DOI:10.19476/j.ysxb.1004.0609.2018.08.14

FeCoCu预合金粉前驱体制备及性能

谢德龙,林 峰,方啸虎,秦海青,潘晓毅,陈 超,肖乐银

(中国有色桂林矿产地质研究院有限公司 广西超硬材料重点实验室,国家特种矿物材料工程技术研究中心,桂林 541004)

摘 要:通过共沉淀法制备FeCoCu预合金粉前驱体,对制备过程中的主要影响因素进行了探讨,并对前驱体的物相组成、微观形貌及加热分解行为进行表征与分析。结果表明,FeCoCu预合金粉前驱体的最佳制备工艺为:在沉淀剂草酸溶液浓度为1.0 mol/L时,反应体系的pH值为2.0,混合金属盐溶液浓度为1.0 mol/L,反应温度为50 ℃,在此条件时既有最高的收得率,也有较细的粉末粒度。SEM及XRD衍射结果表明,前驱体形貌为表面比较光滑的颗粒状,其主要物相是FeC2O4·2H2O、CoC2O4·2H2O、CuC2O4·nH2O等3种草酸盐结晶水合物。DSC曲线表明,前驱体在加热时存在着两个吸热峰,分别对应的是草酸盐沉淀物结晶水的脱水过程和草酸盐的热分解过程。

关键词:FeCoCu预合金粉;前驱体;制备;性能

文章编号:1004-0609(2018)-08-1603-06 中图分类号:TG454 文献标志码:A

目前,在大部分金刚石工具如锯片、钻头、绳锯等的生产过程中,均使用了相当比例的预合金粉[1]。预合金粉的最大优点在于每个粉末颗粒都包含了各种组元,均匀性相当好,因此在使用预合金粉时,将从根本上避免成分偏析,可显著提高金刚石工具胎体的多种优异性能。韩平等[2]指出由于预合金化降低了烧结过程中金属原子扩散所需的激活能,将有效降低烧结温度,缩短烧结时间,从而降低金刚石工具的生产成本。

在现有的预合金粉体系中,FeCoCu预合金粉的研究一直是个热点[3]。但由于Co价格昂贵,且属于国家战略性物质,不适合在金刚石工具中大量使用, 因此,开发出低钴甚至无钴预合金粉,具有重要意义。谢德龙等[4]对不同配比的FeCoCu的结构及烧结性能进行了对比分析,为低钴含量的预合金粉在金刚石工具中的应用提供了参考。

共沉淀法具有工艺简单、成本较低、制备出的粉末性能较好等优点[5-7],在FeCoCu预合金粉制备中被广泛采用。但是,对共沉淀法制备的FeCoCu预合金粉的研究主要集中在其烧结及在金刚石工具的应用方面,关于FeCoCu预合金粉前驱体的制备过程及前驱体的微观结构表征少有报道。预合金粉前驱体制备是共沉淀法工艺最核心的一个环节,影响到最终的预合金粉的成分、粒度、形貌及物相组成,对预合金粉的性能起着决定性作用。本文作者通过共沉淀法制备FeCoCu预合金粉前驱体,对共沉淀制备过程中的影响因素进行分析,通过XRD、SEM电镜对前驱体的物相组成及微观形貌进行分析,并通过热重分析对前驱体的加热分解行为进行探讨,为全面研究FeCoCu预合金粉前驱体及完善共沉淀法制备预合金粉前驱体提供理论依据和实验基础。

1 实验

1.1 FeCoCu预合金粉前驱体制备

实验采用共沉淀法制备FeCoCu预合金粉。Fe、Co和Cu的质量配比为65:15:20。按所述的各元素质量配比称取相应的氯化物原材料,分别溶于去离子水中,形成FeCl2·4H2O、CoCl2·6H2O和CuCl2·2H2O等水化合物,根据实验需要混合配制成一定浓度;另外,还要配制浓度为1.0 mol/L的草酸溶液。将金属盐溶液和草酸溶液通过加液釜以相同速率分别加入到反应釜中进行共沉淀反应,反应温度根据实验需要设定,充分搅拌后加入氨水溶液调整反应溶液的pH值,反应20 min后再静置沉淀2 h,获得FeCoCu复合草酸盐沉淀物。将沉淀物放置在PFD-0.7平板式过滤洗涤机中,用去离子水反复过滤、清洗,当清洗后的去离子水的电导率低于90 μS/cm时为合格。将前驱体产物放入真空干燥箱内,在110~120 ℃的温度区间内进行干燥处理。最后将干燥后的粉末置于JTRF-200/70-3型推杆式脱氧还原炉中进行锻烧还原处理,锻烧温度为550 ℃,锻烧时间为3.5 h。锻烧得到氧化物粉末后,再在NH3分解气保护下进行还原,分解气的流量为2.5 m3/h,还原温度为600 ℃,还原时间为50 min,通过还原得到FeCoCu预合金粉末。

