文章编号:1004-0609(2016)-10-2078-08

高含量SiCp/A356复合材料衍生材料的组织与性能

潘利科,韩建民,张颖骁,杨智勇,李志强,李卫京

(北京交通大学 机械与电子控制工程学院,北京 100044)

摘 要:采用真空半固态搅拌铸造法制备40%(体积分数)的高含量SiCp/A356复合材料;然后以40% SiCp/A356复合材料为原料,采用“稀释法”分别制备出体积分数10%、20%、30% 衍生SiCp/A356复合材料。通过对比分析高体积含量复合材料稀释制备的衍生复合材料(衍生材料)与直接搅拌制备的搅拌SiCp/A356复合材料(搅拌材 料)的断口形貌,发现衍生材料的断口质量及颗粒分布均匀程度均优于相同颗粒含量搅拌材料的;不同颗粒含量的孔隙率、布氏硬度、力学性能变化规律具有稀释效应,即颗粒含量越低,对应数值越小;相同颗粒含量衍生材料的硬度比搅拌材料的高3%~5%左右,力学性能比搅拌材料的力学性能高9%~13%。

关键词:SiCp/A356复合材料;搅拌材料;衍生材料;半固态;搅拌铸造

中图分类号:TB331 文献标志码:A

SiCp/A356复合材料比强度、比刚度高,并且具有较小的热膨胀系数、良好的导热性、耐磨性等,在航空航天、汽车、电子等领域得到广泛应用,是未来高性能轻质材料的首选之一[1-5]。粉末冶金法[6-8]、搅拌铸造法[9-10]、喷射沉积法[11]、浸渗法[12-13]等是制备颗粒增强铝基复合材料的技术相对比较成熟的方法,而搅拌铸造法由于制备成本相对低廉、工艺过程相对简单,便于实现工业化生产等优势,使得其在工业化方面的应用前景更加广阔[14-16]。

搅拌铸造法制备SiCp/A356复合材料,是使用搅拌杆快速搅拌铝合金熔体,将SiC颗粒混入铝合金熔体当中。由于SiC颗粒在半固态温度时不能和铝合金熔体自发润湿,导致SiC颗粒混入困难;即使SiC颗粒混入铝合金熔体当中,颗粒分布均匀程度以及孔隙率等都难以控制,影响复合材料的力学性能[17-18]。因此,搅拌铸造法的进一步改进和完善成为改进复合材料制备质量的有效途径。卢健等[19-21]采用搅拌铸造技术制备的15%(质量分数)SiCp/A356复合材料孔隙率为4.8%,复合材料的力学性能比A356铝合金基体的还低,其通过热挤压复合材料进一步改善性能。GUI等[22]使用液态和半固态二级搅拌的复合工艺,降低SiCp/A356复合材料的孔隙率,提高复合材料的力学性能。KANG等[23]使用电磁和机械复合搅拌改善SiCp/A357复合材料性能。AMIRKHANLOU等[24]将SiC与Al粉一起混合均匀后搅拌制备的SiCp/A356复合材料性能明显优于直接搅拌SiC颗粒制备的复合材料。董普云等[25]通过研究不同的凝固压力对复合材料的微观组织和性能的影响,发现随着压力的增大,复合材料的孔洞等缺陷减少,有效改善复合材料的力学性能。BALAJI[26]、KALA[27]和SONG等[28]分析了搅拌铸造过程对复合材料性能的影响,发现可以通过改进搅拌工艺等提高复合材料的性能。

本文作者首先采用真空半固态搅拌铸造法制备出40%复合材料,然后采用“稀释法”制备出40%高体积含量复合材料的不同SiC颗粒含量的衍生材料。国内外相关文献还未见此类方法的相关报道。在此,本文作者通过此方法提高SiCp/A356复合材料的制备质量和力学性能,并简化复合材料的制备工艺过程,为SiCp/A356复合材料的推广应用提供技术支撑。

1 实验

1.1 实验材料

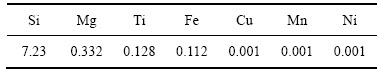

本实验中选用A356铝合金、平均尺寸20 μm的α-SiC作为SiCp/A356复合材料的基体材料和增强颗粒。A356、α-SiC的化学成分如表1和表2所列。A356铝合金的密度为2.68 g/cm3,SiC颗粒的密度为3.18 g/cm3。

