸造对重熔复合材料拉伸性能及硬度的影响

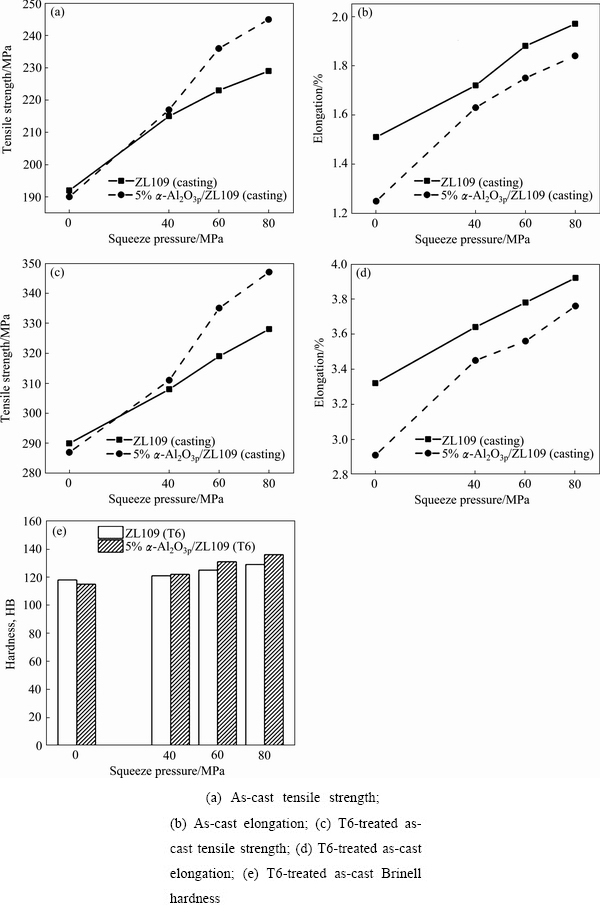

图9所示为不同压射比压条件下重熔ZL109及复合材料的拉伸性能及布氏硬度。图9(a)和(b)显示,铸态下,随压射比压增加,ZL109及复合材料的抗拉强度和伸长率均明显提高。比较ZL109及复合材料的抗拉强度可知,未挤压条件下,复合材料的抗拉强度略低于ZL109基体合金,这与复合材料组织中存在较多的气孔缺陷有关。当施加40 MPa压射比压后,气孔大量消除后,复合材料的抗拉强度略高于ZL109。随压射比压继续增加,气孔缺陷完全消除后,复合材料的抗拉强度显著提高。而伸长率曲线显示,在任何压射比压下,复合材料的伸长率均低于ZL109的,这与复合材料中分布的硬质α-Al2O3颗粒有关。铸态下,复合材料在80 MPa条件下的抗拉强度为245 MPa,与ZL109相比,提高了6.9%;与未挤压态复合材料相比,提高了28.9%;图9(c)、(d)、(e)所示为重熔ZL109及复合材料经T6热处理的抗拉强度、伸长率和布氏硬度。由图9(c)和(d)可知,重熔ZL109及复合材料的T6态抗拉强度和伸长率随压射比压增加而提高的趋势与铸态相同。但因T6热处理显著球化了共晶Si相,故强度和伸长率均明显提高,布氏硬度与强度的变化趋势保持一致。重熔复合材料在80 MPa挤压铸造条件下的T6态抗拉强度和布氏硬度为347 MPa和136 HB,与ZL109相比,提高了5.8%和5.4%;与未挤压态复合材料相比,提高了20.9%和18.3%。

颗粒增强铝基复合材料的强化来自4种机制[16, 19, 23-24]:1) 载荷转移机制。载荷可通过基体传递到基体与颗粒的结合界面及颗粒上,当界面的结合力较强时,可大大提高复合材料的承载能力;2) 热错配强化机制。基体合金与增强颗粒存在的热膨胀系数差异,使得复合材料从成型温度降至室温时,由于热错配的原因将产生一定数量的位错,引起位错密度增加,从而提高了复合材料的强度;3) 细晶强化机制。增强颗粒因异质形核机制或晶界限制长大机制而显著细化了基体晶粒,从而提高了复合材料的强度;4) 奥罗万强化机制。由于弥散分布的细小增强颗粒存在,复合材料在塑性变形过程中,位错的运动将受到颗粒阻碍而起到强化作用。在上述4种机制的作用下,颗粒增强铝基复合材料强度得到较为显著的提高。

