某高磷铁矿提铁降磷研究

朱德庆,春铁军,潘建,危雪梅

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:以湖南某地高磷铁矿为原料,采用还原焙烧-磁选-硫酸浸出工艺进行提铁降磷试验研究。对还原焙烧-磁选粗精矿进行硫酸浸出工艺参数优化,对浸出时间、液固比、硫酸用量和搅拌速度等因素对提铁降磷效果的影响进行研究。研究结果表明:对原矿品位为47.28% Fe(质量分数)和磷含量为1.59%的高磷铁矿石经过还原焙烧-磁选得到的粗精矿,在浸出时间为2 h、液固比为2.5、硫酸用量为50 kg/t和搅拌速度为500 r/min的条件下进行酸性浸出提铁降磷,最终得到铁精矿品位达62.35% Fe,磷含量为0.20%,铁总回收率为90.54%和脱磷率为87.42%。

关键词:高磷铁矿;还原焙烧;磁选;酸性浸出

中图分类号:TD92 文献标志码:A 文章编号:1672-7207(2011)03-0568-06

Upgrading iron and removing phosphorus from high-phosphorus iron ore

ZHU De-qing, CHUN Tie-jun, PAN Jian, WEI Xue-mei

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: The reduction roasting-magnetic separation- sulfuric acid leaching of high-phosphorus iron ores was studied. The process parameters of acid leaching were optimized with rougher iron ore concentrate obtained by reduction roasting-magnetic separation of ROM (run of mine) ores. The effects of various factors on upgrading iron and dephosphorization were discussed in acid leaching. The result shows that the iron ore concentrate, assaying 62.35% iron and 0.20% phosphorus content are achieved at the overall iron recovery of 90.54% and dephosphorization of 87.42% under the conditions of leaching for 2 h, at 2.5 liquid-to-solid mass ratio, 50 kg/t sulfuric acid and 500 r/min agitating speed after the ROM ore with 47.28% iron and 1.59% phosphorus content is pretreated by reduction roasting-magnetic separation.

Key words: high-phosphorus iron ore; reduction roasting; magnetic separation; acid leaching

近十几年来,中国钢铁行业发展迅速。与之相对应的炼铁所需铁矿石的进口量也从1993年的0.33亿t增长到2008年的4.44亿t,对进口铁矿石的依赖度已达49.5%[1-2]。然而,我国大量的高磷铁矿石尚未得到利用。高磷铁矿中的磷主要以磷灰石或碳氟磷灰石形态与其他矿物共生,浸染于铁矿物的颗粒边缘,嵌布于石英或碳酸盐矿物中,少量赋存于铁矿物晶格中,且磷灰石的嵌布粒度较小,有的甚至在2 μm以下,采用物理选矿方法很难分离,属于难选矿石[3]。但是,我国高磷铁矿具有原矿铁品位较高(质量分数为45%左右,远高于我国铁矿石的平均铁品位32.6%[4-6]),储量大(占总储量的14.86%,约74.5亿t[4])等特点,因此,解决高磷铁矿的利用问题,对解决我国铁矿资源供应和钢铁工业的发展有非常重要的意义。针对高磷铁矿的利用,近年来国内外进行了较多的研究。主要工艺有分散—选择性聚团—反浮选、重选、高梯度磁选、化学浸出和生物浸出等[7-11]。浮选、重选和磁选脱磷率低,铁损失大,成本高;生物浸出脱磷周期长,微生物培养难度大,工业化生产困难。原矿直接酸浸法具有对原料粒度没有严格的要求、脱磷效率高、铁损失少、浸矿介质可以重复利用等优点[12-13],但是,不能有效地提高精矿铁品位。还原焙烧-磁选是一种有效的提铁降杂工艺,能够高效地富集铁,但存在脱磷效率低等不足。Jin等[14]的研究表明,原矿酸浸以硫酸浸出效果最佳。因此,本文作者将还原焙烧-磁选工艺与酸浸工艺结合,对湖南某地高磷铁矿进行还原焙烧-磁选-硫酸浸出提铁降磷新工艺试验研究,并对酸浸工序的工艺参数进行优化。

