DOI: 10.11817/j.issn.1672-7207.2015.11.002

旋流-静态微泡浮选柱强化回收微细粒黑钨矿

艾光华1, 3,刘炯天2,曹亦俊2,李小兵1, 2

(1. 中国矿业大学 化工学院,江苏 徐州,221116;

2. 国家煤加工与洁净化工程技术研究中心,江苏 徐州,221116;

3. 江西理工大学 资源与环境工程学院,江西 赣州,341000)

摘要:针对微细粒黑钨矿中钨难回收、工艺流程长、回收率低的问题,应用高效的微细粒分选设备旋流-静态微泡浮选柱强化回收某含钨多金属矿中的微细粒黑钨矿,考察处理量、药剂制度、循环泵工作压力和充气量等对浮选指标的影响,并优化相应的工艺条件和操作参数,在此基础上进行短流程连选试验。研究结果表明:采用浮选柱“一粗二精”流程代替浮选机“一粗三精五扫”工艺流程,可以获得WO3质量分数为42.34%及钨回收率为84.68%的黑钨精矿,比浮选机流程获得的精矿质量分数提高10.43%,回收率提高2.15%,实现了微细粒黑钨矿柱式短流程的高效分选。

关键词:微细粒黑钨矿;旋流-静态微泡浮选柱;强化回收;短流程;浮选

中图分类号:TD923 文献标志码:A 文章编号:1672-7207(2015)11-3983-08

Strengthened recovery of fine wolframite by cyclonic-static microbubble flotation column

AI Guanghua1, 3, LIU Jiongtian2, CAO Yijun2, LI Xiaobing1, 2

(1. School of Chemical Engineering and Technology, China University of Mining and Technology,

Xuzhou 221116, China;

2. National Engineering Research Center of Coal Preparation and Purification, Xuzhou 221116, China;

3. School of Resources and Environmental Engineering, Jiangxi University of Science and Technology,

Ganzhou 341000, China)

Abstract: To solve the problems of difficult recycle of tungsten, long flow and low recovery in wolframite flotation separation, an efficient fine particle separation machine, with cyclonic-static microbubble flotation column was used to strengthen the recovery of fine wolframite from a tungsten polymetallic ore. The effects of processing capacity, reagent system, circulation pump working pressure and aeration rate on the flotation index were investigated, and the corresponding conditions and operating parameters of the process were optimized followed by the short flow continuous separation tests. The results show that replacing “one-stage rough, three-stage cleaning and five-stage scavenging” with flotation machine by the “one-stage scavenging and two-stage cleaning” with flotation column, a wolframite mass fraction of 42.34% with WO3 recovery of 84.68% can be obtained. Compared with the wolframite mass fraction of the process using traditional flotation, the wolframite mass fraction of flotation column process increases by 10.43%, and the recovery increases by 2.15%. Efficient separation of fine grained wolframite via columns in short process is finally achieved.

Keywords: fine wolframite; cyclonic-static microbubble flotation column; strengthen recovery; short flowsheet; flotation

我国钨资源储量丰富,是世界钨资源最丰富的国家,占总储量的40%左右,是优势矿产资源,但是钨矿性脆,容易过粉碎,极易泥化,其表面易被细粒脉石矿物污染而失去原来的浮选性能,据统计,全世界每年约有质量分数为20%的钨以微细粒形式损失于尾矿中[1-3],因此,细粒级的钨矿回收较困难,也是困扰着我国钨矿山选矿的一大难题[4-6]。对于复杂低品位(即质量分数)钨钼铋多金属矿中回收钨,目前较为有效的回收方法是“硫化矿浮选—黑白钨混浮—加温浮选白钨—摇床重选黑钨”和“硫化矿浮选—强磁选分离—白钨加温浮选—浮选黑钨”的工艺,由于硫化矿浮选体系中要细磨使其单体解离才能获得较好的选矿指标,因此,这2种工艺导致黑钨矿过粉碎。目前,在微细粒矿物分选中,浮选机仍占主导地位,但传统浮选机在细粒和微细粒矿物回收方面存在一定困难,往往存在浮选指标不理想、浮选流程长、耗电量大、投资大和运行费用高等问题[7]。因此,强化回收微细粒级黑钨矿技术是充分利用钨资源的重要途径,对于钨选矿具有重大意义。本文作者以某复杂低品位钨钼铋多金属矿为研究对象,采用高效的旋流-静态微泡浮选柱对生产现场开展分流工业试验,考察处理量、药剂制度、循环泵工作压力和充气量等条件对黑钨浮选指标的影响,借助其高选择性和高回收率,采用浮选柱“一粗二精”流程代替浮选机“一粗三精五扫”工艺流程,大大缩短浮选流程,简化工艺,实现微细粒黑钨矿的柱式短流程的高效分选,为微细粒钨矿物的高效回收提供参考。