在共沉淀法制备预合金粉前驱体的过程中,最重要的影响因素是反应体系pH值、溶液浓度及反应体系的温度[8]。因此,在确定沉淀剂草酸溶液的浓度为1.0 mol/L时,采用单因素实验方法,分别讨论pH值、溶液浓度、反应温度对前驱体制备的影响。

1.2 FeCoCu预合金粉前驱体性能表征

采用日本D/max-rA10型X射线衍射仪对FeCoCu预合金粉前驱体进行物相分析,确定其相结构及组成,衍射时采用Cu Kα辐射靶,扫描步长为0.02°,扫描范围20°~100°;用日本JSM-6700F型扫描电镜观察前驱体粉末的微观形貌;用德国生产的STA-449C型热分析仪对前驱体粉末进行差热分析,采用氩气气氛,升温速率为10 ℃/min,升温至1000 ℃结束。对于经锻烧还原处理得到的FeCoCu预合金粉,采用WLP-207-2型费氏粒度仪来测定预合金粉的粒度,并利用费氏粒度结果及粉末收得率(即实际得到的预合金粉的质量与理论应得到质量的比值)作为前驱体制备工艺好坏的一个判定依据。

2 结果与讨论

2.1 FeCoCu预合金粉前驱体制备影响因素分析

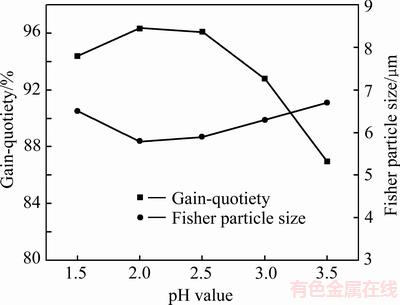

2.1.1 pH值影响

在金属离子浓度为0.8 mol/L、草酸溶液浓度为1.0 mol/L及反应温度为50 ℃时,反应体系pH值分别为1.5、2.0、2.5、3.0和3.5的FeCoCu预合金粉的收得率如图1所示。由图1可知,FeCoCu预合金粉的收得率随反应体系pH值的增大有较大的变化,先增加,到一定值后又开始下降。在pH值约为2.0时, 粉末收得率达到最大值, 为96.3%;在pH值为2.5时,粉末收得率为96.1%,变化不大;当pH值达到3.0时,粉末收得率开始明显降低;当pH为3.5时,粉末收得率下降到87%。pH值较小时,整个反应体系酸性较强,生成的草酸盐沉淀物草酸亚铁、草酸钴等更易于被酸溶解;随着pH值逐渐增大,沉淀物溶解开始下降,因此收得率逐渐变大。而当pH值过大时,生成的草酸盐沉淀物草酸亚铁、草酸钴等有一个反溶现象[9]。pH值越大,这种反溶过程就会加快,因此收得率会有较大的下降。FeCoCu预合金粉的粉末粒度随反应体系pH值的增大先缓慢减小,在pH值超过2.5时粉末粒度又呈增加趋势。pH值低于2.0时,共沉淀体系的过饱和度低,导致形核速率相对偏慢,其他离子易于在晶核上择优生长,因此粒度偏粗。当pH值在2.0至2.5时,此环境下晶粒的形核和生长达到一个平衡值,因此粉末颗粒相对变细。当pH值较高时,由于体系中氨水含量的增加,NH4+及OH-会与Fe2+、Cu2+、Co2+等离子产生络合反应,能产生多晶类球形团聚体颗粒[10],导致粉末粒度偏粗。综合来看,整个反应体系的pH值应控制在2.0比较合适。

