文章编号:1004-0609(2015)-11-3000-11

非等温回归再时效对7055铝合金中厚板的厚向组织及性能均匀性的影响

冯 迪1, 2,张新明3,刘胜胆3

(1. 江苏科技大学 江苏省先进焊接技术重点实验室,镇江 212003;

2. 江苏科技大学 材料科学与工程学院,镇江 212003;

3. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:通过力学性能测试、腐蚀性能测试、透射电镜(TEM)观察和动力学计算研究回归加热、冷却速率的匹配对回归再时效(RRA)态7055铝合金中厚板析出组织均匀性及厚向性能的影响。结果表明:固定回归加热速率,合金的强度、断裂韧性和耐腐蚀性能的均匀性及厚向析出组织的均匀性随着回归冷却速率的降低而提高。但是慢速回归降温增加合金析出相的粗化程度,导致合金强度下降。综合考虑性能及均匀性,建立的包含空冷降温处理以补偿7055铝合金中厚板厚向组织均匀性的“非等温回归再时效”制度为(105 ℃,24 h)+(190 ℃,70 min)(升温速率3 ℃/min,70 min包含加热时间)+(空冷25 min至120 ℃)+(120 ℃,24 h)。经非等温回归再时效处理后,7055铝合金板材心层的抗拉强度、断裂韧性及剥落腐蚀等级分别为619 MPa、24.7 MPa·m1/2和EB-,其强度的厚向均匀性比常规回归再时效处理的提高约50%。

关键词:7055铝合金;中厚板;非等温回归;再时效;均匀性

中图分类号:TG146.2 文献标志码:A

Effect of non-isothermal retrogression and re-ageing on through-thickness homogeneity of microstructure and properties in 7055 aluminum alloy medium thick plate

FENG Di1, 2, ZHANG Xin-ming3, LIU Sheng-dan3

(1. Provincial Key Laboratory of Advanced Welding Technology,

Jiangsu University of Science and Technology, Zhenjiang 212003, China;

2. School of Materials Science and Engineering,

Jiangsu University of Science and Technology, Zhenjiang 212003, China;

3. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effect of matching relationship between retrogression heating and cooling rate on the microstructure homogeneity and through-thickness properties of medium-thick 7055 aluminum alloy plate was investigated by mechanical properties test, corrosion resistance test, transmission electron microscope(TEM) observation and kinetics calculation. The results show that, the through-thickness of strength, fracture toughness, corrosion resistance and microstructure homogeneity increase with the decrease of retrogression cooling rate when heating rate is fixed. However, the slow retrogression cooling rate increases the coarsening degree of precipitates, which results in the deterioration of strength. Considering the compositive request to properties and homogeneity, the “non-isothermal retrogression and re-ageing” temper based on the air cooling treatment to through-thickness homogeneity was established as (105 ℃, 24 h)+(190 ℃, 70 min) (heating rate 3 ℃/min, 70 min including heating time)+(air cooling 25 min to 120 ℃)+( 120 ℃, 24 h). After “non-isothermal retrogression and re-ageing” treated, the tensile strength, fracture toughness and exfoliation corrosion resistance level are 619 MPa, 24.7 MPa·m1/2 and EB-, respectively. The through-thickness homogeneity of strength increases by 50% when compared to that of the conventional RRA treatment.

Key words: 7055 aluminum alloy; medium thick plate; non-isothermal retrogression; re-ageing; homogeneity

高强Al-Zn-Mg-Cu合金经合适的热处理后具有较高的比强度和良好的断裂韧性、抗疲劳、耐腐蚀等性能,因此,自20世纪30年代以来就被用作商业飞机的主要结构材料[1]。7055-T7751态中厚板因其突出的综合性能,已被欧美用于大飞机主承力件的生产和制造。T7751制度源自回归再时效(RRA)[2]技术,其核心理论基础为预析出相在高温(低于固溶温度)下的回溶行为。预析出相的回溶一方面保证回归阶段晶界相的充分断开同时抑制晶内相粗化;另一方面可以提高基体溶质原子过饱和度,保证再时效阶段有足够的时效强化动力[3-9]。

由于T7751制度的保密措施,国内外对该制度的具体时效参数进行了大量研究,提出和建立了基于回归温度和时间以及预时效程度[10],回归加热速率等因素的技术原型[11-12]。上述技术原型是通过实验用小尺寸样品在等温条件下组织与性能的关系研究得到的,未考虑诸如实际产品尺寸、热处理设备功率以及各时效处理阶段之间的相互关系等客观因素,忽视大尺寸/厚截面构件在时效中基本处于非等温状态这一客观事实[13-15]。非等温状态下,扩散系数、形核驱动力和形核势垒等都将受到升/降温速率的影响[16-18]。对于大飞机计划迫切需求的超高强7055铝合金中厚板,由于导热问题的存在,其热处理过程不可避免地存在板材本身的升温和降温过程,且板材厚向不同层之间存在升/降温速率的不同,即同一加热和冷却速率条件下,板材表层升/降温速率快于心层。这种温度场的不均匀性在要求高温短时的回归阶段体现的尤为突出,其影响随着厚板厚度的增加而增加,并最终导致组织及性能的厚向不均匀性。

