文章编号:1004-0609(2009)03-0439-06

纯镁表面真空扩散锌钇共渗层的组织及性能

王红霞1, 2,郭玉玲1, 2, 3,梁 伟1, 2,阴耀鹏1, 2,赵兴国1, 2

(1. 太原理工大学 材料科学与工程学院,太原 030024;

2. 太原理工大学 新材料界面科学与工程教育部重点实验室,太原 030024;

3. 晋中职业技术学院 机电工程系,榆次 030600)

摘 要:采用真空扩散锌钇共渗方法,在400 ℃下对纯镁进行表面合金化改性处理。采用OM、SEM、EDS、XRD和显微硬度、电化学腐蚀极化曲线测试等方法对渗层的组织结构、显微硬度和腐蚀性能进行分析。结果表明:表面合金化处理后,纯镁表面获得了致密的厚约2.7 mm的合金反应渗层,渗层由金属间化合物Mg7Zn3、α-Mg饱和固溶体、α-Mg和I-Phase(Mg40Zn55Y5 或Mg30Zn60Y10)片层共晶组织构成;该锌钇共渗层的显微硬度有很大的提高,并明显改善了纯镁在5% NaCl溶液中的耐腐蚀性能。

关键词:纯镁;锌钇共渗层;显微硬度;耐蚀性

中图分类号:TG 146.2.2 文献标识码:A

Microstructure and property of zinc-yttrium coating on pure magnesium by vacuum solid diffusion

WANG Hong-xia1, 2, GUO Yu-ling1, 2, 3, LIANG Wei1, 2, YIN Yao-peng1, 2, ZHAO Xing-guo1, 2

(1. College of Materials Science and Engineering, Taiyuan University of Technology, Taiyuan 030024, China;

2. Key Laboratory of Interface Science and Engineering in Advanced Materials, Ministry of Education,

Taiyuan University of Technology, Taiyuan 030024, China;

3. Department of Machine and Electric Engineering, Jinzhong Vocational Technology Institute, Yuci 030600, China)

Abstract: Surface modification treatment on pure magnesium was conducted at 400 ℃ by vacuum solid zinc-yttrium co-diffusing. The microstructure, microhardness and corrosion resistance of the zinc-yttrium co-diffusing layer were investigated by OM, SEM, EDS, XRD, microhardness test and electrochemical corrosion polarization curves test. The results show that the zinc-yttrium co-diffusing layer with an thickness of 2.7 mm forms on the surface of pure magnesium after surface modification treatment. The dense layer is composed of intermetallic compounds Mg7Zn3, α-Mg saturate solution, α-Mg and I-phase (Mg40Zn55Y5 or Mg30Zn60Y10) lamellar eutectic phases. The microhardness of the surface diffusion alloying layer increases significantly and its corrosion resistance in 5% NaCl solution also improves obviously.

Key words: pure magnesium; zinc-yttrium co-diffusing layer; microhardness; corrosion resistance

近年来,随着人们对材料可持续发展及节能环保要求的日益提高,镁合金以其轻量性(仅为钢铁1/4,铝合金2/3)、比强度高、导热性、减震性、可回收性、尺寸稳定性好等优势成为重点发展的绿色环保材料,并将逐渐取代塑料制品以利于回收,代替Fe、Al以减轻质量,从而在汽车及通讯电子领域应用得到强劲发展[1]。但是镁合金极低的耐腐蚀性能成为其进一步广泛应用的瓶颈。为此,世界各国开发了许多不同的表面处理工艺,以提高镁合金的耐腐蚀性能和耐磨性能[2],如化学转化处理、表面阳极化处理、气相沉积技术和表面磷化及激光化处理[3?7]等,但是这些方法都不同程度地存在一些问题,如涂层较薄、成本较高、工艺复杂、环境污染等。最近,有学者采用固态扩散渗或液相扩渗的方法实现了镁合金表面合金化。在纯镁、AZ91、ZM5等镁合金表面获得了渗铝、渗锌层[8?12],从而提高了材料表面的耐腐蚀性和耐磨性,但其耗时较长,渗层较薄。本文作者采用锌钇混合渗剂真空扩散渗方法在纯镁表面获得较厚的锌钇混合渗层,并研究锌钇混合渗层的组织结构、显微硬度和耐腐蚀性能。

