文章编号: 1004-0609(2006)05-0919-05

采用固相还原法利用工业废渣治理铬渣

石玉敏1, 李俊杰2, 都兴红1, 隋智通1

(1. 东北大学 材料与冶金学院, 沈阳 110004;

2. 沈阳远大环境工程公司, 沈阳 110161)

摘 要: 采用高温固相还原法, 选用廉价工业废渣——鼓风炉渣M作还原剂, 利用M渣中残余的C将铬渣中主要以Na2CrO4形式存在的Cr(Ⅵ)还原成Cr(Ⅲ), 实现对铬渣的解毒处理。 研究了温度、 反应时间、 铬渣质量分数的影响, 确立了实验优化条件, 并对终渣的安全性进行了分析。 结果表明: 质量分数为23%的铬渣在1350℃反应2h, 终渣中Cr(Ⅵ)浸出值仅为0.063mg/L, 远低于国标GB5085.3—1996规定限值1.5mg/L, 该方法简单、 以废治废、 解毒彻底, 并利用终渣制备了高掺量废渣空心砌块, 强度等级达到《GB 8239—1997普通混凝土小型空心砌块》MU7.5要求, 可作建筑物承重墙使用, 满足我国废渣治理大力提倡的无害化、 资源化要求, 成为铬渣处理处置的一种新途径。

关键词: 铬渣; 鼓风炉渣; 固相还原; 解毒 中图分类号: X75

文献标识码: A

Detoxified treatment of chromium slag with

industrial waste by solid reduction

SHI Yu-min1, LI Jun-jie2, DU Xing-hong1, SUI Zhi-tong1

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China;

2. Shenyang Yuanda Environmental Engineering Company, Shenyang 110161, China)

Abstract: A new solid reduction way to treat and dispose chromium slag with lower cost was proposed. Blast furnace slag, a very cheap industrial waste, was selected as reductant, in which the remained C reduces Na2CrO4 in order to detoxify chromium slag in solid reduction. The effects of temperatures, time and proportions of chromium slag on reaction were tested, and consequently the optimum experimental conditions were determined. The safety of final slag was also investigated. The results show that the leached Cr(Ⅵ) concentration is 0.063mg/L under reduction reaction time of 2h at 1350℃ for 23%chromium slag, far below the GB5085.3—1996 limits, 1.5mg/L. With a simple method, completive detoxification by another industrial waste can be performed. The treated detoxified final slag was prepared into slag-bearing hollow block, and can be used as building materials of main wall, contributing to its satisfaction of MU7.5 of GB 8239—1997, which also meets the need of innoxiousness and utility for hazardous waste of industry, and becomes an efficient approach to chromium slag treatment and disposal technologies.

Key words: chromium slag; blast furnace slag; solid state reduction; detoxification

固体废弃物对环境造成的污染及资源的浪费, 是当今世界环境与资源保护的主要问题之一, 联合国环境规划署将固体废弃物控制列为全球重大问题。 铬渣作为毒性较强的危险废弃物, 是世界首要重金属污染源之一, 被我国列入47种危险固体废弃物之列。 而在国民经济中, 10%的商品品种与铬盐产品有关, 因此铬盐在国际上又被列为最具有竞争力的8种资源性原材料产品之一。 但应用我国现有生产技术, 每生产1t铬盐要排出2.5~3.0t铬渣[1], 国内历年堆存量已达300万t。 铬渣中含有水溶性和酸溶性的六价铬对人、 畜及农作物都有极大危害, 是国际公认的3种致癌金属物之一, 多年来对周围环境造成了严重污染, 成为国家一项急需治理的环境工程。

