双辊薄带振动铸轧工艺最优时域特性

来源期刊:中国有色金属学报2020年第10期

论文作者:孙明翰 郑传幸 郑立康 郭仕鹏 杜凤山

文章页码:2267 - 2280

关键词:振动铸轧;数值仿真;时域特性;振动参数

Key words:vibration cast-rolling; numerical simulation; time-domain characteristic; vibration parameters

摘 要:对双辊薄带振动铸轧新工艺中振动参数的影响开展研究。在振动与非振动状态下进行7075铝合金板带铸轧的对比实验。构建双辊薄带振动铸轧数值仿真模型,并通过出坯温度验证模型的准确性,然后开展对振动铸轧熔池区流场及温度场时域特性的研究。结果表明:振动对熔池区温度场分布存在影响,振动状态下Kiss点位置随时间呈正弦形式波动。同时,通过对流场时域特性的分析,发现振动存在对熔池区施加扰动效果的作用。振动存在细化铸轧板坯微观组织并抑制偏析的作用效果。基于振频、振幅对熔池区流场及温度场影响的不同规律,确立了振动铸轧工艺最优的振动参数为振幅0.56 mm、振频20 Hz。

Abstract: The influence of vibration parameters in the new process of vibration cast-rolling was studied. A comparative experiment of 7075 aluminum alloy cast-rolling under vibration and non-vibration conditions was carried out. A numerical simulation model of vibration cast-rolling was constructed, and the accuracy of the model was verified by experiments. Then the time-domain characteristics of the molten pool flow field and temperature field under vibration condition were studied. The results show that the vibration can not only make the Kiss point position fluctuate sinusoidal with time, but also exert disturbance effect on the molten pool. It is found that the new process can refine the grain and suppress the segregation. Based on the effect of vibration frequency and amplitude on the molten pool, the optimal vibration parameters of this process are amplitude of 0.56 mm and frequency of 20 Hz.

DOI: 10.11817/j.ysxb.1004.0609.2020-37649

孙明翰,郑传幸,郑立康,郭仕鹏,杜凤山

(燕山大学 国家冷轧板带装备及工艺工程技术研究中心,秦皇岛 066004)

摘 要:对双辊薄带振动铸轧新工艺中振动参数的影响开展研究。在振动与非振动状态下进行7075铝合金板带铸轧的对比实验。构建双辊薄带振动铸轧数值仿真模型,并通过出坯温度验证模型的准确性,然后开展对振动铸轧熔池区流场及温度场时域特性的研究。结果表明:振动对熔池区温度场分布存在影响,振动状态下Kiss点位置随时间呈正弦形式波动。同时,通过对流场时域特性的分析,发现振动存在对熔池区施加扰动效果的作用。振动存在细化铸轧板坯微观组织并抑制偏析的作用效果。基于振频、振幅对熔池区流场及温度场影响的不同规律,确立了振动铸轧工艺最优的振动参数为振幅0.56 mm、振频20 Hz。

关键词:振动铸轧;数值仿真;时域特性;振动参数

文章编号:1004-0609(2020)-10-2267-13 中图分类号:TF19 文献标志码:A

双辊薄带铸轧工艺有效地将连铸与轧制两个过程合二为一,能够直接将熔融金属制成薄带坯,具有短流程、低成本、低能耗的优势[1-2]。但由于该工艺包含亚快速冷却凝固过程,工艺窗口较小,需要铸轧速度、熔池液位高度、浇注温度、轧辊直径、辊缝等诸多工艺参数的严密配合,因而有必要探究这些参数对熔池内流场及温度场的影响。双辊薄带铸轧过程是动态的、快速的过程,且温度较高,在实验过程中难以直接观测熔池内的情况。因此,对双辊铸轧过程中流体流动、传热和凝固过程进行综合建模是必不可少的。对此很多学者做了大量的研究以确定其最优工艺,推动铸轧技术的发展[3-6]。

在此基础上,近年来我国铸轧工艺的产业化进程取得了长足的进步。目前宝钢d 800 mm×1430 mm的薄带连铸工业化机组制备出了最薄0.90 mm×1430 mm的热轧卷,主要生产超薄规格集装箱用钢;武钢薄带铸轧高硅钢中试线采用薄带铸轧+温轧技术生产了0.10~0.30mm厚的6.5%Si无取向电工钢;江苏沙钢集团引进纽柯Castrip双辊薄带铸轧技术,已成功建设工业化超薄带生产线。

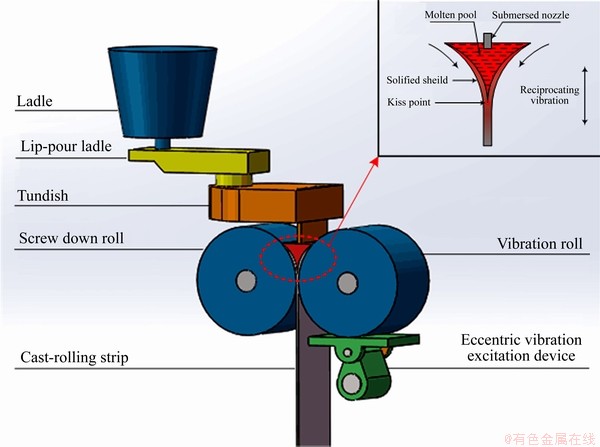

由于传统铸轧工艺流场相对稳定,薄带极易出现中心偏析的缺陷[7-8],而且由于轧辊表面存在单一方向的温度梯度,凝固枝晶定向生长,铸轧板带的微观组织一般情况下呈粗大柱状晶形貌,力学性能较差,在承受高温塑性变形时开裂倾向严重,容易造成断带,影响工艺过程的连续稳定运行[9]。为此有学者采用引入电磁、超声等附加能场的方式用以细化板带晶粒度,实现对板带组织性能的有效控制及预测[10-12]。燕山大学杜凤山教授基于振动凝固细晶与振动搓轧理论[13-14]提出了振动铸轧新技术[15-18]。在外激励下促使单侧铸轧辊作简谐式往复运动,向熔池区施加机械振动,不仅提升形核率,抑制合金元素富集倾向;同时,在塑性变形阶段向轧制区金属施加双向剪切力,产生往复搓轧的效果,强化动态再结晶,以此综合提升产品组织性能。其原理如图1所示。