针对7055铝合金中厚板回归过程中第二相的回溶与析出不均匀造成的材料组织和性能不均匀这一热处理难题,本文作者以非等温回归动力学计算为基 础[19],考虑回归升温、降温速率的优化匹配对强化相回溶/析出均匀性的影响规律,通过强度、断裂韧性、耐蚀性能比较以及不同层的微观组织对比研究,提出 “非等温回归再时效” 概念,建立提高7055铝合金中厚板高向组织及性能均匀性的实用热处理制度。

1 实验

1.1 非等温回归动力学

基于等动力学假设及LSW理论的“非等温回归动力学模型”[19]如式(1)所示:

(1)

(1)

式中:t*代表依赖于温度的时间常数;Tr和tr分别为参考回归温度和回归时间;对应合金的优化回归制度参数;Q为合金析出相的长大/粗化激活能,R为摩尔气体常数。T(t)为中厚板在某一非等温回归制度下的实测温度-时间关系函数;无量纲参数S和Sc为Scheil 积分值,Sc定义为标准回归程度(由所选择的参考回归制度决定),S定义为给定非等温回归制度对应的有效回归程度。

通过动力学计算,可以得到任意非等温回归条件下,板材的有效回归程度S与标准回归程度Sc之间的关系,从而确定在该制度下达到标准回归程度所需的时间及该时间点对应的微观组织特征(相平均尺寸)。本文作者对200 mm×150 mm×30 mm规格的7055中厚板首先进行105 ℃、24 h预时效处理,再以3 ℃/min的回归加热速率升温至190 ℃保温。回归结束后分别进行水冷、风冷、空冷以及随炉冷却处理。在每种冷却过程中板材测量表层和心层的冷却温度-时间关系曲线Tb(t)和Tx(t),并取7055铝合金析出相长大/粗化激活能为115.2 kJ/mol[19],计算每种加热-冷却处理方式对应表层和心层的有效回归程度与参考程度的关系Sb/Sc和Sx/Sc。Sb/Sx越接近,则说明此种加热-冷却方式下,板材厚向的非等温回归效果越均匀。

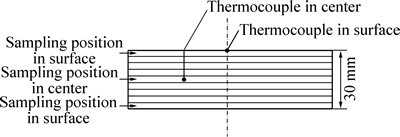

1.2 实验材料及方法

实验材料为7055铝合金(7.68Zn,2.12Mg,2.0Cu,0.12Zr,0.055Fe,0.034Si,其余Al(质量分数,%))30mm热轧板,板材已经过工业固溶及预拉伸。本文作者对该状态板材进行不同回归加热及冷却速率下的回归(再时效)处理。切取不同热处理制度下的板材试样进行分层性能测试和组织分析,分层取样及测温方式见图1。回归加热或冷却时,将热电偶埋入板材不同层的中部位置,由多通道温控仪测量其升、降温温度场,测温误差为±3 ℃。硬度测试在HV-10B小幅度维氏硬度计上进行,载荷为29.4 N,加载时间15 s;电导率测试在7501涡流导电仪上进行。常温拉伸在CSS-44100型试验机上进行,拉伸试样按GB/T228-2002标准制备,拉伸方向为轧向(L)。制备L-T取向的标准紧凑拉伸试样测量合金的断裂韧性。在表层和心层取回归态TEM样品观察比较不同层回归组织的均匀性。组织观察在TecnaiG220型分析电镜上进行,加速电压为200 kV,透射电镜样品直径为3 mm,厚度0.08 mm,在含20%HNO3(体积分数)的甲醇溶液中进行双喷减薄,温度控制在-25 ℃以下,电压为15~20 V。

图1 取样及测温方式示意图(板材厚度为30 mm)

Fig. 1 Schematic diagram of sampling and temperature measurement (plate thickness is 30mm)

2 实验结果

2.1 升温温度场的回归程度与非等温回归时间的关系

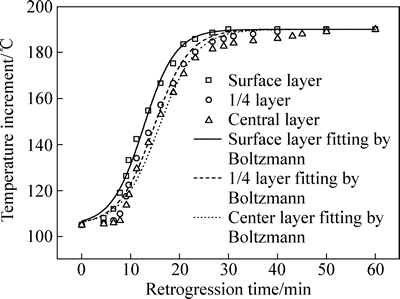

图2所示为7055铝合金中厚板在回归阶段的升温温度-时间曲线。由图2可知,各层达到预设回归温度的时间有明显差异,中厚板温度场的不均匀性主要存在于板材自升温阶段。

由于升温速率与析出相的临界回溶尺寸密切相关,即使较小的回归加热速率差异也可能导致析出相的回溶/粗化程度的较大变化[3, 7-8]。对各层的温度-时间关系曲线做Boltzman形式的拟合(见图2),利用非等温回归动力学模型(见式(1)),计算得到各层组织的回归效果与回归时间的关系见图3(以各层的回归效果与参考制度[19-20]下回归效果之比的形式)。由图3可知,Scheil 积分差异在升温阶段即出现。当非等温回归时间为30min时,表层达到预设回归温度(见图2),此时,表层的Scheil积分已超过0.2,即表层的回归程度已经超过参考制度下回归效果的20%,而此时1/4层和心层的回归效果只达到参考制度下回归效果的15%和13%。随着回归时间的延长,各层都逐渐达到预设的回归温度(190 ℃),Scheil积分的差异不再继续扩大。