1 实验

1.1 原料性能

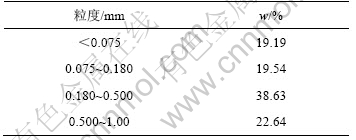

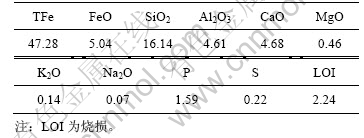

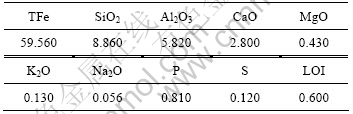

试验所用原料包括湖南某地低品位高磷铁矿原矿、还原剂和硫酸。原矿的粒度分布(质量分数)和化学成分(质量分数,下同)分析结果如表1和2所示。可见:铁矿石品位和磷含量分别为47.28% Fe和1.59%,属于低品位高磷铁矿。矿相分析表明:铁矿石中的磷主要以磷灰石的形式存在;这种磷灰石大部分是呈环状与赤铁矿形成间层,厚度为3~10 μm。因此,大部分的磷无法通过物理选矿的方法进行脱除。

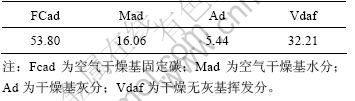

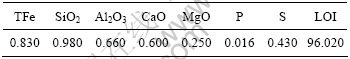

试验用还原煤为新疆奇台煤,其工业分析结果(质量分数)和化学成分分析结果分别如表3和4所示。还

表1 铁矿石粒度分布

Table 1 Size distribution of ROM iron ore

表2 铁矿石原矿化学成分

Table 2 Chemical compositions of ROM iron ore %

表3 还原煤工业分析结果

Table 3 Industrial analysis result of reductant coal %

表4 还原煤化学成分

Table 4 Chemical analysis of reductant coal %

原煤挥发分为32.21%、硫含量(质量分数)为0.43%,属于反应性较好的非结焦煤,可满足还原焙烧过程中还原反应的要求。

试验所用硫酸质量分数为98%,为湖南株洲石英化玻有限公司生产。

1.2 研究方法

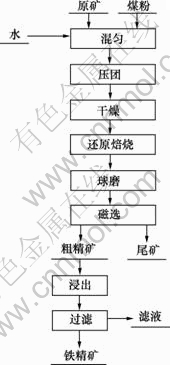

试验流程如图1所示。称取100 g原矿,内配奇台煤(粒度小于1 mm)5%,加水后进行人工混匀。混匀后每次称量2.5 g进行压团,模具尺寸(直径×高)为10 mm×50 mm,压力为2×107 Pa。团块干燥后每次取8个团块外盖焦粉(焦矿质量比为1.5?1.0,焦粉

图1 提铁脱磷试验流程

Fig.1 Test flow sheet of upgrading iron and removing phosphorus

起保护作用)放入铁瓷舟中后在卧式管炉中进行还原焙烧,还原焙烧设备为型号HR-1的自制卧式电热管炉,焙烧结束后迅速将其放入水中冷却。还原焙烧后的团块每次取20 g进行磨选后得到粗精矿。磨矿设备为XMQ240×90型锥形球磨机,磁选设备为XCGS-73型磁选管,直径为50 mm,磁场强度可调。

称取一定量的粗精矿放入烧杯中,按相应的液固比(水的质量与粗精矿质量之比)加入水,然后,根据相应的硫酸用量加入质量分数为98%的浓硫酸。浸出反应在体积为300 mL的烧杯中进行,搅拌机为无级调速搅拌机,转速为50~2 000 r/min。

浸出过程中脱磷反应为[15]:

Ca10(PO4)6X(s)+20H+→6H3PO4+10Ca2++H2X (1)

Ca2+ +SO42- +nH2O=CaSO4·nH2O(s) (2)

n=0, 0.5或者2,取决于反应过程中硫酸的浓度。

在脱磷反应中,反应方程式(2)中形成的CaSO4·nH2O(s) 可以不断地促进反应(1)向右进行,从而实现矿石中磷的脱除。同时,在脱磷反应中,粗精矿中SiO2,Al2O3,MgO和CaO等成分也会与硫酸发生反应,有利于提高精矿铁品位。

硫酸质量分数w、液固比R及硫酸用量Q三者之间的关系为:

(3)

(3)

2 结果与分析

2.1 还原焙烧—磁选预选

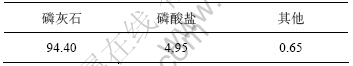

还原焙烧试验是在卧式管炉中以800 ℃的温度焙烧25 min,还原焙烧后的团块球磨3 min后(磨矿粒度小于0.075 mm者的质量分数占93.6%),以63.68 kA/m的磁场强度磁选5 min即可得到Tfe 59.56%,磷0.81%,产率72.58%,铁回收率91.43%,脱磷率49.06%的粗精矿。然后,对粗精矿进行酸浸法进一步提铁脱磷研究。粗精矿的化学成分以及磷物相分析结果(质量分数)分别如表5和表6所示。通过还原焙烧—磁选预选试验,初步实现了对该高磷铁矿的提铁脱磷。同时,经过磁选抛尾减少了后续酸浸工艺的处理量,对降低生产成本有重大意义。

