DOI: 10.11817/j.ysxb.1004.0609.2020-37691

ZnSO4-FeSO4溶液体系高剪切强化针铁矿法除铁宏观动力学研究

汪文超,杨建广,闫万鹏,南天翔,唐朝波,曾伟志,李陵晨

(中南大学 冶金与环境学院,长沙 410083)

摘 要:将有机高分子乳化分散等领域常见的剪切机引入湿法冶金领域针铁矿除铁过程,以ZnSO4-FeSO4溶液体系沉铁过程为研究对象,开展高剪切强化针铁矿法除铁过程的宏观动力学研究。采用单因素试验法考察沉铁过程温度、pH、流场强化方式、剪切速率、氧气浓度对沉铁速率的影响。结果表明:温度、pH、流场强化方式、剪切速率、氧气浓度对沉铁速率影响显著。在此基础上开展的动力学研究结果表明,针铁矿法沉铁受传质过程控制,高剪切强化针铁矿法沉铁符合一级反应特征,Fe2+氧化沉铁的本征反应级数为二级,反应表观活化能约为27.85 kJ/mol。

关键词:剪切;流场强化;动力学;针铁矿

文章编号:1004-0609(2020)-12-2971-09 中图分类号:TF813 文献标志码:A

锌是一种在多领域有重要用途的重金属,近年来随着机械制造、化工材料等行业的发展,对于锌的需求日益增大[1-4]。锌的冶炼方式分为火法与湿法,湿法炼锌是目前最主要的炼锌方式,其产量占世界总产锌量85%左右[5]。湿法炼锌的主要原料是硫化锌矿和氧化锌矿,工艺流程通常为锌精矿焙烧-浸出-净化-电积,按照浸出形式的不同也可分为常规浸出法、热酸浸出法及直接浸出等。锌矿中通常含铁[6],铁随着锌矿浸出进入到锌液,对后续电积步骤产生影响,降低电流效率,所以在净化工序除去锌液中的铁对湿法炼锌工艺至关重要[7]。

常见的除铁工艺有针铁矿法、黄钾铁钒法、赤铁矿法等[8],针铁矿法由于具有沉铁完全、铁渣过滤性能好、有利于回收铟、锗、银等稀散金属等优点,是目前湿法炼锌中溶液除铁的常用方法,由比利时老山公司(Vieille Montagne)于1965~1969年前后研究成功,并于1971年在巴伦(Balen)厂率先投产[9]。国际上迄今已有多家湿法炼锌厂家相继应用针铁矿法沉铁系统进行生产,如美国的Bartlesville厂、比利时的Overpolt厂、意大利的SAMIM公司以及韩国的Onsan厂等[10]。我国典型的湿法炼锌企业如株冶集团、深圳中金岭南丹霞冶炼厂等也于2007~2009年前后相继采用针铁矿法进行溶液除铁。

已开展的研究表明,针铁矿法沉铁包括一系列复杂的物理化学反应过程,包括二价铁离子氧化、三价铁离子水解以及中和反应等。这些化学反应过程受温度、晶种、搅拌速率、催化程度、组分浓度以及pH值等因素影响。铁元素在溶液中的还原、氧化、结晶析出涉及一系列气、液、固三相互相耦合的化学、物理反应,反应机理非常复杂。国内外专家学者对此进行了大量研究工作[11-14],在针铁矿沉铁反应条件优化、沉铁装备改进等方面获得了系列研究成果。但在实际生产中,由于溶液体积量大,沉铁过程溶液中不同位置处Fe2+/Fe3+浓度、pH值和温度呈非线性、时变等特点,依照现有的人员经验调控方式,难以实现对溶液性质的实时调控,铁渣晶型常常难以稳定控制,导致所产铁渣铁品位低、锌含量高,难以实现铁渣资源化全量回收利用。目前研究的焦点是如何有效控制沉铁过程溶液体系结构参数的均一性。

剪切是一种通过固定定子,高速旋转转子产生虹吸,剧烈搅拌气液固体系并高速切割溶液的反应强化手段。高速剪切产生流场快速均一溶液成分,为反应体系带来能量,有力促进溶液中反应的发生[15]。近年来,有许多学者对剪切流场的应用做了研究。例如,陈青等[16]利用剪切流场诱导ipp等温结晶,陈硕等[17]模拟剪切流场条件研究液滴破碎和碰撞行为等。前期,在国家重点研发专项课题的资助下,本课题组将颜料制备、有机高分子乳化分散等领域常采用的剪切流场强化方式引入湿法炼锌领域针铁矿法除铁,取得了较好的效果。本文主要介绍以ZnSO4-FeSO4溶液体系针铁矿法沉铁过程为研究对象,开展的高剪切流场强化针铁矿法除铁过程宏观动力学研究结果,以期为研究同行提供参考。