图2 7055铝合金中厚板不同层的升温温度-时间关系曲线(回归阶段)

Fig. 2 Temperature increment rising-time curves of different layers in medium-thick 7055 aluminum alloy plate (retrogression stage)

图3 7055铝合金中厚板不同层的Scheil 积分-时间关系曲线

Fig. 3 Scheil integral-time curves of different layers in medium-thick 7055 aluminum alloy plate

2.2 降温温度场的回归程度与非等温回归时间的关系

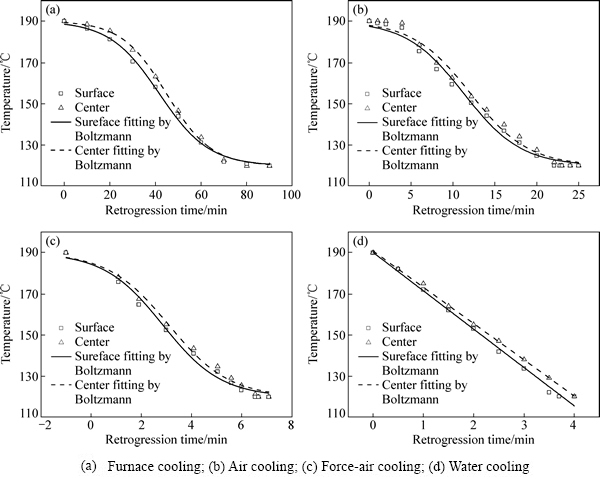

在4种回归冷却方式下,分别测量7055铝合金中厚板表层和心层温度随冷却时间的变化关系,其结果如图4所示。

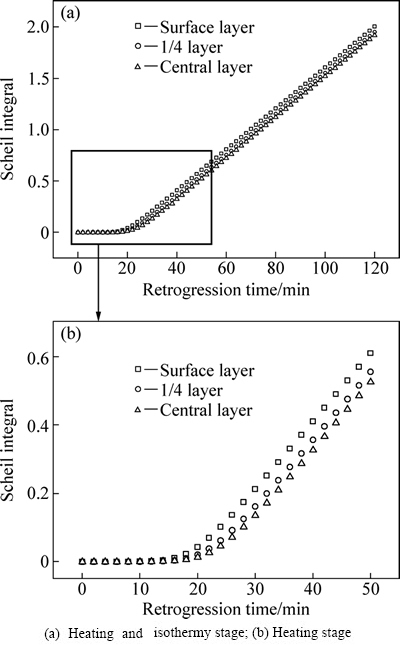

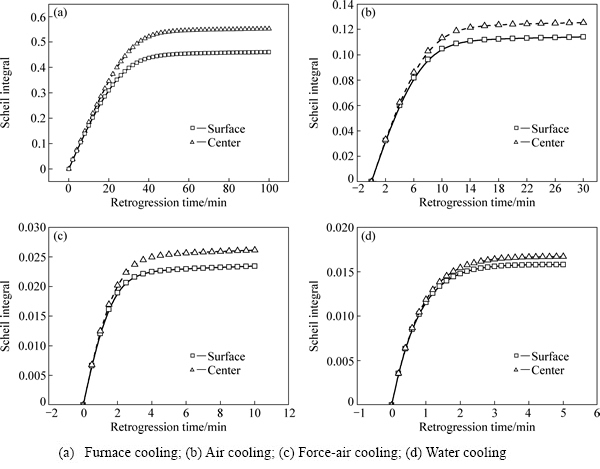

由图4可知,随炉冷却条件下,需要约90 min才能从回归温度(190 ℃)冷却至再时效温度(120 ℃),空冷和风冷条件分别需要25 min和7 min,而水冷则以近似线性的方式降温(见图4(c))。以Bolztman函数拟合随炉冷、空冷和风冷的温度-时间曲线,以线性方程拟合水冷温度-时间曲线,计算得到不同冷却方式下表层和心层组织的回归效果与回归时间的关系(以各层的回归效果与参考制度下回归效果之比的形式,即Scheil 积分形式给出),其结果如图5所示。

由图5可知,随炉冷和空冷冷却阶段的回归程度较风冷和水冷方式明显。在随炉冷却条件下,心层在冷却阶段的回归程度比表层高出约0.1(Scheil 积分),即随炉冷却对升温阶段产生的不均匀性的补偿已经达到参考制度下回归效果的10%(见图5(a))。空冷条件下,其冷却阶段的回归效果比表层高出约0.02(Scheil 积分),即空冷冷却对升温阶段产生的不均匀性的补偿为参考制度下回归效果的2%(见图5(b))。而风冷和水冷条件下,冷却速率很快,其回归效果的差异分别只有约0.003和0.001(Scheil 积分),即这两种冷却方式对升温阶段产生的不均匀性的补偿仅达到参考制度下回归效果的0.3%和0.1%,且回归程度较低(见图5(c))和(d))。因此,风冷和水冷条件下,冷却阶段回归效果不均匀性对升温阶段不均匀性的补偿可以忽略不计。