目前,在铸轧及铸造领域对附加能场作用的研究主要集中于对微观组织演变的探讨。许光明等[19]通过实验研究了电磁场对1100 铝合金铸轧板材微观组织的影响。LUO等[20]通过实验研究了环形电磁搅拌对7005铝合金半连续铸造工艺中晶粒尺寸和微观组织均匀性的影响。ZHANG等[21]基于元胞自动机研究了电磁搅拌对Al-5.0%Cu合金凝固过程中组织演变的影响。赵龙志等[22]通过实验研究了超声辅助铸造过程中,振动频率对Al-24%Si合金(质量分数)微观组织及力学性能的影响。本团队针对于振动铸轧工艺的细晶机理及第二相粒子弥散效果也已进行了一定的研究,证实了振动铸轧新技术对铸轧板带微观组织及力学性能的改善效果[16, 18]。

图1 双辊薄带振动铸轧工艺原理图

Fig. 1 Schematic diagram of twin-roll strip vibration cast-rolling process

但目前针对于附加能场对流场及温度场的影响研究相对较少。在电磁铸造领域YANG等[23]通过构建数值仿真模型研究了电磁搅拌对结晶器内流场及温度场的影响,发现了激发电磁场的电流强度对工艺过程的影响规律。朱苗勇等[24]建立了耦合电磁场、流场、热传导及凝固过程的电磁连铸三维数值仿真模型,研究了电磁场对于凝固过程和结晶器内钢液流动状态的影响。但铸轧工艺与连铸尚存在一定程度的不同,其中Kiss点位置是影响工艺稳定性的一项重要指标。在铸轧过程中施加附加能场对熔池区温度分布的改变,会在一定程度上诱发Kiss点位置的波动,对工艺状态造成影响。但现阶段,极少有学者针对这一问题开展研究。

本团队基于实验级d 160 mm×150 mm振动铸轧机针对熔池区流场和温度场的分布进行了一定程度的研究[15, 17]。但研究过程中忽视了Kiss点位置的时域特性与熔池搅拌效果之间的关系,因而并未能对振动铸轧工艺的最优振动参数进行确定。并且铸轧工艺与设备规格之间密切相关,因而在小规模实验机上进行相关工艺研究,对工业化设备的参考意义较为有限。因此,本文针对于新一代中试级d 500 mm×350 mm双辊薄带振动铸轧机建立了耦合流体流动、传热和凝固过程的振动铸轧工艺数值仿真模型,对振动状态下熔池区流场及温度场的变化情况进行了详细地描述,并采集了出坯温度数据,对模型的准确性进行了有效验证。发现了振动铸轧过程中Kiss点位置正弦形式的变化规律,并根据不同振动参数对Kiss点位置及熔池“扰动”强度的影响确立了最优时域特性。该研究为构建振动铸轧的工艺模型提供了参考,以进一步建立工艺过程中对Kiss点位置及轧制力实时调控的智能化系统。有助于真地的稳定工艺过程,推动振动铸轧新技术的工业化及产业化进程。

1 数学模型

双辊薄带振动铸轧工艺是一个包含金属液流动、凝固、枝晶生长和能量交换等多种现象的复杂过程,而且在振动状态下熔池中温度场及流场随时间不断变化,故需要建立振动状态下多场耦合的数学模型对其进行分析求解,探究熔池区流场及温度场的时域特性,以确定最优振动工艺。

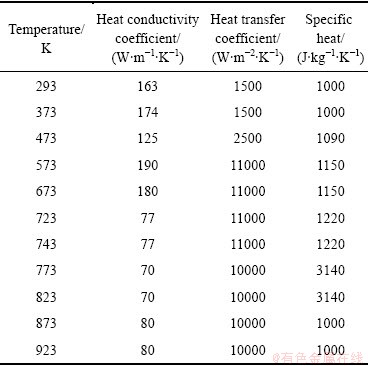

表1 模拟条件

Table 1 Simulation conditions

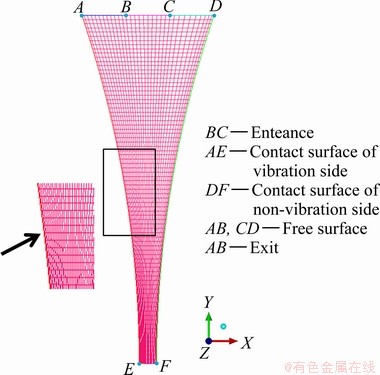

图2 熔池区的几何模型

Fig. 2 Geometric model of molten pool

利用Fluent软件仿照实际铸轧工艺过程1:1构建熔池区热-流耦合数值仿真模型。构建该模型所需的模拟参数如表1所列[25],建立的熔池区几何模型如图2所示。熔池高度为80 mm,由于构成熔池的侧封板及布流器的设计目标是保证熔池内流场及温度场沿辊宽方向分布均匀,因而忽略其影响,将实际三维结构简化为二维模型。另外,假设轧辊物理参数恒定,忽略轧辊与薄带的热变形及带坯与轧辊表面的滑移;假设金属材料的导热系数和黏度是温度的函数,其中7075铝合金的热物性参数如表2所列[26];并且假设熔池内金属液为不可压缩的Newton流体。ABOUTALEBI等[27]通过建立连铸热-流耦合模型发现,由于金属液表面张力较高,熔池液面湍动能极小,因而本文忽略液面的波动,使熔池液面水平固定。

