文章编号:1004-0609(2008)09-1571-06

AZ31镁合金薄板动态再结晶对其拉伸性能的影响

胡丽娟,彭颖红,唐伟琴,李大永,张少睿

(上海交通大学 机械与动力工程学院,上海 200240)

摘 要:基于热粘塑性本构理论,构建拉伸动态再结晶理论模型,并将该模型引入AZ31镁合金薄板变温拉伸的数值仿真。通过数值仿真分析AZ31镁合金薄板动态再结晶对其拉伸性能的影响。采用Gleeble3500热模拟试验机对AZ31镁合金薄板在定应变速率为0.25 /s、不同温度(473、523、573和673 K)条件下进行单向拉伸实验,并利用光学显微镜观察变形中合金微观组织的演变。结果表明:随着镁合金薄板变形温度的升高,动态再结晶晶粒数量逐渐增加,尺寸先增后减,同时分布更趋于均匀;单向拉伸时,动态再结晶导致镁合金板材出现动态软化现象,流动应力降低。

关键词: 动态再结晶;热粘塑性本构;微观组织;拉伸性能

中图分类号:TG 115 文献标识码:A

Effect of dynamic recrystallization on tensile properties of

AZ31 magnesium alloy sheet

HU Li-juan, PENG Ying-hong, TANG Wei-qin, LI Da-yong, ZHANG Shao-rui

(School of Mechanical and Power Engineering, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: On the basis of thermoviscoplastic theory, the dynamic recrystallization (DRX) model of tension was constructed. This model was introduced into the finite element analysis of tension of AZ31 magnesium alloy sheet by changing temperature. The effect of DRX on the tensile properties of AZ31 magnesium alloy sheet was analyzed by numerical and experimental methods. The uniaxial tensile tests were conducted using a Gleeble 3500 thermal-mechanical simulator under fixed strain rate and various temperatures. The true strain-stress curves were obtained, and the microstructures of AZ31 magnesium alloy sheet were analyzed. The results show that the number of DRX grains increase gradually with the increase of temperature. The DRX grain size increases first and then decreases, and the DRX grain distribution of magnesium alloy sheet is more well-distributed. During the plastic deforming, magnesium alloy sheet is softened due to DRX and the flow stress is reduced.

Key words: dynamic recrystallization; thermoviscoplastic constitution; microstructure; tensile property

镁合金以低密度、高比强度等特点,在汽车、航空航天工业及3C行业得到广泛应用[1?3]。由于镁合金的结构为密排六方,在常温下变形时,只有基面滑移系参与,从而限制了其塑性变形能力。但在较高温 度时,镁合金的塑性可大大得到改善。研究表明[4?8],200 ℃以上时,镁合金是通过动态再结晶(DRX)来改善其塑性变形性能。镁合金的动态再结晶主要是从晶界开始的,以弓弯机制进行,并以连续方式进行动态再结晶。动态再结晶可细化晶粒,进而提高镁合金的塑性性能。

镁合金的高温力学性能与动态再结晶紧密相连,而动态再结晶形核机制以及晶粒大小与变形温度、变形速度、变形程度以及原始晶粒组织密切相关。文献[4?5, 9?11]仅从实验的角度研究了动态再结晶对镁合金的变形组织,塑性变形能力以及力学性能的影响,并未从机理上深入分析动态再结晶对拉伸性能的影响。本研究结合热粘塑性本构理论,构建了拉伸动态再结晶理论模型,从理论上系统研究镁合金动态再结晶对塑性拉伸的影响。基于所建立的拉伸动态再结晶理论模型,对AZ31镁合金薄板在变温时单向拉伸性能进行数值仿真,分析了流变应力—应变曲线的变化。在较高温度下进行了AZ31镁合金薄板热模拟拉伸实验,并对拉伸动态再结晶显微组织和拉伸曲线进行了分析。

1 动态再结晶热粘塑性本构模型

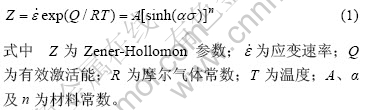

金属材料变形达到稳态时,考虑温度与应变速率,稳态应力可表述为Z因子关系[12?13]:

