DOI: 10.11817/j.issn.1672-7207.2018.11.006

工业纯铝搅拌摩擦焊质量与力学性能

殷琨,黄崇湘,王艳飞,王明赛,黄爱辉

(四川大学 空天科学与工程学院,四川 成都,610065)

摘要:采用不同旋转速度/进给速度(ω/v),研究其对AA1050搅拌摩擦焊焊缝的表面形貌、硬度分布、应力-应变曲线和显微组织的影响。研究结果表明:当ω/v分别为800/100,1 000/200和1 400/300时,焊缝区表面质量较好;焊核区硬度高于母材硬度,焊核区平均维氏硬度最高为42.9;焊核区拉伸强度高于母材拉伸强度,极限拉伸强度最高为105 MPa,与母材的拉伸强度相比提升了64%;当旋转速度固定时,随进给速度增加,极限拉伸强度增加,塑性降低;当ω/v为1 400/300时,焊缝具有较好的力学性能和较强加工硬化能力,高焊缝质量对应的点分布在热输入量与焊核区屈服强度的关系曲线凹处周围。

关键词:1050工业纯铝;搅拌摩擦焊;焊缝质量;力学性能

中图分类号:TG453 文献标志码:A 文章编号:1672-7207(2018)11-2677-07

Quality and mechanical property of aluminum joints after friction stir welding

YIN Kun, HUANG Chongxiang, WANG Yanfei, WANG Mingsai, HUANG Aihui

(School of Aeronautics and Astronautics, Sichuan University, Chengdu 610065, China)

Abstract: Friction stir welding (FSW) joints of AA1050 under various ratios of rotational speed to welding speed (ω/v) were studied. The effects of ω/v on surface appearance, hardness distribution, stress-strain curve and microstructures of the joints were investigated. The results show that fine surface appearance of welded joints can be obtained when ω/v is 800/100, 1 000/200 and 1 400/300. Vickers hardness of stir zone (SZ) is higher than that of base metal (BM) and the highest average Vickers hardness is 42.9. The tensile strength of SZ is also higher than that of BM and the highest ultimate tensile strength (UTS) increase by 64%, up to 105 MPa. At a constant rotation speed, the tensile strength of SZ increases while its ductility decreases with the increase of the welding speed. The welded joint with both good mechanical property and high work-hardening capacity can be obtained when ω/v is 1 400/300. The points corresponding to high welding quality distribute near the inflexion of the curve of yield strength versus heat input.

Key words: AA1050; friction stir welding; weld quality; mechanical property

搅拌摩擦焊(friction stir welding,简称FSW)是新型固相连接方法[1]。该技术通过搅拌头轴肩与材料的高压摩擦以及焊针的高速旋转搅拌使待连接区域材料的晶粒发生剧烈塑性变形、再结晶、退火长大,从而实现金属固相连接。与传统熔焊类方法相比,搅拌摩擦焊因耗能低、焊接变形小、焊缝强度高、缺陷少、无污染等优点而被广泛应用于铝、镁、铜合金等材料的焊接[2-7]。对于各系铝合金,经过搅拌摩擦焊后,焊缝强度与母材的相近,甚至比母材的高[8-9]。搅拌摩擦焊工艺所涉及的主要参数包括搅拌头的旋转速度和进给速度、搅拌针直径、轴肩直径、轴肩压力、冷却条件等。选择不同参数对焊缝的质量和性能有不同程度的影响。有研究表明,改变搅拌头的旋转速度和进给速度会明显影响焊核区的微观结构和力学性能[10],水冷能够提升焊核区的抗拉强度[11],因此,选取合适的旋转速度和进给速度可有效提高焊缝质量。本研究采用具有不同旋转速度ω和进给速度v的9组参数(ω/v)对AA1050铝板进行单道次搅拌摩擦焊加工,从表面宏观形貌、微观结构、硬度分布、拉伸力学性能的角度对焊缝质量进行对比分析,得到优选的工艺参数,并基于焊接参数与焊缝质量的关系提出可用于指导焊接工艺参数选取的理论模型。