图9 挤压铸造重熔ZL109及复合材料的拉伸性能及硬度

Fig. 9 Tensile properties and hardness of squeeze casting remelted ZL109 and composites

2.4 拉伸断口分析

图10所示为重熔ZL109及复合材料经80 MPa压射比压成型后的铸态和铸后T6态拉伸断口形貌。图10(a)所示为ZL109的铸态断口形貌,断面的基本组成为小块的解理台阶,出现了撕裂棱特征及数量较少的韧窝,呈现韧-脆混合,以脆性为主的断裂形式。图10(b)所示为复合材料的铸态断口形貌,断面由数量较多、分布较均匀的细小解理或准解理台阶组成,并且出现较多深度较浅的韧窝,呈现脆-韧混合断裂形式,部分韧窝内部或周围可观察到较多的α-Al2O3颗粒分布。图10(c)所示为铸后T6态ZL109的断口形貌,整个断口均匀分布着尺寸细小的韧窝,呈现非常明显的韧性断裂形式。图10(d)所示为复合材料的铸后T6态断口形貌,与图10(b)相比,复合材料的塑性得到改善。整个断口形貌被大量韧窝和部分细小的解理或准解理台阶组成,韧-脆混合断裂,以韧性断裂为主的形式,可观察到的α-Al2O3颗粒均居于韧窝内部。一般认为,韧窝的形成机理为微孔聚集,即微孔形核、长大、聚集直至断裂的过程。材料内部的诸多微孔,在滑移作用下逐渐长大并和周围微孔连接成较大孔洞,最终形成韧窝状断口。夹杂或第二相颗粒因容易形成应力集中而产生微孔,因此韧窝多于夹杂或第二相颗粒处产生。ZL109基体合金中的共晶Si相,经挤压铸造和T6热处理后,得到显著细化并球化,可视为韧窝的最重要来源,图10(c)中的大量韧窝为很好的佐证。α-Al2O3颗粒与ZL109基体的线膨胀系数不同,复合材料降温凝固过程形成的应变不匹配将在界面处产生应力集中,在拉伸过程中,α-Al2O3颗粒处容易形成微孔并最终形成韧窝。且经挤压铸造后,α-Al2O3颗粒与基体结合性能优越,α-Al2O3颗粒不易脱落,最终留在韧窝内部。

图10 挤压铸造重熔ZL109及复合材料的断口形貌(80 MPa)

Fig. 10 Fracture morphologies of squeeze casting ZL109 and composites (80 MPa)

3 结论

1) 通过Al-SiO2体系,借助半固态机械搅拌,结合电磁搅拌分散工艺制备了5% α-Al2O3p/ZL109(体积分数)复合材料。由于半固态机械搅拌卷气严重,复合材料组织中出现了大量气孔缺陷。

2) 重熔后,经80 MPa挤压铸造后,复合材料的气孔缺陷完全消除。此外,挤压铸造显著细化了ZL109基体合金的显微组织,粗大的α(Al)相树枝晶开始向较为细小的等轴晶转变。

3) 分布在晶界及共晶组织处的α-Al2O3颗粒对于基体α(Al)相存在一定的细化作用,其机理可用晶界限制长大机制解释。

4) 经80 MPa挤压铸造的重熔复合材料的T6态抗拉强度和布氏硬度分别达到347 MPa和136 HB,与ZL109相比,提高了5.8%和5.4%;与未挤压态复合材料相比,提高了20.9%和18.3%。

REFERENCES

[1] 史玉娟. 原位反应制备Al2O3颗粒增强铝基复合材料的研究[D]. 沈阳: 东北大学, 2006: 1-3.

SHI Yu-juan. Research on in situ Al2O3 particle reinforced aluminum matrix composites[D]. Shenyang: Journal of Northeastern University, 2006: 1-3.

[2] 肖华强, 陈维平. Al/TiO2/TiC体系原位合成Ti3AlC2/Al2O3/TiAl3复合材料的反应机理[J]. 中国有色金属学报, 2017, 27(9): 1848-1854.

XIAO Hua-qiang, CHEN Wei-ping. In-situ reaction synthesis mechanism of Ti3AlC2/Al2O3/TiAl3composite from Al/TiO2/ TiC system[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(9): 1848-1854.