2.3 升/降温温度场的优化匹配

由文献[19]可知,7055铝合金中厚板的优化等效回归时间对应Scheil积分为1.1左右(相对于参考回归制度)。在考虑降温处理时,此等效时间应该包括升温、保温和降温时间,即“非等温回归再时效”总时间的确立应该遵循升温、保温和降温阶段的总Scheil积分为1.1的前提条件下,并在此范围内最大可能的缩小回归效果的厚向不均匀性。

由图5(a)和(b)可知,随炉冷却和空冷情况下Scheil积分的最大值分别为0.55和0.125(表层),那么随炉冷和空冷条件下,7055铝合金中厚板升温及保温阶段的Scheil积分应分别为0.55和0.975左右。根据这一积分值确定随炉冷和空冷条件下,非等回归的升温和保温时间(见图3(a))分别为47 min和70 min左右。此时,由于升温温度场的不均匀性导致回归效果差异分别为0.1和0.08(见图3(a)),分别对应参考制度下回归效果的10%和8%。由此可见,随炉冷可以完全补偿由升温带来的高向组织不均匀性,而空冷可以将该不均匀性差异缩小至0.06,即缩小至参考制度下回归效果的6%。

图4 7055铝合金中厚板不同层的温度-时间关系曲线(回归降温阶段)

Fig. 4 Temperature-time curves of different layers in medium-thick 7055 aluminum alloy plate(cooling stage in retrogression)

图5 7055铝合金中厚板不同层的Scheil积分-时间关系曲线(回归降温阶段)

Fig. 5 Scheil integral-time curves of different layers in 7055 aluminum alloy medium thick plate(cooling stage in retrogression)

因此,对中厚板厚向均匀性有明显改善作用的“非等温回归再时效”制度为(105 ℃,24 h)+(190 ℃,70 min)(3 ℃/min升温速率,70 min包含加热时间)+(120 ℃,24 h)(空冷25 min至120 ℃)。

2.4 非等温回归再时效对7055铝合金中厚板组织、性能及厚向均匀性的影响

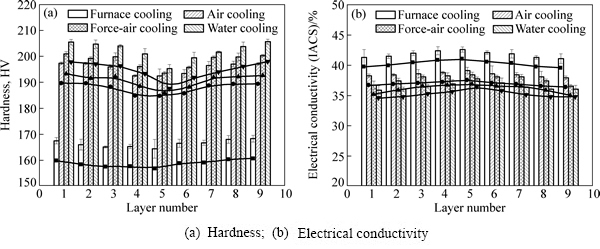

4种非等温回归再时效制度下,7055铝合金中厚板高向电导率和硬度的对比(其中从1到5或从9到5代表从表层至心层)见图6。由图6可知,中厚板的硬度从表层到心层逐渐减小,而电导率则从表层到心层逐渐增加,且电导率的变化幅度也远远小于硬度值的变化幅度。

对7055铝合金中厚板,随炉冷却条件下,无论是硬度或是电导率的差异都是最小的,即不均匀性最小。然而,由于降温速率太慢,7055铝合金中厚板在高温停留的时间长(90 min),导致其晶内析出相粗化严重,使得硬度大幅度下降,相应的电导率大幅度上升。此种冷却方式虽然完全弥补了升温速率带来的厚向组织不均匀性,但是降低了材料的力学性能。空冷条件下,7055铝合金样品的厚向均匀性仅次于随炉冷样品,而冷却速率最快的水冷试样,其不均匀性最大。由此可见,降低冷却速率可以补偿或缩小由回归升温速率带来的性能不均匀性,且不均匀性的补偿效果随着冷却速率的降低而增加。但是冷却速率太低会导致7055铝合金硬度的急剧下降。从硬度和电导率的结果比较来看,回归后空冷冷却既缩小了高向组织的不均匀性,又保证了7055铝合金中厚板的力学性能。

图6 7055铝合金中厚板不同层试样的硬度和电导率

Fig. 6 Hardness and conductivity of different layer samples in 7055 aluminum alloy medium thick plate

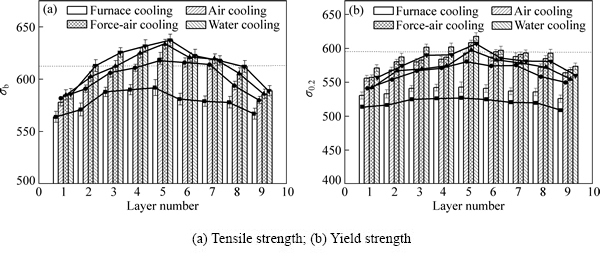

图7 7055铝合金中厚板不同层试样的强度

Fig. 7 Strength of different layer samples in 7055 aluminum alloy medium thick plate