1 实验材料和方法

本文所选用母材为经过600 ℃退火12 h的AA1050铝板,其室温力学性能如表1所示。

铝板长×宽×厚为300 mm×60 mm×5 mm。搅拌头轴肩直径为15 mm,搅拌针直径为2 mm,长度为2 mm。选取具有不同旋转速度(ω,单位为r/min)和进给速度(v,单位为mm/min)的9组工艺,ω/v分别为800/100,800/200,800/300,1000/100,1 000/200,1 000/300,1 400/100,1 400/200,1 400/300。所有焊接过程保持相同的轴肩压力和冷却条件,其中冷却方式采用循环水冷。

表1 AA1050铝板室温力学性能

Table 1 Mechanical properties of annealed AA1050 base metal at room temperature

焊接接头横截面的金相试样经Keller试剂(φ(HF): φ(HCl):φ(HNO3):φ(H2O)=2:3:5:95,φ为体积分数)腐蚀后在NIKON MA100光学显微镜下观察。硬度测试采用DHV-1000Z显微维氏硬度计,硬度测试沿试样横截面焊核区上表面向下0.5 mm的水平方向进行,相邻压痕间隔为0.2 mm。为了测得拉伸曲线,沿平行焊缝方向从核焊区中心截取标距段长×宽×厚为14 mm×3 mm×2 mm的狗骨型板状拉伸试样。拉伸测试采用岛津AG-100kN电子万能试验机,拉伸应变速率为3.0×10-4 s-1。分别在ω/v为800/300和1 400/300时得到的焊核区取样,用水磨砂纸将试样表面磨至平整光滑,用质量分数为86% HClO4-CH3OH(体积比为3:40)溶液电解抛光,电压为20 V,电流为0.8 A,时间约为1 min。然后,在LEO1530场发射扫描电镜中用电子背反射(EBSD)探头观察试样形貌,并通过配套软件系统测量对应区域的晶体取向。

2 结果与讨论

2.1 宏观形貌

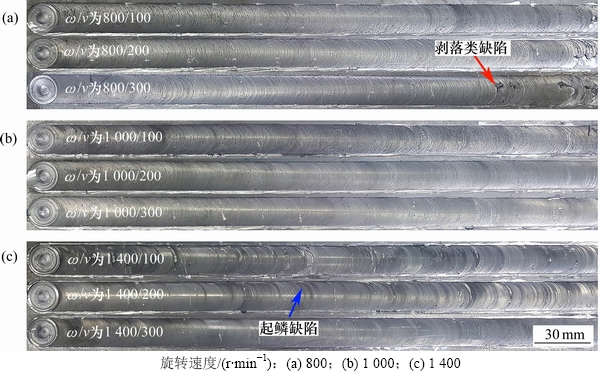

焊缝表面形貌是衡量焊接质量的重要标准。图1所示为采用不同参数组所得焊缝区宏观形貌。由图1可知:9组ω/v下焊缝的宏观形貌表现出明显的差别。表面焊接缺陷主要包括孔洞、剥落类缺陷(见图1(a))和不均匀分布的起鳞缺陷(见图1(c))。质量较好的焊缝表面表现为细密圆环纹理,表面平滑干净无飞边。起鳞缺陷是由于搅拌头轴肩与焊缝表层摩擦生热过多,热量累积于焊缝表层金属,使其熔化并逐渐冷却而形成;剥落缺陷是由于焊缝区金属热塑性流动不充分,无法及时填充焊接过程中留下的瞬时空腔而形成[12-13]。以焊缝区宏观形貌中的缺陷数量作为评价标准,当ω/v分别为800/100,1 000/200和1 400/300时,焊缝区质量较好。

图1 采用不同参数组所得焊缝区宏观形貌

Fig. 1 Macroscopic surface morphology of welding joints processed using different parameter groups

图2所示ω/v为1 000/100时焊缝横截面的金相图。由图2可见:横截面上焊核区(stir zone,简称SZ)和母材(base metal,简称BM)的明显界线构成碗状轮廓,这说明2个区域的微观结构存在明显差异;焊核区内部无缺陷,缺陷出现在焊缝区表面。图2中左侧为前进侧(advancing side,简称为AS),即搅拌头进给方向和搅拌头旋转方向一致的一侧;右侧为后退侧(retreating side,简称为RS),即搅拌头进给方向和搅拌头旋转方向相反的一侧。从图2可以明显看出前进侧焊核区和母材之间的界面轮廓比后退侧的界面轮廓更为明显,表明后退侧有较宽的热机影响区域(thermal mechanically affected zone,简称TMAZ) [14]。