1 矿石性质

本试验所用为某复杂低品位钨钼铋多金属矿。该矿石组成复杂,矿石种类多,主要的金属矿物有黑钨矿、白钨矿、辉钼矿、辉铋矿、方铅矿、黄铁矿、黄铜矿、闪锌矿、磁黄铁矿、磁铁矿和锡石,脉石矿物主要有石英、钾长石、白云母、绢云母、绿泥石、石榴子石、萤石和方解石等。

矿石中黑钨矿的质量虽少,但其嵌布状态却复杂,粒度分布极不均匀。矿石中黑钨矿主要有以下2种嵌布形式:1) 黑钨矿呈不规则粒状分布于绢云母、石英等脉石中,多见成群出现,部分黑钨矿被白钨矿交代,呈残晶;2) 在矿石中多见零星分布于石英中的叶片状、蠕虫状的微细粒黑钨矿,这些黑钨矿多与萤石连生,嵌布粒度极小。

矿石的化学成分和矿石中钨的化学物相分析结果分别如表1和表2所示。

表1 矿石的化学成分分析结果(质量分数)

Table 1 Chemical analysis of ore %

表2 矿石中钨的物相分析结果

Table 2 Phase analysis of tungsten in ore

2 试验

2.1 试验矿样

某复杂低品位钨钼铋多金属原矿经过磨矿分级,先进行硫化矿浮选,硫化矿浮选尾矿进行高梯度磁选分离黑钨矿,强磁选精矿进行浮选得到黑钨精矿,浮选柱系统试验矿样为实际生产中的高梯度磁选精矿浓缩后为柱浮选入料,柱浮选给矿中WO3品位为0.55%~ 0.60%,矿浆的质量分数为35%,粒径小于74 mm的矿石质量占总质量的90%。

2.2 试验药剂

在浮选试验中,采用碳酸钠、氟硅酸钠、水玻璃、硫酸铝和BLR为调整剂,硝酸铅为活化剂,GYB为捕收剂,OS-2为起泡剂的药剂制度进行分选。

2.3 试验设备

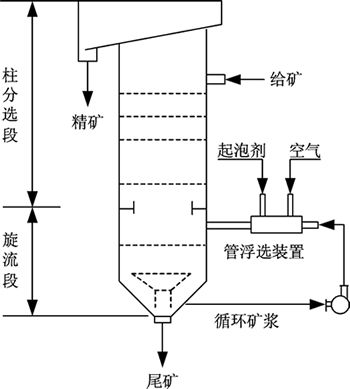

试验采用旋流-静态微泡浮选柱作为分选设备,该装备主体结构包括柱分离段、旋流分离段和管流矿化3部分,是一种性能完备的微细粒高效分选设备,在微细粒矿物分选方面表现出选择性好、富集比高和回收能力强等优势,已经成功应用到铜、铁、铅、锌、钼等矿物的分选中,其分选的基本结构如图1所示[8-10]。

2.4 试验流程

2.4.1 现场分选流程

现场浮选机的浮选工艺流程为:高梯度磁选精矿经过浓缩后加入粗选搅拌桶调浆,在搅拌桶中加入浮选药剂,经过“一粗三精五扫”的流程,得到黑钨精矿产品。传统浮选机浮选工艺的工艺流程图如图2所示。

图1 旋流-静态微泡浮选柱分选原理示意图

Fig. 1 Schematic diagram of separation principle of cyclonic-static microbubble flotation column