图7所示为不同回归冷却条件下7055铝合金中厚板不同层强度的对比。图中虚线所示为AMS 4206A[22]标准性能。由图7可知,随着冷却速率的加快,抗拉强度厚向差异逐渐由随炉冷条件的26 MPa增加至水冷条件下样品的50 MPa,屈服强度厚向差异由14 MPa增加至46 MPa。值得注意的是,板材不同层的硬度值和强度值并不遵循正比关系,这是因为不同层泰勒因子不同[21]。文献[21]中报道30 mm厚7055铝合金轧制板材表层和心层的泰勒因子分别为3.06和3.11,即在没有析出相不均匀性存在的前提下,7055铝合金中厚板的强度差异为3.11τ1-3.06τ2(其中τ1和τ2分别为7055铝合金中厚板心层和表层的临界分切应力,临界分切应力与析出强化程度相关)。当回归加热、冷却速率引入析出强化不均匀性时,7055铝合金中厚板厚向性能差异就由泰勒因子和析出相不均匀性两个因素共同决定。对于随炉冷样品,析出相粗化严重,厚向组织均匀性在4种冷却速率中最高,因此,各层的临界分切应力差异最小(由硬度值比较可以看出),此时泰勒因子起主导作用,高向性能的差异基本等于泰勒因子差值乘以临界分切应力,其厚向性能不均匀性最小,约为20~25 MPa左右。随着冷却速率的增加,析出强化作用的不均匀性不断增大,导致各层临界分切应力(τ1和τ2)逐渐增加的同时,各层临界分切应力的差值(τ1-τ2)也逐渐增加。由于泰勒因子保持不变,此时组织不均匀性起主导作用,从而导致厚向强度不均匀性不断增大,因此,7055铝合金中厚板强度的厚向不均匀性随着冷却速率的增加而增大。

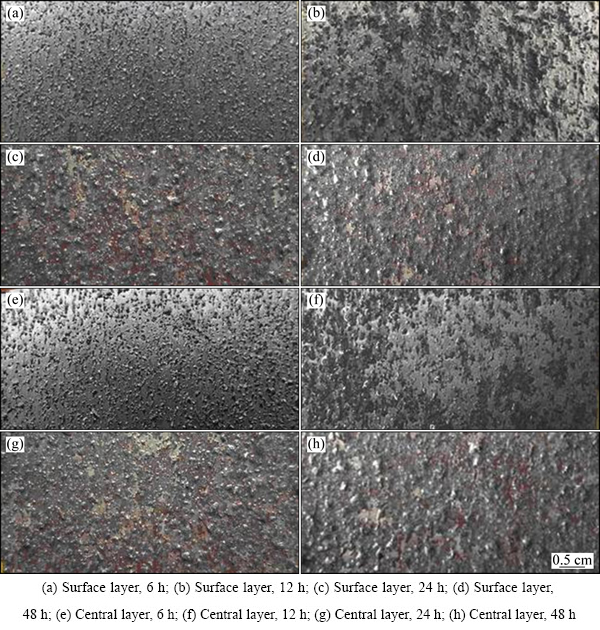

综合考虑板材的性能及厚向均匀性,取(105 ℃,24 h)+(190 ℃,70 min)( 3 ℃/min升温速率,70 min包含加热时间)+(120 ℃,24 h)(空冷25 min至120 ℃)作为7055铝合金中厚板的最佳非等温回归再时效制度,其抗拉强度的均匀性比水冷条件下的提高了近50%。经该非等温回归再时效制度处理后,7055铝合金板材表层和心层的剥落腐蚀形貌对比见图8。由图8可知,表层和心层抗腐蚀能力的不均匀性较低。EXCO溶液中浸泡6 h,两层样品都只出现点蚀现象(见图8(a)和(e))。腐蚀12 h后出现局部鼓泡现象,其中表层的鼓泡现象较心层略微严重(见图8(b)),心层局部位置仍保持点蚀特征(见图8(f))。表层剥落腐蚀程度深的部分原因来自于板材表层更高的再结晶程度(形变和固溶再结晶)。浸泡24 h后,试样出现少量爆皮,有片状腐蚀层突起于试样表面(见图8(c)和(g)),该现象在腐蚀48 h后逐渐加深,表现为表面凸起物的尺寸变大。无论表层或心层试样,剥蚀都未深入合金内部,合金经非等温回归再时效处理后表现出较高的抗剥落腐蚀能力。其剥蚀等级在EB-级水平,表层样品的剥蚀程度稍高于心层。

图8 7055铝合金中厚板“非等温回归再时效”态不同层试样的剥落腐蚀形貌

Fig. 8 Exfoliation corrosion morphologies of different layer samples in 7055 aluminum alloy medium thick plate after non-isothermal retrogression and re-ageing

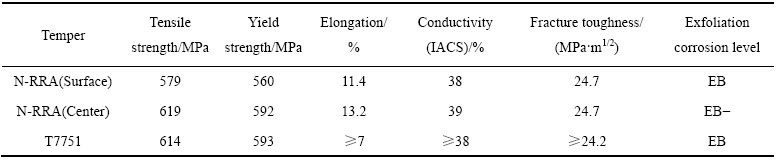

表1 7055 铝合金中厚板非等温回归再时效状态(N-RRA)与7055-T7751状态性能[22] 比较

Table 1 Properties comparison between non-isothermal retrogression and re-ageing (N-RRA) and T7751[22] states of 7055 aluminum medium thick plate