2.2 维氏硬度分布

图3所示为不同ω/v下焊缝横截面的维氏硬度分布。图3中黑色实线表示与焊核区对应宽度范围的母材的维氏硬度分布(平均值为29.9)。从图3可以看出:焊核区的维氏硬度均明显高于母材维氏硬度,当ω/v为800/200时焊核区平均维氏硬度最高,为42.9,比母材高13.0;当ω/v为1 400/300时,焊核区平均维氏硬度最低,为35.0,比母材高5.1。由焊缝表面质量观察结果可知:当ω/v为800/200时焊核区平均维氏硬度最高,焊缝表面质量较差;而当ω/v为1 400/300时,焊核区平均维氏硬度最低,焊缝表面质量较好。这是由于当ω/v为800/200时热输入量较少,导致搅拌加工过程中热塑性流动不充分,进而造成焊核区形成孔洞缺陷和严重塑性变形态的微观结构[14-15]。

图2 ω/v为1 000/100时焊缝横截面的金相图

Fig. 2 Cross-sectional metallurgical image of the welded joint when ω/v is 1 000/100

图3 不同ω/v下焊缝横截面的硬度分布

Fig. 3 Vickers hardness distribution on cross-section of the welded joints processed with different ω/v

图3中各分图虚线之间的区域为前进侧母材区和焊核区之间维氏硬度过渡区,也就是热机影响区。对比图3(d)和图3(f)以及图3(g)和图3(i)可以看出:当旋转速度保持不变时,随着进给速度增大,热机影响区宽度逐渐减小。这是因为随着进给速度增加,热输入量减少使得热机影响区的宽度减小。对比图3(b),(e)和(h)以及图3(c),(f)和(i)可以看出:当进给速度保持不变时,随着旋转速度增大,热机影响区宽度逐渐减小。这是因为随着旋转速度增大,热输入增加,材料的塑性变形程度增加,搅拌区与非搅拌区的摩擦力减小,热机影响区变窄[16]。

2.3 拉伸力学性能

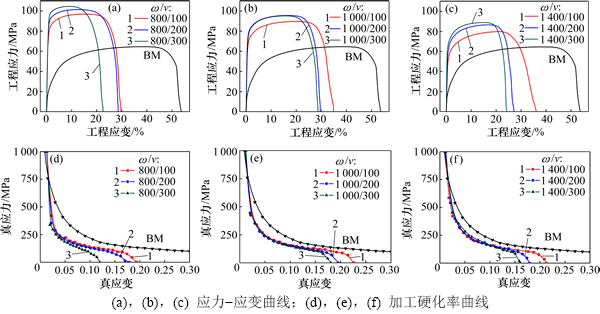

焊缝区的强度和韧性是衡量焊缝质量的重要标准。图4(a),(b)和(c)所示为不同ω/v下焊核区的单轴拉伸应力-应变曲线,其中BM为母材的拉伸曲线。从图4(a),(b)和(c)可以看出:虽然焊核区的塑性较母材有所降低,但其拉伸强度均高于母材拉伸强度。其中,ω/v为800/300时焊核区的极限拉伸强度最高,为105 MPa,相应的屈服强度为94 MPa,其极限拉伸强度相比于母材提升64%。这种由于在FSW过程中产生严重的塑性变形和大量摩擦热,使周围金属塑化,位错密度不断增加,焊缝温度达到再结晶温度后发生再结晶,从而使晶粒细化。这种再结晶过程是塑性材料在焊接热循环作用下发生动态再结晶的过程,形成的晶粒来不及长大就在搅拌的作用下被打碎,从而形成细小的晶粒[17-19]。根据Hall-Petch关系[20-21],材料的拉伸强度随晶粒直径减小而增加,因此焊核区的拉伸强度提高。