图1 预合金粉收得率、粉末粒度与pH值的关系

Fig. 1 Relationships between gain-quotiety, particle size and pH value

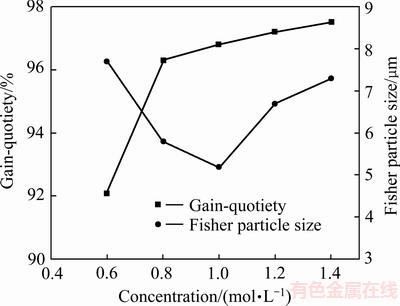

2.1.2 溶液浓度影响

在反应体系pH值为2.0、沉淀剂草酸浓度为1.0 mol/L及反应温度为50 ℃时,金属盐溶液浓度为0.6、0.8、1.0、1.2和1.4 mol/L的FeCoCu预合金粉的收得率及粉末粒度如图2所示。由图2可知,在共沉淀剂草酸溶液浓度不变的情况下,金属盐溶液的浓度越高,则预合金粉的收得率就越大。当混合金属盐溶液的浓度从0.6 mol/L上升至0.8 mol/L时,收得率增加较快,但超过0.8 mol/L后,预合金粉收得率的增加幅度变小。预合金粉末的费氏粒度随着金属盐溶液浓度的增加,出现先变大,到一定值后又减少的趋势。当混合金属盐溶液的浓度为1.0 mol/L时,FeCoCu预合金粉的费氏粒度最细,为5.2 μm。

图2 预合金粉收得率、粉末粒度与萃取浓度的关系

Fig. 2 Relationships between gain-quotiety, particle size and concentration

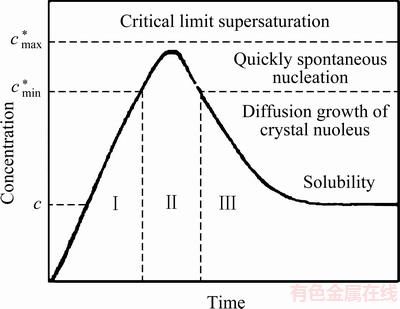

金属盐溶液浓度与粉末平均粒度的关系,可用Lamer模型进行解释。Lamer模型如图3所示。共沉淀法的制备过程可分为两个时期[11],一是晶核形成时期,二是晶粒长大时期。在图3中的第Ⅰ时间段内,反应体系内的溶质浓度随着时间的推移逐渐上升,但这个时期内还没有形成晶核。当溶质浓度达到c*min时,溶质出现过饱和,整个体系进入阶段Ⅱ,即形核阶段,在这一状态下,溶质浓度c仍稍有增加,之后由于快速形核的大量消耗,使溶质浓度c急剧降低,当溶质浓度c降回到c*min 时,形核阶段结束,并进入阶段Ⅲ,即生长阶段。由Lamer模型可知,当金属盐溶液浓度较低时,不仅形核率低,并且由于生成的晶核少,并不能引起晶核附近溶质的明显贫化,因此晶核将继续长大。但当金属盐溶液浓度较高时,会促使沉淀粒子聚集成大颗粒[12]。综合考虑溶液浓度对粉末收得率及粒度影响可知,混合金属盐离子的溶液浓度约为1.0 mol/L较为合理。

图3 Lamer模型

Fig. 3 Lamer model

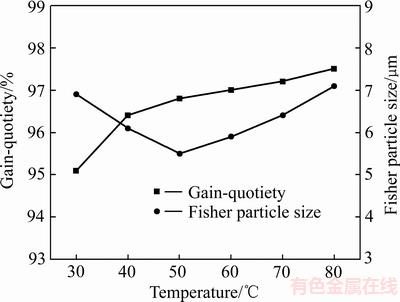

2.1.3 反应温度影响

反应体系pH值为2.0、混合金属盐浓度为1.0 mol/L、草酸溶液浓度为1.0 mol/L时,不同反应温度下的预合金粉的收得率及粉末粒度如图4所示。由图4可知,随着反应温度的升高,粉末收得率也逐步变大,当反应温度超过60 ℃后,增加幅度开始减小。反应温度升高,会影响整个体系的沉淀速度[13],在相同的反应时间内,温度越高,则体系的沉淀物就越多,因此粉末的收得率随着温度升高而增加。另外,随着反应温度的升高,粉末的费氏粒度先减小,在50 ℃达到极值点,随后又增加。依据成核速率公式[14]:

(1)

(1)

式中:I为晶粒成核速率;N为单位体积中的原子数;B为原子在某个晶核上的沉积概率;△Ga为原子在溶液扩散中的势垒;k为Boltzmann常数;T为温度;△Gk为形成晶核的平均势垒,可表示为

(2)

(2)