非等温回归再时效制度下7055铝合金中厚板力学、腐蚀性能与AMS 4206A[22]标准性能的对比见图7及表1所示。对比性能可知,7055铝合金板材经“非等温回归再时效”处理后,心层试样的性能皆达到或超过标准性能指标。需要指出的是,AMS 4206A标准未对7055铝合金板材性能进行分层测试,由文献[25]可知,目前对中厚板强度的评价主要以板材中心层的强度为标准,因此可以推断,AMS 4206A标准给出的性能指标也是以心层材料的力学和腐蚀性能为依据的,而本研究中的“非等温回归再时效”状态的性能已达到或超过该标准水平,且有效地降低了板材厚向的性能不均匀性。

3 分析及讨论

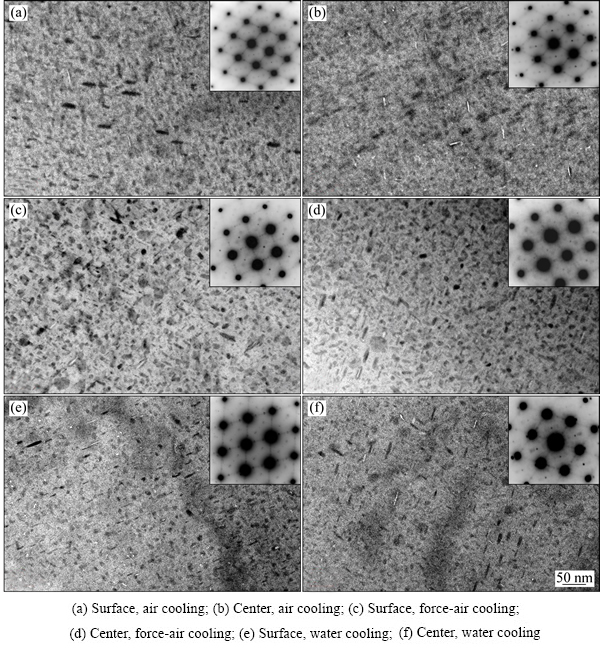

图9所示为不同冷却速率下7055铝合金中厚板表层和心层晶内相的典型形貌(回归态)。由图9可知,晶内回归组织基本由η和η′ 组成。在空冷条件下,析出相在冷却过程中发生了一定程度的粗化。同时,由于回溶产生的溶质原子过饱和度的增加,使得冷却过程中还出现一定程度的析出现象(类似再时效析出)。因此,在回归后空冷条件下,晶内相既包含较为粗大的回归未溶相和冷却过程中粗化的析出相,同时也包含一定量细小的再次析出相(见图9(a)和(b))。在回归后水冷条件下,降温速率极快,其微观组织与回归结束时相同,即保留较为粗大的回归未溶相,但不会出现冷却过程中析出相的长大或者粗化。然而,极短的冷却时间同时也抑制了冷却过程中细小析出相的析出。因此,其析出相的密度较空冷条件下的低,而相平均尺寸较空冷条件下的大(见图9(e)和(f))。在风冷条件下,其冷却速率介于空冷和水冷之间,因此晶内同时包含较为粗大的回归未溶相,一些冷却过程中粗化的析出相和一定量细小的再次析出相(见图9(a)和(b))。其密度和相平均尺寸也介于空冷和水冷之间。

再比较同一冷却制度下,不同层的析出相差异。在回归升温阶段,由于表层升温快于心层的,因此,表层在升温过程中的回归程度高于心层的。在空冷条件下,其冷却时间与回归加热时间基本相当,约为25 min左右。在此阶段,表层冷却速度较心层快,因此,心层在170~190 ℃(回溶的有效温度范围)经历了相对较长的时间,其回归程度较表层的有一定增加。冷却阶段反向的回归效果的差异在一定程度上补偿了回归加热阶段因为表层升温较快而导致的回归不均匀性。除此之外,表层和心层都出现一定量的细小再析出相。因此,经空冷处理后,7055铝合金晶内析出相的密度、平均尺寸以及相尺寸分布范围的不均匀性因升、降温速率的相互补偿而得到有效缩小。在水冷条件下,由非等温回归动力学分析可知,其冷却阶段的回归/粗化效果基本可以忽略不计,由回归加热温度场不均匀性导致的高向析出不均匀性基本保留至冷却组织,即表层相对心层的析出相更加的细小(表层的回归程度较大)。风冷条件下,虽然有一定的不均匀性补偿,但是补偿作用也很小,其不均匀性差异介于空冷和水冷之间。

图9 7055铝合金中厚板不同层晶内相回归态的TEM像

Fig. 9 TEM images of (retrogression state) of transgranular precipitates in different layers of 7055 aluminum medium thick plate