表2 7075铝合金不同温度下的热物性参数

Table 2 Thermal properties of 7075 aluminum alloy at different temperatures

在双辊薄带铸轧过程中,金属液在熔池区内流动较为快速,使用层流模型进行分析会降低液体流动对温度分布的影响,因而选取k-ε湍流模型进行计算[15]。其控制方程为:

(1)

(1)

式中: 为流体密度(kg/m3);uk为流体流速;

为流体密度(kg/m3);uk为流体流速; 为传输变量;

为传输变量; 为等效热传导;

为等效热传导; 为动量或能量方程源项。

为动量或能量方程源项。

另外,由于铸轧工艺中熔池区与轧辊的边界不断变化,若选用标准湍流模型,壁面函数无法准确确定。而低雷诺数湍流模型不需要壁面函数,可以方便地处理流体、两相区和壁面的湍流特性,并且低雷诺数湍流是双辊薄带铸轧工艺熔池区流动的主要状态。故采用LAM 和 BREHORST提出的低雷诺数湍流模型求解[28]。

在熔池流场计算方面,液态金属的流动可直接采用牛顿流体力学原理进行计算。而当金属材料温度位于固液两相区时,为了对熔池中不同固相分数的流动状态进行等效处理,本文采用 Enthalpy-Porosity方法将两相区凝固后的固相视为多孔介质,将两相区流动等效为多孔介质内的流体流动。其动量满足式(2):

(2)

(2)

式中:S为熔融状态下流体的动量值;β为该区域的液相分数;v、vp分别为液相和固相的速度;Amush为两相区常数,该值与凝固组织的二次枝晶间距λ有关。由Kirkwood模型可知二次枝晶间距与冷却速率有关; ,因此固液两相区常数Amush表达式如式(3)所示:

,因此固液两相区常数Amush表达式如式(3)所示:

(3)

(3)

式中:μ为金属液体黏度;A和n为铝合金的凝固常数; 为平均冷却速率,℃/s。

为平均冷却速率,℃/s。

在振动铸轧工艺中,右辊作微幅上下振动,这使得熔池区与轧辊边界持续运动,在仿真中可采用动网格模型进行求解,其过程为把右辊的振动位移方程施加到右辊边界上,使边界发生运动,动网格的控制方程如式(4)所示:

(4)

(4)

式中: 为金属密度,kg/m3;

为金属密度,kg/m3; 为流体流动速度向量;

为流体流动速度向量; 为动网格的网格速度;

为动网格的网格速度; 为扩散系数;

为扩散系数; 为源项。

为源项。

右辊振动位移方程为:

(5)

(5)

式中:A为振幅,mm;f为频率,Hz;t为时间,s。

为保持熔池液面高度不变,入口边界与出口边界秒流量相匹配,入口(BC)边界条件为:

,

, ,

, ,

, (6)

(6)

出口(EF)边界条件为:

(7)

(7)

式中: 为浇铸温度(℃);v为铸轧速度(mm/s);B为辊缝宽度(mm);I为湍流强度;

为浇铸温度(℃);v为铸轧速度(mm/s);B为辊缝宽度(mm);I为湍流强度; 为固相密度(kg/m3);

为固相密度(kg/m3); 为液相密度(kg/m3);

为液相密度(kg/m3); 为入口处湍动能(kW);

为入口处湍动能(kW); 为入口湍动能耗散率;Dh为布流器水力直径(m)。

为入口湍动能耗散率;Dh为布流器水力直径(m)。

基于壁面无滑移假设,辊面(DF/AE)边界条件为:

,

, ,

, (8)

(8)

式中:β为边界单元与轧辊的接触角;λeff为流体有效导热系数;hleft为左侧轧辊对流换热系数(W/(m2·K));T为熔池温度(K);Troller为轧辊表面温度(K)。

对流换热系数考虑了接触热阻、等效热辐射以及振动侧轧辊与熔池接触气隙厚度的影响[29-30]。因此,两侧的对流换热系数并不完全相同,但都在4000~ 6000 W/(m2·K)之间[18]。其余边界均为绝热边界。

模型采用PISO算法进行求解,为力求计算精度,拉速计算的迭代时间步长分别设置为1×10-4 s,在每一个时间步所有独立残差均小于1×10-4 s。

2 数值仿真的实验验证

铸轧实验利用燕山大学的d 500 mm×350 mm双辊薄带微幅振动铸轧机进行,以7075铝合金为研究对象,其成分如表3 所列。铸轧工艺条件如下:开浇温度650 ℃,辊缝4 mm,铸轧速度5 m/min,冷却水压力0.6 MPa,熔池液位高度80 mm。进行了振动铸轧与非振动铸轧对比实验,振动铸轧工艺振频25 Hz,振幅0.38 mm。

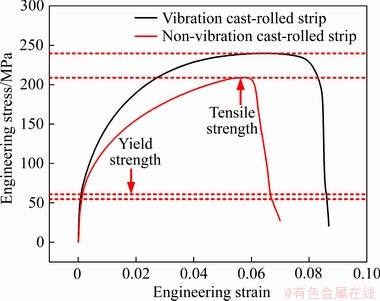

利用CSS-44100电子实验机,按照GB/T 228—2002实验标准对铸轧板带进行了力学性能拉伸测量,其中每组试样个数为3个,取平均值为最终结果。拉伸结果如表4和图5所示,对比铸轧板带力学性能测试结果,振动铸轧板带较传统铸轧板带屈服强度、抗拉强度和伸长率分别提高了9.22%、14.95%和31.25%。说明振动确实有效提高了铸轧板带的力学性能。