1 原料与方法

1.1 试验试剂

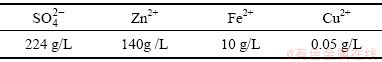

动力学研究所用溶液,为参考中金岭南丹霞冶炼厂除铁前液主要化学成分自行配置的ZnSO4-FeSO4混合溶液,主要化学成分如表1所列。

表1 ZnSO4-FeSO4混合溶液主要化学成分

Table 1 Main chemical components of ZnSO4-FeSO4mixed solution

其他试剂如七水合硫酸铁(FeSO4·7H2O,AR,国药集团化学试剂有限公司生产)、七水合硫酸锌(ZnSO4·7H2O,AR,国药集团化学试剂有限公司生产)、五水合硫酸铜(CuSO4·5H2O,AR,国药集团化学试剂有限公司生产)、氧化锌(ZnO,AR,国药集团化学试剂有限公司生产)等均为分析纯,溶剂水为去离子水。

1.2 试验设备与步骤

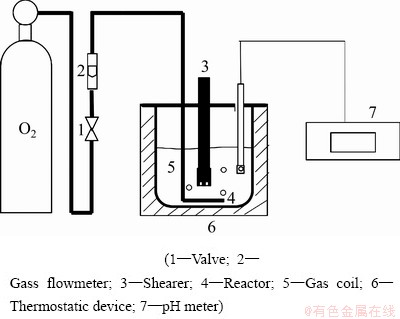

试验设备连接示意图如图1所示。

图1 高剪切强化针铁矿法沉铁反应装置连接示意图

Fig. 1 Schematic diagram of reaction devices of iron removal by goethite method enhanced by high shear

量筒量取上述ZnSO4-FeSO4混合溶液,倒入恒温加热装置中,设置好需要的温度、气体流量、剪切速率等参数后开始计时反应。pH通过实时加入氧化锌全程调控在试验所设固定值,每隔一段时间用移液管移取1 mL反应液,采用化学滴定法测定Fe2+浓度含量。

采用单因素试验法分别考察不同温度、pH、氧气浓度、流场强化方式和剪切速率等条件下,沉铁率随时间的变化情况。采用双膜理论建立模型通过试验数据拟合开展高剪切强化针铁矿法沉铁过程的动力学研究。

1.3 分析方法

采用化学滴定法测定溶液中Fe2+浓度,具体步骤为:以体积比1:1的硫磷混酸预处理待测液,加入二苯胺磺酸钠作为指示剂,用对铁滴定系数为0.002000 g/mL的重铬酸钾标准滴定液滴定Fe2+浓度。

采用XRD表征沉铁渣物相,采用SEM观察沉铁渣微观形貌。

2 结果与讨论

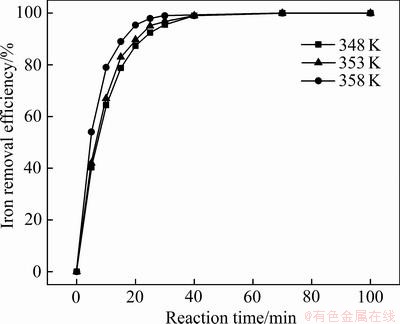

2.1 温度对沉铁速率的影响

不同温度下沉铁率随时间的变化规律如下图2所示。由图2可以看出,沉铁反应速率整体趋势为前期沉铁速率快,后期沉铁速率逐渐下降。这是因为反应前期Fe2+浓度较高,溶液中Fe2+与氧气接触的几率较高,Fe2+氧化比例更大,随着反应进行,Fe2+逐渐消耗,Fe2+氧化比例降低,沉铁速率也逐渐放缓。

同时,实验结果还表明,温度与体系沉铁速率呈正相关。对于高剪切强化针铁矿法沉铁过程,温度升高增加了体系能量,提高了溶液中活性粒子的比例,并增大了粒子碰撞概率,使得单位时间Fe2+与氧分子发生有效碰撞的机会增多,Fe2+氧化速率更快,从而提高了沉铁速率。