表1 A356铝合金的化学成分

Table 1 Chemical composition of A356 (mass fraction, %)

表2 碳化硅的化学成分

Table 2 Chemical composition of SiC (mass fraction, %)

1.2 复合材料的制备方法

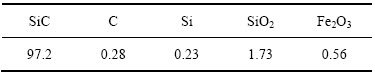

本实验中采用机械搅拌铸造法制备SiCp/A356复合材料,其制备装置如图1所示。首先制备出40%(体积分数)的高含量SiCp/A356复合材料,其制备工艺及过程如下:先将A356铝合金置于真空环境下的坩埚中加热至完全融化;然后将600℃预处理3h的SiC颗粒加入凝固至半固态状态下(温度为590~610℃,固相分数为10%~30%)的铝合金熔体中,并在真空状态下进行机械搅拌,不断调整搅拌工艺直至SiC颗粒完全混入铝合金熔体中,最后升温至700 ℃进行浇注。然后,在40%复合材料中加入一定量的A356铝合金,进行熔炼及半固态搅拌,并控制搅拌工艺,直至颗粒分散均匀;最后在700 ℃下完成浇注,制备出不同含量的高含量复合材料的衍生材料,即所谓的“稀释法”。同时,采用类似于40%复合材料制备的工艺过程直接制备不同体积含量的搅拌材料。

图1 机械搅拌铸造装置示意图

Fig. 1 Schematic diagram of mechanical stirring casting device

1.3 复合材料分析方法

复合材料浇注为d 25 mm×120 mm的圆柱形试样,然后从中间部位砸断试样观察复合材料的断口。

切取部分复合材料试样进行磨光、抛光后,使用NEOPHOT-21型光学显微镜对金相试样表面进行观察并拍照。使用ZEISS EVO-18型扫描电镜观察复合材料的微观形貌。使用Image Pro Plus图像处理软件统计实际SiC颗粒含量,并依据阿基米德原理测试复合材料的孔隙率。

使用HBS-3000型布氏硬度测试复合材料的硬度,加载载荷为1000 N,保压时间为30 s,每个试样测试3个点,取其平均值作为最终记录结果。

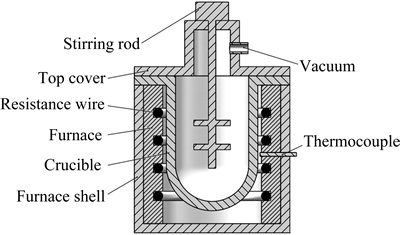

使用MTS810试验系统进行拉伸试验,测试复合材料的抗拉强度、伸长率,每种材料至少测试3根试样并取其平均值。试验机卡头的拉伸速度为0.01 mm/s。拉伸试样尺寸图2所示。

图2 拉伸试样尺寸示意图

Fig. 2 Dimensions of tensile test bar (mm)

1.4 孔隙率检测

所谓孔隙率是指材料中各种孔洞的体积占材料总体积的比率。假定复合材料中无孔隙,则理论密度 的表达式为

的表达式为

(1)

(1)

式中: 为基体材料的体积分数;

为基体材料的体积分数; 为基体密度;

为基体密度; 为SiC颗粒的体积分数;

为SiC颗粒的体积分数; 为SiC颗粒的密度。

为SiC颗粒的密度。

根据阿基米德原理,孔隙率V0可用如下公式进行计算:

(2)

(2)

(3)

(3)

式中:ma为复合材料在空气中的质量;mw为复合材料在水中的质量; 为复合材料的实际密度。

为复合材料的实际密度。

在搅拌铸造法制备SiCp/A356复合材料过程中,由于搅拌过程卷入气体、铝合金溶解气体、SiC颗粒表面吸附气体、铝液与SiC颗粒表面浸润接触不良而存在着孔隙、SiC颗粒团聚等问题,导致孔隙率的产生。高孔隙率会降低材料的性能,准确快速地检测复合材料的孔隙率有助于判断和控制复合材料的质量。

