文章编号:1004-0609(2015)04-0982-08

锌防护层修复涂料组分对防护性能的影响

田东波1,高 瑾1,李晓刚1,李辛庚2

(1. 北京科技大学 新材料技术研究院,北京 100083;

2. 国网山东省电力公司 电力科学研究院,济南 250002)

摘 要:基于锌防护层修复及钢结构防护的背景,针对一种锌防护层修复涂料,研究其组分(复合锌粉、有机-无机杂化改性剂)对涂层防护性能的影响,并与同类进口产品对比分析。结果表明:在颜基比(质量比)4:1时,随复合锌粉含量的增加,涂层的附着力增大;有机-无机杂化改性剂可有效提高涂层的附着力与耐蚀性;多形态复合锌粉涂层的耐蚀性优于球状复合锌粉涂层的。在热浸锌、电镀锌、Q235(St3)基材上,锌防护层修复涂层耐紫外大于2000 h,耐盐雾大于3000 h;且在Q235(St2)基材上耐盐雾大于2000 h,其防护性能远高于同类进口产品的。

关键词:低表面处理涂料;富锌涂料;锌防护层;有机-无机杂化;复合锌粉

中图分类号:TQ630.7 文献标志码:A

Effect of components of protective zinc layer repairing paint on protective performance

TIAN Dong-bo1, GAO Jin1, LI Xiao-gang1, LI Xin-geng2

(1. Institute of Advanced Materials and Technology, Beijing University of Science and Technology,

Beijing 100083, China;

2. Shandong Electric Power Research Institute, State Grid Shandong Electric Power Company, Ji’nan 250002, China)

Abstract: Based on the background of protective zinc layer repair and steel protection, one protective zinc layer repairing paint was studied. The influence of the components (compound zinc powder and organic-inorganic hybrid modifier) on coating performance was analyzed and compared. The results indicate that the coating adhesion increases with increasing the content of compound zinc powder at the pigment/binder mass ratio of 4:1, and the organic-inorganic hybrid modifier enhances the coating adhesion and corrosion resistance. Moreover, the coating with compound zinc powder of multiple forms has superior corrosion resistance than that of different spherical diameters. The resistance of UV accelerated aging and neutral salt spray on hot-dip zinc, galvanized steel sheet and Q235(St3) are more than 2000 h and 3000 h, respectively. The neutral salt spray resistance on Q235(St2) is longer than 2000 h, providing that it has higher protective ability than imported products.

Key words: surface-tolerant coating; zinc-rich paint; protective zinc layer; organic-inorganic hybrid; compound zinc powder

热浸锌、热喷锌、电镀锌、富锌涂料等锌防护层技术广泛用于钢结构的防护,在施工、应用过程中,锌防护层难免产生破损、缺陷,腐蚀失效首先在防护层的破损、缺陷处进行,特别是在沿海、重工业污染区等苛刻环境中[1-3],锌防护层失效大大加快,必须及时修补,否则影响设备安全服役。采用改性铈酸盐等对锌防护层进行表面钝化处理,仅可在一定程度上提高锌防护层的耐蚀性[4-5],且对于输电塔等大型钢结构,严格的表面处理难以实施。低表面处理的锌防护层修复涂层首先要能够对锌防护层阴极防护功能进行修补,其次要能与低表面能的电镀锌、热镀锌表面相容良好且附着性较好,对锌防护层破损锈蚀铁基的低处理表面附着良好并有效防护。富锌涂料具备阴极防护性,可考虑作为锌防护层修复体系;对于如何提高富锌涂料的性能国内外学者做了大量的研究,SCHAEFER等[6]添加纳米锌粉优化球状锌粉间导电性,ARIANPOUYA等[7]添加纳米粘土提高抗渗透性,GERGELY等[8-9]以聚吡咯包覆氧化铝和碳纳米管、AKBARINEZHAD等[10]将纳米粘土与纳米锌、聚苯胺复合,ARIANPOUYA等[11]将纳米粘土和纳米锌复合增加导电性及降低孔隙率;王宇池等[12]对片状、球状锌粉的复合添加进行了探讨,但未对二者在涂层中的耦合作用与防护机理进行深入研究;谢德明等[13]以电化学阻抗谱(EIS)技术研究了球状、鳞片状两种锌粉涂层的失效差异性。这些研究均取得一定效果,但均需在严格处理 (St2.5及以上) 表面进行涂装,低表面处理锌防护层修复涂料报道不多。高翔[14]和陈云等[15]利用双组分环氧树脂为成膜物,匹配鳞片状锌粉、有机转锈剂等制备的低表面带锈富锌涂层,在中性盐雾800 h时发生点蚀,其耐蚀性远不能满足工程需要。因而,开展与锌防护层具有较好相容性、防护性能较高的低表面处理锌防护层修复涂料的研制工作十分必要。