图3 d 500 mm×350 mm双辊薄带微幅振动铸轧机

Fig. 3 d 500 mm×350 mm twin-roll strip vibration cast- rolling machine

图4 7075铝合金铸轧带坯

Fig. 4 Cast-rolled 7075 aluminum alloy strip

表3 7075铝合金化学成分

Table 3 Chemical composition of 7075 aluminum alloy (mass fraction, %)

表4 板带力学性能拉伸结果

Table 4 Tensile results of mechanical properties

图5 振动和非振动铸轧板带工程应力-应变曲线

Fig. 5 Engineering stress-strain curves of strip cast-rolled with vibration and non-vibration

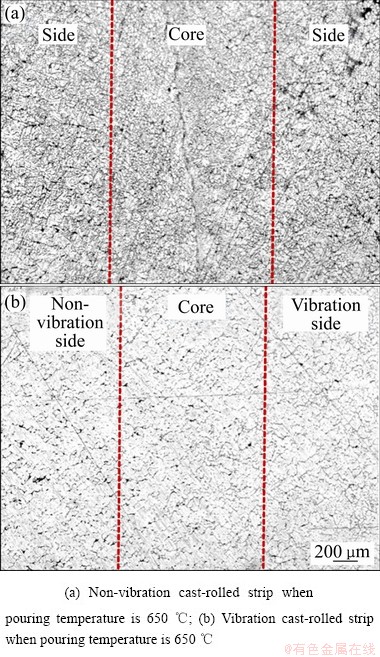

同时对所得铸轧板带进行取样,将取得的试样粗磨、精磨、抛光和腐蚀,利用Leica DMI 5000M金相显微镜观察试样微观组织。图6所示为振动、非振动铸轧板带微观组织对比图。由图6可知,非振动铸轧板带晶粒较为粗大,芯部出现了较窄的线状偏析。振动铸轧板带偏析现象得到显著改善,不存在明显的偏析线或偏析带,只存在少量的点状偏析缺陷且偏析尺寸较小,晶粒细密。图7所示为振动和非振动铸轧板带EDS能谱分析对比图,可以发现非振动铸轧板带在中心处存在较高的合金元素含量,线状偏析明显。振动铸轧板带合金元素分布较为均匀,振动明显减弱了板带的偏析现象,佐证了上述金相分析中的结果。

图6 非振动和振动铸轧板带微观组织

Fig. 6 Microstructures of strip billet cast-rolled with vibration and non-vibration

图7 非振动和振动铸轧板带EDS能谱分析

Fig. 7 EDS analysis of strip billet cast-rolled with vibration and non-vibration

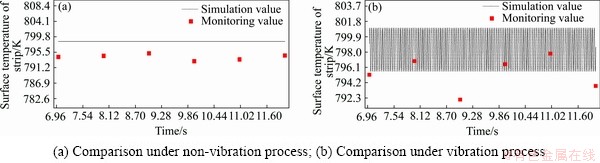

在模型温度场验证方面,目前业内普遍采用测试出坯温度[31-32]和在轧辊内埋入热电偶测取轧辊温度的方式[33]。但本文研究所使用的d 500 mm×350 mm振动铸轧机为中试级设备,规模较大,辊身较长。并且铸轧辊内布有冷却水道,辊套较薄,在轧辊内钻深孔安装热电偶,于加工制造角度较难实现,同时该方式也会极大地降低轧辊的使用寿命。因此,本文参照工业现场中常使用的方法,在实验过程中采用红外测温枪对薄带出口温度进行实时监测并记录整个实验过程中的温度变化。在流场测试方面,国外部分学者采用超声多普勒测速仪[34-35]研究电磁止动对连铸结晶器内金属液流场的影响,但目前本研究尚缺乏这样的实验条件。在热流耦合数值模型中,温度场与流场是交互作用、密切相关,因而温度场的准确可以在一定程度上对流场分布进行侧面的反馈验证。实验过程中采集的若干时间点的温度数据与仿真采集温度的对比如图8所示。由图8可知,实验值与模拟值分布基本吻合,其数值略小于模拟值。究其原因,是由于带坯在高温状态下出坯后表面会形成氧化薄膜,影响其热辐射率,从而降低红外测温枪测量的准确性,由此可验证上述模型的温度计算结果基本准确。

3 振动对熔池区流场温度场的影响

为了详细描述振动状态下熔池区温度场及流场的变化情况,研究振动参数对熔池区温度场和流场分布的影响规律以确定振动铸轧的最优工艺,本研究进行了不同振动参数下的对比仿真实验。

3.1 振动对温度场的影响

仿真结果表明,铸轧熔池区温度场在振动状态下存在明显的时域特性。如图9所示,当轧辊处于不同相位时,熔池区温度分布规律基本一致,沿中心线呈对称状态,但具体数值存在一定的差异。这表明振动带来的流场变化不仅会改变振动侧辊面边界的换热状态,也会对非振动侧造成一定的影响,从而保证了两侧温度分布的相对均匀。避免因温度场紊乱影响工艺状态的稳定性。

图8 非振动和振动条件下实验与仿真的出坯温度对比

Fig. 8 Roll gap temperature of strip produce by non-vibration and vibration cast rolling process compared with simulation result:

图9 振频10 Hz和振幅0.38 mm下不同相位时熔池内温度场分布

Fig. 9 Distribution of temperature field in molten pool with different phases under condition of 10 Hz vibration frequency and 0.38 mm amplitude