本实验中在测试孔隙率时,每种材料分别制取2个d 25 mm×120 mm的圆柱形试样,然后从中间敲断观察断口,同时测试每个敲断试样的孔隙率,孔隙率结果取平均值。

2 结果与讨论

2.1 40%复合材料的显微组织

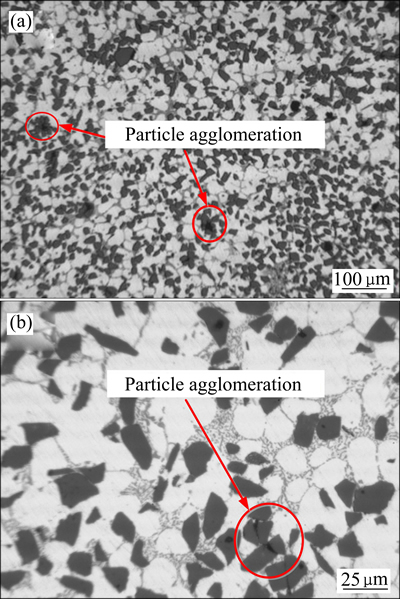

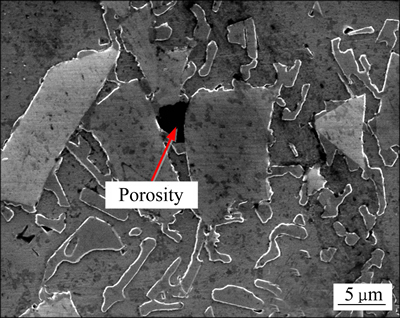

本实验中采用真空半固态搅拌铸造法制备出40%的SiCp/A356复合材料,其金相组织及显微形貌如图3和4所示。从图3和4中可以看出,40%复合材料出现部分颗粒团聚现象,而在颗粒团聚的界面处,常常存在孔洞,造成复合材料的界面结合强度降低。

在机械搅拌制备SiCp/A356复合材料中,孔隙来源主要有基体合金中溶解的气体、搅拌过程中卷入的气体、SiC颗粒表面吸附的气体、搅拌杆表面吸附的气体等。虽然整个搅拌过程在真空环境中,但是由于复合材料的黏度大、真空度不够高、气体容易吸附到SiC表面等原因,复合材料熔体中不可避免存在一定量的气体。如果搅拌工艺达不到最佳工艺参数,部分SiC颗粒团聚将难以完全打开,SiC颗粒表面吸附的气体含量就难以排出,从而出现孔洞。搅拌铸造法不可避免会吸附一定的气体,但是如果气体含量低于1%就可满足一般工业应用,如果更低将会进一步提高复合材料的性能。本实验中制备的40% SiCp/A356复合材料的孔隙率为0.88%。

图3 40% SiCp/A356复合材料的金相组织

Fig. 3 Metallographs of 40% SiCp/A356 composites

图4 40% SiCp/A356复合材料SiC颗粒团聚的微观形貌

Fig. 4 Morphology of SiC particle agglomeration of 40% SiCp/A356 composites

2.2 搅拌材料与衍生材料对比分析

将40% SiCp/A356复合材料与一定量的补偿铝合金一起进行熔炼并搅拌,即采用“稀释法”制备出10%、20%、30%(体积分数)复合材料,并与直接采用搅拌铸造法制备的相同含量的复合材料进行对比分析。

2.2.1 复合材料宏观断口及孔隙率

断口和孔隙率可以用来快速查验复合材料的制备工艺的稳定性和质量的好坏,可以作为铸造复合材料制备质量的快速检验手段。通过断口观察,可以快速查验复合材料是否有夹杂、宏观断口形貌、断口致密度等,快速判断制备质量的好坏。而孔隙率则可以进一步判断复合材料的性能,从而评估和调整制备工艺参数。

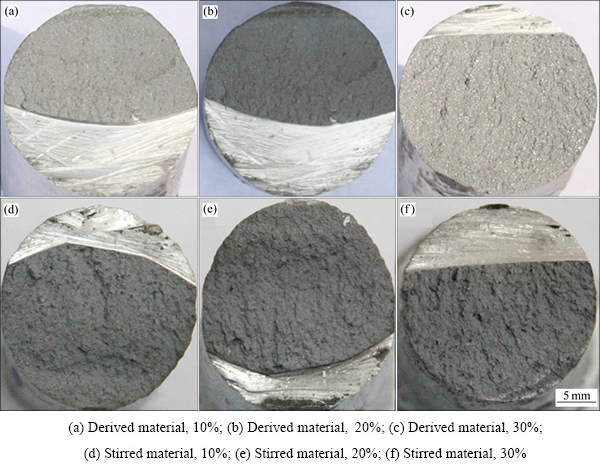

图5所示为衍生材料和搅拌材料不同体积含量SiCp/A356复合材料的宏观断口照片。对比图5(a)~(c)与图5(d)~(f)可以看出,“稀释法”制备的衍生材料相比直接搅拌法制备的搅拌材料致密度更好一些,且两种材料的断口均没有明显夹杂和缺陷,复合材料制备质量均较好。

