Effect of minor RE addition on microstructures and mechanical properties of AZ31 magnesium alloy

ZHONG Hao(钟 皓), YAN Yun-qi(闫蕴琪), ZHANG Hui(张 慧), WENG Wen-pin(翁文凭), CHEN Qi(陈 琦)

Suzhou Institute for Nonferrous Metals Processing Technology, Suzhou 215026, China

Received 28 July 2006; accepted 15 September 2006

Abstract: AZ31 alloy with minor RE addition was investigated. The material was homogenized, hot-rolled and annealed. Optical microscopy, scanning electron microscopy and X-ray diffractometry were employed to characterize the microstructures of AZ31 alloy with RE addition. And micro-hardness test was employed to measure mechanical properties of annealed material. The results show that minor RE addition (0.3% is mass fraction) has little effect on the grain size of as-cast AZ31 alloy, and only Mg17(Al, Zn)12 phase was found in the microstructure of as-cast AZ31RE alloy. The result of X-ray diffraction shows that supersaturation of alloying elements has little effect on the lattice parameters of the α-Mg in homogenized sample; but owing to RE solute with high melting point, AZ31RE alloy exhibits better heat resistance than AZ31 alloy.

Key words: rare earth; AZ31 alloy; microstructures; properties; grain refinement

1 Introduction

Magnesium alloys have been considered as one of most potential advanced structural materials because of its low density (1/3 lower than aluminum), high specific strength and specific stiffness, along with good damping capacity, castability, weldability and machinability[1-3]. So magnesium alloys have been found wide application in aerospace and automotive industries. However, the poor ductility of magnesium makes it difficult to forming because of its hcp structure[2]. Therefore, recent fabrications of magnesium-based material were mainly performed by die casting[4]. But wrought magnesium is noted to have a higher strength and ductility than cast magnesium[1].

Some researches[1, 5-6] showed that adding RE elements to magnesium will not only enhance the elevated temperature performance of material, but also refine material’s grain, which is advantage to improve deformability of magnesium. The grain refinement is mainly caused by constitutional undercooling by RE addition[5]. The improvement of mechanical properties and microstructures of magnesium alloy by RE addition results in a series of RE-bearing die-casting magnesium alloys such as AE41, AE42 and modified AM60, AZ91 alloy exploited[1].

There are lots of researches on effect of RE element upon the microstructures and properties of casting magnesium, such as AZ91 and AM60[7-12]. However researches on wrought magnesium are relatively few, and often focus on high RE content, which will increase cost of alloy. The main objective of this paper is to investigate effect of minor RE addition on the microstructures and properties of wrought AZ31. The material was homogenized, hot rolled, then annealed in various time and temperature. Effect of minor RE addition on microstructures and properties of AZ31 alloy was investigated.

2 Experimental

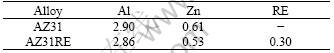

The alloy was melted with commercial AZ31 alloy and Al-RE (Ce, La-rich) master alloy. The composition of material, as measured by inductively coupled plasma (ICP), is given in Table 1. A uniform treatment was carried out at 693 K for 24 h. And the material was hot rolled from 15 mm to 3.4 mm by 3 passes at an initial rolling temperature of 753 K. Then rolled material was annealed at 523 and 673 K for 0.5, 1, 2, 5 and 10 h, respectively.

The microstructures of as-cast, homogenized and annealed material were characterized by optical microscope, scanning electron microscope (JSM 6480) with EDS (GENESIS 7000). X-ray diffraction technique was employed to characterize the cell parameter change of α-Mg by alloying atoms. Mechanical properties of annealed material were measured by micro-hardness test.

Table 1 Alloy composition of experimental alloys

3 Results and discussion

3.1 Microstructures

As shown in Fig.1, 0.3% RE has slight refinement on the grains of as-cast AZ31 alloy. There exist some granular precipitates in the microstructure of as-cast AZ31RE alloy, as shown in Fig. 1(a). EDS analysis of the particle is given in Table 2. The particle is Mg17(Al, Zn)12 phase for its Mg/(Al+Zn) ratio being 17/9.05. The Mg/(Al+Zn) ratio is higher than 17/12, owing to a contribution of the Mg matrix. And RE element dissolves in the Mg17(Al,Zn)12, as given in Table 2. In order to characterize intermetallic compounds in AZ31RE alloy, X-ray diffraction technique was employed. But diffraction peaks of Mg17(Al,Zn)12 with inadequate resolution are difficult to differentiate between the microstructures. And only data of magnesium base in as-cast and homogenized samples is shown in Table 3. As listed in Table 3, all c/a ratios of Mg base in homogenized sample are very close to that of pure Mg. These results strongly suggest that supersaturation of alloying elements have little effect on the lattice spacing of the α-Mg phase. Al4RE and Mg12Ce phases which were found in some researches[1, 5] do not be found in this study.

