文章编号:1004-0609(2013)10-2977-08

基于正交试验闪速熔炼过程操作参数的优化

周 俊1,陈 卓2,谢德成2,毛永宁2,周孑民1, 2

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 中南大学 能源科学与工程学院,长沙 410083)

摘 要:伴随着铜闪速炉产能与熔炼强度的不断提高,闪速炉反应塔内温度场、浓度场等物理场的微观信息分布特点发生了明显的变化,其反应配风之间的参数配比关系对炉内熔炼过程的影响作用更为突出。采用正交设计的方法,就闪速炉生产操作的3个主要配风参数(工艺风、分散风、中央氧)对炉内气、粒混合反应过程的影响关系进行系统仿真研究,得到基准工况条件下的操作参数优化配比方案。仿真结果表明:分散风速度对气、粒混合反应过程的影响占主导地位;在优化工况条件下,炉内熔炼过程效率进一步提高,其烟尘发生率可控制在3.2%左右,炉内氧气基本消耗完全。

关键词:闪速熔炼;数值仿真;正交试验;参数优化

中图分类号:TF811 文献标志码:A

Optimization of operational parameters for flash smelting process based on orthogonal experiment

ZHOU Jun1, CHEN Zhuo2, XIE De-cheng2, MAO Yong-ning2, ZHOU Jie-min1, 2

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. School of Energy Science and Engineering, Central South University, Changsha 410083, China)

Abstract: With an continuous increasing in the productivity and smelting intensity of the copper flash smelting furnace, distributions of physical fields, such as the temperature field and concentration field in the reaction shaft change significantly, and the matching scheme of operational parameters for different air flows becomes more and more important. Based on the orthogonal design method, the simulation study was carried out to investigate the effects of operational parameters of the main three air flows (i.e. the process air, the distribution air and the central oxygen) on the mixing and reaction process in the reaction shaft. The simulation results show that the distribution air velocity has more significant effect on the mixing and reaction process compared to the other two air flows. The smelting efficiency of the optimal case is further improved, of which the dust generation rate can be controlled around 3.2%, and the residual oxygen in the flue is nearly zero.

Key words: flash smelting; numerical simulation; orthogonal experiment; parameter optimization

闪速炉具有生产率高、能耗低、烟气中二氧化硫浓度高等优点。它利用粉状铜精矿巨大比表面积的特点,在炉内高温并充分与氧气接触的条件下以极快的速度完成硫化物的氧化反应,并放出大量的热以实现自热熔炼[1]。但是伴随着闪速熔炼强度和产量的大幅提高,现场技术人员在闪速炉生产过程中发现了一些问题,如反应塔内高温区明显下移,生料率和烟尘率有所增加,熔炼过程反应效率下降,生料率上升等。

通过多年的技术研究和现场实践经验,技术人员意识到这些问题的发生与闪速炉操作参数具有重要关联。

综合目前国内外关于闪速熔炼技术的研究结果发现:大多数研究都是基于闪速炉结构和自动控制技术的优化与改造,较少有对闪速炉配风参数的详细研究,因此一直未有形成明确、系统的闪速炉配风操作制度[2-6]。但在实际生产过程中,合理的操作制度不仅是改善炉内气流组织方式和强化气、粒两相传输过程效率的有力手段,也是实现闪速炉进一步挖潜增产的重要基础。为此,本文作者基于正交试验设计方法,以实现闪速炉内整体反应效果最优为目标,采用Fluent软件对闪速熔炼过程的3大操作参数(工艺风、分散风、中央氧)进行仿真优化研究,以获得各操作参数的最佳水平组合,为实现闪速炉“三高两低”(即高产率、高质量、高寿命、低渣含铜、低燃料消耗率)生产提供技术指导。