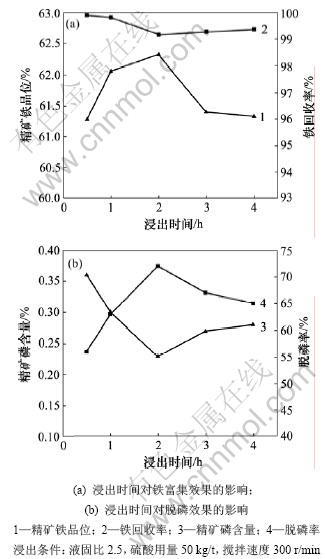

2.2 浸出时间

浸出时间对铁精矿质量和脱磷效果的影响如图2所示。由图2可见:当硫酸浸出时间为0.5~2.0 h时,延长浸出时间,铁精矿品位逐渐升高,磷含量降低,铁回收率略有降低,但也在99%以上;当浸出时间为2 h

表5 粗精矿化学成分

Table 5 Chemical compositions of rougher iron ore concentrate %

表6 粗精矿中磷物相分析

Table 6 Phase analysis of phosphorus in rougher iron ore concentrate

图2 浸出时间对铁精矿质量和脱磷效果的影响

Fig.2 Effects of leaching time on quality of iron ore concentrate and dephosphorization

时,铁精矿品位达最大值为62.32%,铁精矿中磷含量降至0.23%,铁回收率为99.16%;继续延长浸出时间,精矿铁品位有所降低,磷含量稍有增大。这主要是由于随着浸出时间的延长,粗精矿中的磷不断与硫酸发生反应进入溶液中,从而降低了铁精矿中磷含量。随着反应达到平衡,继续延长浸出时间,由于离子吸附作用,进入溶液中的磷会吸附在精矿颗粒表面,磷含量反而有所增加。因此,试验适宜的浸出时间为2 h。

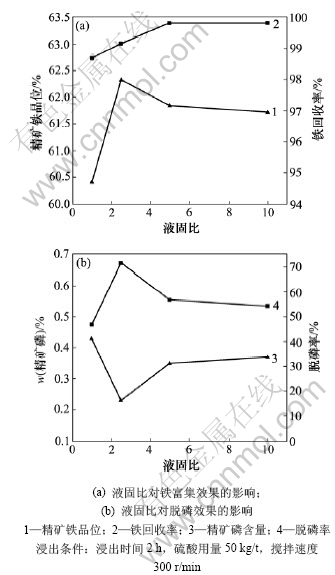

2.3 液固比

液固比对铁精矿质量和脱磷效果的影响如图3所示。由图3可见:随着液固比从1.0增大到2.5(对应硫酸浓度从4.76%降低到1.96%),铁精矿品位由60.41% Fe提高到62.32% Fe,相应铁精矿中磷含量也从0.43%降低到0.23%,铁回收率略有升高至99.16%。

图3 液固比对铁精矿质量和脱磷效果的影响

Fig.3 Effects of liquid-to-solid ratio on quality of iron ore concentrate and dephosphorization

这主要是因为液固比从1.0增大到2.5时,增大液固比,脱磷反应生成的硫酸钙能够较快地扩散到溶液中,有利于脱磷反应的进行,从而降低了铁精矿中的磷含量。然而,当液固比继续增大时,精矿铁品位基本不变,磷含量有所升高。这是因为液固比继续增大,溶液中硫酸浓度逐渐变小,当液固比为10时,对应的硫酸质量分数仅为0.50%,而此时溶液中硫酸的浓度可能是脱磷反应的限制环节,根据脱磷反应(1),降低脱磷反应溶液中的H+的浓度,阻碍了脱磷反应的进行,从而导致铁精矿中磷含量相对较高。因此,试验适宜的液固比为2.5。

