文章编号:1004-0609(2009)10-1754-05

多道次热压缩过程中7050铝合金的再结晶行为

李俊鹏,沈 健,闫晓东,毛柏平,闫亮明

(北京有色金属研究总院,北京 100088)

摘 要:采用Gleeble1500D热模拟实验机按设计的轧制工艺对7050合金进行压缩试验,模拟其多道次热轧过程,采用光学金相显微镜和透射电镜研究不同冷却条件下变形量为80%时试样的显微组织。结果表明:在热压缩过程中,合金未发生明显动态再结晶;合金在压缩后缓冷过程中发生静态再结晶,晶界形核和亚晶合并长大为其主要形核机制;合金中的Al3Zr粒子会阻碍晶界和亚晶界的移动,从而抑制再结晶和再结晶后的晶粒长大。

关键词:7050铝合金;再结晶;形核机制;第二相

中图分类号:TG111.7; TG146.2 文献标识码: A

Recrystallization behavior of 7050 aluminum alloy during multi-pass hot compression process

LI Jun-peng, SHEN Jian, YAN Xiao-dong, MAO Bai-ping, YAN Liang-ming

(General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: Hot compression tests of 7050 aluminum alloy was carried out on Gleeble1500D thermo-mechanical simulator according to the designed rolling processes to simulate the multi-pass hot rolling process. The microstructural features of the samples deformed to a reduction of 80% under different cooling conditions were investigated by OM and TEM. The results show that the dynamic recrystallization is not activated during the hot compression process, however, static recrystallization takes place during slow cooling after hot compression in which the main nucleation mechanisms are strain induced grain boundary migration(SIBM) and sub-grain coalescence and growth. The migration of grain and sub-grain boundaries can be retarded by the Al3Zr particles in the alloy, therefore, recrystallization process and grain growth after recrystallization process are restrained.

Key words: 7050 aluminum alloy; recrystallization; nucleation mechanism; second phase

铝合金热轧的显微组织由热轧时及热轧间隔过程中的回复与再结晶所决定,并对热处理后合金的显微组织与性能产生影响[1-4]。对7×××系高强高韧铝合金而言,了解其热加工过程中微观组织变化对其最终使用性能的控制非常重要。7050合金是Alcoa铝业公司20世纪研制出的优质铝合金,具有高强、高韧和耐腐蚀等优良的综合性能,是目前航空、航天领域广泛采用的一种轻型结构材料,广泛应用于制造飞机的重要结构件[5-6]。目前,7050合金的研究热点多集中在合金铸锭的制备、微合金化和通过优化热处理工艺综合提高其力学性能和抗应力腐蚀性能等方面,对其热加工工艺特别是多道次热轧过程的研究相对较少[1-8]。本文作者对7050合金进行多道次平面应变压缩实验,模拟了工业轧制过程,通过观察热压缩后不同冷却条件下7050铝合金的显微组织,研究变形后不同冷却条件下合金中再结晶行为,分析再结晶的形核机制和第二相粒子对其再结晶行为的影响。

1 实验

试验样品取自西南铝业(集团)提供的铸造扁铸锭,铸锭化学成分如下(质量分数,%):Zn6.00,Mg2.20,Cu2.24,Zr0.10,Mn0.10,Fe0.12,Si0.03,w(Cr)<0.04,w(Ni)<0.05,w(Ti)<0.06,余量为Al。试样经470 ℃,32 h均匀化处理后,加工成10 mm×20 mm×15 mm的长方体平面应变压缩试样,其中高度15 mm为铸造厚度方向。

在Gleeble-1500D热模拟机上进行多道次平面应变压缩试验,将长方体试样10 mm×20 mm面上贴石墨片,以减少摩擦的影响。参考工业生产其他高强铝合金的轧制工艺拟定轧制工艺,在工艺制定过程中,结合生产实际情况,除考虑变形温度外,综合考虑各道次应变量、应变速率及道次间隔时间,按该工艺进行多道次热压缩实验,热压缩开始温度为410 ℃,终了温度为390 ℃;应变速率和道次间隔时间均随道次增加而增大,应变速率介于0.3~4.7 s-1之间,道次间隔时间介于15~45 s之间。样品通过电阻直接加热,压缩过程中通过程序设定保持相应的温度,在道次间隔过程中调整到下一个轧制道次的轧制温度。

经19道次后,将试样压缩至总压下量80%,热压缩实验完成后,分别对样品进行快速水淬(快冷)和自然冷却(缓冷)。采用金相显微镜和透射电镜对不同冷却条件的试样进行观察,观察部位为法向与压缩轴垂直的纵截面的中部区域。