1 仿真计算模型

1.1 物理模型

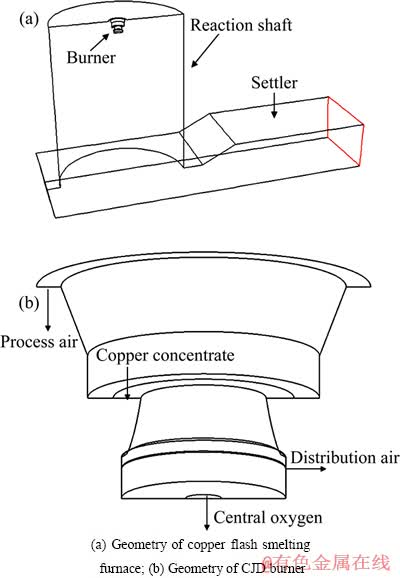

在本研究中,仿真计算主要侧重于研究闪速炉内气、粒两相的流动与混合、反应过程,因此,建立的仿真物理模型包括中央喷射扩散型精矿喷嘴(CJD)、反应塔以及沉淀池气相空间等3大部分。由于闪速炉炉体沿沉淀池长度方向具有良好的对称性,为有效减少模型网格数量与计算时间,建模时仅选取闪速炉炉体的一半作为仿真计算区域,如图1(a)所示。闪速炉精矿喷嘴结构示意图如图1(b)所示。

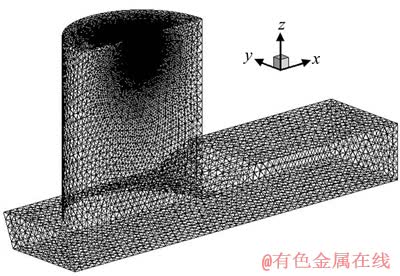

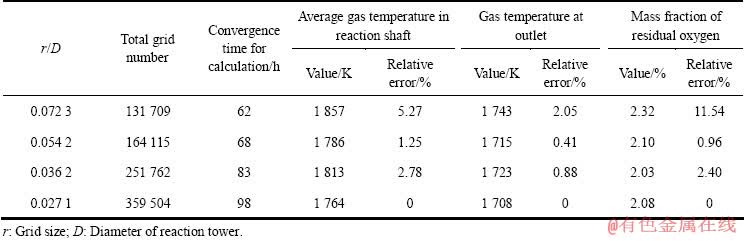

为保证计算精度,模型构建时对精矿喷嘴区域的网格进行局部加密处理,具体网格结构如图2所示,其中体网格平均大小为反应塔直径的5.42%,网格总数为164 115个。网格独立性计算结果表明:与较密网格尺寸的结果相比,该网格尺寸结构下,反应塔内平均温度相对误差小于1.25%;出口烟气温度相对误差小于0.41%;出口氧气浓度误差小于0.96%;节约时间30.61%,如表1所列。

1.2 数学模型

铜闪速熔炼过程涉及气、粒两相的动量、热量与质量传输以及颗粒的化学反应等过程,研究中采用欧拉法求解气相方程,采用拉格朗日法求解颗粒相方程,湍流模型则采用标准k-ε双方程模型进行求解[7-8]。

1.2.1 气相基本方程

闪速炉反应塔内气相流动与燃烧过程数值模型的控制方程组包括:质量守恒方程、动量守恒方程、能量守恒方程、化学组分守恒方程等;这些守恒方程可以用如下通用形式来表示:

(1)

(1)

式中: 为连续相密度,t为时间,xi、ui分别表示三维坐标与速度,i=1, 2, 3,

为连续相密度,t为时间,xi、ui分别表示三维坐标与速度,i=1, 2, 3, 为通用因变量,

为通用因变量, 为输运系数,

为输运系数, 为来自于连续相的源项,

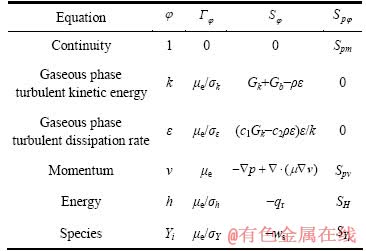

为来自于连续相的源项, 为由来自于颗粒相的源项。表2列出了通用方程在解不同方程时,对应变量的具体形式。

为由来自于颗粒相的源项。表2列出了通用方程在解不同方程时,对应变量的具体形式。

图1 铜闪速熔炼炉仿真模型示意图

Fig. 1 Schematic diagram of simulation model of copper flash smelting furnace

图2 铜闪速熔炼炉网格划分示意图

Fig. 2 Schematic diagram of grid division of copper flash smelting furnace

表1 不同体网格尺寸下气相温度及余氧浓度仿真结果

Table 1 Results of gas temperature and residual oxygen at different grid sizes

表2 直角坐标系下的通用方程形式

Table 2 General equation in form of Cartesian coordinate system

表2中的k为湍动能;ε为湍动能耗散率;v为速度;h为流体的焓;Yi为流体i种组分含量;μe为有效黏度,等于分子动力黏度μ0与湍流动力粘度μT之和,其中 ;