从图4(a),(b)和(c)还可以看出:在相同旋转速度下,随着进给速度增加,焊核区的拉伸强度逐渐增加,塑性逐渐降低。增加进给速度将同时减少累积塑性应变量和热输入量。一方面,过低的累积塑性应变量不足以使晶粒细化,从而阻碍或者延迟再结晶过程。另一方面,热输入量减小能够抑制再结晶晶粒的热退火长大程度,从而减小再结晶晶粒直径。其中,热输入量是影响焊核区晶粒直径的重要因素,焊核区再结晶晶粒直径随着进给速度增加而减小,因此,焊核的强度逐渐增加而塑性逐渐降低[22-24]。

图4(d),(e)和(f)所示为不同ω/v下材料拉伸应力-应变曲线对应的加工硬化率曲线。加工硬化率是反映材料均匀塑性变形能力的重要指标,取决于材料变形过程中对位错等晶格缺陷的储存能力[25]。对于粗晶,材料位错储存能力较强,加工硬化能力较强。对于细晶,材料位错储存能力降低,加工硬化能力较低。因此,晶粒直径降低是焊核区加工硬化率低于母材加工硬化率的主要原因。经比较,焊核区加工硬化率随转速增加而增加,其中ω为1 400 r/min时所得焊核区的加工硬化能力与母材的最接近。这是因为转速增大造成热输入量增加,进而促进焊核区晶粒退火长大。

图4 不同ω/v下焊核区应力-应变曲线及对应的加工硬化率曲线

Fig. 4 Stress-strain curve and strain hardening curve for stir zones at different ratios of ω/v

综合焊核区的强度、塑性及加工硬化能力可知:当ω/v为1 400/300时焊核区质量最高,所得焊缝区的质量也较好。

2.4 热输入与力学性能的关系

在忽略搅拌针周围金属塑性变形热的条件下,搅拌摩擦焊接热输入量E可表示为[26]

(1)

(1)

式中:μ为摩擦因数;p为搅拌头轴肩的压力;r0为轴肩半径;r1为搅拌针的半径;K为常数项。此外,也有相关研究将热输入量E公式简化为[27]

(2)

(2)

式中:K1为常数项。

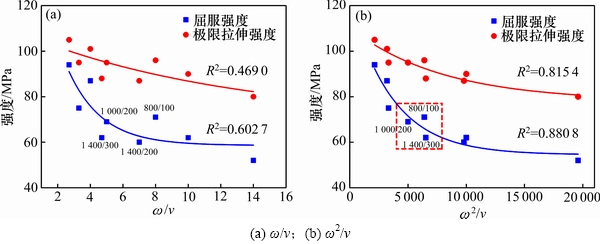

由于9组工艺中K和K1固定,分别用ω/v和ω2/v来表示不同工艺的搅拌摩擦焊热输入量。图5所示为焊核区拉伸及屈服强度与热输入量的关系。其中,实线为指数衰减拟合曲线。由图5可知:极限拉伸强度和屈服强度均随着热输入量增加而降低,降低速度先快后慢。与图5(a)相比,图5(b)中各数据点均匀分布在拟合曲线两侧,拟合误差较小,因此,用ω2/v来表征搅拌摩擦焊热输入量更为合适。从图5(b)可见:质量较高的焊缝所对应的参数组(ω/v为800/100,1 000/200,1 400/300)均分布在屈服强度与热输入量关系曲线凹处周围,即图5(b)中虚线框处。由此推测:最高质量的焊缝所对应的热输入应该位于曲线拐弯处,即ω2/v≈6 066处。据此,可以设计更多能得到高质量焊缝的工艺参数,例如ω/v分别为700/80,950/150,1 200/250等。

2.5 EBSD微观结构

选取焊缝区质量最差和最好的核焊区试样,即ω/v为800/300和1 400/300时所得试样,进行EBSD微观结构分析。图6(a)所示为ω/v为800/300时焊核区的EBSD反极图。从图6(a)可以看出:晶粒取向分布不均匀,且晶粒呈非等轴状。图6(b)所示为ω/v为1 400/ 300时焊核区的EBSD反极图。从图6(b)可以看出:晶粒取向分布均匀,且晶粒为等轴晶。图6(c)为2种ω/v下晶粒直径分布的统计图。由图6(c)可知:ω/v为800/300时所得平均晶粒直径(3.7 μm)小于ω/v为1 400/300时所得平均晶粒直径(6 μm)。这是因为前者热输入量低于后者热输入量,这也与ω/v为800/300时焊核区强度高于ω/v为1 400/300时焊核区强度这一结果相符合。图6(d)所示为2个焊核区的晶粒直径晶粒取向差。由图6(d)可知:当ω/v为800/300时,高角晶界(θ>15°)所占比例为33.4%,远低于当ω/v为1 400/300时高角晶界所占比例(60.5%),说明当ω/v为1 400/300时焊核区发生了更充分的动态再结晶。