1 实验

将工业纯镁线切割成尺寸为10 mm×10mm ×10mm的试样,先后采用600#、800#、1000# SiC砂纸打磨后,在丙酮溶液中超声波清洗10 min,去除纯镁表面的油污。所用渗剂是由粒度为75 μm,纯度分别大于99.5%的锌粉和纯度大于99.8%的钇粉按摩尔比6?1混合,将备好的试样用锌钇混合粉包埋于铁罐中并密封,再将铁罐置于真空度优于0.1 Pa的真空炉内加热,进行锌钇共渗处理。升温速度约为16 ℃/min,于(400±1) ℃保温90 min,保温结束后试样随炉冷却至室温。

试样经表面锌钇共渗处理后,采用MBA2100型光学金相显微镜和JEL6700?F型扫描电镜进行锌钇混合渗层组织结构观察及成分分析;使用KY?2000型X射线衍射仪对不同深度的锌钇混合渗层进行物相分析;利用PS?168A型电化学测试仪器在5%NaCl溶液中对试样进行腐蚀性能测试;使用HX?1型显微硬度计对锌、钇混合渗层进行显微硬度测试(载荷0.49 N,加载时间10 s)。

2 结果与讨论

2.1 渗层的显微组织及成分分析

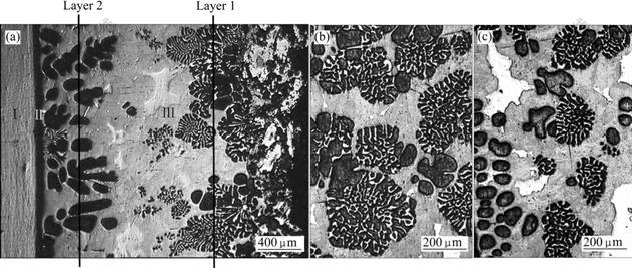

图1所示为真空炉内400 ℃条件下经90 min渗锌、钇(Zn,Y)处理后渗层区域截面组织的金相照片。从图1(a)可见,试样经400 ℃,90 min真空扩渗锌、钇处理后获得了厚2.7 mm的合金渗层,渗层由黑色过渡层Ⅱ和反应合金层Ⅲ组成。黑色过渡层Ⅱ厚度均匀,与基体Ⅰ及反应合金层Ⅲ结合面紧密而平整;反应合金层Ⅲ无明显显微裂纹和空洞出现,但层内组织变化较大,最外层为白色与黑色块状组织,次外层由灰色基体和由外向内生长的黑白相间的片状组织组成,此组织的侧面照片如图1(b)所示,灰色基体分布着团簇状的黑白相间片层组织及少量黑色块状组织。靠近过渡层处,形成由内向外的黑色树枝状组织,其侧面组织如图1(c)所示,灰色基体上,分布着少量团簇状的黑白相间片层组织和大量近于圆形的黑色块状组织及少量白色块状组织。

图1所示为真空炉内400 ℃条件下经90 min渗锌、钇(Zn,Y)处理后渗层区域截面组织的金相照片。从图1(a)可见,试样经400 ℃,90 min真空扩渗锌、钇处理后获得了厚2.7 mm的合金渗层,渗层由黑色过渡层Ⅱ和反应合金层Ⅲ组成。黑色过渡层Ⅱ厚度均匀,与基体Ⅰ及反应合金层Ⅲ结合面紧密而平整;反应合金层Ⅲ无明显显微裂纹和空洞出现,但层内组织变化较大,最外层为白色与黑色块状组织,次外层由灰色基体和由外向内生长的黑白相间的片状组织组成,此组织的侧面照片如图1(b)所示,灰色基体分布着团簇状的黑白相间片层组织及少量黑色块状组织。靠近过渡层处,形成由内向外的黑色树枝状组织,其侧面组织如图1(c)所示,灰色基体上,分布着少量团簇状的黑白相间片层组织和大量近于圆形的黑色块状组织及少量白色块状组织。

图1 纯镁表面扩散渗锌、钇层金相照片

Fig.1 Optical microscope photographs(OMP) of zinc-yttrium coating on pure magnesium: (a) Cross-section of zinc-yttrium coating; (b) Side of Layer 1; (c) Side of Layer 2