[3] 花 程. 原位Al2O3p/Al复合材料反应机理及半固态挤压铸造成形研究[D]. 镇江: 江苏大学, 2015: 1-10.

HUA Chen. Study on the reaction mechanism and semi solid squeeze casting of in situ Al2O3p/Al composite[D]. Zhenjiang: Journal of Jiangsu University, 2015: 1-10.

[4] SEKAR K, ALLESU K, JOSEPH M A. Effect of T6 heat treatment in the microstructure and mechanical properties of A356 reinforced with nano Al2O3 particles by combination effect of stir and squeeze casting[J]. Procedia Materials Science, 2014, 5: 444-453.

[5] 齐丕骧. 挤压铸造[M]. 北京: 国防工业出版社, 1984: 10-35.

QI Pi-xiang. Squeeze casting[M]. Beijing: National Defense Industry Press, 1984: 10-35.

[6] WANG Yong-fei, ZHAO Sheng-dun, ZHANG Chen-yang. Microstructures and mechanical properties of semi-solid squeeze casting ZL104 connecting rod[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(2): 235-243.

[7] 孟凡生, 张卫文, 张大童, 杨 超, 肖志瑜. Zr对挤压铸造Al-5.0Cu-0.4Mn合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2016, 26(1): 23-30.

MENG Fan-sheng, ZHANG Wei-wen, ZHANG Da-tong, YANG Chao, XIAO Zhi-yu. Effect of Zr on microstructures and mechanical properties of squeeze cast Al-5.0Cu-0.4Mn alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 23-30.

[8] DAOUD A, ELKHAIR M T, ABDELAZIM A N. Effect of Al2O3 particles on the microstructure and sliding wear of 7075 Al alloy manufactured by squeeze casting method[J]. Journal of Materials Engineering & Performance, 2004, 13(2): 135-143.

[9] SINGH M, RANA R S, PUROHIT R, SAHU K. Development and analysis of Al-matrix nano composites fabricated by ultrasonic assisted squeeze casting process[J]. Materials Today Proceedings, 2015, 2(4/5): 3697-3703.

[10] SUKUMARAN K, RAVIKUMAR K K, PILLAI S G K, RAJAN T P D, RAVI M, PILLAI R M, PAIP C. Studies on squeeze casting of Al 2124 alloy and 2124-10% SiCp metal matrix composite[J]. Materials Science & Engineering A, 2008, 490(1/2): 235-241.

[11] RAMESH R, SURESHKUMAR S, GOWRISHANKAR S. Production and characterization of aluminium metal matrix composite reinforced with Al3Ni by stir and squeeze casting[J]. Applied Mechanics & Materials, 2015, 766/767: 315-319.

[12] XUE J, HAN Y F, WANG J, SUN B D. Study on squeeze casting of an in situ 5 vol.% TiB2/2014Al composite[J]. Materials Science & Technology, 2013, 29(11): 1373-1382.

[13] LI G R, ZHAO Y T, WANG H M, CHEN G, DAI Q X, CHENG X N. Fabrication and properties of in situ (Al3Zr+Al2O3)p/A356 composites cast by permanent mould and squeeze casting[J]. Journal of Alloys & Compounds, 2009, 471(1/2): 530-535.

[14] 董普云. SiCp/A356搅拌制备与挤压铸造成形的研究[D]. 广州: 华南理工大学, 2012: 18-21.

DONG Pu-yun. Research on squeeze casting processing of SiCp/A356 composites prepared by stirring technology[D]. Guangzhou: South China University of Technology, 2012: 18-21.

[15] HANABE M R, ASWATH P B. Al2O3-Al particle-reinforced aluminum matrix composite by displacement reaction[J]. Journal of Materials Research, 1996, 11(6):1562-1569.

[16] WANG H M, LI G R, ZHAO Y T, CHEN G. In situ fabrication and microstructure of Al2O3particles reinforced aluminum matrix composites[J]. Materials Science & Engineering A, 2010, 527(12): 2881-2885.

[17] ZHAO Y T, ZHANG S L, CHEN G, CHENG X N, WANG C Q. In situ (Al2O3+Al3Zr)np/Al nanocomposites synthesized by magneto-chemical melt reaction[J]. Composites Science & Technology, 2008, 68(6): 1463-1470.