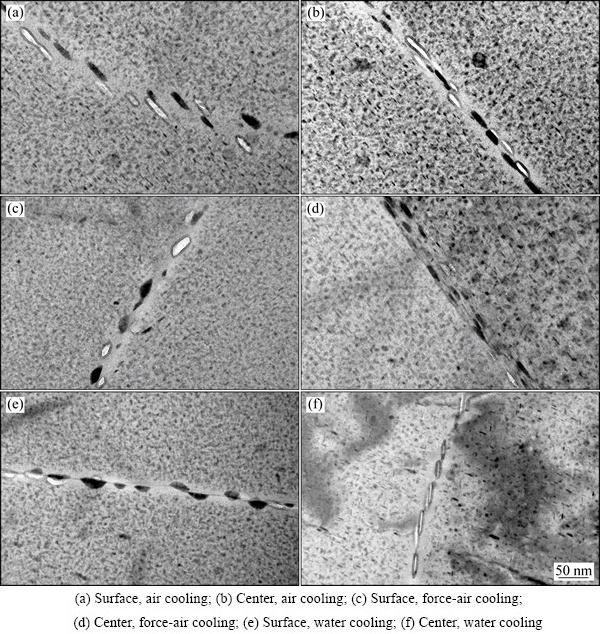

图10所示为不同冷却速率下7055铝合金中厚板表层和心层晶界相的典型形貌(回归态)。由图10可知,各冷却处理条件下,晶界相经回归处理后都经历了较大程度的粗化,但是表层晶界相的粗化和断续程度都高于心层。在空冷条件下,心层降温较慢,其晶界相的粗化比表层的明显,弥补了升温带来的不均匀性。水冷时,由回归加热温度场不均匀性导致的晶界相厚向析出不均匀性基本保留至冷却组织,即表层相对心层的晶界相更加粗大和断续。在风冷条件下,晶界相的不均匀性介于空冷和水冷之间。随着回归冷却速率的降低,晶界相的粗化程度逐渐增大(分别比较图10(a)、(c)、(e)和图10(b)、(d)、(f))。

对本研究中实验条件范围内的实验结果进行总结可知,回归后随炉冷却处理虽然可以最大程度的减小7055铝合金中厚板高向析出不均匀性,但是该处理方式导致强化相严重粗化,大幅度降低合金的强度。风冷和水冷虽然可以保留合金的强度,但是对厚向析出不均匀性的改善作用不明显。采用空冷降温可以有效地减小7055铝合金中厚板厚向析出组织的不均匀性且保证合金的强度。

图10 7055铝合金中厚板不同层晶界相回归态的TEM像

Fig. 10 TEM images of retrogression state of grain boundary precipitates in different layers of 7055 aluminum medium thick plate

4 结论

1) 固定回归加热速率(3 ℃/min),7055铝合金中厚板不同层的硬度随着回归冷却速率的降低而降低,电导率随着回归冷却速率的降低而提高。但是硬度和电导率的不均匀性都随着回归冷却速率的降低而降低。

2) 固定回归加热速率(3 ℃/min),7055铝合金中厚板厚向析出组织的长大或粗化程度不均匀性随着回归冷却速率的降低而降低。其中随炉冷却条件下其均匀性提高幅度最大,空冷效果其次,而水冷和风冷条件对升温阶段产生的不均匀性的补偿效果可以忽略不计。

3) 7055铝合金中厚板的强度随回归冷却速率的降低而降低。随炉冷处理虽然提高了7055铝合金中 厚板厚向析出组织以及电导率的均匀性,但是导致板材的强度大幅度下降,而空冷可在较大程度的减小强度损失的同时提高7055铝合金中厚板厚向组织的均匀性。

4) 优化的“非等温回归再时效”制度为(105 ℃,24 h)+(190 ℃,70 min)(3 ℃/min升温速率,70 min包含加热时间)+(120 ℃,24 h)(空冷25 min至120 ℃),经“非等温回归再时效”处理后,7055铝合金板材心层的抗拉强度,断裂韧性及剥落腐蚀等级分别为619 MPa,24.7 MPa·m1/2和EB-,其强度的厚向不均匀性比常规回归再时效处理下降约50%。

REFERENCES

[1] 张新明, 刘胜胆. 航空铝合金及其材料加工[J]. 中国材料进展, 2013, 32(1): 39-55.

ZHANG Xin-ming, LIU Sheng-dan. Aerocraft aluminum alloys and their materials processing[J]. Materials China, 2013, 32(1): 39-55.

[2] CINA B M. Reducing the susceptibility of alloys, particularly aluminum, to stress corrosion cracking: US3856584[P]. 1974.

[3] MARAUD T, DESCHAMPS A, BLEY F, LEFEBVRE W, BAROUX B. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an AlZnMgCu alloy[J]. Acta Materialia, 2010, 58(14): 4814-4826.

[4] WANG Y L, PAN Q L, WEI L L, LI B, WANG Y. Effect of retrogression and reaging treatment on the microstructure and fatigue crack growth behavior of 7050 aluminum alloy thick plate[J]. Materials & Design, 2014, 55: 857-863.

[5] PENG G S, CHEN K H, CHEN S Y, FANG H C. Influence of repetitious-RRA treatment on the strength and SCC resistance of AlZnMgCu alloy[J]. Materials Science and Engineering A, 2011, 528(12): 4014-4018.