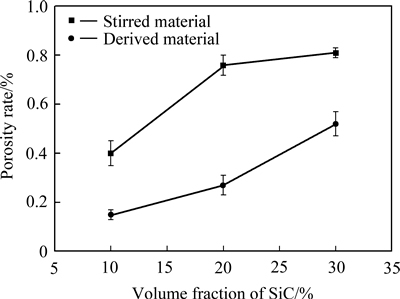

图6所示为两种不同方法制备的不同体积含量SiCp/A356复合材料的孔隙率。由图6可以看出,两种方法制备的复合材料的孔隙率均在1%以下。衍生材料和搅拌材料的孔隙率均随SiC颗粒含量的减小而降低,相同SiC颗粒含量的衍生材料的孔隙率低于搅拌材料的孔隙率,不同SiC颗粒含量的衍生材料和搅拌材料的孔隙率变化规律符合“稀释效应”,即随着颗粒含量降低,其孔隙率减小。由于不同SiC颗粒含量的衍生材料都是以SiC颗粒含量为40%的搅拌材料为原料通过“稀释法”制备的,铝合金的孔隙率低于复合材料的孔隙率水平,SiC颗粒含量为40%的搅拌材料的孔隙含量相当于被补偿铝合金所“稀释”,因此,对于衍生材料SiC颗粒含量越低孔隙率越小。不同SiC颗粒含量的搅拌材料在制备过程中互相之间不产生影响,其孔隙率数值是独立的;随着SiC颗粒含量增加,熔体黏度增大,气体不易排出,搅拌难度增大,因此,对于搅拌材料SiC颗粒含量越高孔隙率越大。此外,衍生材料还进行了二次半固态搅拌,其颗粒分散性更好,也是导致孔隙率低的另一个原因。复合材料在二次搅拌过程中,其中的颗粒群再次受到搅拌杆剪切力以及半固态中的固相成分的作用,使得一次搅拌时已经分散的颗粒再次重新分散,进一步提高了颗粒的分散均匀性。

图5 不同SiC颗粒含量SiCp/A356复合材料的宏观断口形貌

Fig. 5 Macroscopic fractures in SiCp/A356 composites with different SiC contents

图6 不同SiC颗粒含量的衍生材料和搅拌材料的孔隙率

Fig. 6 Porosity rate of derived material and stirred material with different SiC contents

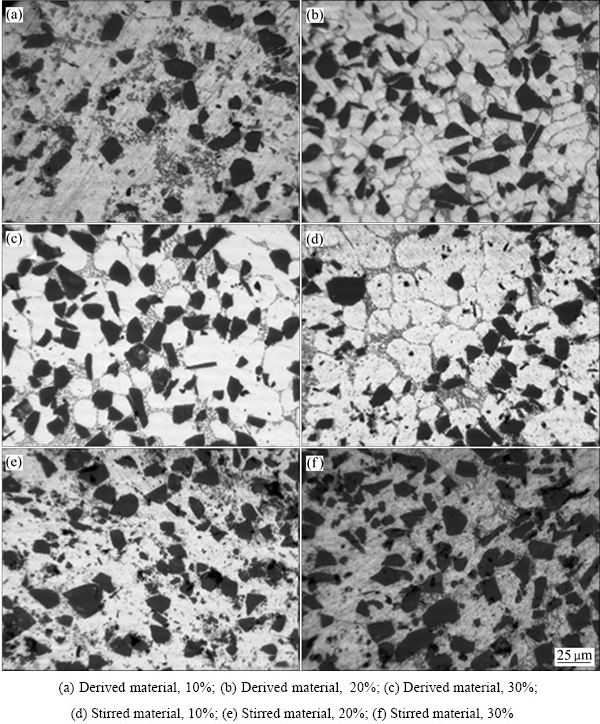

2.2.2 复合材料显微组织

图7所示为10%、20%、30%颗粒含量SiCp/A356衍生材料和搅拌材料的金相组织。对比图7(a)~(c)与图7(d)~(f)可以看出,衍生材料和搅拌材料的SiC颗粒均没有明显的多个颗粒团聚现象,但衍生材料相比搅拌材料SiC颗粒分布更加均匀,并且颗粒周围的黑色孔洞更少。