2.4.2 浮选柱分选流程

为了确保分流试验矿浆与浮选机分选矿浆性质相一致,确定在浮选机粗选搅拌桶给矿处为分流试验的取样点,通过手动闸门控制给料量,给矿质量分数为35%。黑钨矿的分选采用“一粗二精”的流程,试验采用中国矿业大学研制的旋流-静态微泡浮选柱的系统,系统包括调浆系统、柱分选系统和自动控制系统,粗选采用1台400 mm×4 000 mm(浮选柱直径×高) 型浮选柱,精Ⅰ过程采用1台250 mm×3 800 mm型浮选柱,精Ⅱ过程采用1台200 mm×3 800 mm型浮选柱,中矿采用依次返回的顺序。柱分选工艺系统设备示意图如图3所示。

图2 传统浮选机浮选工艺的工艺流程图

Fig. 2 Flow sheet of traditional flotation process using flotation machine

3 结果与分析

3.1 循环压力对黑钨矿浮选指标的影响

循环压力是指浮选柱分流试验工艺系统的中矿循环泵出口处的压力,该压力通过装在泵出口的压力表的显示而得,循环泵即反映了中矿循环量规模,也直接关系到气量,因此,循环压力是浮选柱提高分选效率和强化分选效果的重要参数,循环压力的选择对浮选指标影响较大[11-12]。在矿浆pH为8~9,处理量为7 t/d,粗选(碳酸钠质量分数为164 g/t、氟硅酸钠质量分数为7 g/t、水玻璃质量分数为600 g/t、硫酸铝质量分数为185 g/t、BLR质量分数为16 g/t、硝酸铅质量分数为300 g/t、GYB质量分数为25 g/t及OS-2质量分数为11 g/t),精Ⅰ(水玻璃质量分数为50 g/t及硫酸铝质量分数为10 g/t)和精Ⅱ(氟硅酸钠质量分数为2 g/t及BLR质量分数为3 g/t)药剂质量分数固定不变的条件下,调整循环量,考察粗选循环压力对浮选指标的影响,结果如图4所示。

图3 黑钨矿浮选柱分选工艺系统设备示意图

Fig. 3 Schematic diagram of set-up used in column flotation separation process for fine wolframite

图4 浮选柱粗选循环压力对黑钨矿浮选指标的影响

Fig. 4 Effect of roughing circulation pressure on column flotation performance for fine wolframite

由图4可知:在一定程度上增大循环压力,气泡发生器中流体紊流度增加,微细粒的矿化加强,同时气泡发生器吸入的进气量大,从而使柱体中弥散的气泡数量增多,颗粒与气泡碰撞的概率增加,黑钨精矿的回收率逐步提高,黑钨精矿品位逐步下降。当循环压力由0.22 MPa升至0.28 MPa时,回收率由62.34%增大到82.77%,此时,粗选黑钨精矿品位为22.78%;继续增大循环压力,粗选精矿的回收率和品位均下降,这是因为当循环压力过大时,大量循环中矿量通过泵的压力输送至柱体内,可能会对柱体的分选环境产生较强的紊流效应,浮选柱下部旋流场过强。由于黑钨矿质量较大,将会导致已经黏附在气泡上的黑钨矿颗粒与气泡脱落,黑钨矿颗粒进入尾矿,使粗选精矿回收率下降;同时,随着循环压力的增大,微细颗的矿化加强,部分微细粒的石榴子石等脉石矿物随矿化气泡上浮进入黑钨精矿,使黑钨精矿品位下降。因此,粗选循环压力为0.28 MPa较合适。

3.2 捕收剂质量分数对黑钨矿浮选指标的影响

在循环压力为0.28 MPa、碳酸钠质量分数为164 g/t、硝酸铅质量分数为300 g/t、氟硅酸钠质量分数为7 g/t、水玻璃质量分数为600 g/t、硫酸铝质量分数为185 g/t、BLR质量分数为16 g/t及OS-2质量分数为11 g/t的条件下,考察不同质量分数捕收剂GYB对黑钨矿浮选指标的影响,结果如图5所示。

图5 捕收剂GYB质量分数对黑钨矿浮选指标的影响

Fig. 5 Effect of GYB mass fraction on column flotation performance for fine wolframite

由图5可知:当GYB质量分数较小时,黑钨精矿品位较高,但回收率低;随着捕收剂GYB质量分数的增加,黑钨精矿品位逐渐降低,精矿回收率增加。因此,确定GYB质量分数为30 g/t较适宜,可以获得WO3质量分数为12.21%,回收率为85.56%的黑钨精矿。