图2 不同温度下沉铁率随时间的变化关系

Fig. 2 Relationship between temperature and iron removal efficiency with time

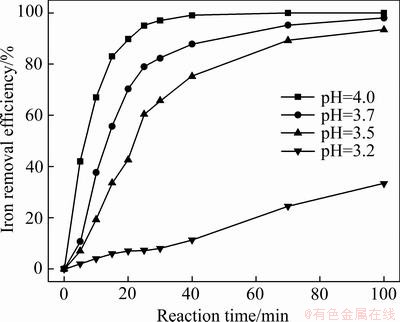

2.2 pH值对沉铁速率的影响

溶液pH值对沉铁反应的影响规律如图3所示。由图3可以看出,体系pH值越高,沉铁速率越快,试验范围内pH值4.0为最优条件。pH值对高剪切强化针铁矿法沉铁过程的影响主要体现在改变氢离子浓度。氢离子是沉铁反应产物之一,其浓度较高会抑制反应向右(沉铁)进行的趋势,从而降低反应速率。反之,氢离子浓度较低时将促进Fe2+向针铁矿转变,提高反应速率。在高剪切流场条件下,传质速度大大加快,溶液中H+浓度分布更加均匀,有利于沉铁过程pH值的控制。但是,过高或过低的pH值对反应均有不利影响,pH值过高会使得溶液中锌离子沉淀,pH值过低则会抑制针铁矿的生成甚至使针铁矿返溶。

图3 不同pH下沉铁率随时间的变化

Fig. 3 Relationship between pH value and iron removal efficiency with time

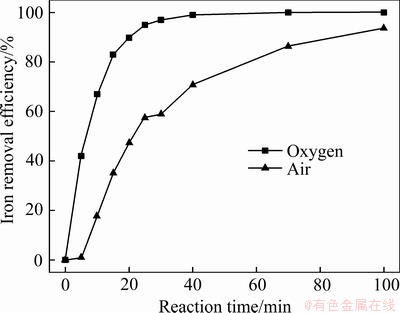

2.3 氧气浓度对沉铁速率的影响

以含氧100%(体积分数)的纯氧与含氧21%(体积分数)的空气分别作为氧化剂,通过控制气体流速,使得两种气体单位时间通入反应体系的氧气体积相同,考察通入氧气体积相同,氧气浓度不同时沉铁率随时间的变化,实验结果如图4所示。由图4可以看出,不同氧气浓度会改变针铁矿法沉铁过程反应速率,氧气浓度越高,反应速率越快。这可能有两方面原因,一方面,两种情况(氧气、空气)下氧气的总量虽然一致,但是氧气浓度较低的空气体积要远大于纯氧的,也就是空气流速要大于纯氧流速,使得气体在溶液中的逗留时间大大减少,氧分子与溶液中Fe2+的接触时间变短,Fe2+氧化发生的可能性降低。另一方面,同等条件下单位体积内空气中氧分子浓度低于纯氧气气体的浓度,也使得以空气为氧化剂时的沉铁速率低于同等条件下以氧气为氧化剂时的沉铁速率。

图4 不同含氧量下沉铁率随时间的变化

Fig. 4 Relationship between oxygen concentration and iron removal efficiency with time

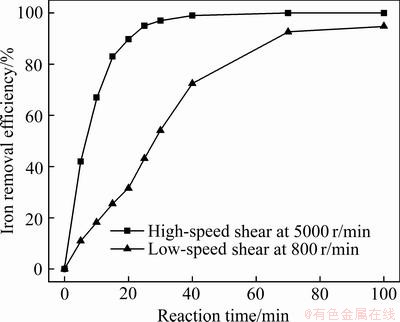

2.4 流场强化方式对沉铁速率的影响

剪切流场与传统搅拌流场相比,具有破碎反应物和产物颗粒、增大反应面积、细化晶粒、增大流场能量、更易达到溶液性质均一等多个优势。选取剪切设备可控稳定高速5000 r/min与传统针铁矿法沉铁搅拌设备可达转速800 r/min,对比考察高速剪切与低速(相对剪切的高速而言)搅拌两种形式对沉铁速率的影响,结果如下图5所示。结果表明高速剪切对反应速率的提升更大。传统搅拌方式能实现溶液均质,加快溶液中Fe2+与气体接触机会来加快反应进程,而高速剪切流场能实现更快速的均质,极大地提高反应物之间的接触机会,同时剪切流场能为针铁矿法沉铁反应过程提供更多能量,更有利于跨越能垒,促进沉铁反应进行。

图5 不同强化方式下沉铁率随时间的变化

Fig. 5 Relationship between strengthening way and iron removal efficiency with time

