零件设计过程多学科协同优化

陈志刚1,李梦奇1,付伟2,周廷明2,刘志辉1

(1. 邵阳学院 机械与能源工程系,湖南 邵阳,422004;

2. 株洲易力达机电有限公司,湖南 株洲,421000)

摘要:基于传统零件设计与优化遵循顺序过程无法达到面向载荷—结构—工艺的全局最优,对轴类零件的过程设计多学科优化进行研究;以质量为系统级目标函数,以集中载荷截面的弯矩和扭矩、安全系数变化、切削加工去除材料总量为学科目标函数,建立过程协同优化模型,以遗传-粒子群算法进行求解,并以某电动助力转向器(EPS)输出轴为研究对象进行优化计算。研究结果表明:输出轴质量减小5.5%,在300 N·m扭矩或80 N·m助力转矩2种状态下优化后最大变形分别减小4.2%和9.6%,最大应力分别减小4.4%和10.1%。

关键词:多学科设计优化;协同优化;设计过程;输出轴

中图分类号:TH11 文献标志码:A 文章编号:1672-7207(2012)03-0947-06

Multidisciplinary collaborative optimization for parts design process

CHEN Zhi-gang1, LI Meng-qi1, FU Wei2, ZHOU Ting-ming2, LIU Zhi-hui1

(1. Department of Mechanical and Energy Engineering, Shaoyang University, Shaoyang 422004, China;

2. Zhuzhou Elite Electro Mechanical Co. Ltd., Zhuzhou 421000, China)

Abstract: Based on the fact that sequential process of parts design and optimization cannot achieve the global optimization for the load-structure-process, the process of shaft multidisciplinary design optimization was built. Taking quality as the system-level objective function, and taking the bending moment and concentrated load torque, the changed safety factors and the total amount of material removal machining as the disciplines objective function in cross-section, genetic-particle swarm algorithm method was built, and the optimization calculation of EPS output shaft was made. The results show that the output mass is reduced by 5.5%, and at electric power-assisted moment of 300 N·m and 80 N·m, the maximum deformations reduce by 4.2% and 9.6%, and the maximum stresses decrease by 4.4% and 10.1%, respectively.

Key words: multidisciplinary design optimization; collaborative optimization; design process; output shaft

当前,零件设计采用的危险截面法普遍遵循“载荷确定危险截面,根据计算准则求得危险截面面积,然后进行结构设计获得零件形状,最后编制制造工艺”的顺序[1-2],即“载荷-结构-工艺”顺序计算方式,载荷决定结构,结构决定工艺,没有考虑后续工作对前面计算的影响,优化设计局限于属于不同学科每个阶段内,无法实现全局优化[3-4]。零件设计“载荷-结构-工艺”优化需要在各个阶段进行学科优化,同时需要进行整体优化。整体优化的目标又不等同于任何学科优化目标,属于多级优化的范畴[5]。多学科设计优化(MDO)从设计问题本身入手,从设计计算结构、信息组织的角度研究问题,是在具体寻优算法的基础上提出设计计算框架,将设计对象各学科知识与这些具体的寻优算法结合起来,形成一套有效解决复杂对象的优化求解方法,为零件优化设计提供了新思 路[6-8]。在此,本文作者将MDO理论应用于轴类零件设计整体优化,建立多学科协同优化模型,采用遗 传-粒子群算法进行计算,并以电动助力转向系统(EPS)输出轴为例进行设计优化计算。

1 设计过程协同优化(CO)建模

1.1 顺序过程设计问题

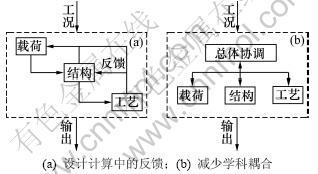

设计计算采用顺序过程,反馈较少,信息在学科间单向流动,优化设计只能在过程内部实现,整体优化需要对零件的受力、结构、加工工艺进行全面考虑,将设计计算过程从单向顺序式变成多向循环式(如图1(a)所示),计算量急剧增加且收敛性无法保证。MDO通过系统级别的总体协调减少顺序过程所属学科间耦合,将学科间耦合转变为各个学科与总体协调之间的关系(如图1(b)所示),从而实现全面优化。