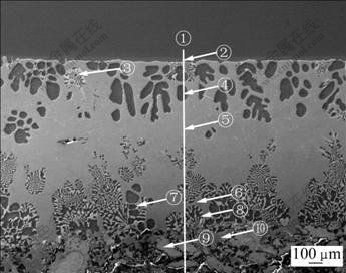

图2所示为扩渗试样横截面的SEM像。从图2中可清楚地看出渗层区域成分分布具有明显分形特征,即渗层区域成分分布不均匀,组织变化较大。为了量化分析不同位置的成分差异,对图2中的典型位置(如标号所示)进行了能谱分析,分析结果如表1所列。根据表1中所列的各点元素成分分析结果可知,图2中位置①为镁基体,位置②为渗层与基体的过渡层,厚约50 μm,从各元素的摩尔比可推出此组织为固溶了大量Zn、Y的α-Mg固溶体。在反应合金层中,由成分分析可知,位置④处的黑色块状组织为α-Mg饱和固溶体,连成基体的亮灰色组织,即位置⑤和⑥处组织,其成分基本接近,Mg、Zn摩尔比约为7?3,与Mg7Zn3相符,灰色基体上分布着的团簇状片层组织中位置⑧所指黑色层片也是α-Mg饱和固溶体,位置③和⑦白色层片成分明显不同,但都是镁、锌、钇化合物。根据能谱分析三元素摩尔比并结合文献[13?14],可推断③处可能为准晶相Mg40Zn55Y5(I相),⑦处可能为准晶相Mg30Zn60Y10(I相)。位置⑨处白亮块成分与位置⑦处相近,可能是准晶相Mg30Zn60Y10(I相),根据测定的摩尔比,外层灰色块状组织可能是固溶了少量钇的Mg7Zn3。

图2 纯镁表面扩渗锌、钇混合层横截面的扫描照片

Fig.2 Cross-sectional SEM image of zinc-yttrium coating on pure magnesium

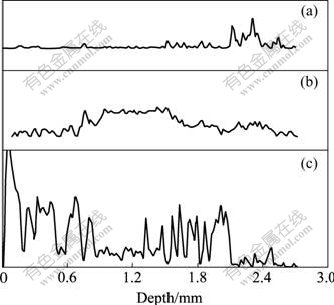

表1 图2所示各点成分分析结果

Table 1 EDS analysis results of representative zones shown in Fig.2

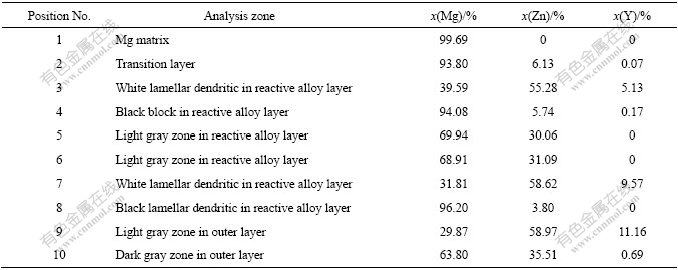

图3所示为沿着图2中白线所示渗层由基体向最外层的线扫描结果,从Mg元素的分布可知,在0 mm处,Mg基体处出现最高峰,在反应合金层0.2~0.8 mm和1.3~2.1 mm两个区段出现次高峰,说明这两个区段有大量α-Mg存在。而Zn、Y元素从约0.15 mm处,也就是过渡层处才开始出现。Zn元素在渗层中间区段含量最高,这与图2中此区段存在大量Mg7Zn3化合物一致;由基体向外层Y元素的浓度逐渐增加,在2.1~2.6 mm处浓度最高。故此段渗层有大量的镁锌钇化合物形成。