3.3 OS-2质量分数对黑钨矿浮选指标的影响

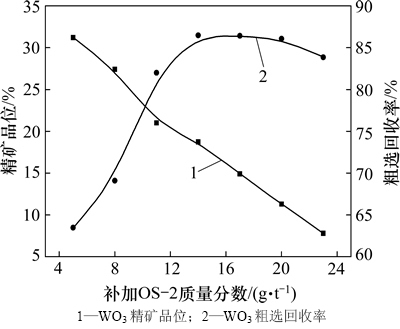

硫化矿浮选的尾矿进行高梯度磁选分流后,黑白钨矿进行分别浮选工艺中,采用新型的选矿药剂OS-2,该药剂具有辅助捕收性能和起泡性能,在循环压力为0.28 MPa,GYB质量分数为30 g/t,其他药剂质量分数不变的情况下,考察OS-2在不同质量分数下对黑钨矿浮选指标的影响,OS-2质量分数试验结果如图6所示。

由图6可知:当OS-2质量分数较大时,精矿泡沫较多,尾矿品位低,但精矿产率大,且黑钨精矿的品位低,粗选压力不稳定;当OS-2质量分数较小时,精矿品位高,但回收率较低。因此,OS-2质量分数为14 g/t较合适,可以获得含WO3质量分数为18.73%,回收率为86.47%的黑钨精矿。

图6 OS-2质量分数对黑钨矿浮选指标的影响

Fig. 6 Effect of OS-2 mass fraction on column flotation performance for fine wolframite

3.4 调整剂质量分数对黑钨矿浮选指标的影响

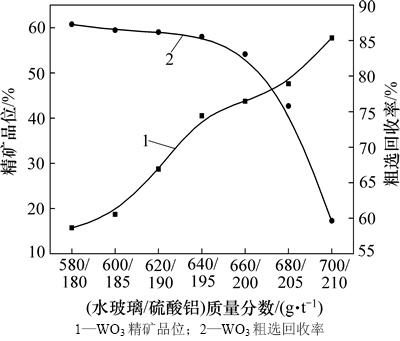

在循环压力为0.28 MPa,GYB质量分数为30 g/t,OS-2质量分数为14 g/t,其他药剂质量分数不变的条件下,考察水玻璃和硫酸铝在不同配比质量分数下对黑钨矿浮选指标的影响,结果见图7。

图7 水玻璃、硫酸铝的质量分数对黑钨矿浮选指标的影响

Fig. 7 Effect of mass fraction of water glass and aluminium sulfate on column flotation performance for wolframite

由图7可知:随着水玻璃和硫酸铝质量分数的逐步增大,黑钨精矿品位呈逐渐上升的趋势,当水玻璃质量分数为640 g/t、硫酸铝质量分数为195 g/t时,继续增大水玻璃和硫酸铝质量分数,黑钨精矿品位反而下降。在保证浮选柱分流试验工艺系统的精矿品位和回收率的前提下,以节省药剂质量分数为原则,综合考虑,选定的水玻璃质量分数为640 g/t、硫酸铝质量分数为195 g/t为宜,可以获得含WO3质量分数为41.73%,回收率为85.55%的黑钨精矿。

3.5 处理量对浮选指标的影响

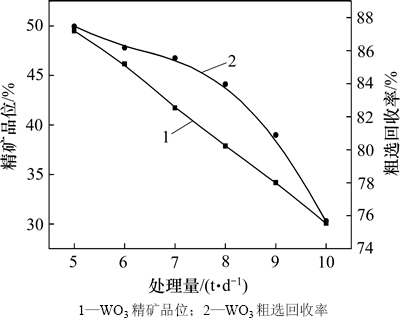

处理量是考察浮选工艺系统的重要指标,一方面浮选系统处理量的规模在分选过程中直接反映浮选时间,浮选时间是影响浮选工艺系统最后的回收率和精矿品位的主要因素;另一方面,浮选系统处理量最后反映到生产现场即选厂的生产能力,这一指标直接关系到选厂的经济效益。另外,处理量还是将来浮选柱工业系统选型的主要依据。在循环压力为0.28 MPa,GYB质量分数为30 g/t,OS-2质量分数为14 g/t,水玻璃质量分数为640 g/t,硫酸铝质量分数为195 g/t,其他药剂质量分数不变的条件下,考察不同处理量对黑钨矿浮选指标的影响,试验结果见图8。