2 实验结果

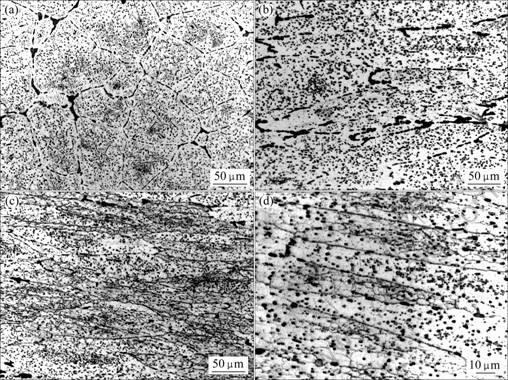

图1所示为7050合金热压缩前和热压缩后的金相显微组织。7050合金压缩前(均匀化处理态)的显微组织如图1(a)所示,视场内未观察到大量的非平衡共晶,铸态组织中存在的网状晶界化合物不再连续,晶界较细,合金的平均晶粒尺寸为72 μm,可以满足轧制生产要求。图1(b)所示为7050合金热压缩后快冷后的显微组织。由于冷却速度较快,可认为这是热压缩刚结束时的显微组织,由图中可以观察到当变形量为80%时(应变为-1.85),晶粒的压扁拉长现象较大,但晶界较平直,没有发生动态再结晶的迹象。图1(c)和(d)所示为7050合金热压缩后缓冷的显微组织。由图1(c)中可看出,空冷后合金的显微组织仍呈现明显的压扁状,但与图1(b)所示合金的显微组织明显不同,局部晶界呈现锯齿状特征,在某些晶粒的边缘及内部可以发现明显的再结晶组织。由图1(d)中可看出,再结晶晶粒尺寸较小,约为2~5 μm。

图1 不同状态下7050合金的显微组织

Fig.1 Microstructures of 7050 samples under different conditions: (a) Uniform heat treatment; (b) Water quenched after deformed to reduction of 80%; (c), (d) Slow cooling after deformed to reduction of 80%

为进一步研究热压缩中以及热压缩后7050合金的再结晶现象,对累计变形量为80%不同冷却方式合金的显微组织进行了透射电镜观察。图2所示为变形量为80%不同冷却方式合金的典型TEM像。图中孔洞为双喷制样过程中第二相脱落所致。其中热压缩后急冷试样的TEM组织如图2(a)和(b)所示。由图2(a)可以发现在此状态下,晶粒内存在大量亚晶,但亚晶之间的取向差较小,由图2(b)中也可以观察到同样的现象。在图2(b)中可以观察到在两个晶粒的中间存在一尺寸较大的亚晶,约为3 μm,其一侧的亚晶界明显弓出,存在向周围亚晶长大的迹象,表明这是再结晶核或动态再结晶晶粒。

图2 变形量为80%时7050合金在不同冷却条件下的TEM像

Fig.2 TEM images of 7050 samples deformed to reduction of 80% under different cooling conditions: (a), (b) Water quenched; (c), (d) Slow cooling

图2(c)和(d)所示为热压缩后缓冷试样的TEM像。由图2(c)可以看出,在部分亚晶界上存在较多细小的析出相,其尺寸约为80 nm,研究表明此析出相为均匀化过程中析出的Al3Zr粒子[7-8]。在图2(c)中右侧也可以观察到一再结晶晶粒的晶界呈弓形插入相邻的晶粒,其弓形晶界处可观察到第二相存在的迹象。在图中左侧可观察到一较平直原始晶界,其上分布大量第二相。在图2(d)中可以观察到存在两个与两侧基体取向差较大的再结晶晶粒,其位置处于两原始晶粒的交界处,其大小界于2~4 μm之间;在这两个晶粒下方存在另一再结晶晶粒,可观察到亚晶合并的迹象。在图2(d)中可明显地观察到图片下方的原始晶界,晶界较平直,且分布有尺寸界于0.5~2.0 μm之间的第二相。

3 分析与讨论

3.1 7050合金多道次热轧过程中的再结晶行为及形核机制

在热加工过程中,加工硬化和由于回复和再结晶产生的软化决定了其流变应力大小与显微组织演化,并影响在后续加工和热处理过程中的组织和性能演化。在7050合金的多道次热轧过程中,在轧制时可能会发生动态回复或动态再结晶,在轧制道次间发生静态回复或静态再结晶,变形参数如应变速率、应变温度、应变量和合金中存在的析出相和夹杂等以及变形后的材料的温度和冷却方式均会对其产生复杂的影 响[1-3, 9-10]。