式中: 为晶核形成时的界面张力;M为晶粒的平均分子量;

为晶核形成时的界面张力;M为晶粒的平均分子量; 为沉淀物的密度;

为沉淀物的密度; 表示相变热焓;Te表示相变温度;

表示相变热焓;Te表示相变温度; 表示过冷度。

表示过冷度。

相对△Gk而言,△Ga在整个共沉淀过程中波动较小,一般情况下,可认为其不随共沉淀过程发生改变,即可视为常数。根据成核公式(1)和(2)可知,当提高整个反应体系的温度时,过冷度下降,因此形成晶核的平均势垒增大,不利于形核及结晶。但是,温度过高时,式(1)中的成核速率增大,即对晶核形成有利。由于这两个相反的因素在影响着成核速率,故存在一最佳温度点,使晶粒成核速率I呈最大值。在I最大值附近,成核数目多,因而能获得粒度最细的沉淀颗粒。

图4 预合金粉收得率、粉末粒度与反应温度的关系

Fig. 4 Relationships between gain-quotieties, particle size and temperature

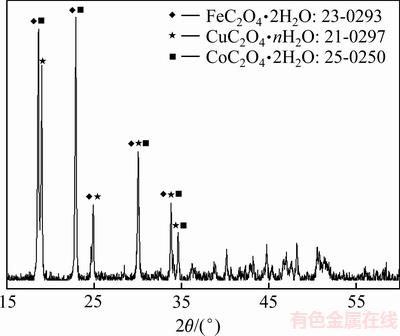

2.2 前驱体物相组成

图5所示为FeCoCu预合金粉前驱体的XRD谱。由图5可知,通过共沉淀反应得到的前驱体的主要物相为FeC2O4·2H2O、CoC2O4·2H2O、CuC2O4·nH2O等3种草酸盐结晶水合物。草酸铜中的结晶水分子数n是一个介于0到1间的不确定数值,其晶体结构是一种类似沸石的架状结构,水分子数与温度相关[15]。

图5 FeCoCu预合金粉前驱体的XRD谱

Fig. 5 XRD pattern of precursors of FeCoCu pre-alloyed powders

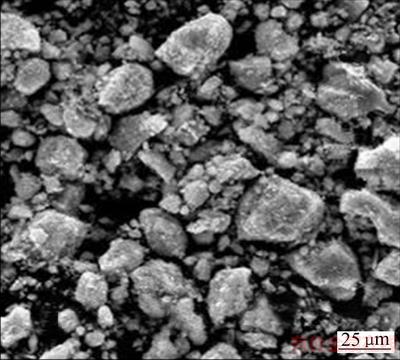

2.3 前驱体粉末形貌

图6所示为预合金粉前驱体的SEM像。由图6可知,前驱体为颗粒状,颗粒尺寸有一定的差别,这是因为前驱体为复合草酸盐共沉淀物,没有经锻烧和还原处理,部分颗粒依靠分子间作用力紧紧结合在一起,因此颗粒相对较粗。颗粒表面比较光滑,这是因为生成的复合草酸盐共沉淀物含有一定的结晶水,因此颗粒光滑且较为致密。

图6 FeCoCu预合金粉前驱体SEM像

Fig. 6 SEM image of precursors of FeCoCu pre-alloyed powders

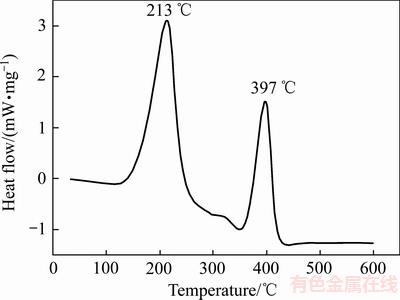

2.4 前驱体加热过程分解行为

图7所示为前驱体的DSC曲线。由图7可知,在DSC曲线上有两个明显的吸热峰。第一个吸热峰峰值为213 ℃,其对应的是草酸盐沉淀物结晶水的脱水过程[16]。第二个吸热峰峰值为397 ℃,其对应的是草酸盐的热分解过程[17]。由分析可知,FeCoCu前驱体加热时的分解主要有两步:

MC2O4·nH2O→MC2O4+nH2O↑ (3)

MC2O4→MO+CO2↑ (4)