图5 焊核区拉伸及屈服强度与热输入量的关系

Fig. 5 Relationship between yield strength and tensile strength and heat input

图6 不同ω/v下焊核区的EBSD反极图及2个焊核区的晶粒直径和晶界角分布图

Fig. 6 EBSD microstructures processed with different ω/v and distribution of grain size and corresponded misorientation angle in SZs

3 结论

1) 在循环水冷条件下,当旋转速度/进给速度(ω/v)为800/100,1 000/200,1 400/300时,AA1050工业纯铝搅拌摩擦焊能使焊缝的表面质量较高。

2) 焊核区维氏硬度均高于母材维氏硬度,其中ω/v为800/200时焊核区平均维氏硬度最高,为42.9,比母材高13.0。

3) 焊核区拉伸强度均高于母材拉伸强度,其中最高极限拉伸强度为105 MPa,与母材拉伸强度相比提高了64%;固定旋转速度时,随着进给速度增加,焊核区极限拉伸强度增加,塑性下降,这是由于晶粒直径减小造成的;综合考虑力学性能和加工硬化能力,当ω/v为1 400/300时可得到质量较高的焊缝。

4) 焊核区拉伸及屈服强度随热输入量增加而逐渐降低;质量较好的焊缝所对应的工艺参数(ω/v)集中在屈服强度与热输入量关系曲线凹处周围,可为焊接工艺参数的选取提供参考。

参考文献:

[1] THOMAS W M, NICHOLAS E D, NEEDHAM J C, et al. Friction stir welding: PCT/GB 92/02203 [P]. 1991-10-06.

[2] FULLER C B, MAHONEY M W, CALABRESE M, et al. Evolution of microstructure and mechanical properties in naturally aged 7050 and 7075 Al friction stir welds[J]. Materials Science & Engineering A, 2010, 527: 223-2240.

[3] SQUILLACE A, FENZO A D E, GIORLEO G, et al. A comparison between FSW and TIG welding techniques: modifications of microstructure and pitting corrosion resistance in AA 2024-T3 butt joints[J]. Journal of Materials Processing Technology, 2004, 152: 97-105.

[4] VENKATESWARAN P, REYNOLDS A P. Factors affecting the properties of friction stir welds between aluminum and magnesium alloys[J]. Materials Science & Engineering A, 2012, 545: 26-37.

[5] NAIK B S, CAO X, WANJARA P. Residual stresses and tensile properties of friction stir welded AZ31B-H24 magnesium alloy in lap configuration[J]. Metallurgical and Materials Transactions B, 2015, 46(4): 1626-1637.

[6] TAN Caiwang, JIANG Zhenguo, LI Liqun, et al. Microstructural evolution and mechanical properties of dissimilar Al-Cu joints produced by friction stir welding[J]. Materials & Design, 2013, 51(5): 466-473.

[7] CHEN Binxi, CHEN Ke, HAO Wei, et al. Friction stir welding of small-dimension Al3003 and pure Cu pipes[J]. Journal of Materials Processing Technology, 2015, 223: 48-57.

[8] MISHRA R S, MA Z Y. Friction stir welding and processing[J]. Materials Science & Engineering R, 2005, 50(1/2): 1-78.

[9] CHEN Yu, DING Hua, LI Jizhong, et al. Influence of multi-pass friction stir processing on the microstructure and mechanical properties of Al-5083 alloy[J]. Materials Science & Engineering A, 2016, 650(5): 281-289.

[10] KHODAVERDIZADEH H, MAHMOUDI A, HEIDARZADEH A, et al. Effect of friction stir welding (FSW) parameters on strain hardening behavior of pure copper joints[J]. Materials & Design, 2012, 35(11): 330-334.