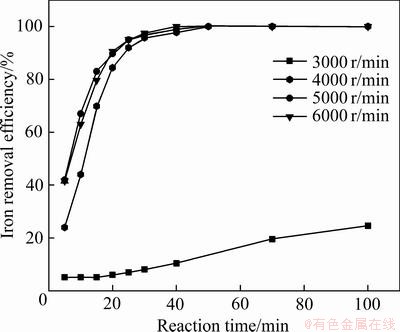

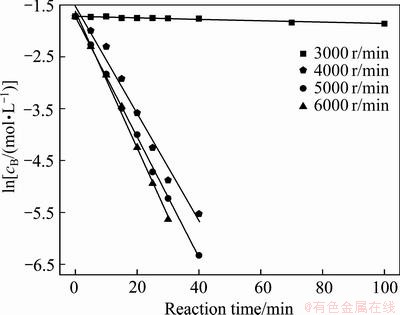

2.5 剪切速率对沉铁速率的影响

剪切速率也是影响反应速率的重要因素,剪切速率的差异可基本表征剪切机对体系剪切强度的差异,考察剪切速率对沉铁的影响实际上是考察剪切强度的影响。不同剪切速率下沉铁率随时间的变化关系如下图6所示。由图6可以看出,随着剪切速率的上升,反应速率迅速提高,3000 r/min时Fe2+在2 h后仅氧化了20%;而当转速达到5000 r/min后,反应在40 min左右几乎反应完全,但此后继续提升转速对沉铁速率影响不明显。显然,在低转速下,剪切机对溶液作用有限,剪切强度较低,无法及时充分均一溶液,Fe2+不能及时与氧气接触使得沉铁速率较低,传质是反应主要限制因素。而高转速情况下,高速剪切使得微观粒子发生剧烈碰撞,碰撞赋予整个体系大量动能并使得更多粒子活化,大大加快了反应进程。此时,由于剪切已满足满足体系传质和赋能的要求,Fe离子本身浓度对反应过程成为主要影响因素,继续提升剪切速率不再能显著加快沉铁反应过程。

图6 不同剪切速率下沉铁率随时间的变化

Fig. 6 Relationship between shear velocity and iron removal efficiency with time

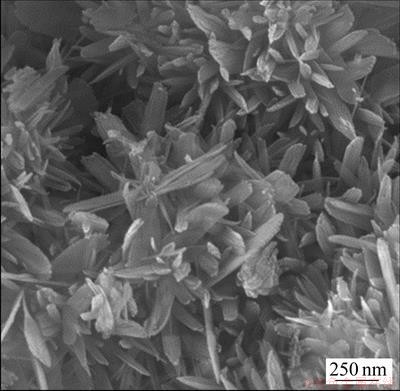

2.6 反应产物的矿物学特征

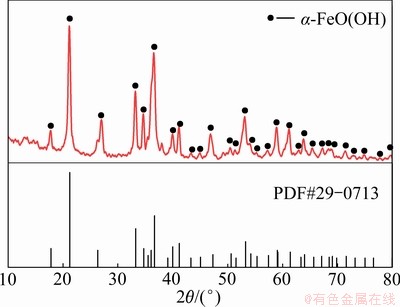

沉铁反应结束后用滤纸对沉铁后液进行液固分离,将固体产物恒温干燥后送往X射线衍射和扫描电镜检测。结果分别如图7和图8所示。

图7表明剪切形式产生的针铁矿具有花瓣状结构且形貌完整,与通过水热法传统搅拌方式制备的针铁矿一致[18],其形貌具有代表性。这种形貌的针铁矿通常具有较大的比表面积,具有较好的吸附性能。这代表高速剪切产生的针铁矿产物也许具有材料化回用的价值,提升了高速剪切针铁矿法工艺和相关理论研究的意义。

图7 高剪切针铁矿沉铁获得的针铁矿渣SEM像

Fig. 7 SEM image of goethite residue produced by goethite process enhanced by high shear

图8所示为水热法剪切强化合成的针铁矿XRD谱。由图8可以看出,剪切生成的针铁矿的X射线衍射谱与针铁矿标准谱(PDF#29-0731)吻合,这表明采用高剪切溶液流场强化可以实现含铁溶液针铁矿法沉铁。

图8 高剪切针铁矿沉铁获得的针铁矿渣XRD谱

Fig. 8 XRD pattern of goethite residue produced by goethite process enhanced by high shear

3 针铁矿宏观动力学

高剪切作为一种强化手段对体系的作用一方面是提供高速流场、加快传质促进反应;另一方面是通过体系激烈碰撞給反应过程提供能量(包括氧化沉铁和晶体形成过程中为反应粒子提供能量,降低反应发生阈值)。由于传统针铁矿沉铁采用搅拌形式,高剪切条件下强化场对体系充分赋能,其动力学结论与传统形式或有差别。