; 、

、 、

、 、

、 分别为湍动能方程、耗散方程、能量方程、组分传输方程的普朗特常数;Gk表示层流速度梯度产生的湍流动能;Gb表示由于浮力产生的湍流动能;Cμ、C1、C2为常数;-qr为来自热辐射或化学反应的热量;-ws为燃烧或化学反应过程的物质生产率;Spm、Spv、SYi、SH分别表示为颗粒带给各个方程的源项;pm为颗粒质量;pv为颗粒速度。

分别为湍动能方程、耗散方程、能量方程、组分传输方程的普朗特常数;Gk表示层流速度梯度产生的湍流动能;Gb表示由于浮力产生的湍流动能;Cμ、C1、C2为常数;-qr为来自热辐射或化学反应的热量;-ws为燃烧或化学反应过程的物质生产率;Spm、Spv、SYi、SH分别表示为颗粒带给各个方程的源项;pm为颗粒质量;pv为颗粒速度。

对于二维直角坐标系,可有

(2)

(2)

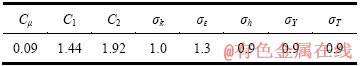

式中,各常数如表3所列[9]。

表3 方程中的常数

Table 3 Constants in equations

1.2.2 颗粒相传输方程

1) 颗粒相运动方程

精矿颗粒运动过程采用拉格朗日法求解,其控制方程如下:

(3)

(3)

其中:vp、v分别表示颗粒相与连续相速度矢量;g为重力加速度;ρp、ρ分别表示颗粒与连续相密度;F表示颗粒相所受的除阻力和重力外的外力;FD表示颗粒运动中受到的气相作用力,其可描述为

(4)

(4)

式中:Re为雷诺数, ;CD为阻力系数,

;CD为阻力系数, ;dp为颗粒的平均直径。

;dp为颗粒的平均直径。

2) 颗粒相的能量方程

颗粒相与气相之间热量传递通过如下方程耦合:

(5)

(5)

式中:mc为连续相中氧气的质量;cp为氧气定压比热容;T为温度;t为时间;Qr为化学反应热;Qc为气相与颗粒表面的对流传热,其中

,d为颗粒平均直径,

,d为颗粒平均直径, 为颗粒导热系数,Re为雷诺数,

为颗粒导热系数,Re为雷诺数, 为动力黏度,Tg为气相温度,Tp为颗粒温度;Qrad为气相和颗粒相之间的辐射传热,

为动力黏度,Tg为气相温度,Tp为颗粒温度;Qrad为气相和颗粒相之间的辐射传热, ;

; 为颗粒表面有效发射率;

为颗粒表面有效发射率; 为气体在温度Tg下的发射率;ag为气体在温度Tp下的吸收率;

为气体在温度Tg下的发射率;ag为气体在温度Tp下的吸收率; 为斯特藩-波耳兹曼常量。

为斯特藩-波耳兹曼常量。

3) 颗粒相传质方程

在高温情况下,可认为化学反应主要由气固边界层的气体的扩散速度决定。在颗粒的氧化过程中,这个速率由O2从气体中向气固边界层迁移的速率决定。因此,可以通过如下的方程来控制反应速率:

(6)

(6)

式中:mc是连续相中氧的质量分数;mF和mFG分别是连续相和颗粒相中氧的质量分数;D是连续相中的质量组分的扩散率;Sh是舍伍德数,

,

, 为对流传质系数,dp为颗粒的平均直径[9]。

为对流传质系数,dp为颗粒的平均直径[9]。

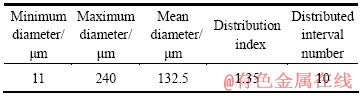

精矿颗粒大小采用MASTERSIZER激光衍射粒度分析仪对入炉物料进行粒度分析后,采用Rosin-Rammler方法计算粒度分布规律,得出具体参数如表4所列。

表4 精矿颗粒粒径分布及平均粒径

Table 4 Particle distribution and mean diameter

1.2.3 铜闪速熔炼反应数值模型

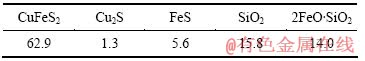

通过对闪速炉入炉物料取样并经过X光衍射分析与环境扫描电镜分析,确定炉料的主要物相组成有CuFeS2、Cu2S、FeS、Fe3O4、SiO2,2FeO·SiO2等,其具体成分组成如表5所列。