颗粒分布均匀程度是影响复合材料性能的一个重要因素。由于颗粒增强铝基复合材料是通过界面由基体有效地将载荷传递到增强颗粒上,从而强化材料性能。因此,颗粒分布的更加均匀,其强化效果将更加明显。但是搅拌铸造法很难实现理论上的颗粒均匀分布,即颗粒的间距相等。因此,尽可能保证颗粒或者颗粒群以一种规律性的“阵列”样式分布,颗粒之间更加分散,并且减少颗粒团聚的可能性是最为有效可行的工程方案。本实验中制备的衍生材料颗粒分布相对比较均匀,并且相比于搅拌材料,颗粒间的团聚情况更少,其孔洞也更少,是由于衍生材料中补偿铝合金的加入在降低孔隙率的同时,还通过二次搅拌实现颗粒的均匀分布和提高颗粒间的分散性。

图7 不同SiC颗粒含量SiCp/A356复合材料的颗粒分布

Fig. 7 Particle distribution in SiCp/A356 composites with different SiC contents:20%

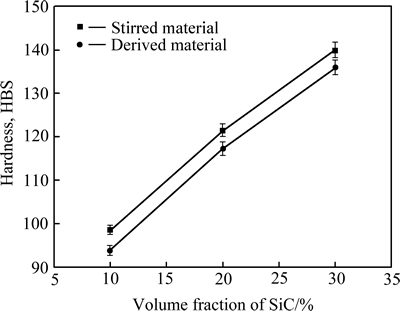

2.2.3 复合材料硬度

图8所示为不同SiC颗粒含量的衍生材料和搅拌材料的布氏硬度。从图8可以看出,不同SiC颗粒含量的复合材料的硬度值都在90 HBS以上,其中SiC颗粒含量为30%的衍生材料硬度值最高,达到140.0 HBS。衍生材料和搅拌材料的硬度值均随SiC颗粒含量的增加而增加,其增加趋势接近于线性,且相同SiC颗粒含量的衍生材料的硬度均高于搅拌材料的硬度,衍生材料的硬度比搅拌材料的高3%~5%左右。这是由于衍生材料中颗粒的分散均匀性更好,其孔隙率含量更低,提高了颗粒与基体的界面结合程度,从而有力于载荷的传递,表征为硬度的提高。

图8 不同SiC颗粒含量的衍生材料和搅拌材料的布氏硬度

Fig. 8 Brinell hardness of derived material and stirred material with different SiC contents

2.2.4 复合材料力学性能

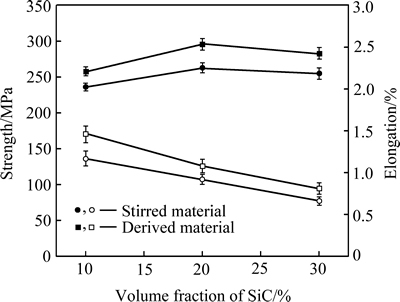

图9所示为不同SiC颗粒含量的衍生材料和搅拌材料的抗拉强度和伸长率。由图9可知,衍生材料和搅拌材料的强度均在230 MPa以上,其中SiC颗粒含量为20%的衍生材料抗拉强度最高,达到296 MPa,SiC颗粒含量为10%的搅拌材料抗拉强度最低,为236 MPa。不同SiC颗粒含量的衍生材料相对比,其抗拉强度随着颗粒含量的增加不断提高,不同SiC颗粒含量搅拌材料的抗拉强度与之有相似的规律。采用“稀释法”制备的SiC颗粒含量为10%、20%、30%的衍生材料的抗拉强度比直接搅拌复合制备的同等SiC颗粒含量的搅拌材料的抗拉强度分别高出9%、13%、11%。