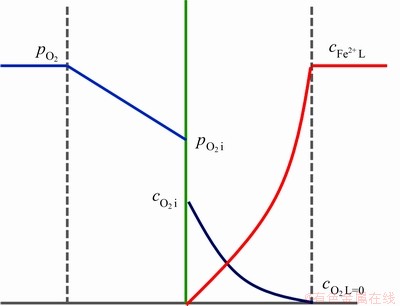

针铁矿沉铁反应属于多相反应,涉及到气、液相的传质和相关的化学反应。反应过程中,反应器底部盘管不断鼓入氧气,氧气以气泡形式在溶液中短暂停留。假设每个气泡不与其他气泡直接碰撞,用双膜理论[19-20]分析氧气扩散的过程,针铁矿沉铁反应要经历以下步骤。

1) 氧气由气相主体向气液相界面扩散。

2) 氧气与Fe2+在相界面发生反应,之后一边在液膜中扩散一边与Fe2+反应,反应式如式(1)所示:

Fe2++O2+H+=Fe3++H2O (1)

3) 反应生成的Fe3+与水结合形成针铁矿释放氢离子,可表示为式(2):

Fe3++H2O=FeOOH+H+ (2)

4) 中和剂消耗生成的H+,反应式可写为式(3):

ZnO+2H+=Zn2++H2O (3)

其中,步骤1)属于传质步骤,步骤2)涉及传质和化学反应,步骤3)属于化学反应步骤,式(2)由于不涉及到跨相传质,可认为是瞬时反应。

综合式(1)与(2),可写出总包反应式(4):

Fe2+(液相B)+O2(气相A)+H2O=FeOOH+H+ (4)

假设Fe2+与水和氧气的反应是不可逆气液相反应,反应对氧气和Fe2+的级数分别为m和n。那么,气液相间传质速率方程可用式(5)表示:

NA=kG(pA-pAi)=EkL(cAi-cAL) (5)

式中:NA表示传质速率;kG为气相总传质系数;kL为液相总传质系数;pA表示氧气在气相本体的分压,Pa;pAi表示氧气在相界面的分压,Pa;cAi为氧气在相界面的浓度,mol/L;cAL为氧气在液相本体的浓度,mol/L;E为增强因子[21]:

(6)

(6)

式中:Ha为八田常数[22],其表达式为

(7)

(7)

式中:m为氧气反应级数;n为Fe2+反应级数;km,n为m,n级本征反应速率常数;DAL表示氧气扩散系数,cm2/s;cBL表示液相主体中Fe2+浓度,mol/L。

根据试验数据,认为针铁矿法沉铁反应属于快速反应。针对快速反应[23],反应过程如图9所示。图中, 为氧气占气相本体的分压,Pa;

为氧气占气相本体的分压,Pa; 为氧气在相界面浓度,mol/L;

为氧气在相界面浓度,mol/L; 为氧气在相界面的分压,Pa;

为氧气在相界面的分压,Pa; 为Fe2+在液相本体的浓度,mol/L;

为Fe2+在液相本体的浓度,mol/L; 为O2在液相本体的浓度,mol/L。

为O2在液相本体的浓度,mol/L。

图9 快速反应反应过程

Fig. 9 Process of rapid reaction

气液相界面处平衡条件cAi=HApAi,液相主体中cAL=0,得出Fe2+的反应速率:

(8)

(8)

式中:HA表示氧气的亨利系数,mol/(L·Pa);cB表示Fe2+浓度,mol/L;t表示反应时间,s;a表示气泡比表面积,m2/m3。

快速反应为传质过程控制,而且全部集中在液膜内进行,此时Ha>3,得出E=Ha,从而有

(9)

(9)

式中:k为速率常数,

(10)

(10)