国内外治理及综合利用铬渣可分为3大类[2, 3]: 固化法、 还原法和络合法。 国外主要采用固化填埋方法[4-6], 但须加入大量水泥、 动力消耗大, 不适合我国国情。 我国铬渣治理方法也已达20余种, 固相还原法以碳粉、 木屑、 稻壳、 煤矸石、 亚铁盐等为还原剂与铬渣进行高温熔融反应, 使铬渣中的Cr(Ⅵ)还原成Cr(Ⅲ), 最终以玻璃态或尖晶石形态存在, 解毒彻底、 稳定, 是铬渣资源化处理的首选方法[7, 8]。 但该法一般需要高温条件, 工业化生产能耗大, 成本高, 在铬渣治理应用上受到一定限制。 近年来, 一些研究人员积极探索资源化利用铬渣新途径, 选取其他固体废弃物为原料, 降低能耗, 以废治废, 成为固相还原法处理处置铬渣的发展方向[9-11]。

本研究即采用固相还原法, 选用廉价工业废渣——鼓风炉渣M中残余的碳作为还原剂, 对铬渣中主要以水溶性Cr(Ⅵ)形式存在的Na2CrO4进行高温熔融解毒处理。 通过对终渣中水溶性Cr(Ⅵ)浸出值的测定, 研究温度、 反应时间、 铬渣质量分数对该固相反应的影响, 对终渣组成和稳定性也进行了分析。 该实验方法简单, 以废治废, 成本极其低廉, 终渣可做空心砌块等建材原料, 是铬渣无害化、 资源化处理的有效途径。

1 实验

1.1 实验原料和设备

选用沈阳新元化工厂的铬渣为原料, 铬渣的主要化学成分见表1, 其中水溶性Cr(Ⅵ)的质量分数为0.3%。 廉价鼓风炉渣M选自新元化工厂附近某厂。 主要设备为实验室自制二硅化钼高温炉, PTC-Ⅱ智能温度控制仪, TU-1800PC型紫外光-可见光分光光度计, 往复式水平震荡器((110±10)r/min), SSX-550日本岛津扫描电子显微镜, PW1700型菲利普X射线衍射分析仪。

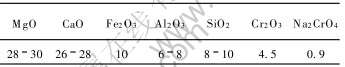

表1 铬渣的化学组成

Table 1 Composition of chromium slag (mass fraction, %)

1.2 实验方法

铬渣和鼓风炉渣M磨至粒径1mm以下, 按一定配比混合均匀, 在1300~1450℃进行高温反应, 终渣自然降温冷却至室温。

将终渣破碎至粒度小于10mm以下, 水溶液浸取。 浸出液的制备方法按照GB/T15555.1—1995《固体废物总汞的测定冷原子吸收分光光度法》中的附录B进行, 采用GB/T 15555.4—1995二苯碳酰二肼分光光度法进行浸出液中Cr(Ⅵ)浓度的测定。

2 分析与讨论

2.1 温度的影响

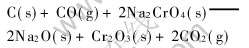

铬渣中Cr(Ⅵ)化合物主要以Na2CrO4为主[12-14], 鼓风炉渣M对铬渣的解毒机理也即为炉渣中残余的C与铬渣中残余的Na2CrO4的高温固相还原反应。 即

由Kirchhoff定律

而

Δcp=Δa+ΔbT+Δc′T-2(2)

将式(2)代入式(1), 得

ΔH=ΔH0+ΔaT+1/2ΔbT2-Δc′T-1(3)

将相关热力学常数[15, 16]代入式(3), 可计算出热力学常数:

Δa=71.03 (J/(K2·mol))

Δb=5.62×10-2 (J/(K2·mol))

Δc=-3.18×106 (J/(K2·mol))

ΔH0=-3.43×104 (J/mol)

将上述参数代入式(3), 得

ΔH=-3.43×104-3.18×106/T+

71.03T+2.81×10-2T2

由上式可知在反应温度1330~1450℃之间, ΔH值为154.42~182.22kJ/mol, 因此C对Na2CrO4的高温固相还原反应是个吸热反应, 升高温度有利于正向反应进行, 而且温度越高, 反应越容易发生。