式中:M代表Fe、Co、Cu等3种金属元素,加热后的前驱体在经过还原,即可得到FeCoCu预合金粉。

图7 FeCoCu预合金粉前驱体的DSC曲线

Fig. 7 DSC curve of precursors of FeCoCu pre-alloyed powders

3 结论

1) 在沉淀剂草酸溶液的浓度为1.0 mol/L时,65%Fe-15%Co-20%Cu预合金粉前驱体的合理工艺为:整个反应体系的pH值应保持在2.0,体系反应温度应为50 ℃,混合金属盐溶液浓度应为1.0 mol/L,在此条件时既有较高的收得率,也有较细的粉末粒度。

2) 共沉淀反应得到的前驱体的主要物相为FeC2O4·2H2O、CoC2O4·2H2O、CuC2O4·nH2O等3种草酸盐结晶水合物。

3) SEM像表明,FeCoCu预合金粉前驱体为表面光滑的颗粒状结构;DSC曲线表明,前驱体加时的分解主要分为两步,对应的分别为草酸盐深沉物结晶水的脱水过程及草酸盐的热分解过程。

REFERENCES

[1] 杨 展. 预合金粉胎体钻头性能的研究[J]. 青岛科技大学学报(自然科学版), 2013, 34(1): 71-75.

YANG Zhan. Performance of diamond bit matrix fabricated by pre-alloyed powder materials[J]. Journal of Qingdao University of Science and Technology (Natural Science Edition), 2013, 34(1): 71-75.

[2] HAN P, XIAO F R, ZOU W J, LIAO B. Influence of hot pressing temperature on the microstructure and mechanical properties of 75%Cu-25%Sn alloy[J]. Materials and Design, 2014, 53: 38-42.

[3] AN K. Pressure assisted master sintering surface of Co, Cu and Fe powder mixture[J]. Powder Technology, 2013, 234: 117-122.

[4] 谢德龙, 万 隆, 宋冬冬, 王 帅. 金刚石工具用FeCoCu预合金粉组成对烧结特性的影响[J]. 中国有色金属学报, 2016, 26(3): 577-585.

XIE De-long, WAN Long, SONG Dong-dong, WANG Shuai. Effect of composition of FeCoCu pre-alloyed powders on sintering characters used for diamond tools[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(3): 577-585.

[5] WANG Fang, LIU Ying-wei, GAN Yu-hua. Study on the modification of Cu-based catalysts with cupric silicate for methanol synthesis from synthesis gas[J]. Fuel Processing Technology, 2013, 110(18): 190-196

[6] 卫志强, 宋尚德, 王晓栋, 张 征, 吴建中, 李利民. 草酸盐共沉淀法制备金刚石金属结合剂[J]. 金刚石与磨料磨具工程, 2007, 159(3): 47-51.

WEI Zhi-qiang, SONG Shang-de, WANG Xiao-dong, ZHANG Zheng, WU Jian-zhong, LI Li-min. Preparation of diamond metal matrix by oxalate co-precipitation method[J]. Superhard Material Engineering, 2010, 22(2): 47-51.

[7] 潘 超, 秦海青, 吕 智, 王进保, 程 柳, 张振军, 陈 光. 并流共沉淀法制备铜锡镧复合预合金粉末的研究[J]. 超硬材料工程, 2010, 22(2): 35-39.

PAN Chao, QIN Hai-qing, Lü Zhi, WANG Jin-bao, CHENG Liu, ZHANG Zhen-jun, CHEN Guang. Study on Cu-Sn-La pre-alloyed powder made by coprecipitation[J]. Superhard Material Engineering,, 2010, 22(2): 35-39.

[8] 黄艳华, 贺跃辉, 谢志刚, 向 波. 金刚石工具用Ni-Co合金粉末的制备及表征[J]. 超硬材料工程, 2006, 18(5): 1-5.

HUANG Yan-hua, HE Yue-hui, XIE Zhi-gang, XIANG Bo. Preparation and characterization of Ni-Co alloyed powder used in diamond tools[J]. Superhard Material Engineering, 2006, 18(5): 1-5.

[9] 谢志刚, 秦海青, 刘心宇, 王进保, 蒋剑峰. 金刚石制品用FeCoCu预合金粉末的制备及应用研究[J]. 材料工程, 2011(3): 1-5.

XIE Zhi-gang, QIN Hai-qing, LIU Xin-yu, WANG Jin-bao, JIANG Jian-feng. Study on the preparation of the prealloyed powder and its application for diamond tools[J]. Materials Engineering, 2011(3): 1-5.