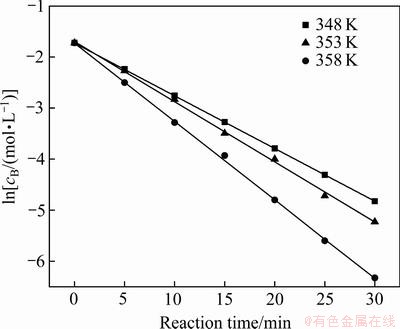

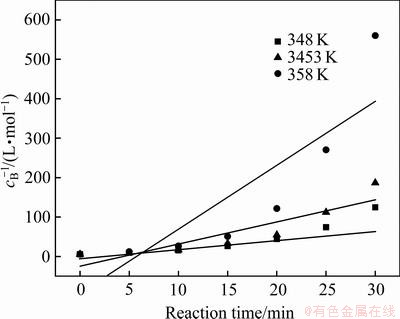

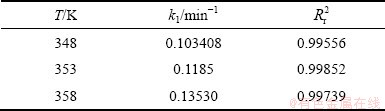

对348~358 K温度条件下的试验数据分别按照一级反应和二级反应的特点进行拟合,结果如图10和11所示。显然,沉铁反应更符合一级反应特征。

图10 不同温度下 线性拟合图

线性拟合图

Fig. 10 Linear relationship between  and reaction time at various temperatures

and reaction time at various temperatures

图11 不同温度下 线性拟合图

线性拟合图

Fig. 11 Linear relationship between  and reaction time at various temperatures

and reaction time at various temperatures

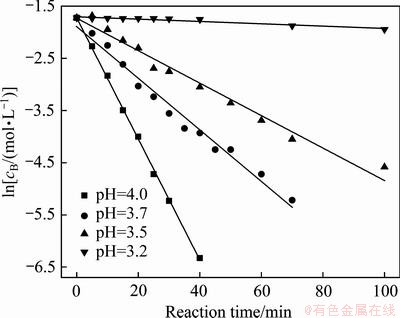

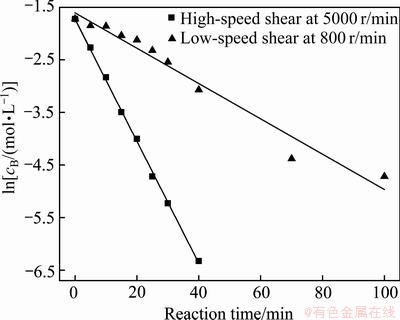

按照一级反应特征对其他单因素条件得到的试验数据对时间进行处理,以不同条件下Fe2+浓度的自然对数对时间作图并进行线性拟合,结果如图12~15所示。根据拟合直线计算不同温度条件反应表观速率常数与线性拟合系数,其值如表2所列(表中,k1表示表观速率常数; 表示线性拟合系数)。

表示线性拟合系数)。

图12 不同pH下 线性拟合图

线性拟合图

Fig. 12 Linear relationship between  and reaction time at various pH values

and reaction time at various pH values

图13 不同氧气浓度下 线性拟合图

线性拟合图

Fig. 13 Linear relationship between  and reaction time at various oxygen concentrations

and reaction time at various oxygen concentrations

图14 不同流场强化方式下 线性拟合图

线性拟合图

Fig. 14 Linear relationship between  and reaction time in different strengthening ways by flow field

and reaction time in different strengthening ways by flow field

图15 不同剪切速率下 线性拟合图

线性拟合图

Fig. 15 Linear relationship between  and reaction time at various shear-velocity

and reaction time at various shear-velocity

表2 不同温度 图参数

图参数

Table 2 Parameters of  versus time at various temperatures

versus time at various temperatures

不同条件下试验数据均能较好地与一级反应拟合,与预期相符合,故认为高剪切针铁矿法除铁过程符合一级反应动力学特征。

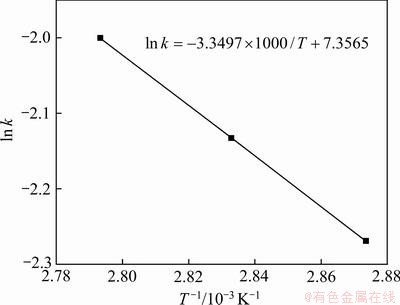

根据阿伦尼乌兹公式:

(11)

(11)

式中:A为指前因子;Ea为活化能,kJ/mol;R为摩尔气体常数,R=8.314 J/(mol·K)。取不同温度下反应速率常数的对数对温度的倒数作图,如图16所示。

计算出宏观活化能与指前因子分别是:Ea=27.85 kJ/mol,A=1.57×103,宏观速率常数表示为

(12)

(12)

由于化学滴定法在Fe2+浓度很低时误差较大,故未采用Fe2+浓度低于0.01 mol/L时的部分数据。在试验所测反应物浓度范围内,针铁矿沉铁反应均较好的符合了一级反应模型,结合式(9),得出n=2,故认为针铁矿法沉铁反应对于Fe2+离子的本征反应级数为二级。

图16 ln k-T-1线性拟合图

Fig. 16 Linear relationship between arrhenius plot of ln k and T-1

4 结论

1) 采用溶液高剪切方式能显著强化针铁矿法除铁动力学过程,加快沉铁反应速率,生成的针铁矿符合传统针铁矿结构及形貌特征。

2) 温度、pH、强化方式、剪切速率、氧气浓度等因素对高剪切强化针铁矿法沉铁速率影响显著。

3) 高剪切强化针铁矿法沉铁反应过程可以用双膜理论模型解释,反应在液膜内进行,受传质过程控制。其动力学过程对于Fe2+符合一级反应特征,对Fe2+的本征反应级数为二级,反应活化能为27.85 kJ/mol。

REFERENCES

[1] MURALI A, SOHN H Y. Photocatalytic properties of plasma-synthesized zinc oxide and tin-doped zinc oxide (TZO) nanopowders and their applications as transparent conducting films[J]. Journal of Materials Science: Materials in Electronics, 2018, 29(17): 14945-14959.