图8 处理量对黑钨矿浮选指标的影响

Fig. 8 Effect of throughput on column flotation performance for fine wolframite

由图8可知:当处理量由5 t/d逐步增大到10 t/d时,黑钨精矿品位和回收率均呈下降的趋势;当处理量较小时,矿物在柱体中的浮选时间较长,柱体对目的矿物回收较充分,但设备处理能力低;当处理量增大时,由于浮选时间较短,部分目的矿物将损失于尾矿中,从而导致回收率下降。综合考虑试验的浮选指标,以及处理量小会增大生产成本这2个因素,试验最后选定的适宜的处理量为7 t/d,可以获得含WO3质量分数为41.65%,回收率为85.62%的黑钨精矿。

3.6 充气量对浮选指标的影响

充气量是影响浮选柱逆流矿化效果的重要因素,直接影响到浮选速率[13]。在循环压力为0.28 MPa,GYB质量分数为30 g/t,OS-2质量分数为14 g/t,水玻璃质量分数为640 g/t,硫酸铝质量分数为195 g/t,处理量为7 t/d,其他药剂质量分数不变的条件下,考察充气量对黑钨矿浮选指标的影响,结果见图9。

由图9可知:随着充气量的增加,品位逐渐下降,回收率升高,当充气量达0.24 m3/(m2·min)时,黑钨精矿的回收率有所降低,因此,选取充气量为0.24 m3/(m2·min),可以获得含WO3质量分数为41.02%,回收率为86.83%的黑钨精矿。

3.7 浮选柱短流程连选试验

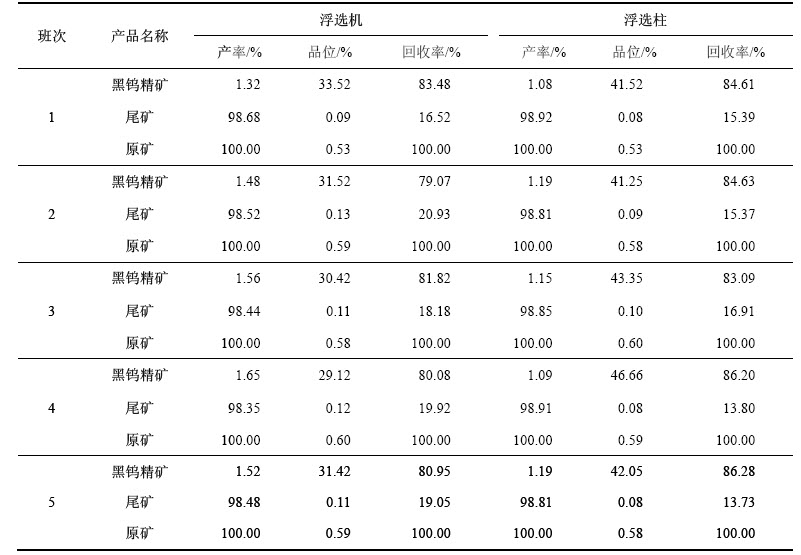

连选试验的目的是考察在矿石性质变化情况下的系统运行稳定性和技术参数的可靠性,在上述确定的最佳工艺参数和操作条件的基础上,进行浮选柱分流试验系统的“一粗二精”流程的连选试验,同班次浮选柱“一粗二精”流程与浮选机“一粗三精五扫”流程的试验结果见表3所示,2种流程对比的效果如表4所示。

从表3和表4可知:采用浮选柱“一粗二精”流程,浮选柱系统的分选指标显著优于浮选机系统的分选指标;当处理量为7 t/d时,浮选柱的精矿品位为42.34%,回收率为84.68%,与浮选机工艺的生产指标相比,精矿品位提高了10.43%,回收率提高了2.15%,浮选柱系统的分选指标,尤其是精矿质量明显优于浮选机系统所得精矿的质量,浮选柱具有高的富集比和较强的回收能力,充分体现了旋流-静态微泡浮选柱在选择性和精矿回收率方面的优势。