图9 不同SiC颗粒含量衍生材料和搅拌材料的抗拉强度和伸长率

Fig. 9 Strength and elongation of derived material and stirred material with different SiC contents

SiC颗粒含量的增加使材料中传递到单个颗粒的载荷降低,进一步提升了材料的整体承载能力,表征为强度提高。但因复合材料的孔隙率随SiC颗粒含量增加而增多,使材料的强度降低。当SiC颗粒的含量增加到一定值后,SiC颗粒通过转移载荷使材料增强的作用不明显,孔隙率增加使得材料的界面结合变弱,从而引起强度降低的作用占主导,从而表现出复合材料的强度随SiC颗粒含量的增加总体呈现先增加再降低的特性。

从图9还可以看出,不同SiC颗粒含量的衍生材料和搅拌材料的伸长率均低于2%,说明其塑性较差。衍生材料和搅拌材料的伸长率均随SiC颗粒含量的增加而降低,相同SiC颗粒含量衍生材料的伸长率高于搅拌材料的。

3 结论

1) 采用真空半固态搅拌铸造法制备的复合材料断口无明显缺陷和夹杂,孔隙率均在1%以下,40%复合材料存在部分颗粒团聚现象。

2) 不同SiC颗粒含量的复合材料的孔隙率随着颗粒含量的降低不断减小,具有“稀释效应”;衍生材料相比搅拌材料断口更加致密,衍生材料的孔隙率低于搅拌材料的。

3) 衍生材料相比搅拌材料,颗粒分布更加均匀,金相组织无明显黑色孔洞。

4) 不同SiC颗粒含量的衍生材料相比搅拌材料的布氏硬度和抗拉强度也具有“稀释效应”,即随着颗粒含量的降低,其对应数值不断变小。衍生材料的布氏硬度和抗拉强度比对应同等含量的搅拌材料分别提高3%~5%、9%~13%。

REFERENCES

[1] 王 行, 谢敬佩, 郝世明, 王爱琴.碳化硅颗粒增强铝基复合材料研究现状与展望[J]. 稀有金属与硬质合金, 2013, 41(3): 50-53, 64.

WANG Xing, XIE Jing-pei, HAO Shi-ming, WANG Ai-qin. The latest development and prospect of SiC particle reinforced Al-based composite[J]. Rare Metals and Cemented Carbides, 2013, 41(3): 50-53, 64.

[2] LLOYD D J. Particle reinforced aluminium and magnesium matrix composites[J]. International Materials Reviews, 1994, 39 (1): 1-23.

[3] 郑喜军, 米国发. 碳化硅颗粒增强铝基复合材料的研究现状及发展趋势[J]. 热加工工艺, 2011, 40(12): 92-96.

ZHENG Xi-jun, MI Guo-fa. Research status and development trend of SiCp/Al composite[J]. Hot Working Technology, 2011, 40(12): 92-96.

[4] RANA R S, PUROHIT R, DAS S. Review of recent studies in Al matrix composites[J]. International Journal of Scientific & Engineering Research, 2012, 3(6): 1-16.

[5] IBRAHIM I R, MOHAMED F A, LAVEMIA E J. Particulate reinforced metal matrix composite-a review[J]. Journal of Materials Science, 1991, 26(5): 1137-1156.

[6] 马国俊, 丁雨田, 金培鹏, 刘国龙. 粉末冶金法制备铝基复合材料的研究[J]. 材料导报, 2013, 27(8): 149-154.

MA Guo-jun, DING Yu-tian, JIN Pei-peng, LIU Guo-long. Research on powder metallurgy processing for preparing Al matrix composites[J]. Materials Review, 2013, 27(8): 149-154.

[7] LI Ai-bin, XU Hong-yu, GENG Lin. Preparation and characterization of SiCp/2024Al composite foams by powder metallurgy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S1): s33-s38.

[8] HAO Shi-ming, XIE Jing-pei, WANG Ai-qin, WANG Wen-yan, LI Ji-wen, SUN Hao-liang. Hot deformation behaviors of 35%SiCp/2024Al metal matrix composites[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(8): 2468-2474.

[9] COPALAKRISHNAN S, MURUGAN N. Production and wear characterization of AA 6061 matrix titanium carbide particulate reinforced composite by enhanced stir casting method[J]. Composites B, 2012, 43: 302-308.