[2] MARIKKANNAN M, DINESH A, MAYANDI J, VISHNUKANTHAN V, PEARCE J M. Properties of Al-doped zinc oxide and In-doped zinc oxide bilayer transparent conducting oxides for solar cell applications[J]. Materials Letters, 2018, 222: 50-53.

[3] XIAO Zhen-yu, SUN Ya-yong, BAO Yu-xiang, SUN Yue-xin, ZHOU Ru-jie, WANG Lei. Two new inorganic-organic hybrid zinc phosphate frameworks and their application in fluorescence sensor and photocatalytic hydrogen evolution[J]. Journal of Solid State Chemistry, 2019, 269: 575-579.

[4] 安茂忠. 电镀锌及锌合金发展现状[J]. 电镀与涂饰, 2003, 22(6): 40-45.

AN Mao-zhong. Current development of zinc and zinc alloy electroplating[J]. Clectroplating & Finishing. 2003, 22(6): 40-45.

[5] 孙德堃. 国内外锌冶炼技术的新进展[J]. 中国有色冶金, 2004, 6(3): 5-8.

SUN De-kun. New progress of zinc metallurgical technology at home and abroad[J]. China Nonferrous Metallurgy, 2004, 6(3): 5-8.

[6] 吴克明, 孙大林, 胡 杰. 湿法炼锌过程中除铁工艺的进展[J]. 矿产综合利用, 2014(6): 11-14.

WU Ke-ming, SUN Da-lin, HU Jie. Progress of technology optimization of precipitation of iron in zinc hydrometallurgy[J]. Multipurpose Utilization of Mineral Resources, 2014(6): 11-14.

[7] 孙 备, 张 斌, 阳春华, 桂卫华. 有色冶金净化过程建模与优化控制问题探讨[J]. 自动化学报, 2017, 43(6): 880-892.

ZHANG Bei, SUN Bin, YANG Chun-hua, GUI Wei-hua. Discussion on modeling and optimal control of nonferrous metallurgical purification process[J]. Acta Automatica Sinica, 2017, 43(6): 880-892.

[8] 袁芳沁, 吴克明, 丁倩倩. 湿法炼锌除铁工艺的现状与展望[J]. 矿产综合利用, 2011(2): 32-34.

YUAN Fan-qin, WU Ke-ming, DING Qian-qian. Status and prospect of technology for iron removal in zinc hydrometallurgy[J]. Multipurpose Utilization of Mineral Resources, 2011(2): 32-34.

[9] 王 莎. 直接浸出炼锌针铁矿法串级沉铁过程Fe2+浓度梯度优化[D]. 长沙: 中南大学, 2012.

WANG Sha. Fe2+ concentration gradient optimization in the process of iron removal by goethite method during direct leaching of zinc[D]. Changsha: Central South University, 2012.

[10] 胡鹏飞. 湿法炼锌的热酸浸出工艺流程综述[J]. 工程设计与研究, 1998(1): 12-16.

HU Peng-fei. Hot acid leaching process of zinc hydrometallurgy: A review[J]. Engineering Design & Research, 1998(1): 12-16.

[11] CHOI H B, CHUN M P, CHUN S Y, H J A. Synthesis and shape control of goethite nano particles[J]. Journal of the Korean Institute of Electrical and Electronic Material Engineers, 2016, 29(9): 552-558.

[12] CLAASSEN J O, MEYER E H O, RENNIE J, SANDENBERGH R F. Iron precipitation from zinc-rich solutions: Defining the zincor process[J]. Hydrometallurgy, 2002, 67(1): 87-108.

[13] LOAN M, NEWMAN O M G, COOPER R M G, FARROW J B, PARKINSON G M. Defining the paragoethite process for iron removal in zinc hydrometallurgy[J]. Hydrometallurgy, 2005, 81(2): 104-129.

[14] 郑莉莉. 针铁矿法除铁工艺实践[J]. 工程技术与管理(英文), 2017(3): 242-243.