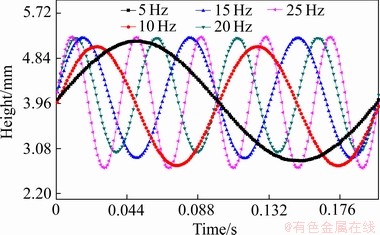

由图9可知,振动会使板带出口处的温度发生变化,这种变化反映出振动会引起Kiss点高度上下波动。其中Kiss点是指铸轧熔池中凝固坯壳的焊合点。由于铸轧过程多场耦合,因此Kiss点高度成为衡量铸轧工艺综合稳定性的一项重要指标。Kiss点过高会导致轧制力过大,板带易衍生裂纹,严重时会导致“轧卡”现象,致使生产难以为继;Kiss点过低则致使铸轧工艺塑性变形区过小,板带易出现缩孔缩松问题,严重时会出现“漏液”事故。在仿真模拟中本文采用液相率30%的等值线中的最低点,作为铸轧仿真模拟中的Kiss点。为了确定振动铸轧的最优工艺参数,确保Kiss点稳定,现提取不同振动参数下Kiss点高度的变化情况进行分析,如图10和11所示。

由图10和11可知,振幅对Kiss点位置的波动影响较大,而振频只改变Kiss点的波动频率。当振频为10 Hz时,不同振幅下Kiss点偏距的最大值约为4.9 mm,最小值约为3.9 mm。其变化幅度最大值为10 mm,最小值为2.5 mm。

3.2 振动对流场的影响

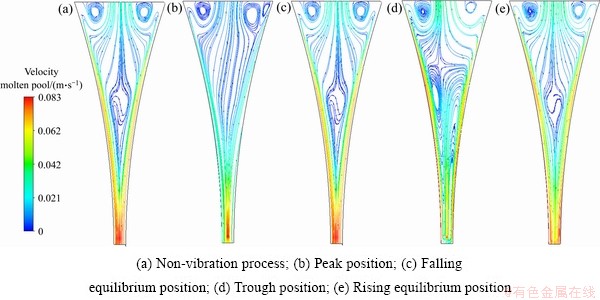

图12所示为振幅0.38 mm振频10 Hz工况下熔池区流场的时域分布与非振动状态下熔池区流场分布。

图10 振幅0.2 mm时不同频率下Kiss点高度随时间变化情况

Fig. 10 Variation of Kiss point height with time at different frequencies under amplitude of 0.2 mm

由图12可知,当轧辊处于波峰、波谷位置时,熔池区流场分布规律与非振动情况下基本一致,而在平衡位置时变化较大。由上升平衡位置到下降平衡位置的速度变化会对流场产生一种扰动效果,研究发现这种扰动效果会增加熔池区的形核率,细化晶粒[16, 18],并且由吕征等[7]的研究表明,铸轧过程中的中心偏析问题主要是合金元素在流场作用下于Kiss点位置处富集导致的。而振动带来的扰动效果会对熔池区起到搅拌作用,均化熔池区溶质场分布,抑制合金元素局部富集,有效改善铸轧带坯中心偏析问题。因此,这种扰动效果越大越好,故而选取上升平衡时刻与下降平衡时刻熔池中心线上的速度进行分析。

图11 振频10 Hz时不同振幅下Kiss点高度随时间变化情况

Fig. 11 Variation of Kiss point height with time at different amplitudes under frequency of 10 Hz

图12 一个周期内熔池的流场时域分布图

Fig. 12 Time domain distribution of molten pool flow field in one period

图13 振动参数对熔池中心线X方向速度差的影响

Fig. 13 Influence of vibration parameters on X-direction velocity difference at center line of molten pool

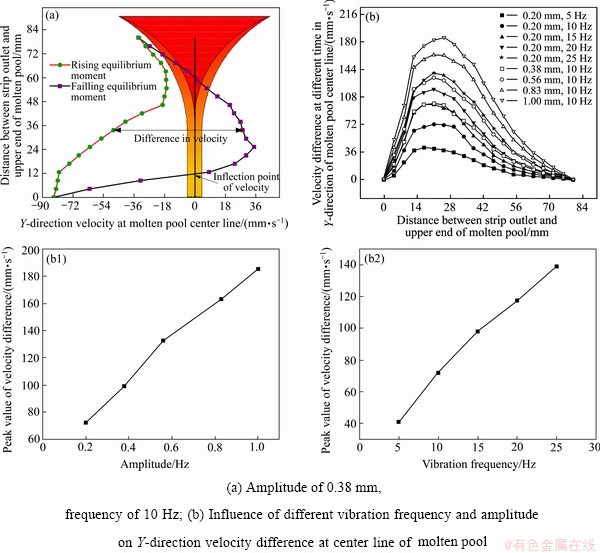

图13(a)所示为在振幅0.38 mm、振频10 Hz下熔池中心线X方向在上升平衡时刻和下降平衡时刻的速度分布情况。设铸轧方向为速度负方向,速度为零即表征流体速度方向转变。由图13(a)可知,上升平衡时刻和下降平衡时刻熔池中心线X方向的速度呈对称分布,在下降平衡时刻,随着熔池高度的增加,X方向的速度先增大后减小,方向不发生改变,其峰值位于熔池上部。这一现象是由于振动侧涡流随着振动加剧逐渐增大挤压非振动侧涡流,致使熔池区流场分布向非振动侧倾斜导致的。为了对振动的扰动效果进行量化分析,现提取不同振动参数下熔池中心线X方向在上升平衡时刻和下降平衡时刻的速度差,如图13(b)所示。由图13(b)可知,振频与振幅对该速度差的影响规律相似。随熔池高度的增加,该速度差先增加后减小,而且其峰值均随振频与振幅的增加而增加。