本文作者前期以含强极性基团的双组份三元共聚树脂为成膜物,匹配复合锌粉、防锈颜料,添加有机-无机杂化改性剂,制备在锌防护层、Q235(St3)及Q235(St2)基材上防护性能优异的锌防护层修复涂料。在此,本文作者研究涂料组分(复合锌粉、有机-无机杂化改性剂)对涂层防护性能的影响,并与同类进口产品对比分析,为高性能锌防护层修复涂料的应用奠定了基础。

1 实验

1.1 涂层制备

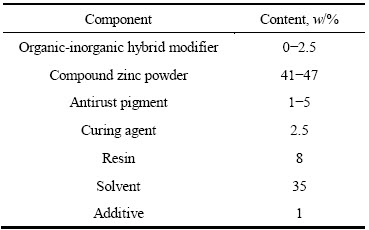

基体试样为Q235钢、电镀锌、热浸锌及锈蚀Q235钢,经100 μm砂纸磨制后(锈蚀Q235钢处理至St2级(即应存在一定锈蚀),用丙酮擦拭。手工刷涂,常温干燥小于4 h,得到涂层,放置7 d后进行中性盐雾、紫外加速老化试验及其他性能测试。涂料基本配方如表1所列。

1.2 涂层性能测试

涂层性能测试和参考标准如表2所列。

表1 涂料基本配方

Table 1 Basic recipe of paint

表2 涂层基本力学性能测试及参考标准

Table 2 General mechanical and protective performance test and referenced standards

2 结果与讨论

2.1 复合锌粉含量对涂层附着力的影响

涂层附着力是其防护性能的基础,颜料和成膜物的相对含量是影响涂层附着性能的重要因素。防锈颜料的合理添加是涂层对低处理表面金属基材有效防护的保证,因此,与一般富锌涂料不同,本文作者在锌防护层修复涂料中添加了多种防锈颜料。在颜基比(质量比)为4:1、有机-无机杂化改性剂含量为2.5%(质量分数)的情况下,改变球状复合锌粉与防锈颜料的相对含量,得到Q235(St2)与电镀锌板上涂层附着力随锌粉含量的变化规律如图1所示。

由图1可知,当复合锌粉含量在70%~80%(质量分数)范围内增加时,Q235(St2)及电镀锌上涂层中附着力逐步增大。

2.2 有机-无机杂化改性剂对附着力的影响

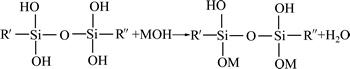

溶胶-凝胶法[16]制备的有机-无机杂化改性剂中部分—Si—OH可与金属基材表面形成化学键(见式1),从而提高涂层与基材的结合强度[17-18]。

图1 附着力随涂层中复合锌粉含量变化

Fig. 1 Changes of adhesion with compound-zinc content in coating

图2 附着力随有机-无机杂化改性剂含量的变化

Fig. 2 Changes of adhesion with amount of organic-inorganic hybrid modifier

(1)

(1)

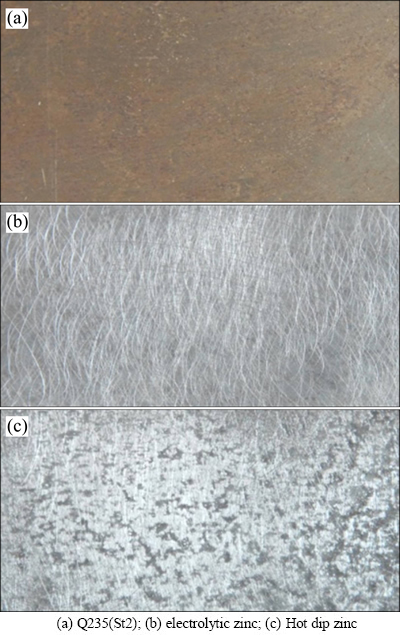

由图2可见,有机-无机杂化改性剂加入量对涂层在热浸锌、Q235(St2)、电镀锌上附着力影响显著。与未添加有机-无机杂化改性剂时相比,添加有机-无机杂化改性剂的涂层在热浸锌、Q235(St2)、电镀锌上的附着力均大幅提高。在Q235(St2)、镀锌板上,涂层附着力随有机-无机杂化改性剂含量的增加而增大,在热浸锌上,涂层附着力则呈现先增加后减小的趋势。这和基材的表面状态有关(见图3)。