式(1)仅适用于稳态流变应力计算,只考虑了温度及应变速率对材料变形流动应力的影响。对于镁合金,未考虑该类合金在热变形趋于稳态过程动态再结晶对应力的影响。考虑动态再结晶对应力的影响[14]

式中 dD为动态再结晶晶粒直径;σD为考虑动态再结晶的应力;d为原始晶粒直径;a、b、c和e为材料常数,p≈0.8。

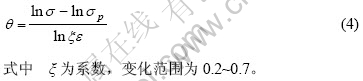

在较高温度及较低应变速率条件下发生热变形时,金属材料即产生非连续动态再结晶[15],这将导致变形过程产生应变软化效应。考虑此因素,在变形过程引入应变软化因子

应变软化因子θ与应变ε关系如下[16]:

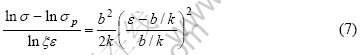

式中 k和b为材料常数。

对式(5)进行积分,应变软化因子表述为

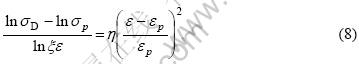

因此

由于b/k = εp, b2/2k = η,联立式(3),式(7)也可表述为

即

2 数值仿真

基于上述理论,采用有限元软件Marc对镁合金AZ31薄板不同温度下单向拉伸进行仿真,将模型划分为3 460个实体单元。镁合金AZ31的其它材料特性为:弹性模量E=45 GPa,泊松比μ=0.35。基于动态再结晶热粘塑性理论,拉伸初始网格如图1所示。

图1 变形初始网格

Fig.1 Initial mesh of tensile deformation

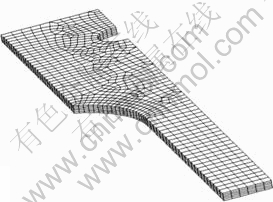

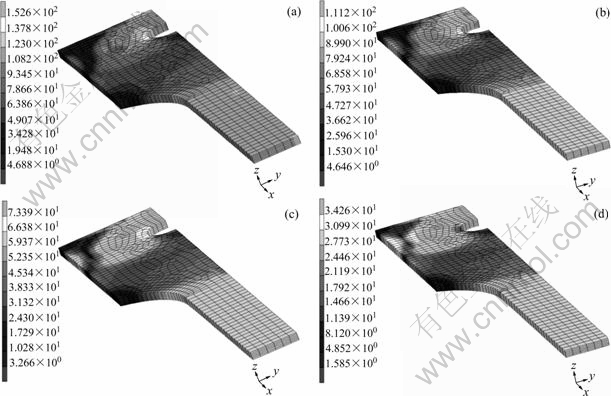

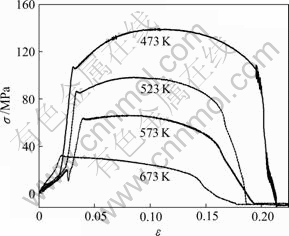

在定应变速率的条件下( =0.25),通过有限元仿真得不同温度下拉伸应力分布(见图2)。从图2中可看出,不同温度下,AZ31镁合金拉伸过程中应力分布基本一致;且随着温度升高,应力值趋于下降,说明温度对材料变形抗力影响甚大。图2(d)中的应力最大处与图2(a)、(b)和(c)中的应力最大处有所不同,这说明随着温度升高,镁合金板材在变形过程软化现象明显。变形应力—应变曲线可更好地说明温度对变形过程材料软化的影响(见图3)。当变形温度为473 K时,镁合金薄板在拉伸过程有明显的应变强化效应,在应力—应变曲线中表现为屈服后应力上升阶段;当温度为523 K时,与473 K拉伸相比,镁合金变形过程应变强化效应降低,应力上升趋势变缓;当温度为573 K时,应变强化效应几乎消失,且随着应变的增加,应力保持均匀一致;当温度升高到673 K时,镁合金板材无屈服现象,应力迅速增加到最大值,并随应变的增加呈下降趋势。