[10] 谭 锐, 唐 骥. 铸造法制备SiCp/Al复合材料的研究现状[J]. 铸造, 2005, 54(7): 642-647.

TAN Rui, TANG Ji. Study on properties of high reinforcement-content aluminum matrix composite for electronic packages[J]. Foundry, 2005, 54(7): 642-647.

[11] SHARMA M M, ZIEMIAN C W, EDEN T J. Fatigue behavior of SiC particulate reinforced spray-formed 7XXX series Al-alloys[J]. Materials and Design, 2011, 32: 4304-4309.

[12] XIU Zi-yang, YANG Wen-shu, CHEN Guo-qing, JIAGN Long-tao, MA Kang, WU Gao-hui. Microstructure and tensile properties of Si3N4p/2024Al composite fabricated by pressure infiltration method[J]. Materials and Design, 2012, 33: 350-355.

[13] 袁 曼, 于家康, 陈代刚, 于 威, 李华伦, 曹禄华. SiCp/ZL101基复合材料的界面与性能[J]. 中国有色金属学报, 2013(3): 779-785.

YUAN Man, YU Jia-kang, CHEN Dai-gang, YU Wei, LI Hua-lun, CAO Lu-hua. Interface and properties of SiCp/ZL101 matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 779-785.

[14] 徐正国, 王承志, 张玉妥.搅拌法制备SiC颗粒增强铝基复合材料的研究现状与展望[J]. 铸造设备研究, 2007(5): 35-38.

XU Zheng-guo, WANG Cheng-zhi, ZHANG Yu-tuo. The actuality and trend of SiC reforcement Al matrix composites produced by stirring method[J]. Research Studies on Foundry Equipment, 2007(5): 35-38.

[15] MAZAHERY A, SHABANI M O. Microstructural and abrasive wear properties of SiC reinforced aluminum-based composite produced by compocasting[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(7): 1905-1914.

[16] 杨 锐, 王筱峻, 吴星平, 陈明海, 刘 宁, 李清文.搅拌铸造制备SiC颗粒增强铝基复合材料研究现状[J]. 材料导报, 2013, 27(5): 131-136.

YANG Rui, WANG Xiao-jun, WU Xing-ping, CHEN Ming-hai, LIU Ning, LI Qing-wen. Progress in stir-casting process for fabricating SiCp/Al composites[J]. Materials Review, 2013, 27(5): 131-136.

[17] 李 昊, 桂满昌, 周彼德. 搅拌铸造金属基复合材料铸锭的气孔率[J]. 宇航材料工艺, 1997(2): 30-32.

LI Hao, GUI Man-chang, ZHOU Bi-de. Porosity rate of metal matrix composites fabricated by stirring cast[J]. Aerospace Materials & Technology, 1997(2): 30-32.

[18] 程建锋, 王 开, 刘昌明, 陈绪宏. 搅拌铸造颗粒增强铝基复合材料颗粒分散性研究[J]. 铸造, 2010, 59(11): 1178-1181.

CHENG Jian-feng, WANG Kai, LIU Chang-ming, CHEN Xu-hong. Research on the dispersion of SiC particles during the fabrication of SiCp/Al composites by stir casting[J]. Foundry, 2010, 59(11): 1178-1181.

[19] 卢 健, 高文理, 苏 海, 冯朝晖, 陆 政. 搅拌铸造法制备SiCp/A356铝基复合材料的研究[J]. 铸造设备与工艺, 2009(4): 15-17, 43.

LU Jian, GAO Wen-li, SU Hai, FENG Zhao-hui, LU Zheng. Study on SiCp/A356 aluminum matrix composites fabricated by stir casting[J]. Foundry Equipment and Technology, 2009(4): 15-17, 43.

[20] 毛 成, 高文理, 苏 海, 卢 健, 陆 政. 搅拌铸造SiCp/A356复合材料的显微组织及力学性能[J]. 特种铸造及有色合金, 2010, 30(3): 256-259.

MAO Cheng, GAO Wen-li, SU Hai, LU Jian, LU Zheng. Microstructure and mechanical properties of SiCp/A356 aluminum matrix composites prepared by stirring casting[J]. Special Casting & Nonferrous Alloys, 2010, 30(3): 256-259.