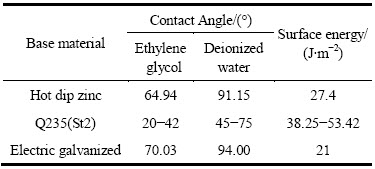

以去离子水、乙二醇为探测液体,测得两种液体在3种基材上的接触角代入热力学方程(2)和(3),解得涂装前3种基材的表面能[19]如表3所列。

图3 涂装前的基材宏观形貌

Fig. 3 Macroscopic morphologies of substrates before painting

表3 基材表面接触角与表面能

Table 3 Surface contact angle of substrates and surface energies

(2)

(2)

(3)

(3)

式中: 为气-液界面自由能,去离子水

为气-液界面自由能,去离子水 为72.8 J/m2,乙二醇

为72.8 J/m2,乙二醇 为48.3 J/m;

为48.3 J/m; 为气-液界面自由能的极性部分,去离子水

为气-液界面自由能的极性部分,去离子水 为51 J/m,乙二醇

为51 J/m,乙二醇 为19 J/m;

为19 J/m; 为气-液界面自由能的色散部分,去离子水

为气-液界面自由能的色散部分,去离子水 为21.8 J/m2,乙二醇

为21.8 J/m2,乙二醇 为29.3 J/m2;

为29.3 J/m2; 为固体表面自由能;

为固体表面自由能; 为固体表面自由能的极性部分;

为固体表面自由能的极性部分; 为固体表面自由能的色散部分。

为固体表面自由能的色散部分。

电镀锌结构较为致密、粗糙度较低,表面能最低(见表3),不利于涂料浸润,涂层附着力不高,随着有机-无机杂化改性剂含量的增加,其与电镀锌表面形成的化学键随之增多,涂层附着力也随之增大,当有机-无机杂化改性剂含量为2.5%(质量分数)时,涂层附着力达5 MPa。热浸锌具有较低的表面能,但其表面较为粗糙且多孔,涂层可以机械铆合的形式附着,附着力较大,当有机-无机杂化改性剂含量为0.75% (质量分数)时,涂层附着力可达17.8 MPa;但有机-无机杂化改性剂含量过高时,涂料固化反应加快,涂料在成膜过程中黏度升高较快,对热浸锌孔隙的渗透性降低,机械铆合作用减弱,附着力减小;当有机-无机杂化改性剂含量为2.5%(质量分数)时,涂层附着力仍可达到10 MPa左右;Q235(St2)表面能较高,有利于涂料浸润,随着有机-无机杂化改性剂含量的增加,附着力增大,但由于残余的锈层对涂层附着不利,涂层附着力增加有限;当有机-无机杂化改性剂含量为2.5%时,附着力达到11.6 MPa,加入有机-无机杂化改性剂可大幅提高涂层附着力。

考虑添加有机-无机杂化改性剂的涂层在3种基材上附着情况的差异性,选取有机-无机杂化改性剂添加量为1.8%(质量分数)的涂层进行性能测试。结果表明,涂层各项力学性能优异,附着力(划圈法)、耐弯曲性、耐冲击性等性能为该项性能的较优级。