图1 零件设计多学科协同优化任务

Fig.1 Task of CO for parts

1.2 过程协同优化模型

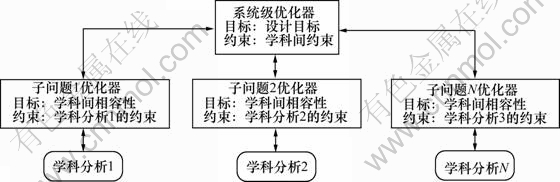

协同优化[7]是一种针对复杂系统设计问题的分布式、多级优化方法。Kroo针对工程设计提出具有双层结构的分布式协同优化方法,用于多目标、多学科的优化设计,将复杂优化设计问题分解为各学科优化设计以及一个系统级优化问题,通过系统级等式约束来协调各学科之间的共享设计变量和耦合状态变量[7]。协同优化的基本框架如图2所示。框架包含系统级优化和各分系统优化2个主要环节。分系统优化设计变量包括共享设计变量、学科间的耦合状态变量以及只属于本学科的局部设计变量,只需满足本学科的约束,分系统的优化目标是使该分系统优化方案与系统级的目标方案之间的差异最小。系统级优化的任务是使整个系统目标最优,并通过等式约束条件保证学科之间的共享设计变量和耦合状态变量的一致性。该方法的优点是消除了复杂的系统分析,各个子系统能并行地进行分析和优化,子系统优化目标不直接涉及整个系统的目标值。但是,由于将状态变量看作设计变量扩大了设计变量的维数,CO会使子系统分析的次数增加,且只有当系统级所有等式约束满足时才存在优化解,常常应用现代优化算法如遗传算法、粒子群算法实现。轴类零件机械设计的最优目标有最终材料成本(质量)和加工成本(为便于计算,去除材料成本计入本部分)都可以转换为轴类零件质量。加工成本与工艺相关,为了便于计算,本文采用固定工艺过程的切削体积(切削体积反映加工时间)。轴类零件优化系统层优化问题描述为:

Find X

min m=f(D1(X), D2(X))

s.t. gi(X)≤0

式中:m为输出轴向的质量;X为设计变量,D1(X)和D2(X)分别为轴类零件最终质量和加工去除质量;gi(X)为约束条件(载荷条件M,F和T等)。

1.3 遗传-粒子群算法(GA-PSO)

粒子群算法(Particle swarm optimization, PSO)是Kennedy等[9]提出的一种进化计算技术。PSO首先初始化一群随机粒子(随机解),然后,粒子追随当前的最优粒子在解空间中搜索,即通过迭代找到最优解。

图2 协同优化算法框图

Fig.2 Frame of collaborative optimization

在每一次迭代中,粒子通过跟踪2个最优解来更新:第一个是粒子本身所找到的最优解,即个体极值pbest;另外一个是整个种群目前找到的最优解,即全局最优解gbest。PSO基于种群的迭代搜索,不同个体之间不断进行信息交流和传递,通过候选解组成的群体在进化过程中寻求最优解,具有规则简单、并行性、易于编程实现、收敛速度快、面向实数等特点,适用于无明显解析表达式的目标函数问题优化。求解中只需目标函数的取值信息,无需梯度等高价值信息,可求解不可微分方程,是一种全局最优化方法。

改进的粒子群算法通过与其他智能算法相结合,实现连续变量与离散变量之间的代换。本文采用粒子群算法与遗传算法[10]相结合(GA-PSO),解决非线性约束离散变量设计问题。GA-PSO算法原理为:利用遗传算法中的杂交概念,在每次迭代中,根据杂交概率选取指定数量的粒子放入杂交池内,池中的粒子随机两两杂交,产生同样数目的子代粒子(child),并用子代粒子替换亲代粒子(parent)。子代位置由父代位置进行算术交叉得到:

或

其中:p为0到1之间的随机数。子代的速度由下式计算:

或

GA-PSO算法的基本步骤如下。

Step 1:随机初始化种群中各微粒的位置和速度。

Step 2:评价每个微粒的适应度,将当前各微粒的位置和适应值存储在各微粒的pbest中,将所有pbest中适应值最优个体的位置和适应值存储于gbest中。

Step 3:更新每个微粒的速度和位置。

Step 4:对每个微粒,将其适应值与其经历过的最好位置进行比较,若较好,则将其作为当前的最好位置。

Step 5:比较当前所有pbest和gbest,更新gbest。

Step 6:根据杂交概率选取指定数量的粒子放入杂交池内,池中的粒子随机两两杂交产生同样数目的子代粒子。子代的位置和速度计算公式如下:

保持pbest和gbest不变。

Step 7:若满足停止条件(预设的运算精度或者迭代次数),则搜索停止,输出结果;否则,返回Step 3,继续搜索。

2 EPS输出轴优化计算

2.1 学科函数

2.1.1 载荷优化

EPS输出轴载荷随着轴承位置不同而不同,调整轴承位置,使载荷分布尽可能均匀,使得各个危险截面弯矩和扭矩尽可能相等或者等效。取减速机构和轴承安装位置x、输出轴在x方向每个截面的抗弯截面系数W为设计变量,以输出轴危险截面(集中载荷截面)弯矩和扭矩为目标函数,满足相应的安装要求为约束条件,输出轴载荷优化子学科数学模型为:

X(xi)

min f(X)= {M(x);T(x)}

s.t. xi ∈[ci1, ci2]

式中:i=1, 2, 3;x1,x2和x3分别为轴承1、减速机构和轴承2在输出轴上的位置;M(x)和T(x)分别为弯矩和扭矩;ci1和ci2分别为轴承和减速机构安装位置。

2.1.2 结构优化

结构设计包括确定结构外形和结构尺寸。轴上减速机构和轴承的尺寸、定位方式及加工工艺决定了EPS输出轴结构;结构尺寸决定于轴上载荷大小、方向及分布情况,是结构优化的重点。结构计算采用强度、刚度、疲劳等设计计算准则,安全系数是常用的衡量手段。输出轴结构优化则是力求各位置安全系数大于规定要求(满足强度条件),并尽量使各安全系数相等。以输出轴在x方向每个截面外径yz1(x)、内径yz2(x)为设计变量,以输出轴安全系数的最大值Smax与最小值Smin之差最小为目标函数,以满足静强度、刚度、疲劳强度为约束条件,则输出轴结构优化子学科数学模型为:

X=[yz1(x), yz2(x)]T

min Smax-Smin

s.t.  ≥

≥ , x∈x1

, x∈x1

≥

≥ , x∈x2

, x∈x2

≥

≥ , x∈x3

, x∈x3

≤

≤

式中:S为安全系数;ST为扭转安全系数;[ST]为许用扭转安全系数;[τT]为许用切应力;Wt为抗扭截面系数;T为扭矩;Sσ为应力安全系数;[Sσ]为许用应力安全系数;[σ-1]为对称循环变形时的许用弯曲应力;W为抗弯截面系数;M为弯矩;a为折合系数,当扭转切应力为静应力、脉动循环变应力、对称循环变应力时,分别取0.3,0.6和1.0;[σb]为许用屈服应力;[Sb]为许用屈服安全系数;φ为扭转角;[φ]为允许扭转角;L为阶梯轴受扭矩作用长度;G为材料的剪切弹性模量;Ti,li和Ipi分别代表阶梯轴第i段上的扭矩、长度、极惯性矩;z为阶梯轴的段数。

2.1.3 工艺优化

一般地,结构形式和尺寸决定了工艺过程,加工时间与零件尺寸有关,本质上是与加工刀路轨迹正相关。输出轴结构形式相似,加工工艺相同,建立加工刀路轨迹(加工时间)与结构尺寸关系可以进行加工工艺的优化。以空心轴内径基本值yz(x)为设计变量,空心轴内外切削毛坯余量分别为Δ1和Δ2,则以输出轴切削加工去除材料总量为目标函数,以零件截面满足结构设计的强度、刚度条件(W确定)为约束条件,输出轴工艺优化子学科数学模型为:

X=yz(x)

min

2.2 计算过程

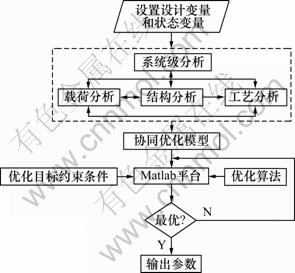

输出轴多学科协同优化在进行各要素参数化基础上,设定系统级变量和学科级变量,通过自编程序对自定的、统一格式的参数文件进行操作,分别生成符合输出轴总体优化目标和进行工况下载荷优化分析,满足强度、刚度要求的结构优化分析、加工工艺优化分析及学科之间的耦合分析,通过Matlab平台实现学科间耦合作用和集成,从而实现输出轴的设计优化,分析与优化集成流程,如图3所示。

2.3 优化结果

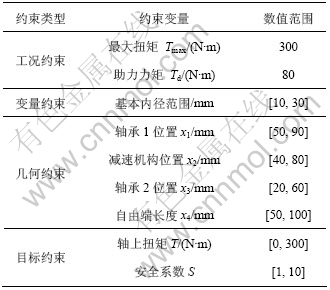

输出轴协同优化学科间的耦合主要表现在输出轴截面尺寸上。选取空心轴的1个内径作为参考基准,优化的约束条件包括1个变量,截面尺寸满足2个工况约束条件、4个几何约束条件及2个目标约束条件,其范围如表1所示。

图3 输出轴优化设计流程

Fig.3 Design optimization process of output shaft

表1 输出轴协同优化约束条件

Table 1 Constraint of CO for output shaft

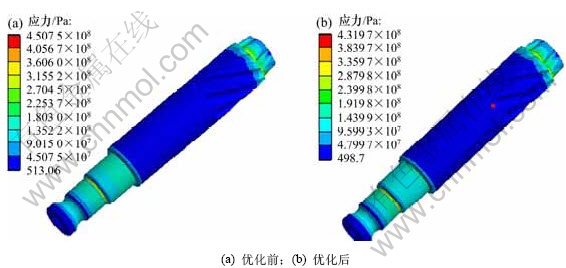

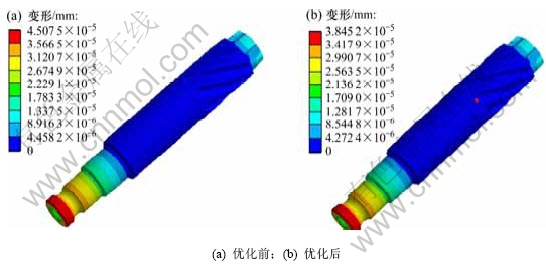

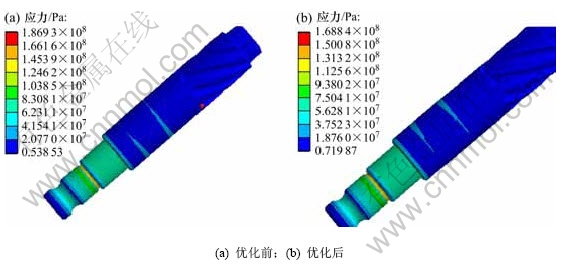

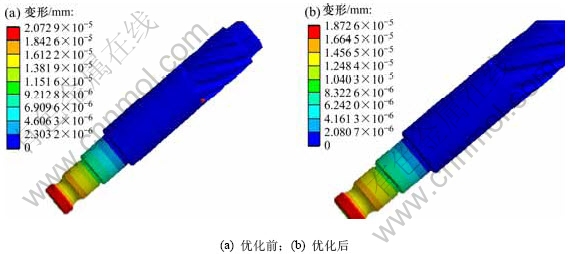

输出轴质量优化设计前为480.0 g,优化设计后为453.8 g,减少5.5%。通过有限元软件计算验证优化计算结果对输出轴的影响,分别计算极限300 N·m纯扭矩、80 N·m助力力矩2种状态下的应力和变形,如图4~7所示。从图4~7可见:在300 N·m极限状态下,优化后最大变形减小4.2%,最大应力减小4.4%;在最大助力力矩(80 N·m)状态下,优化后最大变形减小9.6%,最大应力减小10.1%。