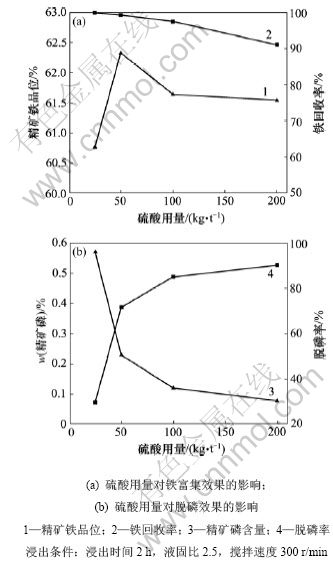

2.4 硫酸用量

图4所示为硫酸用量对铁精矿质量和脱磷效果的影响。由图4可见:在硫酸用量从25 kg/t增大到50

图4 硫酸用量对铁精矿质量和脱磷效果的影响

Fig.4 Effects of sulfuric acid consumption on quality of iron ore concentrate and dephosphorization

kg/t(对应硫酸浓度从0.99%增大到1.96%),铁精矿品位从60.76% Fe提高至62.32% Fe,铁回收率略有下降,但仍在99%左右;铁精矿中磷含量则从0.57%下降至0.23%。这是因为在液固比不变的情况下,硫酸用量越多,溶液中H+的浓度越高,有利于脱磷反应的进行。继续增大硫酸用量至200 kg/t,铁精矿中磷含量降低至0.1%以下,但是,过多的硫酸也使得脱磷反应过程中铁损失较大,铁精矿品位下降至61.46%,铁回收率仅有91.13%。综合生产成本以及铁回收率考虑,适宜的硫酸用量为50 kg/t,另外,由于脱磷反应中的硫酸不可能完全被消耗,可以循环重复利用;同时,一些研究表明脱磷反应中产生的磷酸经过处理可变成高纯度的磷酸,从而降低浸出成本[14]。

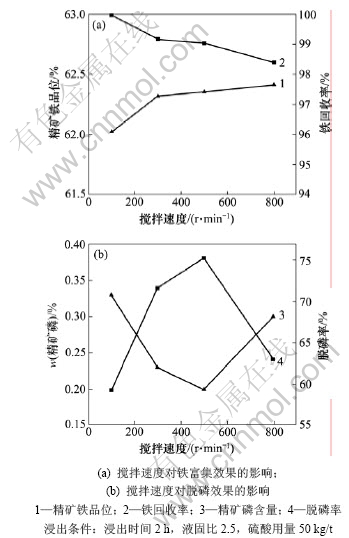

2.5 搅拌速度

图5所示为搅拌速度对铁精矿质量和脱磷效果的影响。由图5可见:当搅拌速度从100 r/min增大到

图5 搅拌速度对铁精矿质量和脱磷效果的影响

Fig.5 Effects of speed of agitator on quality of iron ore concentrate and dephosphorization

800 r/min,铁精矿品位逐渐增大至62.41%,铁回收率略有降低,但仍在98%以上。然而,对应的铁精矿中磷含量则在转速500 r/min时达到最小值0.20%,当转速超过500 r/min时,脱磷率出现下降。这是由于浸出所用的矿样粒度较小,当搅拌速度过大时,细粒颗粒很容易被搅拌所产生的漩涡带动高速旋转,导致作用在颗粒表面的相对搅拌速度降低,从而影响脱磷反应的进行[14]。因此,试验适宜的搅拌速度为500 r/min。

2.6 综合条件下全流程试验

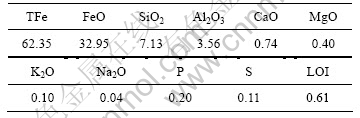

粗精矿在浸出时间为2 h,液固比为2.5,硫酸用量为50 kg/t,搅拌速度为500 r/min的条件下,得到的铁精矿化学成分(质量分数)如表7所示。经过还原焙烧-磁选-酸浸工艺后,铁矿石品位由47.28%提高到62.35%,磷含量由1.59%降低到0.20%,SiO2和S等有害成分的含量也均有所降低,全流程铁总回收率为90.54%,脱磷率为87.42%。因此,对于高磷铁矿,还原焙烧-磁选-硫酸浸出工艺是一种有效的提铁脱磷 手段。

表7 成品铁精矿的化学成分

Table 7 Chemical compositions of final iron ore concentrate %

3 结论

(1) 采用还原焙烧—磁选工艺能够有效地对湖南某地高磷铁矿进行预先富集,初步实现提铁脱磷。粗精矿的铁品位由原矿47.28%提高到59.96%,磷含量由1.59%降低到0.81%,铁的作业回收率为91.43%。

(2) 对粗精矿进行硫酸浸出也取得了良好的提铁脱磷效果。在浸取时间为2 h、液固比为2.5、硫酸用量为50 kg/t和搅拌速度为500 r/min的条件下,铁精矿品位为62.35%,磷含量为0.20%,铁的作业回收率为99.03%。

(3) 还原焙烧—磁选—硫酸浸出工艺是处理高磷铁矿的有效手段之一,不仅能高效地富集铁,而且有效地脱磷,制备出优质铁精矿。

(4) 对浸出过程中废酸的循环利用以及清洗酸浸后精矿等问题还有待进一步研究,以利于进一步降低生产成本,改善环境。

参考文献:

[1] 2008年世界铁矿石主要出口国出口量[EB/OL]. [2009-03-13]. http://www.chinamining.com

Exports of iron ore from the major exporters in 2008[EB/OL]. [2009-03-13]. http://www.chinamining.com

[2] 2008年我国对进口矿依存度[EB/OL]. [2009-03-10]. http://www.lrn.cn

The dependent degree on imported iron ore in China, 2008[EB/OL]. [2009-03-10]. http://www.lrn.cn

[3] 郝先耀, 戴惠新, 赵志强. 高磷铁矿石降磷的现状与存在问题探讨[J]. 金属矿山, 2007, 367(1): 7-11.

HAO Xian-yao, DAI Hui-xin, ZHAO Zhi-qiang. State of phosphorous reduction of high phosphorus iron ore and discuss on its problems[J]. Metal Mine, 2007, 367(1): 7-11.

[4] 孟嘉乐, 曹晶. 高磷铁矿湿法脱磷研究[J]. 冶金研究, 2008(12): 287-288.

MENG Jia-le, CAO Jing. Study on the phosphorus from the phosphorus-containing iron ore by hydrometallurgy[J]. Metallurgy Research, 2008(12): 287-288.

[5] 孙富来. 中国铁矿资源[J]. 矿产资源利用, 1995(7): 4-6.

SUN Fu-lai. Iron ore resources of China[J]. Utilization of Mineral Resources, 1995(7): 4-6.

[6] 张泾生. 我国铁矿资源开发利用现状及发展趋势[J]. 中国冶金, 2007, 17(1): 1-6.

ZHANG Jing-sheng. Status and trend of exploitation and utilization of iron ore resources in China[J]. China Metallurgy, 2007, 17(1): 1-6.

[7] 毕学工, 周进东, 黄治成, 等. 高磷铁矿脱磷工艺研究现状[J]. 河南冶金, 2007, 15(6): 3-7.

BI Xue-gong, ZHOU Jin-dong, HUANG Zhi-cheng, et al. Present investigation situation of dephosphorization processes for high phosphorus content iron ores[J]. Henan Metallurgy, 2007, 15(6): 3-7.

[8] 纪军. 高磷铁矿石脱磷技术研究[J]. 矿冶, 2003, 12(2): 33-37.

JIN Jun. Study on dephosphorization technology for high-phosphorus iron ore[J]. Mining & Metallurgy, 2003, 12(2): 33-37.

[9] 衣德强, 刘安平. 梅山选矿降磷工艺研究及应用[J]. 宝钢技术, 2003(1): 13-17.

YI De-qiang, LIU An-ping. Study and application of dephosphorization process for ore dressing at Meishan[J]. Baosteel Technology, 2003(1): 13-17.

[10] 周立群, 高志. 难选铁矿石微生物脱磷技术[J]. 金属矿山, 2008, 368(8): 58-60.

ZHOU Li-qun, GAO Zhi. Microorganism dephosphorization technology for refractory iron ores[J]. Metal Mine, 2008, 368(8): 28-60.

[11] 何姜毅, 周平, 庄故章, 等. 某高磷铁矿降磷技术研究[J]. 云南冶金, 2007, 36(6): 17-20.

HE Jiang-yi, ZHOU Ping, ZHUANG Gu-zhang, et al. Study on dephosphorization process for an ore of high phosphor[J]. Yunnan Metallurgy, 2007, 36(6): 17-20.

[12] Mamoun M, ZHANG Yu. A hydrometallurgical process for the dephosphorization of iron ore[J]. Hydrometallurgy, 1989(21): 277-292.

[13] Forssberg R, Asolfsson G. Dephosphorization of high- phosphorus iron ores by means of acid leaching[J]. Erzmetal, 1981(34): 316-322.

[14] JIN Yong-shi, JIANG Tao, YANG Yong-bin, et al. Removal of phosphorus from iron ore by chemical leaching[J]. Journal of Central South University of Technology, 2006, 13(6): 673-677.

[15] ZHANG Yu, Muhammed M. An integrated process for the treatment of apatite obtained from dephosphorization of iron ore[J]. Chem Tech Biotechnol, 1990(47): 47-60.

(编辑 陈爱华)

收稿日期:2009-12-02;修回日期:2010-04-25

基金项目:湖南省国土资源厅资助项目(2007K02);中南大学研究生学位论文创新基金资助项目(1343-74335000021)

通信作者:春铁军(1984-),男,河南漯河人,博士研究生,从事铁矿资源综合利用研究;电话:13467517647;E-mail: springcsu@126.com