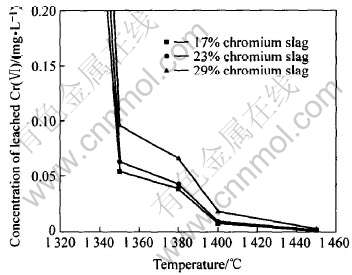

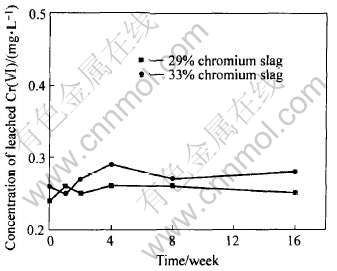

实验通过测定终渣中残余的水溶性Cr(Ⅵ)浸出值, 确定反应进行程度。 图1所示为质量分数为17%、 23%和29%的铬渣加入到鼓风炉渣M中, 在1330℃到1450℃不同温度条件下保温2h测得的Cr(Ⅵ)浸出值结果。 由图1可知, 随着温度升高, Cr(Ⅵ)浸出值明显降低, 当温度达到1450℃时, 固相还原反应已十分彻底, 与理论分析相符。

图1 温度和铬渣质量分数对固相还原反应的影响

Fig.1 Effects of temperature and content of chromium slag on reduction reaction

2.2 铬渣质量分数的影响

由图1可知, 随铬渣质量分数的增加, Cr(Ⅵ)浸出值也随之增大, 但在1350℃反应时间为2h条件下, 铬渣质量分数达到23%时, Cr(Ⅵ)浸出值仅为0.063mg/L, 远远低于 GB5085.3—1996限定值1.5mg/L。 综合实验室及工业实验能耗等要求, 优化条件选择反应温度为1350℃, 铬渣质量分数为23%。

2.3 反应时间的影响

鼓风炉渣M对铬渣中Cr(Ⅵ)解毒处理, 是两种废渣在熔融状态下C与Na2CrO4进行高温固—固反应, 固—固反应动力学条件较差, 一般均需要较长时间才能反应完全。

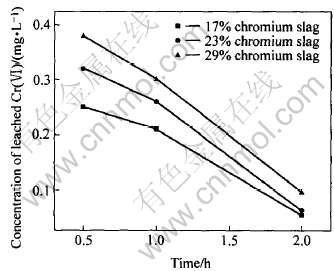

图2所示为质量分数为17%、 23%和29%的铬渣与鼓风炉渣M在1350℃高温条件下, 反应时间分别为0.5、 1.0和2.0h对Cr(Ⅵ)浸出值的影响。 可以看出Cr(Ⅵ)的浸出值随反应时间增长而减少; 反应时间为0.5和1h的Cr(Ⅵ)的浸出浓度相差不大, 但随时间的延长, 反应2h的Cr6+的浸出值明显降低, 固相反应基本完全, 因此反应时间选择为2h。

图2 反应时间对固相还原反应的影响

Fig.2 Effect of reaction time on reduction reaction for chromium slag

2.4 终渣安全性

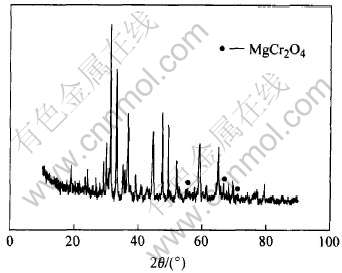

将铬渣质量分数分别为29%和33%的试样, 在1350℃下与鼓风炉废渣M进行还原反应 0.5h后, 将终渣破碎至粒度小于5mm, 放置环境中16周, 测定Cr(Ⅵ)的浸出值, 确定该高温固相还原反应对铬渣解毒的安全性。 由图3安全性实验可知随着放置时间的延长, Cr(Ⅵ)的浸出值变化不大, 表明终渣稳定, 几乎没有发生再氧化成Cr(Ⅵ)现象。