在总变形量为80%变形后,急冷的7050合金的OM象中(见图1(b))未观察到明显动态再结晶的迹象;而在变形后缓冷合金中的OM组织中(见图1(d))可以观察到大量的再结晶组织,表明热压缩后缓冷过程中发生了再结晶。

虽未在变形后急冷的7050合金的OM组织中观察到再结晶现象的发生,但在其TEM组织观察过程中,发现了再结晶核,如图2(b)中所示。这表明在变形过程中,已经形成再结晶核心,只是由于单道次变形时间较短(0.03 s),动态再结晶过程只处于形核阶段,即再结晶核尚未能长大成再结晶晶粒。在热变形后,由于不再需要形核孕育期,这些再结晶核会造成突发性静态再结晶,这种再结晶也称为亚动态再结 晶[9-10],因此,在变形后缓冷的试样中可观察到大量的再结晶组织(见图1(c)和(d))。

由图2(c)可以发现,新形成的再结晶晶粒分布于原始晶界处,晶界存在明显的弓弯现象,且与一侧的原始晶粒取向差较小,表明晶界形核(应变诱导晶界移动,SIBM)为其再结晶形核机制之一。SIBM的重要条件之一为晶界两侧位错密度存在较大差别,通常认为当冷变形量较小时,易按此种机制形核[9]。然而,在7050合金的多道次热轧模拟实验过程中,合金在压缩后仍处于高温状态(390 ℃),在其后缓冷过程中合金可进行静态回复,从而造成位错密度的差异,这种位错密度差异成为晶界弓弯的驱动力,促成了再结晶核的形成。

由图1(d)和2(d)可以观察到,原始晶粒内部也存在再结晶晶粒,在图2(d)中还可以观察到亚晶合并的迹象,图像衬度显示再结晶晶粒与原始晶粒存在较大的取向差,这表明亚晶合并长大为其静态再结晶机制。研究表明,在7050合金热压缩后缓冷时,合金将进行静态回复,在回复过程中,亚晶通过吞并与其邻接的其他亚晶以减少亚晶界面能,这种吞并过程也使得长大的亚晶与邻近亚晶的取向差变大[11-14],减少了亚晶随后连续长大的阻力。当亚晶达到一定尺寸后便成为再结晶核。

3.2 第二相粒子对再结晶行为的影响

均匀化处理后的7050合金中,存在着大小不同的第二相粒子,包括尺寸为0.5~2 μm较粗大的第二相如平衡相(MgZn2(η)相)与少量Al2CuMg(S)相等和均匀化过程中析出的尺寸为50~100 nm的Al3Zr粒子[7-8, 15]。这些粒子的存在会影响再结晶以及再结晶后晶粒的 长大。

研究表明,粗大第二相粒子的存在有利于再结晶形核,其原因为:粗大的第二相粒子与基体不存在共格关系,在变形过程中,在这些粗大的第二相周围形成了强烈的晶格畸变区,该区域的亚晶大小不一,且取向差较大,亚晶内位错密度较高,由此可提供较大的亚晶界迁移驱动力,促进再结晶形核[9-10]。然而,在本实验过程中,在图2(d)的下部区域可观察到原始晶界上存在较多尺寸为0.5~2.0 μm之间的第二相,但第二相的周围区域均未观察到再结晶现象。表明本实验条件下,尺寸为0.5~2.0 μm之间的第二相不能促进再结晶的形核。也有研究认为[12, 14],在铝合金中粒子促进形核(Particle stimulated nucleation, PSN)通常发生在低温高应变速率下。本实验过程中发现合金中存在的尺寸为10 μm左右的夹杂周围产生了明显的再结晶组织,也验证了NES等[9, 16]提出的PSN机制存在粒子的临界尺寸现象。

在7050合金均匀化过程中析出细小的Al3Zr粒子,粒子细小且分布弥散,Al3Zr粒子的存在会阻碍位错的运动、亚晶界及晶界的迁移[7-8, 15]。在合金的TEM观察过程中(见图2(d))可观察到大量的Al3Zr分布在亚晶界和再结晶晶界上,表明Al3Zr的存在可有效地阻碍亚晶界与再结晶晶界的移动,因而会抑制再结晶形核和再结晶后晶粒的长大。

4 结论

1) 在7050合金多道次热轧实验中,当总变形量为80%时,在热压缩中未发生动态再结晶;热压缩后缓冷过程中发生了静态再结晶,晶界形核和亚晶合并长大为其主要的形核方式。

2) 7050合金中存在的尺寸为0.5~2.0 μm之间的第二相不能促进再结晶的形核,Al3Zr粒子会抑制再结晶形核和再结晶晶粒长大。

REFERENCES

[1] SHERCLIFF H R, LOVATT A M, JENSEN D J, BEYNON J H. Modeling of microstructure evolution in hot deformation[J]. Philosophical Transactions: Mathematical, Physical and Engineering Sciences, 1999, 357(1756): 1621-1643.