图3 渗层线扫描元素浓度分布图

Fig.3 Line scanning spectra corresponding to Fig.2: (a) Y; (b) Zn; (c) Mg

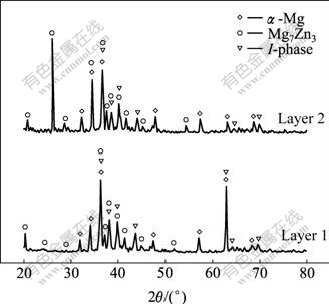

2.2 渗层的物相分析

为了进一步确定渗层组织中的物相,利用XRD对渗层的不同厚度处进行衍射分析。图4所示为纯镁表面渗锌钇层的X射线衍射谱,层1为渗层靠外组织层,层2为渗层靠内组织层,如图1(a)所示位置。从图4可知,层1和层2的物相主要为α-Mg、Mg7Zn3及少量I相,但是两层中各相的衍射强度不同,层1中α-Mg衍射强度明显强于层2,Mg7Zn3衍射强度又大大低于层2。由此可见,层1中含有较多的α-Mg,层2中含有较多的Mg7Zn3相。对比层1和层2中I相的衍射强度,层1中含有更多的I相。可见,渗层靠外边层1组织是由大量的α-Mg和I相片层状共晶组织及Mg7Zn3组成(见图1(b))。靠近基体层2的组织是由大量的Mg7Zn3和少量黑色块状α-Mg及α-Mg和I相片层状共晶组织组成,如图1(c)所示。

图4 纯镁表面扩散渗锌、钇混合层的XRD谱

Fig.4 XRD patterns of zinc-yttrium coating on pure magnesium

2.3 渗层形成过程分析

根据Mg-Zn-Y三元相图[15]可知,Mg、Zn共晶温度为340 ℃,Mg、Zn、Y三元共晶温度为400 ℃。在Zn、Y共渗的初始阶段,由于温度较低,Zn、Y原子以固态扩散方式进入纯镁表面。随着温度的升高,Zn、Y原子因活性增强而快速扩散进入纯Mg内部,同时离纯镁表面较远处的原子迅速补充进入镁合金内部原子位置。由于纯镁表面Zn、Y原子不断增多,造成局部熔点下降,当升温至340 ℃时,Mg、Zn接触的区域开始局部熔化,而Mg、Zn、Y三元素接触的区域仍为固态。在局部熔化区域,由于液体表面张力作用,Zn、Y原子更易于扩散,大量Zn、Y原子沿着由外向内的液相通道快速扩散至纯镁表面。温度进一步升高到400 ℃时,Mg、Zn、Y三元素接触的区域,也开始熔化,大量Zn、Y原子沿着此液相通道由外向内快速扩散至纯镁表面。随着纯镁表面渗入的Zn、Y原子进一步增多,熔融区域向深度和宽度两个区域扩展,熔融区域逐渐接触并连接起来,在温度达到400 ℃的一瞬间形成一层较薄但连续的液相层。在随后400 ℃保温过程中,Zn、Y原子通过液相层快速扩散并抵达纯镁深层,随即又形成一层液相层,使液相层加厚;当保温结束,纯镁表面液相层开始逐渐冷却凝固。Mg、Zn和Y的原子半径分别为1.72 ?、1.53 ?和2.27 ?,由于Mg、Zn原子半径相差不大,又同为密排六方结构,故Zn 在Mg中扩散比较快,Y的原子半径比Mg、Zn大,故Y在Mg中扩散较慢。在靠近镁基体处液相层中Mg、Zn含量高,Y含量低(见图3),所以首先析出黑色块状初生α-Mg相和少量α-Mg与I相的层片状共晶组织。在靠近渗层外侧液相中含Y量高(见图3),所以析出大量α-Mg与I相的层片状共晶组织,使Y含量迅速降低。当温度降到340 ℃时,整个合金反应层析出Mg7Zn3化合物,构成渗层基体。

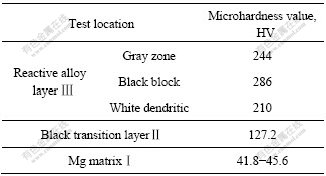

表2 经400 ℃真空扩散锌钇共渗90 min后试样的硬度值

Table 2 Microhardness values of specimen by vacuum solid zinc-yttrium co-diffusing for 90 min on pure magnesium at 400 ℃