表5 精矿成分及含量

Table 5 Composition of concentrate fed into reaction shaft (mass fraction, %)

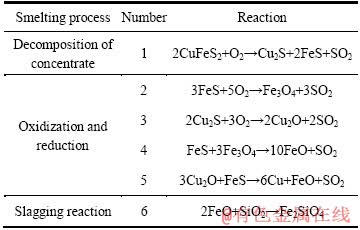

闪速熔炼过程根据其反应特点大致可以划分为精矿分解反应、氧化还原反应与造渣反应等几种反应类型[10-12],具体反应如表6所列。

表6 闪速熔炼过程化学反应模型

Table 6 Reactions model of flash smelting process

1.3 模型验证

为了对仿真计算模型进行验证,研究中采用特制的双铂铑热电偶装置(该型热电偶分度号为B,量程范围300~1 800 ℃),针对投料量为182 t/h的稳定炉况开展了工业测温实验,得到了反应塔内部与沉淀池气相空间不同位置处共4个检测点温度值。通过计算两者相对误差小于7%,由此证明本研究所用数值模型准确可靠[13]。

2 正交试验方案设计

2.1 正交试验设计

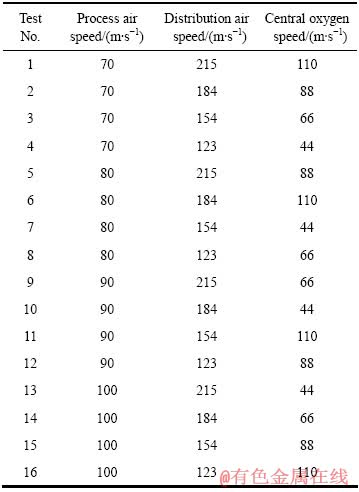

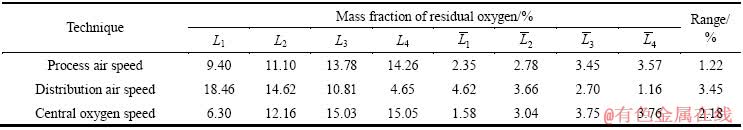

为了研究闪速炉生产操作的3个主要配风参数(工艺风、分散风、中央氧)对炉内气和粒混合反应过程的影响强弱以及主次关系,选取工艺风速度、分散风速度与中央氧速度作为试验因素,其中每个因素选取4个不同的参数水平。由于炉内熔炼过程主要为铜精矿颗粒的氧化反应,烟气中最终残余氧气量越少,则说明气、粒混合越好,熔炼反应进行的越完全,因此研究中以沉淀池出口处烟气中剩余氧含量作为考察炉内气、粒混合反应效果的指标。根据闪速炉各因素的实际可调范围,设计了如表7所列三因素四水平L16(43)正交实验表[14-15]。为便于描述,3个因素分别用各操作参数英文首字母P(process air),D(distribution air),C(central oxygen)表示,各试验组合分别用试验号1~16标列。

2.2 正交试验结果及分析

利用所建立的铜闪速炉多场耦合模型,分别对16个试验工况进行了数值模拟,得到了各试验工况沉淀池出口烟气中剩余氧气质量分数,结果如表8所列。

为了研究工艺风、分散风、中央氧等气流的喷吹速度对炉内气、粒混合反应过程影响的主次关系,对试验结果进行极差分析,用Li表示任一列上因素水平号为i(本研究中i=1, 2, 3, 4)时所对应的试验结果之和,用 表示Li的平均效应值,即

表示Li的平均效应值,即 =Li/n,在本试验中,n=4,极差分析结果详见表9。

=Li/n,在本试验中,n=4,极差分析结果详见表9。

表7 正交试验表

Table 7 Orthogonal experiment table

表8 出口烟气中余氧质量分数

Table 8 Mass fraction of residual oxygen in flue at outlet

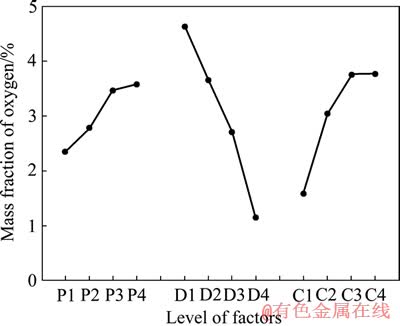

图3所示为工艺风速度、分散风速度、中央氧速度与沉淀池出口烟气中氧气质量分数的关系图。结合表9分析可知:

1) 随着工艺风速度、中央氧速度的增大,闪速炉内综合氧气利用效率下降,致使烟气中余氧含量升高。而氧气利用效率随着分散风速度的增加而升高。具体而言,工艺风速度、中央氧速度以1水平为优,分散风速度以4水平为优。因此最优工况条件为:P1D4C1。

2) 工艺风速度、分散风速度、中央氧速度这3种因素对优化指标的影响程度的由大到小顺序为分散风速度、中央氧速度、工艺风速度。

图3 3个因素下出口烟气中含氧质量分数变化关系

Fig. 3 Change of O2 mass fraction in outlet flue under three factor-settings

表9 余氧的极差分析

Table 9 Range analysis of residual oxygen

3 优化工况与设计工况对比

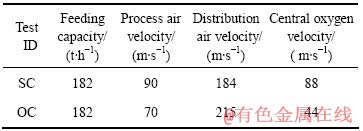

对以上分析得到的优化工况条件进行仿真计算后发现:在此工况下,沉淀池出口烟气中余氧质量分数为0,这表明在该条件下,反应塔内气粒混合与反应充分,氧利用完全。为了详细探明该优化工况条件下闪速炉内气粒混合与熔炼反应的具体情况,在此与闪速熔炼基准工况进行了详细对比,其中基准工况记为SC(Standard case),优化工况条件P1D4C1标记为OC(Optimal case),具体操作参数见表10。

表10 操作参数比较

Table 10 Operational parameters of two simulation cases

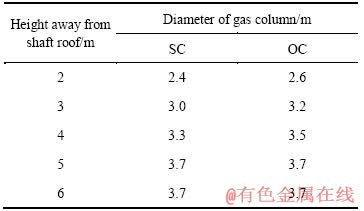

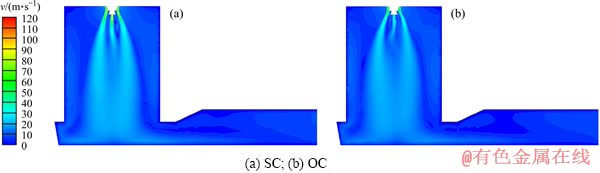

3.1 炉内速度场分布特点比较

图4所示为两工况条件下反应塔中心截面气相速度分布仿真结果。从图4中可以看出:在两个不同工况条件下,工艺风进入反应塔后体积均迅速发生膨胀,在距塔顶3.0 m左右处其体积变化趋于稳定,并在反应塔中心形成一个轮廓明显的主体气柱。对距离反应塔顶不同高度处轴截面上的气柱大小进行比较时(见表11)发现:在反应塔上部(h<3 m),优化工况(OC)条件下的主体气柱沿塔高膨胀更为迅速;而在反应塔底部两工况气柱大小基本相同,这表明优化工况条件对反应塔内上部气流运动有较为显著的影响,而随着气流逐渐膨胀至底部时,这种影响逐渐减弱。

表11 不同工况条件下沿塔高气柱大小

Table 11 Diameter of gas column at different cases

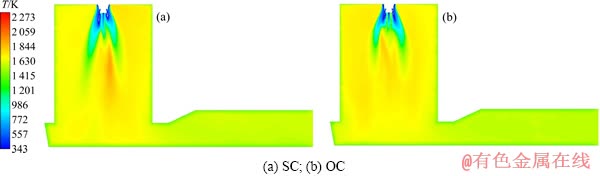

3.2 炉内温度场分布特点比较

图5所示为不同工况条件下的气相温度云图。由图5可以看出:在两种工况条件下,喷嘴下方皆存在明显的低温区域;而后随着精矿颗粒的着火反应,气相温度沿反应塔中心向下有显著上升;但在工艺风外围区域气、粒升温缓慢,形成了翅翼状的升温感应区;相比之下,基准工况(SC)条件下气相中翅翼状的升温感应区较长,而在优化工况条件下,精矿喷嘴下方的气粒加热感应区范围有所减小,说明该工况下气相升温较快。