=0.25),通过有限元仿真得不同温度下拉伸应力分布(见图2)。从图2中可看出,不同温度下,AZ31镁合金拉伸过程中应力分布基本一致;且随着温度升高,应力值趋于下降,说明温度对材料变形抗力影响甚大。图2(d)中的应力最大处与图2(a)、(b)和(c)中的应力最大处有所不同,这说明随着温度升高,镁合金板材在变形过程软化现象明显。变形应力—应变曲线可更好地说明温度对变形过程材料软化的影响(见图3)。当变形温度为473 K时,镁合金薄板在拉伸过程有明显的应变强化效应,在应力—应变曲线中表现为屈服后应力上升阶段;当温度为523 K时,与473 K拉伸相比,镁合金变形过程应变强化效应降低,应力上升趋势变缓;当温度为573 K时,应变强化效应几乎消失,且随着应变的增加,应力保持均匀一致;当温度升高到673 K时,镁合金板材无屈服现象,应力迅速增加到最大值,并随应变的增加呈下降趋势。

图2 不同温度下拉伸应力分布

Fig.2 Distribution of tensile stress at different temperatures: (a) 473 K; (b) 523 K; (c) 573 K; (d) 673 K

图3 仿真拉伸应力—应变曲线

Fig.3 Stress—strain curves of simulation tensile

3 结果及分析

3.1 实验条件及方法

实验材料为厚度为12 mm商用AZ31镁合金挤压板,经多道次单向轧制与均匀化退火处理,得到厚度为0.8 mm的薄板。拉伸试样尺寸按照GB6395—86(金属高温拉伸持久实验方法)设计。在Gleeble 3500热模拟试验机上进行轴对称拉伸实验,定应变速率 =0.25,温度T为473、523、573和673 K,试样尺寸为110 mm×10 mm×0.8 mm,拉伸后用电火花线切割机自断口附近取样,表面经研磨、抛光和腐蚀处理后,用光学显微镜观察微观组织。

=0.25,温度T为473、523、573和673 K,试样尺寸为110 mm×10 mm×0.8 mm,拉伸后用电火花线切割机自断口附近取样,表面经研磨、抛光和腐蚀处理后,用光学显微镜观察微观组织。

3.2 温度对微观组织的影响

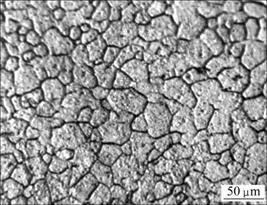

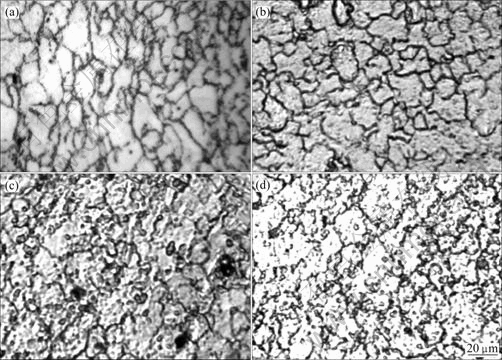

AZ31镁合金薄板原始组织如图4所示。由图4可看出,试样晶粒大小均匀,不存在粗大晶粒。在应变速率为0.25时,进行不同温度条件下持续拉伸,变形后显微组织如图5所示。由图5(a)可看出,当温度为473 K时,晶粒沿拉伸方向伸长,在晶界产生动态再结晶“项链”结构,晶内出现细小再结晶晶粒,晶界锯齿化,大部分原始晶粒仍然保留;当温度升高到523 K时,显微组织如图5(b)所示,晶界产生的动态再结晶晶粒更多,再结晶晶粒沿晶界连成更大的晶粒。与473 K时相比,晶粒数量增加,尺寸变大,晶内出现较大且不均匀再结晶晶粒;动态再结晶进一步发展,DRX晶粒大量出现,包围了原始晶粒,晶界更加粗糙,原始晶粒被拉长,内部出现更多细小等轴晶粒;当温度为673 K时,动态再结晶晶粒在多数原始晶粒内部出现,与473、523和573 K的显微组织相比,DRX晶粒数量增加,分布更加均匀,DRX晶粒优先在原始晶界形核长大,原始晶界被吞噬。