2.4 渗层的显微硬度经(400±1) ℃保温90 min表面扩渗Zn、Y处理后,纯镁试样截面各区域显微硬度测试结果如表2所列。由表2可见,纯镁试样经表面扩渗Zn、Y处理后形成的反应合金层(Ⅲ区域)中灰色Mg7Zn3基体显微硬度达HV244,约为纯镁基体硬度的6倍,黑色块状饱和α-Mg固溶体显微硬度为HV210,白色I相枝晶显微硬度高达HV286,约为基体硬度的7倍,过渡层(Ⅱ区域)显微硬度达HV127.2,约为基体硬度的3倍。硬度大幅度提高主要是由于在试验条件下,通过扩渗Zn、Y处理实现纯镁表面合金化,使其表层区域的组织结构发生变化,形成大量金属间化合物Mg7Zn3和准晶相I相。这些高硬度合金相的存在对纯镁耐磨性的提高有积极作用。

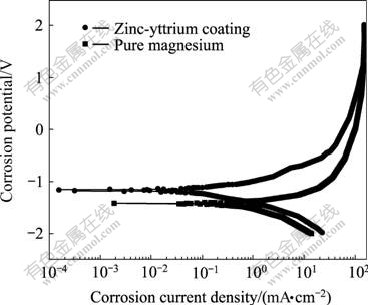

2.5 渗层的电化学腐蚀极化曲线

图5所示为纯镁及其真空扩散锌、钇共渗处理的试样在5%NaCl 溶液中的阳极极化曲线。由图5可以看出经过真空扩散锌、钇共渗后,试样表现出较正的自腐蚀电位,自腐蚀电位由纯镁的?1 459 mV提高到?1 240 mV,正移219 mV。自腐蚀电流密度从渗锌、钇前的2.10×10?2 mA/cm2变为1.93×10?4 mA/cm2,降低了约两个数量级。以上结果表明,经真空扩散锌钇共渗后,纯镁表面的耐腐蚀性能得到了明显的提高。这主要是由于纯镁经真空扩散锌、钇共渗处理后形成一层连续且较厚的反应合金层,合金层最外层的金属间化合物Mg7Zn3和准晶相I相的电极电位高于纯镁基体,隔离了盐水与基体的接触,减缓了试样的腐蚀速率。

图5 纯镁表面真空扩散渗Zn-Y前后的电化学腐蚀极化曲线

Fig.5 Electrochemical corrosion polarization curves before and after vacuum solid zinc-yttrium co-diffusing on pure magnesium

3 结论

1) 纯镁表面经400 ℃真空扩散Zn、Y共渗90 min后,表面获得厚2.7 mm的混合渗层,该渗层是合金反应层,由α-Mg饱和固溶体、Mg7Zn3和I相(Mg40Zn55Y5或Mg30Zn60Y10)组成,合金反应层最外层是由Mg7Zn3 和Mg30Zn60Y10组成的,厚约400 μm的金属间化合物层;次外层是以Mg7Zn3为基体,分布着大量α-Mg与Mg30Zn60Y10黑白相间的片层共晶组织和少量黑色块状α-Mg饱和固溶体的复合组织层;靠近过渡层的内层也是以Mg7Zn3为基体,分布着少量团簇状α-Mg与Mg40Zn55Y5的黑白相间片层共晶组织和大量近圆形的黑色α-Mg饱和固溶体及少量白色块状Mg30Zn60Y10的复合组织层。

2) 经真空扩散锌、钇共渗后,纯镁表面形成由大量合金化合物组成的渗层,使合金表面显微硬度从镁基体的HV 41.8~45.6升高到HV 210~286。

3) 真空扩散锌、钇共渗后,试样在5%NaCl水溶液的电化学腐蚀试验中表现出好的耐腐蚀性能。

REFERENCES

[1] MORDIKE B L, EBERT T. Magnesium properties- applications-potential[J]. Mater Sci Eng A, 2001, 302(1): 37?45.

[2] SONG Guang-ling. Recent progress in corrosion and protection magnesium alloys[J]. Advanced Engineering Materials, 2005, 7(7): 563?586.

[3] JIANG Y F, ZHAI C Q, LIU L F, ZHU Y P, DING W J. Zn-Ni alloy coatings pulse-plated on magnesium alloy[J]. Surface and Coatings Technology, 2005, 191(2/3): 393?399.

[4] CHONG K Z, SHIH T S. Conversion coating treatment for magnesium alloys by a permanganate phosphate solution[J]. Material Chemistry and Physics, 2003, 80: 191?200.