图4 极限300 N·m纯扭矩下的应力

Fig.4 Stress under extreme torque 300 N·m

图5 极限300 N·m纯扭矩下的变形

Fig.5 Deformation under extreme torque 300 N·m

图6 80 N·m最大助力矩作用下的应力

Fig.6 Stress under maximum power-assisted moment 80 N·m

图7 80 N·m最大助力矩作用下的变形

Fig.7 Deformation under maximum power-assisted moment 80 N·m

3 结论

(1) 采用MDO方法进行轴类“载荷—结构—工艺”全过程协同优化,考虑学科间迭代和耦合,为实现零件全局优化提供了一种新方法。

(2) EPS输出轴通过多学科协同优化设计,减小输出轴质量,减少零件变形和应力,优化加工工艺。优化后质量减小5.5%,在300 N·m纯扭矩和80 N·m助力转矩2种状态下优化后,有限元计算最大变形分别减小4.2%和9.6%,最大应力分别减小4.4%和10.1%。

参考文献:

[1] Ullman D G. The mechanical design process[M]. Beijing: China Machine Press, 2006: 53-55.

[2] Otto K N, Wood K L. Product design: Techniques in reverse engineering and new product development[M]. QI Chun-ping, GONG Xiao-dong, ZHANG Fan, et al, transl. Beijing: Electronics Industry Press, 2006: 20-80.

[3] 马明旭, 王成恩, 张嘉易, 等. 复杂产品多学科设计优化技术[J]. 机械工程学报, 2008, 44(6): 15-26.

MA Ming-xu, WANG Cheng-en, ZHANG Jia-yi, et al. Multidisciplinary design optimization for complex product review[J]. Chinese Journal of Mechanical Engineering, 2008, 44(6): 15-26.

[4] 刘海强, 祁国宁, 纪杨建. 支持多学科设计优化的集成产品过程建模方法[J]. 计算机辅助设计与图形学学报, 2009, 21(11): 1638-1645.

LIU Hai-qiang, QI Guo-ning, JI Yang-jian. An integrated product process modeling method for supporting multidisciplinary design optimization[J]. Journal of Computer-Aided Design & Computer Graphics, 2009, 21(11): 1638-1645.

[5] Balling R J, Sobieszezanski-Sobieski J. Optimization of coupled system: A critical overview of approaches[J]. AIAA Journal, 1996, 34(1): 6-7.

[6] 鄂加强, 李志鹏, 袁丁, 等. 新型双向硬密封旋球阀多学科设计优化[J]. 中南大学学报:自然科学版, 2010, 41(2): 553-559.

E Jia-qiang, LI Zhi-peng, YUAN Ding, et al. Multidisciplinary optimization design on new type rotating ball valve with double direction metal sealing[J]. Journal of Central South University: Science and Technology, 2010, 41(2): 553-559.

[7] 苏瑞意, 桂良进, 吴章斌, 等. 大客车车身骨架多学科协同优化设计[J]. 机械工程学报, 2010, 46(18): 128-133.

SU Rui-yi, GUI Liang-jin, WU Zhang-bin, et al. Multidisciplinary design and collaborative optimization for bus body[J]. Journal of Mechanical Engineering, 2010, 46(18): 128-133.

[8] 仝令胜, 石博强, 申焱华, 等. 基于FORM的齿轮传动多学科优化设计[J]. 机械工程学报, 2010, 46(3): 42-46.

TONG Ling-sheng, SHI Bo-qiang, SHEN Yan-hua, et al. First-order reliability method based multidisciplinary design optimization on gear transmission[J]. Journal of Mechanical Engineering, 2010, 46(3): 42-46.

[9] Kennedy J, Eberhart R. Particle swarm optimization[C]//IEEE Int Conference on Neural Networks. Piscataway. NJ: IEEE Service Center, 1995: 1942-1948.

[10] Goldberg D E. Genetic algorithms in search, optimization and machine learning[M]. Addison-Wesley Publishing Company, 2005: 15-25.

(编辑 陈灿华)

收稿日期:2011-07-05;修回日期:2011-09-27

基金项目:湖南省自然科学基金资助项目(11JJ6035)

通信作者:陈志刚(1970-),男,湖南邵阳人,副教授,从事机械设计制造及自动化研究;电话:0739-5305016;E-mail: chenzg70@sina.com