图9 充气量对黑钨矿浮选指标的影响

Fig. 9 Effect of aeration rate on column flotation performance for fine wolframite

表3 浮选柱“一粗二精”流程连选试验结果

Table 3 Results of continuous tests using flotation column by “one-stage scavenging and two-stage cleaning”

表4 浮选柱短流程试验结果与浮选机流程指标对比

Table 4 Comparison of experimental results between microbubble flotation column process and flotation machine process

由于旋流-静态微泡浮选柱集柱浮选与旋流分选于一体,构建旋流粗选、管流矿化、旋流扫选的循环中矿分选链,突破“逆流碰撞”的柱浮选原理,形成由“柱浮选”到“柱分选”的方法创新,形成针对难浮微细粒黑钨矿的高紊流矿化多重矿化方式为核心的强化分选回收机制,克服了浮选机回收微细粒级能力差的弊端[14-16]。同时增加了二段柱精选,大大提高了微细粒黑钨矿的精矿品位,浮选柱“一粗二精”流程代替浮选机“一粗三精五扫”工艺流程,得到了较优的选矿指标。

4 结论

1) 旋流-静态微泡浮选柱作为一种有效的微细分选设备,对强化微细粒黑钨矿分选具有较好的选择性和较强的回收能力。

2) 利用半工业浮选柱试验系统进行黑钨矿的分选试验,较合适的操作参数为:处理量为7 t/d,捕收剂GYB质量分数为30 g/t,OS-2质量分数为14 g/t,水玻璃质量分数为640 g/t,硫酸铝质量分数为195 g/t,循环压力为0.28 MPa,充气量为0.24 m3/(m2·min)。

3) 旋流-静态微泡浮选柱半工业试验在“一粗二精”的工艺流程下,获得含WO3质量分数为42.34%,回收率为84.68%黑钨精矿,精矿品位比浮选机工艺所得精矿的品位提高了10.43%,回收率提高了2.15%。

4) 旋流-静态微泡浮选柱选择性好、回收率高,“一粗二精”三段工艺可以替代浮选机的“一粗三精五扫”九段工艺,实现了短流程高效回收。

参考文献:

[1] 李平, 管建红, 李振飞, 等. 钨细泥选矿现状及试验研究分析[J]. 中国钨业, 2010, 25(2): 20-23.

LI Ping, GUAN Jianhong, LI Zhenfei, et al. The current situation of tungsten slime dressing and its experimental analysis [J]. China Tungsten Industry, 2010, 25(2): 20-23.

[2] 艾光华, 刘炯天. 钨矿选矿药剂和工艺的研究现状及展望[J]. 矿山机械, 2011, 19(4): 1-4.

AI Guanghua, LIU Jiongtian. Research status and flotation reagents and techniques of tungsten ores[J]. Mining Machinery, 2011, 19(4): 1-4.

[3] 邓丽红, 周晓彤, 罗传胜, 等. 江西某钨矿钨细泥选矿新工艺应用研究[J]. 矿产综合利用, 2010(3): 8-9.

DENG Lihong, ZHOU Xiaotong, LUO Chuansheng, et al. Application research on the new technology for separating tungsten slimes produced from a tungsten mine in Jiangxi[J]. Multipurpose Utilization of Mineral Resources, 2010(3): 8-9.

[4] 周晓彤, 邓丽红. 提高某选厂钨细泥钨回收率的试验研究[J]. 矿产综合利用, 2009(9): 16-17.

ZHOU Xiaotong, DENG Lihong. Experimental research for increasing tungsten recovery in the fine tungsten slime in a concentrator[J]. Multipurpose Utilization of Mineral Resources, 2009(9): 16-17.

[5] 方夕辉, 钟常明. 组合捕收剂提高黑钨细泥选矿回收率的试验研究[J]. 中国钨业, 2007, 22(4): 26-28.

FANG Xihui, ZHONG Changming. Experimental research on improving fine wolframite recovery by combination collector[J]. China Tungsten Industry, 2007, 22(4): 26-28.

[6] 周晓彤, 邓丽红. 黑白钨细泥选矿新工艺研究[J]. 材料研究与应用, 2007, 1(4): 303-304.

ZHOU Xiaotong, DENG Lihong. Study on a new technology of separating refractory fine scheelite and wolframite sediments[J]. Material Research and Application, 2007, 1(4): 303-304.