图14(a)所示为在振幅0.38 mm、振频10 Hz下熔池中心线Y方向在上升平衡时刻和下降平衡时刻的速度分布情况。由图14(a)可知,在下降平衡时刻,熔池中心线上Y方向速度均随熔池高度的减小先增加后减小,方向发生两次转变,并在两次转变之间达到峰值,在出口位置处回归铸轧速度。而在上升平衡时刻,由于轧辊运动速度与铸轧速度方向相同,在两者的共同作用下,中心线Y方向速度持续为负。图14(b)所示为不同振动参数下熔池中心线Y方向在上升平衡时刻和下降平衡时刻的速度差。由图14(b)可知,振频与振幅对熔池中心线Y方向速度差的影响规律与X方向的影响规律相似,区别在于Y方向的速度差数值较大,而且其峰值处于熔池的下部。对比振频与振幅对熔池中心线Y方向速度差的影响规律,可以发现振频、振幅越大,振动对熔池的扰动效果越好,而且振幅的影响效果略大于振频。

3.3 最优振动参数的确定

对于双辊薄带振动铸轧新工艺,其所期望达到的最优作用效果为:能够达到较为强烈的熔池流场扰动效果,从而细化晶粒、抑制偏析,而又不使Kiss点的波动过于剧烈,影响工艺过程的稳定性。

图14 振动参数对熔池中心线处Y方向速度差的影响

Fig. 14 Influence of vibration parameters on Y-direction velocity difference at center line of molten pool

由上文所述可知,振幅对Kiss点位置的波动范围影响较大。虽然在振幅1 mm的极限状态下,Kiss点位置的最低值依然在辊缝位置之上,不会发生“漏液”事故,但为了保证铸轧板带微观组织和力学性能沿轧制方向分布的稳定性,还是应维持Kiss点位置波动在合理范围内。由图9可知,Kiss点位置波动范围和平均高度均随振幅呈持续增长趋势,但在振幅0.38 mm至0.56 mm的调控范围内,涨幅并不显著,超过0.56 mm后涨幅明显增加。因此,就Kiss点波动情况而言,只需将振幅控制在0.56 mm以下即可满足工艺稳定的要求。

在振动铸轧工艺中,若铸轧辊振动过于剧烈,其加速度大于重力加速度,则有可能出现脱坯的问题,不仅影响振动侧辊面的换热情况,严重时还会发生熔池侧漏事故。为了保证铸轧过程中凝固坯壳始终与辊面贴合,需要计算每种振动工况下的峰值加速度,当其小于重力加速度,方可使铸轧过程稳定进行,因此对式(5)求两阶导可得出振动铸轧的振动参数需满足的条件:A(2πf)2≤9800 mm/s2,其中A为振幅(mm),f为振频(Hz)。由于限于本轧机的机械结构,其可调振幅档位分为5档,故而不同振幅档位所对应的极限振频如表5所列。

表5 不同振幅档位所对应的极限频率

Table 5 Limit frequency for different amplitude gears

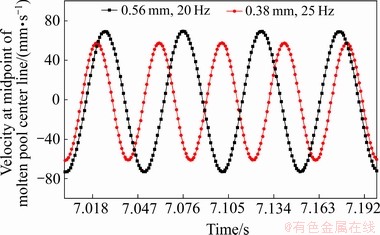

由上文所述可知,振频、振幅越大,振动对熔池的扰动效果越好,而本文所述d 500 mm×350 mm双辊薄带振动铸轧机的调频上限为25 Hz,因而在图15中,对振幅0.38 mm、振频25 Hz与振幅0.56 mm振频20 Hz两种振动参数下熔池区中点位置的速度进行对比分析,以确定振动铸轧工艺中的最优振动参数。由图15可知,振幅0.56 mm、振频20 Hz的振动参数下熔池区扰动效果更为强烈,因而可确定振幅0.56 mm、振频20 Hz为7075铝合金振动铸轧工艺的最优振动参数。

图15 不同振动参数下熔池中点位置速度对比图

Fig. 15 Comparison of velocity at midpoint of molten pool under different vibration parameters

4 结论

1) 建立了考虑凝固的热-流耦合振动铸轧数值仿真模型,并通过出坯温度采集数据验证了仿真模型结果的准确性。在振动状态下熔池区温度场和流场分布及Kiss点位置变化具有时域特性。振幅对Kiss点波动影响较大,振幅和振频对熔池区流场均能起到较大的扰动作用。

2) 通过7075振动铸轧实验发现,振动对熔池区流场的扰动作用可以促使板带晶粒细化,改善板带合金元素偏析问题,从而对板带力学性能起到强化效果。

3) 确定了7075铝合金振动铸轧工艺的最优振动参数为振幅0.56 mm、振频20 Hz。

REFERENCES

[1] KAWALLA R, ULLMANN M, HENSELER T, PRAHL U. Magnesium twin-roll casting technology for flat and long products-state of the art and future[J]. Materials Science Forum, 2018, 941: 1431-1436.

[2] WECHSLER R. The status of twin-roll casting technology. Comparison with conventional technology[J]. Revue de Metallurgie, 2002, 99(11): 941-948.

[3] RODRIGUES C, LUDWIG A, KHARICHA A, WU M H. Modeling of the twin-roll casting process: Transition from casting to rolling[J]. Transactions of the Indian Institute of Metals, 2018, 71(11): 2645-2649.

[4] ZHANG N, TANG P, ZHU M M, WEN G H, MA F J. Research metal delivery system of twin-roll thin strip continuous caster for magnesium alloys[J]. Materials Review, 2010, 24(16): 237-240.