[2] 林高用, 杨 伟, 孙利平, 彭大暑. Al-Zn-Mg-Cu-Cr合金厚板组织细化[J]. 中国有色金属学报, 2008, 18(8): 1423-1439.

LIN Gao-yong, YANG Wei, SUN Li-ping, PENG Da-shu. Structures refinement of Al-Zn-Mg-Cu-Cr alloy thick plates[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(8): 1423-1439.

[3] RICKS R A, HOWE A, BROWN L M, BEYNON J H, HANSEN N. The deformation models needed by the aluminum industry[J]. Philosophical Transactions: Mathematical, Physical and Engineering Sciences, 1999, 357(1756): 1513-1529.

[4] ROBSON J D. Micro-structural evolution in aluminum alloy 7050 during processing[J]. Mater Sci Eng A, 2004, 382(1/2): 112-121.

[5] MUKHOPADHYAY A K. High strength aluminum alloys for structural application. Metals materials and processes[J]. Metals Materials and Processes, 2007, 119(1): 1-26.

[6] 陈昌麒. 超高强铝合金的发展[J]. 中国有色金属学报, 2002, 12(Special): 22-26.

CHEN Chan-qi. Development of ultra-high strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(Special): 22-26.

[7] 赵志浩, 王 静, 左玉波, 崔建忠. 均匀化处理对低频电磁铸造7050铝合金微观组织的影响[J]. 金属学报, 2007, 43(9): 956-960.

ZHAO Zhi-hao, WANG Jing, ZUO Yu-bo, CUI Jian-zhong. Effect of homogenization treatment on the microstructure of low frequency electromagnetic casting 7050 aluminum alloy[J]. Acta Metallurgica Sinica, 2007, 43(9): 956-960.

[8] 贺永东, 张新明, 游江海. 7A55合金均匀化处理[J]. 中国有色金属学报, 2006, 16(4): 638-644.

HE Yong-dong, ZHANG Xin-ming, YOU Jiang-hai. Homogenizing treatment of 7A55 alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(4): 638-644.

[9] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena[M]. Oxford: Pergamon Press, 2000.

[10] DOHERTY R D, HUGHES D A, HUMPHREYS F J, JONAS J J, JUUL-JENSEN D, KASSNER M E, KING W E, MCNELLEY T R, MCQUEEN H J, ROLLETT A D. Current issues in recrystallization: a review[J]. Mater Sci Eng A, 1997, 238(2): 219–274.

[11] YAMAGATA H, OHUCHIDA Y, SAITO N, OTSUKA M. Nucleation of new grains during discontinuous dynamic recrystallization of 99.998 mass% aluminum at 453 K[J]. Scipta Materialia, 2001, 45(9): 1055–1061.

[12] MCQUEEN H J. Development of dynamic recrystallization theory[J]. Mater Sci Eng A, 2004, 387/389(12): 203-208.

[13] MCQUEEN H J, KASSNER M E. Comments on ‘a model of continuous dynamic recrystallization’ proposed for aluminum[J]. Scipta Materialia, 2004, 51: 461-465.

[14] KASSNER M E, BARRABES S R. New developments in geometric dynamic recrystallization[J]. Mater Sci Eng A, 2005, 410/411(11): 152-155.

[15] ROBSON J D, PRANGNELL P B. Modelling Al3Zr dispersoid precipitation in multi- component aluminium alloys[J]. Mater Sci Eng A, 2003, 352(1/2):240-250.

[16] VATNE H E, FURU T, ?RSUND R, NES E. Modelling recrystallization after hot deformation of aluminium[J]. Acta Materialia, 1996, 44(11): 4463-4473.

收稿日期:2008-10-25;修订日期:2009-05-31

通信作者:沈 健,教授级高级工程师,博士;电话:010-82241929;传真:010-62012579;E-mail: jshen@grinm.com

(编辑 龙怀中)