2.3 有机-无机杂化改性剂对涂层防护性能的影响

2.3.1 耐中性盐雾性能

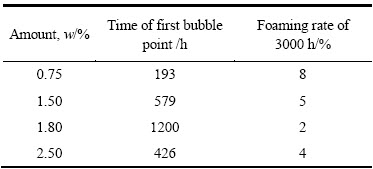

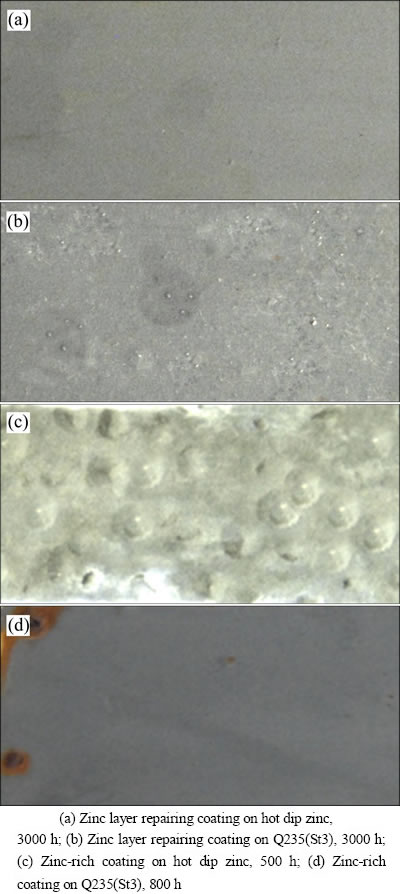

热浸锌表面不同有机-无机杂化改性剂含量的锌防护层修复涂层(厚度为(150±20) μm)中性盐雾试验后的表面形貌如图4所示,表4所列为涂层第一泡点出现时对应的中性盐雾试验时间及试验时间为3000 h时涂层起泡面积占涂层总面积的比例。由图4和表4可以看出,改性剂含量为1.8%的涂层耐中性盐雾性能最佳(2%局部起泡可能是涂层缺陷所致),且随有机-无机杂化改性剂含量的增加,涂层第一泡点中性盐雾试验时间呈现先增大后减小的趋势,而3000 h中性盐雾试验后涂层起泡比例呈现先减小后增大的趋势。

随有机-无机杂化改性剂含量增加,涂层耐蚀性呈现先增强后减弱的趋势。分析认为,有机-无机杂化改性剂以化学成键的形式提高涂层在基材表面的附着力(如前所述),且有机-无机杂化改性剂中的—OH与固化剂中—NCO反应,参与成膜,见式(4),增加膜的致密性,使涂层耐盐雾性提高;但当有机-无机杂化改性剂含量过高时,附着力大幅下降(见图2),使耐蚀性下降。综合考虑附着性能与耐中性盐雾性,有 机-无机杂化改性剂含量为1.8%的涂层性能最佳。

图4 中性盐雾试验后涂层宏观形貌(3000 h)

Fig. 4 Macroscopic morphologies of coating after 3000 h neutral salt fog experiment

表4 不同有机-无机杂化改性剂含量涂层防护性能

Table 4 Protective performance of coating with different amount of organic-inorganic hybrid modifier

(4)

(4)

2.3.2 耐紫外加速老化性能

热浸锌表面有机-无机杂化改性剂含量为0、1.8%的锌防护层修复涂层(厚度为(150±20) μm)加速老化试验后的宏观形貌如图5所示。由图5可看出,未添加有机-无机杂化改性剂的涂层800 h时,涂层开始泛白,出现轻微粉化;而有机-无机杂化改性剂含量为1.8%的涂层2000 h时,涂层颜色变浅,未出现粉化、锈蚀等现象。

对比可知,有机-无机杂化改性剂大大提高了涂层的耐老化性。分析其原因,有机-无机杂化改性剂参与了涂料的成膜交联反应(见式(4)),使涂层中含有了Si—O键,Si—O键能(446 kJ/mol)远大于C—C键能(358 kJ/mol),涂层耐老化性明显增强。

图5 紫外加速老化试验后涂层宏观形貌

Fig. 5 Macroscopic morphologies of coating after UV accelerated aging experiment

2.4 复合锌粉组分对涂层耐中性盐雾性能的影响

2.4.1 耐中性盐雾性能

在锌防护层破损锈蚀铁基处,复合锌粉组分对涂层防护行为的影响尤为重要。Q235(St2)表面不同复合锌粉组分的锌防护层修复涂层(厚度为(150±20) μm)中性盐雾试验后的宏观形貌如图6所示,采用球状复合锌粉的锌防护层修复涂层在中性盐雾试验800 h时出现起泡和点蚀,而采用多形态复合锌粉的锌防护层修复涂层在中性盐雾试验2000 h未见起泡和点蚀,采用多形态复合锌粉涂层的耐蚀性优于采用球状复合锌粉的涂层,这与锌粉在涂层中的空间分布有关。