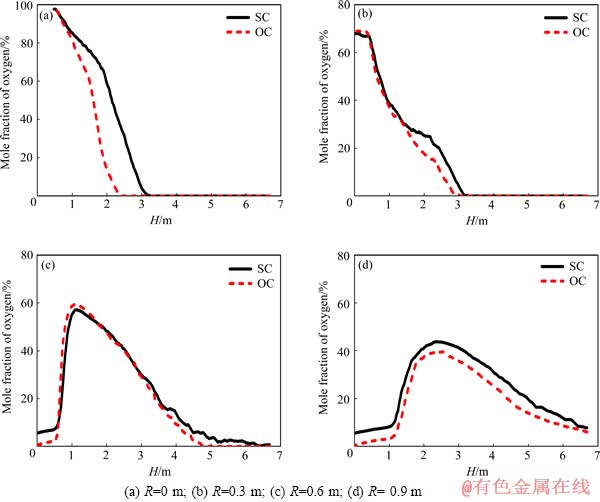

3.3 炉内浓度场分布特点比较

图6所示为反应塔不同半径处气相中O2摩尔分数随塔高的变化曲线。相比之下,优化工况下的O2沿塔高向下消耗速率更快,在反应塔中心半径R=0处这种趋势表现更为明显,O2距塔顶高度约为2.4 m处即消耗殆尽。结合炉内温度分布可以发现,优化工况下,分散风横向扰动的作用明显增强,料锥范围明显增大,这为塔内颗粒的有效分散创造了条件;虽然基准工况条件下反应塔中心外围与中下部气相温度较高,但因不能创造合适的颗粒分散条件,因此,整体反应效率较低。

图4 反应塔中心截面气相速度云图

Fig. 4 Velocity contours of gaseous phase in cross-section of reaction shaft

图5 反应塔中心截面气相温度云图

Fig. 5 Temperature contours of gaseous phase in cross-section of reaction shaft

图6 反应塔中心截面上不同半径处O2摩尔分数随塔高变化曲线

Fig. 6 Change of O2 mole fraction along height in cross-section of reaction shaft

3.4 综合比较结果

综合对比基准工况(SC)与优化工况(OC)多场耦合仿真结果可知,在优化工况条件下:

1) 反应塔上部空间气流扰动强度较大,这有利于该空间内的气、粒运动、混合与反应过程。

2) 工艺风沿塔高膨胀较为迅速,这有利于塔内精矿颗粒的分散过程,但可能引起烟尘率上升,并造成高温熔融颗粒对反应塔中下部的冲刷蚀损加剧,这一点在生产操作中应引起关注[16]。

3) 反应塔中心区域气、粒着火速度明显加快,高温区域有所上移,这对反应塔中心精矿颗粒密集区域的气、粒混合与着火反应有所帮助;在反应塔中心外围,虽然基准工况条件下气相沿塔高升温较为迅速,但因为没有形成物料适度分散的条件,因此导致炉内整体反应效率反而较差。

4 结论

1) 3大操作参数(分散风速度、工艺风速度、中央氧速度)的不同配套方案是影响炉内气粒混合与反应的重要因素。在优化工况条件下,塔内颗粒得到了适度分散,炉内熔炼过程效率得到进一步提高,其烟尘发生率可控制在3.2%左右,炉内氧气基本消耗完全。

2) 闪速炉操作过程中,工艺风、分散风与中央氧的速度对熔炼过程影响程度由大到小依次为分散风速度、中央氧速度、工艺风速度。操作中应重点调控影响塔内气粒分散效果的分散风速度,其次应该注意调节影响反应塔中心气粒混合与着火反应的中央氧速度,相比之下,工艺风速度的调节效果较小。

REFERENCES

[1] 彭容秋. 铜冶金[M]. 长沙: 中南大学出版社, 2004: 26-65.

PENG Rong-qiu. Copper metallurgy[M]. Changsha: Central South University Press, 2004: 26-65.

[2] 陈 卓, 王云霄, 宋修明. 高投料量下炼铜闪速炉内熔炼过程的数值模拟[J]. 中国有色金属学报, 2011, 21(11): 2916-2921.

CHEN Zhuo, WANG Yun-xiao, SONG Xiu-ming. Numerical simulation of smelting process in copper flash smelters at high loading rate[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2916-2921.

[3] CHEN Hong-rong, MEI Chi. Operation optimization of concentrate burner in copper flash smelting furnace[J]. Transactions of Nonferrous Metals Society of China, 2004, 16(3): 382-386.

[4] 王华骏, 谢剑才. 金隆闪速炉炉体改造[J]. 铜业工程, 2010(4): 35-37.