[11] HEIRANI F, ABBASI A, ARDESTANI M. Effects of processing parameters on microstructure and mechanical behaviors of underwater friction stir welding of Al5083 alloy[J]. Journal of Manufacturing Processes, 2017, 25: 77-84.

[12] LEE W B, YEON Y M, JUNG S B. The joint properties of dissimilar formed Al alloys by friction stir welding according to the fixed location of materials[J]. Scripta Materialia, 2003, 49(5): 423-428.

[13] KIM Y G, FUJII H, TSUMURA T, et al. Three defect types in friction stir welding of aluminum die casting alloy[J]. Materials Science & Engineering A, 2006, 415(1/2): 250-254.

[14] GAN Wenying, ZHOU Zheng, ZHANG Hang, et al. Evolution of microstructure and hardness of aluminum after friction stir processing[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 975-981.

[15] SATO M Y S, KOKAWA H, KURIHARA M S. Systematic examination of precipitation phenomena associated with hardness and corrosion properties in friction stir welded aluminium alloy 2024[J]. Welding in the World, 2011, 55(11/12): 39-47.

[16] ABNAR B, KAZEMINEZHAD M, KOKABI A H. Effects of heat input in friction stir welding on microstructure and mechanical properties of AA3003-H18 plates[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2147-2155.

[17] LIPI SKA M, OLEJNIK L, PIETRAS A, et al. Microstructure and mechanical properties of friction stir welded joints made from ultrafine grained aluminium 1050[J]. Materials & Design, 2015, 88: 22-31.

SKA M, OLEJNIK L, PIETRAS A, et al. Microstructure and mechanical properties of friction stir welded joints made from ultrafine grained aluminium 1050[J]. Materials & Design, 2015, 88: 22-31.

[18] SAKTHIVEL T, SENGAR G S, MUKHOPADHYAY J. Effect of welding speed on microstructure and mechanical properties of friction-stir-welded aluminum[J]. International Journal of Advanced Manufacturing Technology, 2009, 43(5/6): 468-473.

[19] KHORRAMI M S, KAZEMINEZHAD M, KOKABI A H. Mechanical properties of severely plastic deformed aluminum sheets joined by friction stir welding[J]. Materials Science & Engineering A, 2012, 543: 243-248.

[20] PETCH N J. The cleavage strength of polycrystals[J]. Journal of the Iron and Steel Institute,1953, 174(1): 25-28.

[21] HALL E O. The deformation and ageing of mild steel: Ⅱ Characteristics of the Lüders deformation[J]. Proceedings of the Physical Society, 1951, 64(9): 742.

[22] AMIRI M, KAZEMINEZHAD M, KOKABI A H. Energy absorption of friction stir welded 1050 aluminum sheets through wedge tearing[J]. Materials & Design, 2016, 93: 216-223.

[23] Song K H, Fujii H, Nakata K. Effect of welding speed on microstructural and mechanical properties of friction stir welded Inconel 600[J]. Materials & Design, 2009, 30(10): 3972-3978.

[24] VALIEV R Z, ALEXANDROV I V, ZHU Y T, et al. Paradox of strength and ductility in metals processed by severe plastic deformation[J]. Journal of Materials Research, 2011, 17(1): 5-8.

[25] ZHU Yutian, LIAO Xiaozhou. Nanostructured metals: retaining ductility[J]. Nature Materials, 2004, 3(6): 351.

[26] HEURTIER P, JONES M J, DESRAYAUD C, et al. Mechanical and thermal modelling of friction stir welding[J]. Journal of Materials Processing Tech, 2006, 171(3): 348-357.

[27] JIN Z, Beaudoin A, Bieler T A, et al. Hot deformation of Al alloys III[M]. New Jersey, USA: John Wiley & Sons Inc, 2003: 313-327.

(编辑 伍锦花)

收稿日期:2017-12-11;修回日期:2018-02-20

基金项目(Foundation item):国家自然科学基金资助项目(11672195);四川省青年科技基金资助项目(2016JQ0047) (Project(11672195) supported by the National Natural Science Foundation of China; Project(2016JQ0047) supported by the Science and Technology Foundation for Youths of Sichuan Province)

通信作者:黄崇湘,博士,教授,从事先进材料力学行为研究;E-mail: chxhuang@scu.edu.cn