图6 中性盐雾试验后涂层宏观形貌

Fig. 6 Macroscopic morphologies of coatings after neutral salt fog experiment

多形态复合锌粉中除不同粒径的球状锌粉外,还含有一定的片状锌粉,在涂料成膜过程中,片状锌粉的密度小于球形锌粉的,沉降速度慢,在成膜固化过程中,大部分片状锌粉堆积在涂层的上层,而球状锌粉堆积在下层,少量的片状锌粉散列其中。多形态复合锌粉涂层截面的SEM像如图7所示。在涂层表面片状锌粉(如图7中A所示)形成“迷宫效应”大大延长了腐蚀介质的扩散路径,使得涂层屏蔽性增强[20]。同时,涂层中片状锌粉的搭接作用(如图7中B所示)及不同粒径球状锌粉的紧密堆积(如图7中C所示)优化了锌粉间的电流传输作用,使阴极防护性增强,因而,涂层的耐蚀性得到提高。

图7 多形态复合锌粉涂层截面SEM像

Fig. 7 SEM image of section of polymorphous compound zinc powder coating

涂层中复合锌粉含量较低时,阴极防护性较弱;涂层中复合锌粉含量为80%时,防锈颜料含量降至1.6%(质量分数),涂层对低处理表面金属基材的防护性欠佳。复合锌粉含量为73%~78%(质量分数)时,涂层中锌粉的阴极防护作用与防锈颜料的防锈作用得到很好兼顾,Q235(St2)和Q235(St3)上涂层耐中性盐雾分别可达2000 h(见图6)和3000 h(见图8), 因此,涂层中复合锌粉含量在73%~78%范围内为宜。

2.4.2 与同类进口产品对比

Q235(St3)及热浸锌表面锌防护层修复涂层(厚度为(150±20) μm)及同类进口涂层(厚度为(150±20) μm)中性盐雾试验后的宏观形貌如图8所示。由图8可看出,经3000 h中性盐雾试验后,Q235(St3)和热浸锌上的锌防护层修复涂层仅出现轻微起泡;经500 h中性盐雾试验后,热浸锌上某进口富锌涂层已大面积起泡;经800 h中性盐雾试验后,Q235(St3)上某进口富锌涂层出现起泡及锈蚀。

锌防护层修复涂层具有如此高的耐蚀性,分析认为有以下3点原因:1) 采用的树脂是以氯乙烯、羟基乙烯醇、醋酸乙烯酯为单体的三元共聚树脂,含大量强极性基团—Cl,可以和基材良好附着;树脂中羟基和异氰酸酯类固化剂发生交联反应(如式(5))使漆膜致密性好。同时,生成的NH—CO键使树脂与填料及基材强力粘合;2) 添加的有机-无机杂化改性剂可在涂层-基材界面形成化学键,大大提高了涂层附着力,并可与异氰酸酯类固化反应,在涂层内部形成有机-无机杂化链段,引入高键能的Si—O键,大幅提高耐老化性;3) 多形态锌粉可在固化成膜过程中形成片状层与球状层的双层分布,涂层的屏蔽性及阴极防护性得到增强。

图8 中性盐雾试验后涂层宏观形貌

Fig. 8 Macroscopic morphologies of coating after neutral salt fog experiment

(5)

(5)

3 结论

1) 锌防护层修复涂层中复合锌粉含量由70%增加到80%(质量分数)时,涂层附着力逐步增加;多形态复合锌粉可在涂层中形成片状层、球状层的双层分布,涂层屏蔽性增强,且电流传输作用得到优化,阴极防护性增强,涂层耐中性盐雾性显著提高,Q235(St2)基材出现锈蚀的时间由800 h提高到2000 h以上。

2) 锌防护层修复涂料中有机-无机杂化改性剂可在涂层-基材界面处形成的化学键,在电镀锌、Q235(St2)、热浸锌表面涂层附着力分别可提高0.5倍、2.2倍、2.1倍;有机-无机杂化改性剂在涂层内部与异氰酸固化剂反应,形成有机-无机杂化链段,增强涂层致密性,提高涂层耐蚀性,在锌防护层、Q235(St3)上涂层的耐中性盐雾性3000 h后,引入高键能的Si—O键使涂层的耐老化性明显提高,紫外加速老化2000 h后仍未出现粉化、锈蚀,其防护性能远高于同类进口产品的,可用于大气环境中锌防护层的修复及复杂钢铁构件的长期防护。

REFERENCES

[1] 施彦彦, 张 昭, 张鉴清, 曹楚南. 锌及其合金的大气腐蚀研究现状[J]. 中国腐蚀与防学报, 2005, 25(6): 373-379.