[7] 黄光耀, 冯其明, 欧乐明, 等. 浮选柱法从浮选尾矿中回收微细粒级白钨矿的研究[J]. 稀有金属, 2009, 25(2): 263-266.

HUANG Guangyao, FENG Qiming, OU Leming, et al. Recovery of fine scheelite from flotation by column flotation[J]. Rare Metals, 2009, 25(2): 263-266.

[8] Yoon R H. Microbubble flotation[J]. Minerals Engineering, 1993, 6(6): 619-630.

[9] Eisele T C, Kawatra K S. Reverse column flotation of iron ore[J]. Minerals & Metallurgical Processing, 2007, 24(1): 61-65.

[10] 刘炯天, 李小兵, 王永田. 旋流-静态微泡浮选柱浮选某难选钼矿的试验研究[J]. 中南大学学报(自然科学版), 2008, 39(2): 300-305.

LIU Jiongtian, LI Xiaobing, WANG Yongtian. Experimental study on separation some molybdenum ore by using cyclonic-static micro-bubble flotation column[J]. Journal of Central South University (Science and Technology), 2008, 39(2): 300-305.

[11] 刘炯天, 王永田, 曹亦俊, 等. “十五”国家科技攻关计划项目研究报告: 大型矿用微泡柱分选设备的研制[R]. 徐州: 中国矿业大学浮选柱研究中心, 2003: 1-18.

LIU Jiongtian, WANG Yongtian, CAO Yijun, et al. The key technologies R&D program for the 10th Five-year plan: Research on technologies of large mineral micro bubble flotation column[R]. Xuzhou: China University of Mining and Technology. Flotation Column Research Center, 2003: 1-18.

[12] 周强, 曹亦俊, 李小兵, 等. 旋流-静态微泡浮选柱分选某白钨矿的半工业试验研究[J]. 有色金属(选矿部分), 2011(1): 39-40.

ZHOU Qiang, CAO Yijun, LI Xiaobing, et al. Study on cyclone-static micro-bubble flotation column of scheelite ores[J]. Nonferrous Metals (Beneficiation Section), 2011(1): 39-40.

[13] 张海军, 刘炯天, 王永田. 磁铁矿浮选柱阳离子反浮选试验研究[J]. 中国矿业大学学报, 2008, 37(1): 67-71.

ZHANG Haijun, LIU Jiongtian, WANG Yongtian. Research on cationic reverse flotation of magnetite using a flotation column[J]. Journal of China University of Mining & Technology, 2008, 37(1): 67-71.

[14] 刘炯天, 王永田. 自吸式微泡发生器充气性能研究[J]. 中国矿业大学学报, 1998, 27(1): 27-31.

LIU Jiongtian, WANG Yongtian. Study on performance of self-absorbing micro bubble generator[J]. Journal of China University of Mining & Technology, 1998, 27(1): 27-31.

[15] 马子龙, 刘炯天, 曹亦俊, 等. 旋流-静态微泡浮选柱用于金川镍矿的可行性研究[J]. 有色金属(选矿部分), 2009(2): 32-36.

MA Zilong, LIU Jiongtian, CAO Yijun, et al. The study on the possibility of application the cyclone static micro-bubble column flotation in the flotation of Jin chuan nickel mine[J]. Nonferrous Metals (Benefication Section), 2009(2): 32-36.

[16] 张海军, 刘炯天, 王永田. 矿用旋法-静态微泡浮选柱的分选原理及参数控制[J]. 中国矿业, 2006, 16(5): 70-72.

ZHANG Haijun, LIU Jiongtian, WANG Yongtian. Separation principle and parameter controlling for cyclonic-static micro-bubble flotation column[J]. China Mining Magazine, 2006, 16(5): 70-72.

(编辑 刘锦伟)

收稿日期:2014-11-02;修回日期:2015-01-15

基金项目(Foundation item):国家“十一五”科技支撑计划重点项目(2008BAB31B02) (Project(2008BAB31B02) supported by the Key Projects of the National Science & Technology Pillar Program during the Eleventh Five-year Plan Period)

通信作者:刘炯天,教授,博士生导师,从事微细粒分选理论和洁净煤技术研究;E-mail: scetljt@126.com