[5] FRANK H, RENATE W, JANA S. Characteristics of PVD coating on AZ31 hp magnesium alloys[J]. Surface and Coatings Technology, 2003, 162: 261?268.

[6] HOCHEN, SCHEERER H, PROBST D, BROSZEIT E, BERGER C. Plasma anodisation as an environmental harmless method for the corrosion protection of magnesium alloys[J]. Surface and Coatings Technology, 2003, 174: 1002?1007.

[7] IGNAT S, SALLAMAND P, GREVEY D, LAMBERTIN M. Magnesium alloys laser (Nd:YAG) cladding and alloying with side injection of aluminium powder[J]. Applied Surface Science, 2004, 225: 124?134.

[8] 刘奋成, 梁 伟, 赵兴国, 李线绒, 滕尚君. 纯镁表面真空扩散渗铝层的组织和性能[J]. 金属热处理, 2007, 3(25): 18?20.

LIU Feng-cheng, LIANG Wei, ZHAO Xing-guo, LI xian-rong, TENG Shang-jun. Microstructure and properties of aluminized layer on pure magnesium treated by vacuum solid diffusion[J]. Heat Treatment of Metals, 2007, 3(25): 18?20.

[9] 朱立群, 刘慧丛, 李卫平, 宋光龄. AZ91D 镁合金表面热扩散渗锌膜层研究[J]. 北京航空航天大学学报, 2005, 31(1): 8?12.

ZHU Li-qun, LIU Hui-cong, LI Wei-ping, SONG Guang-lin. Zinc alloyed coating on AZ91D magnesium alloys[J]. Journal of Beijing University of Aeronautics and Astronautics, 2005, 31(1): 8?12.

[10] 马幼平, 刘鹏飞, 温维新, 徐可为. 固态扩渗锌处理对纯镁表面组织和性能的影响[J]. 有色金属, 2005, 57(2): 29?31.

MA You-ping, LIU Peng-fei, WEN Wei-xin, XU Ke-wei. Effect of solid diffusion zinc treatment on microstructure and properties of alloyed layer of pure magnesium[J]. Nonferrous Metals, 2005, 57(2): 29?31.

[11] 谭成文, 郭冠伟, 王潇屹, 王富耻, 才鸿年. AZ31 镁合金表面液相渗铝的工艺与性能[J]. 中国有色金属学报, 2007, 17(7): 1053?1054.

TAN Cheng-wen, GUO Guan-wei, WANG Xiao-yi, WANG Fu-chi, CAI Hong-nian. Processes and properties of liquid aluminized coating on AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1053?1054.

[12] MA You-ping, XU Ke-wei, WEN Wei-xin, HE Xi-peng, LIU Peng-fei. The effect of solid diffusion surface alloying on properties of ZM5 magnesium alloy[J]. Surface and Coatings Technology, 2005(190): 165?170.

[13] 张金山, 杜宏伟, 梁 伟, 李天宝, 许春香, 王红霞. Mn对Mg-Zn-Y合金中准晶相凝固组织形貌的影响[J]. 稀有金属材料与工程, 2007, 36(3): 381?385.

ZHANG Jin-shan, DU Hong-wei, LIANg Wei, LI Tian-bao, XU Chun-xiang, WANG Hong-xia. Effect of Mn on solidification microstructure morphology of quasicrystal phase in Mg-Zn-Y alloy[J]. Rare Metal Materials and Engineering, 2007, 36(3): 381?385.

[14] LUO Z P, ZHANG S Q. On the stable quasicrystals in slowly cooled Mg-Zn-Y alloy[J]. Metall Mater Trans A, 1996, 27A(7): 1779?1784.

[15] LANGSDORF A, RITTER F, ASSMUS W. Determination of the primary solidification area of the iscosahedral phases in the ternary phases diagram of Mg-Zn-Y alloy[J]. Philo Mag Let, 1997, 75(6): 381?387.

基金项目:山西省大学生创新创业专项基金资助项目(07010727);山西省青年科技研究基金资助项目(2008021033);山西省归国留学基金资助项目(2007-25)

收稿日期:2008-06-10;修订日期:2008-09-10

通讯作者:梁 伟,教授;电话:0351-601839;E-mail: liangwei@tyut.edu.cn

(编辑 李向群)