图4 AZ31镁合金的原始微观组织

Fig.4 Initial microstructure of AZ31 Mg alloy

图5 不同变形温度试样动态再结晶的显微组织

Fig.5 Microstructures of DRX of specimens deformed at different temperatures: (a) 473 K; (b) 523 K; (c) 573 K; (d) 673 K

随着变形温度变化,动态再结晶晶粒尺寸也发生变化。当温度为473 K时,图中可观察到原始晶粒周围出现许多细小的等轴晶粒,DRX晶粒与原始晶粒尺寸差距非常大,细小晶粒的尺寸约为2 μm,而大晶粒的尺寸可达25 μm;当温度为523 K时,原始晶界被DRX晶粒取代,晶界加粗,晶内出现少量DRX晶粒,DRX晶粒与原始晶粒尺寸差距与473 K时接近。在较低的变形温度下,晶粒尺寸产生如此大的差异,说明发生了不完全动态再结晶;573 K时,DRX晶粒尺寸增加,原始晶界周围出现更多较大DRX晶粒,尺寸可达6 μm;673 K时,与573 K相比,DRX晶粒尺寸有所下降,大小更加均匀,晶粒尺寸约为3 μm。在较低温度变形时,动态再结晶晶粒不能充分长大,故尺寸较小;随着温度的升高,晶界扩散和晶界迁移能力增加,再结晶晶粒尺寸相应增加;当温度达到673 K时,动态再结晶充分进行,再结晶晶粒数量增加,从而使晶粒在长大过程相互碰撞概率增大,这阻碍晶粒的进一步长大,使得再结晶晶粒尺寸下降。

3.3 动态再结晶对流动应力的影响

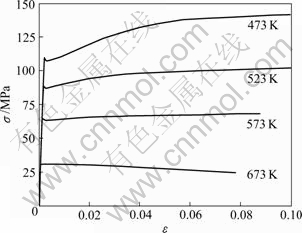

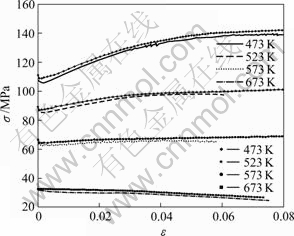

利用测得的载荷—位移曲线,计算并转换得到流动真应力—真应变曲线(见图6)。由图6可看出,当温度为473、523和573 K时,在变形开始阶段,随着应变的增加,应力迅速上升;当应变达0.03左右时,流动应力出现一个峰值。在变温加载的条件下,当流动应力达到峰值之前,动态再结晶已经发生,但加工硬化仍占主导地位,应力曲线仍继续上升,但斜率渐减;当流动应力达最大值时,动态再结晶加速,与加工硬化作用相抵消,应力保持平稳。随着继续保温及应变增加,动态再结晶作用大于加工硬化作用,流动应力开始下降,直至AZ31薄板拉断。673 K时,由于温度较高,动态再结晶作用明显,变形开始阶段虽然应力迅速增加,出现峰值后,曲线一直趋于下降,直至薄板断裂。镁合金拉伸断裂后形态如图7所示。

图6 不同温度下流动应力—应变曲线

Fig.6 Flow stress—strain curves at different temperatures

图7 不同温度下镁合金拉伸断裂形状

Fig.7 Shapes of tensile failure breaking of Mg alloy at different temperatures

由仿真与实验方法得到的塑性流动应力-应变曲线对比如图8所示。由图8可看出,仿真与实验曲线变化趋势相吻合,仅在473 K与523 K的塑性变形开始阶段,应力仿真值变化比实验值剧烈。这说明基于动态再结晶热粘塑性理论的数值仿真可以较好地模拟AZ31镁合金的变形过程,理论模型具有实际意义。

图8 不同温度下仿真与实验塑性流动应力—应变曲线

Fig.8 Plastic flow stress—strain curves of simulation and test at different temperatures