SHI Yan-yan, ZHANG Zhao, ZHANG Jian-qing, CAO Chu-nan. Status of atmospheric corrosion research of zinc and its alloys[J]. Journal of Chinese for Corrosion and Protection, 2005, 25(6): 373-379.

[2] 李言涛, 刘建国, 侯保荣. 喷涂铝覆盖层在实海浪花飞溅区的腐蚀行为[J]. 中南大学学报: 自然科学版, 2011, 42(5): 1244.

LI Yan-tao, LIU Jian-guo, HOU Bao-rong. Corrosion behavior of sprayed aluminum coatings at splash zone[J]. Journal of Central South University: Science and Technology, 2011, 42(5): 1244.

[3] 屈 庆, 严川伟. Zn初期大气腐蚀中NaCl和SO2的协同效应[J]. 中国有色金属学报, 2002, 12(6): 1272-1276.

QU Qing, YAN Chuan-wei. The synergistic effect of NaCl and SO2 in the initial atmospheric corrosion of zinc[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1272-1276.

[4] 孔 纲, 吴 双, 林德鑫, 王 霞, 黎汉昌, 卢锦堂. 热镀锌层柠檬酸改进型铈盐转化膜的生长机理[J]. 中国有色金属学报, 2012, 22(5): 1390-1397.

KONG Gang, WU Shuang, LIN De-xin, WANG Xia, LI Han-chang, LU Jin-tang. Growth mechanism of cerium salt conversion coating modified with citric acid on galvanized steel[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1390-1397.

[5] 吴海江, 卢锦堂. 热镀锌钢表面铈转化膜的表征与腐蚀电化学行为[J]. 中国有色金属学报, 2011, 21(5): 1009-1015.

WU Hai-jiang, LU Jin-tang. Characterization and electrochemical corrosion behavior of cerium conversion coating on hot-dip galvanized steel[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 1009-1015.

[6] SCHAEFER K, MISZCZYK A. Improvement of electrochemical action of zinc-rich paints by addition of nanoparticulate zinc[J]. Corrosion Science, 2013, 66: 380-391.

[7] ARIANPOUYA N, SHISHESAZ M, ARIANPOUYA M, ASHRAFI A. Evaluation of synergistic effect of nanozinc/ nanoclay additives on the corrosion performance of zinc-rich polyurethane nanocomposite coatings using electrochemical properties and salt spray testing[J]. Surface and Coatings Technology, 2013, 216: 199-206.

[8]  E. Corrosion protection with zinc-rich epoxy paint coatings embedded with various amounts of highly dispersed polypyrrole- deposited alumina monohydrate particles[J]. Progress in Organic Coatings, 2013, 76(1): 17-32.

E. Corrosion protection with zinc-rich epoxy paint coatings embedded with various amounts of highly dispersed polypyrrole- deposited alumina monohydrate particles[J]. Progress in Organic Coatings, 2013, 76(1): 17-32.

[9] GERGELY A,  E. Novel zinc-rich epoxy paint coatings with hydrated alumina and carbon nanotubes supported polypyrrole for corrosion protection of low carbon steel: Part Ⅱ: Corrosion prevention behavior of the hybrid paint coatings[J]. Materials and Corrosion, 2013, 64(12): 1091-1103.

E. Novel zinc-rich epoxy paint coatings with hydrated alumina and carbon nanotubes supported polypyrrole for corrosion protection of low carbon steel: Part Ⅱ: Corrosion prevention behavior of the hybrid paint coatings[J]. Materials and Corrosion, 2013, 64(12): 1091-1103.

[10] AKBARINEZHAD E, EBRAHIMI M, SHARIF F, ATTAR M M, FARIDI H R. Synthesis and evaluating corrosion protection effects of emeraldine base PANi/clay nanocomposite as a barrier pigment in zinc-rich ethyl silicate primer[J]. Progress in Organic Coatings, 2011, 70: 39-44.