[5] ZHANG X M, JIANG Z Y, LIU X H. Simulation of fluid flow, heat transfer and micro-segregation in twin-roll strip casting of stainless steel[J]. Journal of Materials Science and Technology, 2006, 22(3): 295-300.

[6] ZHANG X M, JIANG Z Y, YANG L M, LIU X H, WANG G D, TIEU A K. Modelling of coupling flow and temperature fields in molten pool during twin-roll strip casting process[J]. Journal of Materials Processing Technology, 2007, 187: 339-343.

[7] 杜凤山, 吕 征, 黄华贵, 许志强, 安仲健. 双辊薄带铸轧中心线偏析机理与实验研究[J]. 中国有色金属学报, 2015, 25(10): 2738-2744.

DU Feng-shan, Lü Zheng, HUANG Hua-gui, XU Zhi-qiang, AN Zhong-jian. Mechanism and experiment research on centerline segregation of twin-roll strip casting[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 2738-2744.

[8] CHANG L L, CHO J H, KANG S K. Microstructure and mechanical properties of twin roll cast AM31 magnesium alloy sheet processed by differential speed rolling[J]. Materials & Design, 2012, 34: 746-752.

[9] GRAS C, MEREDITH M, HUNT J D. Microdefects formation during the twin-roll casting of Al-Mg-Mn aluminium alloys[J]. Journal of Materials Processing Technology, 2005, 167(1): 62-72.

[10] 乐 鹏, 毛大恒, 李建平, 赵苏琨, 扶宗礼. 电磁-超声能场对3003铝合金铸轧组织和性能的影响[J]. 中国有色金属学报, 2014, 24(3): 615-623.

LE Peng, MAO Da-heng, LI Jian-ping, ZHAO Su-kun, FU Zong-li. Effect of electromagnetic-ultrasonic energy-field on structure and properties of roll-casting 3003 aluminum alloy strips[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 615-623.

[11] SU X, XU G M, FENG Y H. Effect of magnetostatic field on microstructure of 7075 aluminum alloy strip manufactured by twin-roll casting[J]. Advanced Materials Research, 2013, 652/654: 2427-2431.

[12] 谭湘夫, 毛大恒, 蔡安辉, 安伟科, 张晓红. 镁合金板带双辊连续铸轧试验研究[J]. 机械工程学报, 2012, 48(16): 30-35.

TAN Xiang-fu, Mao Da-heng, CAI An-hui, AN Wei-ke, ZHANG Xiao-hong. Experimental study on twin-roll casting magnesium alloy strip[J]. Journal of Mechanical Engineering, 2012, 48(16): 30-35.

[13] LIMMANEEVICHITR C, PONGANANPANYA S, KAJORNCHAIYAKUL J. Metallurgical structure of A356 aluminum alloy solidified under mechanical vibration: An investigation of alternative semi-solid casting routes[J]. Materials & Design, 2009, 30(9): 3925-3930.

[14] ZHANG S H, ZHAO D W, GAO C R, WANG G D. Analysis of asymmetrical sheet rolling by slab method[J]. International Journal of Mechanical Sciences, 2012, 65(10): 168-176.

[15] XU Z Q, MENG Z R, XUE S H, ZHANG D Q, DU F S. Effect of oscillation parameters to flow field in the pool during the oscillating twin-roll strip casting process[J]. Chinese Journal of Mechanical Engineering, 2018, 31(6): 177-184.

[16] 孙明翰, 杨玉青, 朱志旺, 魏洁平, 杜凤山. 20CrMn钢双辊薄带振动铸轧细晶机理试验[J]. 机械工程学报, 2019, 55(4): 54-59.

SUN Ming-han, YANG Yu-qing, ZHU Zhi-wang, WEI Jie-ping, DU Feng-shan. Experimental study on twin-roller strip cast-rolling under vibration of 20CrMn steel[J]. Journal of Mechanical Engineering, 2019, 55(4): 54-59.

[17] 杜凤山, 孙明翰, 黄士广, 魏洁平, 黄华贵, 许志强. 双辊薄带振动铸轧机理及其仿真实验[J]. 中国机械工程, 2018, 29(4): 477-484.

DU Feng-shan, SUN Ming-han, HUANG Shi-guang, WEI Jie-ping, HUANG Hua-gui, XU Zhi-qiang. Mechanism and simulation experiments on twin-roll thin-strip vibration casting[J]. China Mechanical Engineering, 2018, 29(4): 477-484.

[18] 魏洁平, 许志强, 孙明翰, 朱志旺, 王海军, 杜凤山. 20CrMn钢双辊振动铸轧薄带性能的试验[J]. 钢铁, 2018, 53(12): 124-129.

WEI Jie-ping, XU Zhi-qiang, SUN Ming-han, ZHU Zhi-wang, WANG Hai-jun, DU Feng-shan. Experimental research of vibratory cast-rolling strips for 20CrMn alloy steel[J]. Iron & Steel, 2018, 53(12): 124-129.

[19] 许光明, 潘江深. 电磁场对1100铝合金铸轧板材组织的影响[J]. 东北大学学报(自然科学版), 2017, 38(7): 946-949.

XU Guang-ming, PAN Jiang-shen. Effect of electromagnetic field on microstructure of 1100 aluminum alloy sheet during roll casting[J]. Journal of Northeastern University, 2017, 38(7): 946-949.

[20] LUO Y J, ZHANG Z F, LI B, GAO M W, QIU Y, HE M. Effects of annular electromagnetic stirring coupled with intercooling on grain refinement and homogeneity during direct chill casting of large-sized 7005 alloy billet[J]. JOM, 2017, 69(12): 2640-2643.

[21] ZHANG Z F, KIM J M, HONG C P. Numerical simulation of grain structure evolution in solidification of an Al-5.0wt%Cu alloy under electromagnetic stirring and its experimental verification[J]. ISIJ International, 2005, 45(2): 183-191.