4 结论

1) 结合拉伸动态再结晶理论模型,对AZ31镁合金薄板变温拉伸进行了数值仿真,仿真结果与实验结果相一致。

2) 镁合金薄板高温下塑性变形的动态再结晶与温度关系密切,随镁合金薄板变形温度升高,动态再结晶晶粒数量逐渐增加,尺寸先增后减,同时分布更趋于均匀。

3) 塑性变形时,动态再结晶使镁合金薄板出现动态软化现象,流动应力降低。

REFERENCES

[1] AGHION E, BRONFIN B, ELIEZER D. The role of the magnesium industry in protecting the environment[J]. J Mater Proc Tech, 2001, 117(3): 381?385.

[2] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277?288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277?288.

[3] MORDIKE B L, EBERT T. Magnesium: properties- applications-potential[J]. Mater Sci Eng A, 2001, 302(1): 37?45.

[4] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Mater, 2001, 49(9): 1199?1207.

[5] TAN J C, TAN M J. Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet[J]. Mater Sci Eng A, 2003, 339(1/2): 124?132.

[6] VARZANEH S M F, HANZAKI A Z, BELADI H. Dynamic recrystallization in AZ31 magnesium alloy[J]. Mater Sci Eng A, 2007, 456(1/2): 52?57.

[7] SPIGARELLI S, MEHTEDI M E, CABIBBO M, EVANGELISTA E, KANEKO J, J?GER A, GARTNEROVA V. Analysis of high-temperature deformation and microstructure of an AZ31 Magnesium alloy[J]. Mater Sci Eng A, 2007, 462(1/2): 197?201.

[8] BARNETT M R, BEER A G, ATWELL D, OUDIN A. Influence of grain size on hot working stresses and microstructures in Mg-3Al-1Zn[J]. Scripta Mater, 2004, 51(1): 19?24.

[9] P?REZ-PRADO M T, VALLE J A, CONTRERAS J M, RUANO O A. Microstructural evolution during large strain hot rolling of an AM60 alloy[J]. Scripta Mater, 2004, 50(5): 661?665.

[10] YI S B, ZAEFFERER S, BROKMEIER H G. Mechanical behaviour and microstructural evolution of magnesium alloy AZ31 in tension at different temperatures[J]. Mater Sci Eng A, 2006, 424(1/2): 275?281.

[11] HELIS L, OKAYASU K, FUKUTOMI H. Microstructure evolution and texture development during high-temperature uniaxial compression of magnesium alloy AZ31[J]. Mater Sci Eng A, 2006, 430(1/2): 98?103.

[12] MCQUEEN H J, YUE S, RYAN N D, FRY E. Hot working characteristics of steels in austenitic state[J]. J Mater Proc Tech, 1995, 53(1/2): 293?310.

[13] MCQUEEN H J, RYAN N D. Constitutive analysis in hot working[J]. Mater Sci Eng A, 2002, 322(1/2): 43?63.

[14] DOHERTY R D, HUGHES D A, HUMPHREYS F J, JONAS J J, JENSEN D J, KASSNER M E, KING W E, MCNELLEY T R, MCQUEEN H J, ROLLETT A D. Current issues in recrystallization: a review[J]. Mater Sci Eng A, 1997, 238(2): 219?274.

[15] GALIYEV A, SITDIKOV O, KAIBYSHEV R. Deformation behavior and controlling mechanisms for plastic flow of magnesium and magnesium alloy[J]. Mater Trans, 2003, 44(4): 426?435.

[16] LIU J, CUI Z S, LI C X. Modelling of flow stress characterizing dynamic recrystallization for magnesium alloy AZ31B[J]. Comput Mater Sci, 2008, 41(3): 375?382.

基金项目:国家重点基础研究发展计划基础预研资助项目(2006CB708611);上海科委资助项目(06dj14005;06QA14026)

收稿日期:2007-12-24;修订日期:2008-06-01

通讯作者:彭颖红,教授,博士;电话:021-34206794;E-mail: yhpeng@sjtu.edu.cn

(编辑 李艳红)