[21] 苏 海, 高文理, 毛 成, 张 辉, 刘洪波, 卢 健, 陆 政. 搅拌铸造SiCp/2024铝基复合材料的显微组织与力学性能[J]. 中国有色金属学报, 2010, 20(2): 217-225.

SU Hai, GAO Wen-li, MAO Cheng, ZHANG Hui, LIU Hong-bo, LU Jian, LU Zheng. Microstructures and mechanical properties of SiCp/2024 aluminum matrix composite synthesized by stir casting[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 217-225.

[22] GUI M C, WANG D B, WU J J, YUAN G J, LI C G. Microstructure and mechanical properties of cast (Al-Si)/SiCp composites produced by liquid and semisolid double stirring process[J]. Materials Science and Technology, 2000, 16: 556-563.

[23] KANG C G, YOUN S W. Mechanical properties of particulate reinforced metal matrix composites by electromagnetic and mechanical stirring and reheating process for thixoforming[J]. Journal of Materials Processing Technology, 2004, 147: 10-22.

[24] AMIRKHANLOU S, NIROUMAND R. Synthesis and characterization of 356-SiCp composites by stir casting and compocasting methods[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S3): s788-s793.

[25] DONG Pu-yun, ZHAO Hai-dong, CHEN Fei-fan, LI Jun-wen. Microstructures and properties of A356–10%SiC particle composite castings at different solidification pressures[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(8): 2222-2228.

[26] BALAJI V, SATEESH N, HUSSAIN M M. Manufacture of aluminium metal matrix composite (Al7075-SiC) by stir casting technique[J]. Materials Today Proceedings, 2015, 2(4/5): 3403-3408.

[27] KALA H, MER K K S, KUMAR S. A review on mechanical and tribological behaviors of stir cast aluminum matrix composites[J]. Procedia Materials Science, 2014, 6: 1951-1960.

[28] SONG Jing-ya, GUO Qiang, OUYANG Qiu-bao, SU Yi-shi, ZHANG Jie, LAVERNIA E J, SCHOENUNG J M, ZHANG Di. Influence of interfaces on the mechanical behavior of SiC particulate-reinforced Al-Zn-Mg-Cu composites[J]. Materials Science and Engineering A, 2015, 644: 79-84.

Microstructure and properties of derived material for high content SiCp/A356 composites

PAN Li-ke, HAN Jian-min, ZHANG Ying-xiao, YANG Zhi-yong, LI Zhi-qiang, LI Wei-jing

(School of Mechanical, Electronic and Control Engineering, Beijing Jiaotong University, Beijing 100044, China)

Abstract: SiCp/A356 composites with high content of 40% (volume content) were prepared by vacuum semi-solid stirring method, and the derived composites with 10%, 20%, 30% (volume content) particle content were prepared by dilution method with 40% (volume content) composites. By comparing the derived materials prepared by dilution of high content composites with the stirred material, prepared by direct stirring casting, it is found that the macroscopic fracture surface quality and particle distribution of the derived material are better than those of stirred material with the same particle size. The porosity, hardness and mechanical properties of the different particle content have dilution effect, that is, the lower the particle content, the smaller the corresponding value. The hardness of derived material is 3%-5% higher than that of the stirred material, and the mechanical properties of derived material are 9%-13% higher than those of the stirred material at the same SiC content.

Key words: SiCp/A356 composites; stirred material; derived material; semi-solid; stirring casting

Foundation item: Project(2015BAG12B01-09) supported by the National Science and Technology Pillar Program; Projects(51371022, 51271014) supported by the National Natural Science Foundation of China; Project(2015JBM076) supported by the Fundamental Research Funds for the Beijing Jiaotong University, China

Received date: 2015-12-04; Accepted date: 2016-04-10

Corresponding author: HAN Jian-min; Tel: +86-10-51683300; E-mail: jmhan@bjtu.edu.cn

(编辑 龙怀中)

基金项目:国家“十二五”科技支撑计划资助项目(2015BAG12B01-09);国家自然科学基金资助项目(51371022,51271014);北京交通大学基本科研业务费资助项目(2015JBM076)

收稿日期:2015-12-04;修订日期:2016-04-10

通信作者:韩建民,教授,博士;电话:010-51683300;E-mail: jmhan@bjtu.edu.cn