[11] ARIANPOUYA N, SHISHESAZ M, ASHRAFI A. Analysis of synergistic effect of nanozinc/nanoclay additives on the corrosion performance of zinc-rich polyurethane nanocomposite coatings[J]. Polymer Composites, 2012, 33(8): 1395-1402.

[12] 王宇池, 张小琴, 王永青, 韩力挥. 混合型水性无机富锌涂料的制备及其性能研究[J]. 化学与生物工程, 2013, 30(6): 52-55.

WANG Yu-chi, ZHANG Xiao-qin, WANG Yong-qing, HAN Li-hui. Preparation of mixed waterborne inorganic zinc-rich coatings and its performance study[J]. Chemistry & Bioengineering, 2013, 30(6): 52-55.

[13] 谢德明, 童少平, 冯 海, 张鉴清. 锌粒形态对富Zn涂层在3.5%NaCl溶液中电化学行为的影响[J]. 金属学报, 2005, 41(7): 769-774.

XIE De-ming, TONG Shao-ping, FENG Hai, ZHANG Jian-qing. Influence of the pigment shape on the electrochemical behaviors of zinc-rich paint coatings in 3.5%NaCl solution[J]. Acta Metallurgica Sinica, 2005, 41(7): 769-774.

[14] 高 翔. 低表面处理带锈富锌涂料及其中涂漆的制备及性能研究[D]. 长沙: 湖南大学, 2011: 32-35.

GAO Xiang. Preparation and performance of surface tolerant residual rust Zinc-rich coating and its intermediate coating[D]. Changsha: Hunan University, 2011: 32-35.

[15] 陈 云, 陈 新, 张文梅, 药宁娜. 输电铁塔防护用低表面处理涂料[J]. 腐蚀与防护, 2012, 33(5): 426-429.

CHEN Yun, CHEN Xin, ZHANG Wen-mei, YAO Ning-na. Tolerant coating for transmission tower protection[J]. Corrosion and Protection, 2012, 33(5): 426-429.

[16] 李爱坤, 李丽娅, 吴隆文, 易健宏. 溶胶-凝胶法制备SiO2包覆Fe85Si9.6Al5.4软磁复合粉末[J]. 中国有色金属学报, 2013, 23(4): 1065-1072.

LI Ai-kun, LI Li-ya, WU Long-wen, YI Jian-hong. Preparation of Fe85Si9.6Al5.4 soft magnetic composite powder with silica insulation coating by sol-gel method[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 1065-1072.

[17] 高红云, 张招贵. 硅烷偶联剂的偶联机理及研究现状[J]. 江西化工, 2003(2): 30-34.

GAO Hong-yun, ZHANG Zhao-gui. The coupling mechanism of silane coupling agent and research status[J]. Jiangxi Chemical, 2003(2): 30-34.

[18] 赵 平, 孙广霞, 杨玉鹏, 王 宏, 张发余. 有机硅烷偶联剂在涂装前处理中的应用[J]. 电镀与精饰, 2010, 32(3): 25-28.

ZHAO Ping, SUN Guang-xia, YANG Yu-peng, WANG Hong, ZHANG Fa-yu. Application of organic silane coupling agents on metal surface pretreatment for painting[J]. Plating and Finishing, 2010, 32(3): 25-28.

[19] 崔正刚. 表面活性剂、胶体与界面化学基础[M]. 北京: 高等教育出版社, 2013: 162-163.

CUI Zheng-gang. Surfactant, colloid and interface chemistry[M]. Beijing: Higher Education Press, 2013: 162-163.

[20] 杨振波, 杨忠林, 郭万生, 李运德, 师 华. 鳞片型醇溶性无机富锌涂料的研制及其防腐蚀性的研究[J]. 上海涂料, 2010, 48 (1): 1-4.

YANG Zhen-bo, YANG Zhong-lin, GUO Wan-sheng, LI Yun-de, SHI Hua. Development of alcohol-soluble flaky inorganic zinc-rich coatings and study on its anticorrosion mechanism[J]. Shanghai Coatings, 2010, 48(1): 1-4.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51071027,51133009)

收稿日期:2014-07-28;修订日期:2014-12-11

通信作者:高 瑾,研究员;电话:010-62333975-514;E-mail: g.jin@163.com