[18] LI Q L, LI F B, XIA T D, LAN Y F, JIAN Y S, TAO F. Effects of in-situ γ-Al2O3particles and heat treatment on the microstructure and mechanical properties of A356 aluminium alloy[J]. Journal of Alloys & Compounds, 2015, 627(5): 352-358.

[19] STEFANESCU D M, DHINDAW B K, KACAR S A, MOITRA A. Behavior of ceramic particles at the solid-liquid metal interface in metal matrix composites[J]. Metallurgical Transactions A, 1988, 19(11): 2847-2855.

[20] SEN S, JURETZKO F, STEFANESCU D M, DHINDAWB K, CURRERIET P A. In situ observations of interaction between particulate agglomerates and an advancing planar solid/liquid interface: Microgravity experiments[J]. Journal of Crystal Growth, 1999, 204(1/2): 238-242.

[21] KAPTAY G. Further discussion of particle engulfment and pushing by solidifying interfaces: Part II. Microgravity experiments and theoretical analysis[J]. Metallurgical & Materials Transactions A, 2000, 31(6): 1695-1700.

[22] 王章忠. 材料科学基础[M]. 北京: 机械工业出版社, 2005: 226-228.

WANG Zhang-zhong. Material science foundation[M]. Beijing: China Machine Press, 2005: 226-228.

[23] ZHANG Z, CHEN D L. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength[J]. Scripta Materialia, 2006, 54(7): 1321-1326.

[24] KIN C S, SOHN I, NEZAFATI M, FERGUSON J B, SCHULTZ B F, BAJESTANI G Z. Prediction models for the yield strength of particle-reinforced unimodal pure magnesium (Mg) metal matrix nanocomposites (MMNCs)[J]. Journal of Materials Science, 2013, 48(12): 4191-4204.

Effects of squeeze casting on microstructure and properties of remelted in-situ α-Al2O3p/ZL109 composites

XU Jin-kang1, CHEN Gang1, 2, ZHANG Zhen-ya1, 2, ZHAO Yu-tao1, 2, ZHOU Xiang1, LIU Xin1, YAN Qing1

(1. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China;

2. Jiangsu Province Key Laboratory of High-end Structure Materials, Jiangsu University, Zhenjiang 212013, China)

Abstract: 5% α-Al2O3/ZL109 (volume fraction) composites were prepared by semi-solid mechanical stirring with aid of electromagnetic stirring through Al-SiO2 system, and the remelted composites were also studied by squeeze casting. The microstructure observation results show that squeeze casting is very effectively to eliminate serious porosity defects caused by semi-solid mechanical stirring and refine the microstructure of ZL109 matrix. When the squeeze pressure reaches 80 MPa, the porosity defects completely disappear, coarse α(Al) dendrites transform into fine equiaxed crystals, and the eutectic Si is refined into rod-like. α-Al2O3 particles distributing along grain boundaries also refine α(Al) grains to some extent. The mechanical property test results show that the tensile strength and Brinell hardness of T6-treated composites remelted at 80 MPa are 347 MPa and 136 HB, respectively, which increase by 5.8% and 5.4% compared with those of remelted ZL109 matrix alloy, and increase by 20.9% and 18.3% compared with those of non-squeeze casting composites.

Key words: Al-SiO2 system; α-Al2O3/ZL109 composite; squeeze casting; microstructure; mechanical property

Foundation item: Project(U1664254) supported by the National Natural Science Foundation of China; Project (BA2016159) supported by Jiangsu Province Special Funds of Transformation of Scientific and Technological Achievements, China; Project(BE2015148) supported by Jiangsu Province Key Research and Development Plan, China; Project(BE2012135) supported by Jiangsu Province Science and Technology Supporting Plan, China

Received date: 2018-03-06; Accepted date: 2018-05-22

Corresponding author: CHEN Gang; Tel: +86-13952860956; E-mail: gchen@ujs.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金重点资助项目(U1664254);江苏省科技成果转化专项资金项目(BA2016159);江苏省重点研发计划项目(BE2015148);江苏省科技支撑计划项目(BE2012135)

收稿日期:2018-03-06;修订日期:2018-05-22

通信作者:陈 刚,教授,博士;电话:13952860956;E-mail:gchen@ujs.edu.cn