[6] LIU D M, XIONG B Q, BIAN F G, LI Z H, LI X W, ZHANG Y A, WANG F, LIU H W. In situ studies of microstructure evolution and properties of an Al-7.5Zn-1.7Mg-1.4Cu-0.12Zr alloy during retrogression and reaging[J]. Materials & Design, 2014, 56: 1020-1024.

[7] LI Z H, XIONG B Q, ZHANG Y A, ZHU B H, WANG F, LIU H W. Microstructural evolution of aluminum alloy 7B04 thick plate by various thermal treatments[J]. Transactions of Nonferrous Metals Society of China, 2008, 18: 40-45.

[8] NICOLAS M, DESCHAMPS A. Characterisation and modelling of precipitate evolution in an Al-Zn-Mg alloy during non-isothermal heat treatments[J]. Acta Materialia, 2002, 51(20): 6077-6094.

[9] LIU D M, XIONG B Q, BIAN F G, LI Z H, LI X W, ZHANG Y A, WANG F, LIU H W. Quantitative study of precipitates in an Al-Zn-Mg-Cu alloy aged with various typical tempers[J]. Materials Science and Engineering A, 2013, 588: 1-6.

[10] 韩小磊, 熊柏青, 张永安, 李志辉, 朱宝宏, 王 锋. 欠时效态7150合金的高温回归时效行为[J]. 中国有色金属学报, 2011, 21(1): 81-87.

HAN Xiao-lei, XIONG bai-qing, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng. High-temperature retrogression behavior of under-aged 7150 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 81-87.

[11] LI G F, ZHANG X M, LI P H, YOU J H. Effects of retrogression heating rate on microstructures and mechanical properties of aluminum alloy 7050[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(6): 935-941.

[12] XU D K, BIRBILIS N, ROMETSCH P A. The effect of pre-ageing temperature and retrogression heating rate on the strength and corrosion behaviour of AA7150[J]. Corrosion Science, 2012, 54: 17-25.

[13] HUTCHINSON C R, GOUNE M, REDJAIMIA. A Selecting non-isothermal heat treatment schedules for precipitation hardening systems: An example of coupled process–property optimization[J]. Acta Materialia, 2007, 55(1): 213-223.

[14]  , SHERCLIFF H R. Microstructural modeling in metal processing[J]. Progress in Materials Science, 2002, 47(2): 163-282.

, SHERCLIFF H R. Microstructural modeling in metal processing[J]. Progress in Materials Science, 2002, 47(2): 163-282.

[15] 张 雪. 7050铝合金非等温过程组织演变研究[D]. 哈尔滨: 哈尔滨工业大学, 2012.

ZHANG Xue. Study on the microstructural evolution of 7050 aluminum alloy during non-isothermal ageing process[D]. Harbin: Harbin Institute of Technology, 2012.

[16] JIANG J T, XIAO W Q, YANG L, SHAO W Z, YUAN S J, ZHEN L. Ageing behavior and stress corrosion cracking resistance of a non-isothermally aged Al-Zn-Mg-Cu alloy[J]. Materials Science and Engineering A, 2014, 605: 167-175.

[17] LIU Y, JIANG D M, LI B Q, YANG W S, HU J. Effect of cooling aging on microstructure and mechanical properties of an Al-Zn-Mg-Cu alloy[J]. Materials & Design, 2014, 57: 79-86.

[18] LIU Y, JIANG D M, LI B Q, YING T, HU J. Heating aging behavior of Al-8.35Zn-2.5Mg-2.25Cu alloy[J]. Materials & Design, 2014, 60: 116-124.

[19] FENG D, ZHANG X M, LIU S D, DENG Y L. Non-isothermal “retrogression and re-ageing” treatment schedule for AA7055 thick plate[J]. Materials & Design, 2014, 60: 208-217.

[20] 冯 迪, 张新明, 邓运来, 刘胜胆, 吴泽政, 郭奕文. 预时效温度及回归加热速率对7055铝合金组织及性能的影响[J]. 中国有色金属学报, 2014, 24(5): 1141-1150.

FENG Di, ZHANG Xin-ming, DENG Yun-lai, LIU Sheng-dan, WU Ze-zheng, GUO Yi-wen. Effect of pre-ageing temperature and retrogression heating rate on microstructure and properties of 7055 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1141-1150.

[21] 陈军洲. AA 7055 铝合金的时效析出行为与力学性能[D]. 哈尔滨: 哈尔滨工业大学, 2008.

CHEN Jun-zhou. Ageing precipitation behavior and mechanical properties of AA7055 aluminum alloy[D]. Harbin: Harbin Institute of Technology, 2008.

[22] AMS 4206A. Aluminum Alloy, Plate (7055-T7751) 8.0Zn-2.3Cu-2.0Mg-0.16Zr Solution Heat Treated, Stress Relieved, and Overaged[S]. 2006.

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(2012CB619500);江苏高校优势学科建设工程资助项目

收稿日期:2015-03-24;修订日期:2015-06-10

通信作者:冯 迪,博士,讲师;电话:13852908966;E-mail:difeng1984@aliyun.com