Table 2 Chemical composition of precipitate(mole fraction, %)

After homogenization, the material was hot rolled and annealed. Microstructural evolution of AZ31RE and AZ31 alloys during annealing are shown in Fig.2 and Fig.3, respectively. As shown in Fig.2, during annealing process, the grains of rolled AZ31RE alloy grow up. But compared Fig.2 with Fig.3, it can be found that the grains of annealed AZ31RE are smaller than that of AZ31, owing to the contribution of RE solute in the microstructure of annealed AZ31RE alloy (see Fig.4). RE solute with high melting point would hinder grain boundary migration of AZ31RE alloy during elevated temperature annealing, therefore AZ31RE rolled plate exhibits a better resistance of grain coarsening than AZ31 rolled plate.

Fig.1 Micrographs of as-cast AZ31RE (a) and AZ31 (b) alloys

Fig.2 Micrographs of AZ31RE alloy annealed at 523 K for 10 h (a) and at 673 K for 10 h (b)

Table 3 Selected X-ray diffraction angles with corresponding characteristics of Mg

Fig.3 Micrographs of AZ31 alloy annealed at 523 K for 10 h (a) and at 673 K for 10 h (b)

Fig.4 Line scan results of AZ31RE alloy annealed at 673 K for 10 h

3.2 Micro-hardness

Fig.5 shows the comparison of AZ31RE and AZ31 alloys in stability of property during annealing. As shown in Fig. 5, AZ31RE alloy exhibits higher stability of property than AZ31 alloy. This result indicates that minor RE addition will enhance heat resistance of AZ31 alloy[1].

Fig.5 Relationship between annealing time and micro- hardness at various annealing temperatures: (a) AZ31RE alloy; (b) AZ31 alloy

4 Conclusions

Minor RE addition (0.3%) has little effect on the grain size of as-cast AZ31 alloy, and only Mg17(Al, Zn)12 phase was found in the microstructure of as-cast AZ31RE alloy. The result of X-ray diffraction shows that supersaturation of alloying elements has little effect on the lattice parameters of the α-Mg in homogenized sample; but owing to RE solute with high melting point, AZ31RE alloy exhibits better heat resistance than AZ31 alloy.

References

[1] LIU Ying, CHEN Wei-ping, ZHANG Wei-wen, ZHANG Da-tong. Effects of RE on microstructures and mechanical properties of hot-extruded AZ31 magnesium alloy[J]. Journal of Rare Earths, 2004, 22(4): 527-532.

[2] MA Chun-jiang, ZHANG Di, QIN Jin-jing, HU Wen-bin, SHI Zhong-liang. Aging behavior of Mg-Li-Al alloys[J]. Trans Noferrous Met Soc China, 1999, 9(4): 772-777.

[3] ZHONG Hao, LIU Pei-ying, ZHOU Tie-tao, LI Huan-xi. Design of an age hardening Mg-Li alloy and its aging behavior[J]. Journal of University of Science and Technology Beijing, 2005, 12(2): 182-186.

[4] ZHONG Hao, ZHANG Hui, WENG Wen-ping, CHEN Qi, ZHAN Zhi-qiang, YAN Yu-qi. Effect of hot extrusion on microstructure and mechanical properties of AZ31 magnesium alloy[J]. Heat Treatments of Metals, 2006, 31(8): 79-82.

[5] YU Kun, LI Wen-xian, ZHANG Shi-jun. Mechanism of grain refining by adding cerium in Mg and Mg alloys[J]. Rare Metal Materials and Engineering, 2005, 34(7): 1013-1016.

[6] ZHANG Shi-jun, LI Wen-xian, YU Kun. The effect of Ce on the grain size and as-cast mechanical properties of magnesium alloy AZ31[J]. Foundary, 2002, 51(12): 767-771.

[7] LIU Chang, ZHOU Hong, SUN Guang-ping, SUN Na. Effect of Rare earth Y, Ce and Si on microstructure of AZ91 magnesium alloy[J]. Foundry Technology, 2006, 27(5): 485-488.

[8] WANG Jun, LIU Yong-bing, YANG Xiao-hong. Effect of Cerium on microstructures and elevated temperature properties of die-cast AZ91 magneisum alloys[J]. Journal of the Chinese Rare Earth Society, 2005, 23(3): 378-381.

[9] WANG Kai-kun, ZHANG Kui. Effects of rare earth elements on the microstructure and properties of magnesium alloy AZ91D[J]. Journal of University of Science and Technology Beijng, 2002, 9(5): 363-366.

[10] SONG Bo, LIU Yong-bing, YANG Xiao-hong, AN Jian. Effects of Y addition and solid solution treatment on microstructure and mechanical properties of AM60 magnesium alloys[J]. Transactions of Materials and Heat Treatment, 2006, 27(20): 34-36.

[11] CAO Xing, PENG Li-ming, ZENG Xiao-qin, ZHU Yan-ping, DING Wen-jiang. Effects of rare earth additions and solid solution treatment on microstructure and mechanical properties of AM60B magnesium alloy[J]. Materials of Mechanical Engineering, 2003, 27(2): 21-24.

[12] WANG Kai-kun, ZHANG Kui. Effect of rare earth elements on the microstructure and property for magnesium alloy AM60B[J]. Journal of University of Science and Technology Beijing, 2002, 9(6): 466-469.

(Edited by YANG Hua)

Corresponding author: ZHONG Hao; Tel:+86-512-62585622; Email:buaahao@163.com