[10] 刘志宏. 镍钴草酸盐制备中的形貌与粒度控制[D]. 长沙: 中南大学, 2007: 17-25.

LIU Zhi-hong. Morphology and size control of nickel and cobalt oxalate particles[D]. Changsha: Central South University, 2007: 17-25.

[11] 黄艳华, 谢志刚, 贺跃辉, 向 波. 草酸盐共沉淀前驱体的热分解过程研究[J]. 粉末冶金材料科学与工程, 2007, 12(1): 35-38.

HUANG Yan-hua, XIE Zhi-gang, HE Yue-hui, XIANG Bo. Thermal decomposition process of oxalate coprecipitation precursor[J]. Materials Science and Engineering of Powder Metallurgy, 2007, 12(1): 35-38.

[12] LEI Jia-hang, YUAN Qi-hua, LUO Da-bing. Technology study of ZnO ultra-fine powder synthesized by oxalate thermal decomposition method[J]. Journal of Wuhan University of Technology, 1999, 21(4): 7-9.

[13] 贾佩云, 刘石明, 钱晓良. 共沉淀法合成超细陶瓷催化剂粉体[J]. 中国陶瓷, 2001, 37(5): 1-3.

JIA Pei-yun, LIU Shi-ming, QIAN Xiao-liang. Synthesis of fine ceramic powders by the co-precipitation method[J]. China Ceramics, 2001, 37(5): 1-3.

[14] 张传福, 邬建辉, 湛 菁, 黎昌俊, 戴 曦. 纤维状纳米镍粉前驱体的合成[J]. 有色金属, 2003, 55(3): 24-29.

ZHANG Chuan-fu, WU Jian-hui, ZHAN Jing, LI Chang-jun, DAI Xi. Precursor synthesis of fibrillar nanocrystalline nickel powder[J]. Nonferrous Metals, 2003, 55(3): 24-29.

[15] GAO X, CHEN D, DOLLIMORE D. Identification of solid solution of coprecipitated Ni-Co oxalates using XRD, TG and SEM techniques[J]. Thermochimica Acta, 1993, 220: 75-89.

[16] NIKUMBH A K, ATHARE A E, RAUT V B. A study of the thermal decomposition of cobalt(II) and nickel(II) oxalate dehydrate using direct current electrical conductivity measurements[J]. Thermochimica Acta, 1991, 186: 217-233.

[17] ZHANG Chuan-fu, ZHAN Jing, WU Jian-hui. Preparation of fibrous nickel oxide particles[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(6): 1441-1442.

Preparation and properties of FeCoCu pre-alloyed powder precursors

XIE De-long, LIN Feng, FANG Xiao-hu, QIN Hai-qing, PAN Xiao-yi, CHEN Chao, XIAO Le-yin

( Guangxi Key Laboratory of Superhard Materials, National Engineering and Technology Research Center for Special Mineral Materials, China Nonferrous Metal (Guilin) Geology and Mining Co., Ltd., Guilin 541004, China)

Abstract: The FeCoCu pre-alloyed powder precursors were manufactured by co-precipitation method and the major influence factors of the preparation process were discussed. The phase composition, microstructure and heating decomposition behavior were analyzed. The results show that the optimal preparation parameters are that the pH is 2.0, the solution concentration is 1.0 mol/L and the reaction temperature is 50 ℃ (when the concentration of the precipitant is 1.0 mol/L); under these conditions, the pre-alloyed powders have the highest gain-quotiety and the finest particle size. The SEM images show that the microstructure of the precursors is smooth particle and the XRD patterns show that the FeC2O4·2H2O, CoC2O4·2H2O and CuC2O4·nH2O are the main phases. The DSC curves show that two endothermic peaks exit in the heating process, which correspond to the crystal water dehydration and the oxalates decomposition, respectively.

Key words: FeCoCu pre-alloyed powder; precursor; preparation; property

Foundation item: Project(2017GXNSFBA198147) supported by the Natural Science Foundation of Guangxi Province, China

Received date: 2017-07-14; Accepted date: 2018-01-24

Corresponding author: LIN Feng; Tel: +86-773-5636866; E-mail: 569958378@qq.com

(编辑 何学锋)

基金项目:广西自然科学基金项目(2017GXNSFBA198147)

收稿日期:2017-07-14;修订日期:2018-01-24

通信作者:林 峰,教授级高工,博士;电话:0773-5636866;E-mail: 569958378@qq.com