ZHRNG Li-li. The industrial practice of iron removal by goethite method[J]. Engineering Technology & Management, 2017(3): 242-243.

[15] 祝春水, 孙振亚. 生物矿化针铁矿吸附铬的机理探讨[J]. 环境污染与防治, 2007(3): 178-203.

ZHU Chun-shui, SUN Zhen-ya. Adsorption of chromium on biomineralized goethite[J]. Environmental Pollution & Control, 2007(3): 178-203.

[16] 陈 青, 范毓润, 郑 强. 剪切流场诱导iPP等温结晶行为的研究[J]. 高分子学报, 2007(5): 70-74.

CHEN Qing, FAN Yu-run, ZHEN Qiang. Shear induced crystallization of isotactic polypropylene[J]. Acta Polymerica Sinica, 2007(5): 70-74.

[17] 陈 硕, 尚 智. 简单剪切流条件下液滴破碎和碰撞模拟[J]. 工程热物理学报, 2007, 28(1): 189-192.

CHEN Shuo, SHANG Zhi. Simulating the breakup and collision of drops in simple shear flow[J]. Journal of Engineering Thermophysics, 2007, 28(1): 189-192.

[18] 蒋天骄. 磷酸改性花状针铁矿的制备及从水溶液中去除U(Ⅵ)的实验研究[D]. 衡阳: 南华大学, 2018.

JIANG Tian-jiao. Preparation of a phosphate-modified flower-like α-FeOOH composite and its application for aqueous U(Ⅵ) removal[D]. Hengyang: University of South China, 2018.

[19] WANG J. Flow reactor models for fluid-fluid systems, based on the two-film theory[J]. Chemical Engineering Journal & the Biochemical Engineering Journal, 1995, 60(1/3): 105-110.

[20] HANSEN E, MOLLERUP J. Application of the two-film theory to the determination of mass transfer coefficients for bovine serum albumin on anion-exchange columns[J]. Journal of Chromatography A, 1998, 827(2): 259-267.

[21] KUMAR P S, HOGENDOORN J A, FERON P H M. Approximate solution to predict the enhancement factor for the reactive absorption of a gas in a liquid flowing through a microporous membrane hollow fiber[J]. Journal of Membrane Science, 2003, 213(1/2): 231-245.

[22] ALAGY J, TRAMBOUZE P, van LANDEGHEM H. Designing a cyclohexane oxidation reactor[J]. Industrial & Engineering Chemistry Process Design and Development, 1974, 13(4): 317-323.

[23] 李大珍, 邓希贤, 王郁文, 侯恩鉴. 高锰酸钾与乙酰丙酮快速反应动力学[J]. 物理化学学报, 1993(5): 692-697.

LI Da-zhen, DENG Xi-xian, WANG Yu-wen, HOU En-jian. Studies on kinetics of the fast reaction between potassium permanganate and acetylacetone[J]. Acta Physico-chimica Sinica, 1993(5): 692-697.

Study of macro-kinetic of iron removal by goethite process enhanced by high shear on ZnSO4-FeSO4 solution system

WANG Wen-chao, YANG Jian-guang, YAN Wan-peng, NAN Tian-xiang, TANG Chao-bo, ZENG Wei-zhi, LI Ling-chen

(School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: Shear used commonly in polymer emulsification and dispersion was introduced into the process of iron removal by goethite method in the field of hydrometallurgy. In order to study the macro-kinetic of iron removal by goethite process enhanced by high shear, ZnSO4-FeSO4 solution system was taken as research object. The effects of temperature, pH, strengthening way by flow field, shear-velocity and oxygen concentration on the velocity of iron removal were investigated by single factor test method. The results show that temperature, pH, strengthening way by flow field, shear-velocity and oxygen concentration have significant effects on the velocity of iron removal. Kinetic data based on the results show that the process of iron removal by goethite method is controlled by mass transfer process, and the reaction is in line with the characteristics of first-order reaction. The reaction of iron removal by goethite method by high shear is second-order with respect to Fe2+ with activation energy of 27.85 kJ/mol.

Key words: shear; strengthening way by flow field; kinetic; goethite

Foundation item: Project(2018YFC1900403) supported by The National Key Research and Development Program of China

Received date: 2019-07-09; Accepted date: 2020-06-11

Corresponding author: YANG Jian-guang; Tel: +86-731-88830470; E-mail: jianguang_y@163.com

(编辑 王 超)

基金项目:国家重点研发专项课题资助项目(2018YFC1900403)

收稿日期:2019-07-09;修订日期:2020-06-11

通信作者:杨建广,教授,博士;电话:0731-88830470;E-mail:jianguang_y@163.com