[22] 赵龙志, 李 洋, 张 坚, 赵明娟. 振动频率对间接超声辅助铸造Al-24%Si合金的影响[J]. 中国有色金属学报, 2016, 26(6): 1167-1174.

ZHAO Long-zhi, LI Yang, ZHANG Jian, ZHAO Ming-juan. Influence of vibration frequency on indirect ultrasonic aided casting Al-24%Si alloy. The Chinese Journal of Nonferrous Metals, 2016, 26(6): 1167-1174.

[23] YANG B, DENG A Y, LI Y, XU X J, WANG E G. Numerical simulation of flow and solidification in continuous casting process with mold electromagnetic stirring[J]. Journal of Iron and Steel Research International, 2019, 26(3): 219-229.

[24] JIANG D B, ZHU M Y. Flow and solidification in billet continuous casting machine with dual electromagnetic stirrings of mold and the final solidification[J]. Steel Research International, 2015, 86(9): 993-1003.

[25] 班春燕, 崔建忠, 巴启先, 张北江. 电磁场对7075铝合金液固相线温度的影响[J]. 特种铸造及有色合金, 2004(1): 26-27.

BAN Chun-yan, CUI Jian-zhong, BA Qi-xian, ZHANG Bei-jiang. Influence of electromagnetic field on the liquidus and solidus temperatures of 7075 Al alloy[J]. Special-cast and Non-ferrous Alloys, 2004(1): 26-27.

[26] 苏 鑫. 7075铝合金电磁铸轧工艺及理论研究[D]. 沈阳: 东北大学, 2015.

SU Xin. Study on electromagnetic twin-roll casting process and theory for 7075 aluminum alloy[D]. Shenyang: Northeastern University, 2015.

[27] ABOUTALEBI M R, HASAN M, GUTHRIE R. Coupled turbulent flow, heat, and solute transport in continuous casting processes[J]. Metallurgical and Materials Transactions B, 1995, 26(4): 731-744.

[28] TAHA M A, El-MAHALLAWY N A, El-MESTEKAWI M T, HASSAN A A. Estimation of air gap and heat transfer coefficient at different faces of Al and Al-Si castings solidifying in permanent mould[J]. Metal Science Journal, 2001, 17(9): 1093-1101.

[29] LI C, THOMAS B G. Thermomechanical finite-element model of shell behavior in continuous casting of steel[J]. Metallurgical and Materials Transactions B, 2004, 35(6): 1151-1172.

[30] KANG C G, KIM Y D. A thermal elastic-plastic finite-element analysis to roll-life prediction on the twin roll strip continuous casting process[J]. Metallurgical and Materials Transactions B, 1997, 28(6): 1213-1225.

[31] LI Q, ZHANG Y K, LIU L G, ZHANG P, ZHANG Y, FANG Y, YANG Q X. Effect of casting parameters on the freezing point position of the 304 stainless steel during twin-roll strip casting process by numerical simulation[J]. Journal of Materials Science, 2012, 47(9): 3953-3960.

[32] ZENG J, KOITZSCH R, PFEIFER H, FRIEDRICH B. Numerical simulation of the twin-roll casting process of magnesium alloy strip[J]. Journal of Materials Processing Technology, 2009, 209(5): 2321-2328.

[33] RP T, ISAC M, RIL G. Roll-strip interfacial heat fluxes in twin-roll casting of low-carbon steels and their effects on strip microstructure[J]. ISIJ International, 1998, 38(12): 1353-1361.

[34] MIAO X, TIMMEL K, LUCAS D. Effect of an electromagnetic brake on the turbulent melt flow in a continuous-casting mold[J]. Metallurgical and Materials Transactions B, 2012, 43(4): 954-972.

[35] CHAUDHARY R, THOMAS B G, VANKA S P. Effect of electromagnetic ruler braking (EMBr) on transient turbulent flow in continuous slab casting using large eddy simulations[J]. Metallurgical and Materials Transactions B, 2012, 43(3): 532-553.

SUN Ming-han, ZHENG Chuan-xing, ZHENG Li-kang, GUO Shi-peng, DU Feng-shan

(National Engineering Research Center for Equipment and Technology of Cold Strip Rolling, Yanshan University, Qinhuangdao 066004, China)

Abstract: The influence of vibration parameters in the new process of vibration cast-rolling was studied. A comparative experiment of 7075 aluminum alloy cast-rolling under vibration and non-vibration conditions was carried out. A numerical simulation model of vibration cast-rolling was constructed, and the accuracy of the model was verified by experiments. Then the time-domain characteristics of the molten pool flow field and temperature field under vibration condition were studied. The results show that the vibration can not only make the Kiss point position fluctuate sinusoidal with time, but also exert disturbance effect on the molten pool. It is found that the new process can refine the grain and suppress the segregation. Based on the effect of vibration frequency and amplitude on the molten pool, the optimal vibration parameters of this process are amplitude of 0.56 mm and frequency of 20 Hz.

Key words: vibration cast-rolling; numerical simulation; time-domain characteristic; vibration parameters

Foundation item: Project(U1604251) supported by the National Natural Science Foundation of China; Project (E2017203043) supported by the Natural Science Foundation of Hebei Province, China

Received date: 2019-11-20; Accepted date: 2020-08-31

Corresponding author: DU Feng-shan; Tel: +86-13803354838; E-mail: fsdu@ysu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(U1604251);河北省自然科学基金资助项目(E201303342)

收稿日期:2019-11-20;修订日期:2020-08-31

通信作者:杜凤山,教授,博士;电话:13803354838;E-mail:fsdu@ysu.edu.cn