WANG Hua-jun, XIE Jian-cai. Reconstruction of Jinlong flash furnace[J]. Copper Engineering, 2010(4): 35-37.

[5] SOLNORDAL C B, JORGENSEN F R A, PETER T L, KOH P T L, HUNT A. CFD modelling of the flow and reactions in a flash furnace smelter reaction shaft[C]// Third International Conference on CFD in the Minerals and Process Industries. Melbourne, Victoria, Australia: CSIRO Materials, 2003: 161-166.

[6] 周 俊. 金隆闪速熔炼扩产后的运行实践[J]. 有色金属: 冶炼部分, 2009(2): 5-10.

ZHOU Jun. Operational practice of Jinlong flash smelting after expansion[J]. Nonferrous Metals: Extractive Metallurgy, 2009(2): 5-10.

[7] 李欣峰. 铜闪速炉数值仿真[J]. 中南工业大学学报: 自然科学版, 2001, 32(3): 262-266.

LI Xin-feng. Numerical simulation of copper flash smelting furnace[J]. Journal of Central South University of Technology: Natural Science, 2001, 32(3): 262-266.

[8] 陈 卓, 毛永宁, 赵荣升,刘安明. 闪速炉熔炼配风对反应过程的影响[J]. 中南大学学报: 自然科学版, 2011, 43(2): 730-737.

CHEN Zhuo, MAO Yong-ning, ZHAO Rong-sheng, LIU An-ming. Influences of reaction air parameters on smelting process in flash furnace[J]. Journal of Central South University: Science and Technology, 2011, 43(2): 730-737.

[9] 梅 炽, 周孑民, 彭小奇. 有色冶金炉窑仿真与优化[M]. 北京: 冶金工业出版社, 2001: 227-229.

MEI Chi, ZHOU Jie-ming, PENG Xiao-qi. Simulation and optimization of furnaces and kilns for nonferrous metallurgical engineering[M]. Beijing: Metallurgical Industry Press, 2001: 227-229.

[10] 周力行. 湍流气粒两相流动和燃烧的理论与数值模拟[M]. 陈文芳, 林文漪, 译. 北京: 科学出版社, 1994.

ZHOU Li-xing. Theory and numerical simulation for turbulent gas-particle flow and combustion[M]. CHEN Wen-fang, LIN Wen-yi, transl. Beijing: Science Press, 1994.

[11] SOLNORDAL C B, JORGENSEN F R A, KOH P T L, HUNT A. CFD modelling of the flow and reactions in the Olympic Dam flash furnace smelter reaction shaft[J]. Applied Mathematical Modelling, 2006, 30: 1310-1325.

[12] 陈红荣, 梅 炽, 谢 锴. 闪速熔炼渣含铜的数值模拟[J]. 有色金属, 2008, 60(2): 71-74.

CHEN Hong-rong, MEI Chi, XIE Kai. Numerical simulation on flash smelting copper loss in slag[J]. Nonferrous Metals, 2008, 60(2): 71-74.

[13] 毛永宁. 高强度铜闪速熔炼过程数值仿真与操作参数配套方案优化研究[D]. 长沙: 中南大学, 2012.

MAO Yong-ning. Numerical simulation and optimization research on the matching scheme of the operational parameters for high intensity copper flash smelting process[D]. Changsha: Central South University, 2012.

[14] 北京大学数学力学系概率统计组. 正交设计法[M]. 北京: 石油化学工业出版社, 1976.

Probability Statistics Group in Department of Mathematics and Mechanics, Peking University. Orthogonal design method[M]. Beijing: Petroleum Chemical Industry Press, 1976.

[15] 马希文. 正交设计的数学理论[M]. 北京: 人民教育出版社, 1981.

MA Xi-wen. The mathematical theory of orthogonal design[M]. Beijing: People’s Education Press, 1981.

[16] 张法平. 奥托昆普闪速熔炼和闪速吹炼工艺[J]. 有色冶金设计与研究, 1993, 14(4): 50-58.

ZHANG Fa-ping. Outokumpu flash smelting and flash blowing process[J]. Nonferrous Metals Engineering & Research, 1993, 14(4): 50-58.

(编辑 李艳红)

基金项目:湖南省科技厅科技计划项目(2011GK3207)

收稿日期:2012-11-06;修订日期:2013-07-20

通信作者:陈 卓,教授,博士;电话:13974891750;E mail: chenzhuo@csu.edu.cn