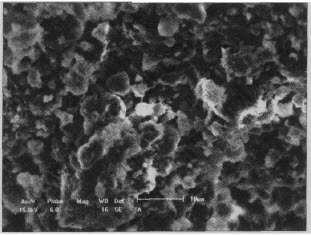

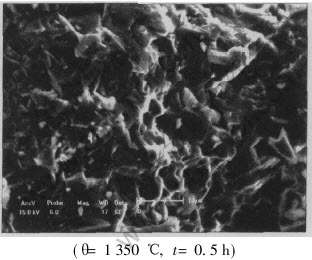

图4和5所示为铬渣反应前后的SEM像, 可以看出反应前铬渣表面粗糙, 结构松散; 反应后终渣呈玻璃体, 结构致密, 铬被包熔在玻璃体内, 因此安全稳定。 通过对终渣的X射线衍射分析(图6), 发现有镁铬尖晶石(MgCr2O4)生成。 这是由于两种废渣中都含有较高含量的MgO, 铬渣中被C还原的Na2CrO4, 反应后生成Cr2O3将在高温状态下极易与MgO生成结构非常稳定的镁铬尖晶石。 根据式(4)计算可知, 无论高温和常温条件下, ΔG负值均较大, 生成镁铬尖晶石的反应容易发生, 生成物结构稳定, 因此终渣中Cr(Ⅲ)几乎不再发生再氧化现象, 解毒彻底。

ΔG=b+aT=- 4037.8+2.257T(4)

式中 b为平均热焓, a为平均熵变。

当T=1623K时, ΔG1623=-386.05(J/mol)

当T=298K时, ΔG298=-3367.35(J/mol)

图3 环境放置时间对终渣稳定性的影响

Fig.3 Effects of time of exposure to air on final slag stability

图4 反应前铬渣的SEM像

Fig.4 SEM micrograph of chromium slag before reduction reaction

图5 终渣的SEM像

Fig.5 SEM micrograph of final slag

图6 终渣的X射线衍射谱

Fig.6 XRD pattern of final slag

2.5 终渣的应用

鼓风炉渣M与铬渣高温固相还原后, 不仅对Cr(Ⅵ)进行了解毒处理, 终渣还可以做作为很多建材的原料得以资源化利用, 在生产石膏、 微晶玻璃、 水泥、 空心砌块等方面均可应用。

本课题针对国家禁止使用实心粘土砖, 提倡利用工业废渣等生产空心砌块作为墙体材料的要求, 将终渣制备为高掺量废渣空心砌块建筑材料。 具体工艺为: 将终渣、 水泥及粉煤灰、 电石渣、 磷石膏以一定配比混合, 加入某种高效活化剂, 轮碾、 熟化, 加水搅拌、 成型, 制备废渣空心砌块[17]。 经测试该砌块密度为983kg/m3; 吸水率为21.4%; 抗压强度为8.9MPa。 强度等级达到GB 8239—1997《普通混凝土小型空心砌块》MU7.5要求, 可用于建筑物的承重墙使用。

3 结论

1) 鼓风炉渣M可将铬渣中Cr(Ⅵ)在1350℃高温固相还原, 升高温度有利于反应正向进行; 炉渣M与质量分数为23%的铬渣反应2h对Cr(Ⅵ)的还原基本完全; Cr(Ⅵ)被还原后生成镁铬尖晶石(MgCr2O4), 结构稳定, 长时间放置环境中安全, 几乎不再发生再氧化现象。

2) 该法简单, 解毒彻底, 以废治废, 终渣可做高掺量废渣空心砌块等建材原料, 是理想的铬渣资源化处理途径。

REFERENCES

[1]兰嗣国. 浅谈铬渣解毒技术[J]. 环境科学研究, 1998, 11(3): 53-56.

LAN Si-guo. Detoxification techniques for chromium slag[J]. Research of Environmental Sciences, 1998, 11(3): 53-56.

[2]丁翼, 纪柱. 铬化合物生产与应用[M]. 北京: 化学工业出版社, 2003. 272-300.

DING Yi, JI Zhu. Production and Application of Chromium Containing Compounds[M]. Beijing: Chemical Engineering Press, 2003. 272-300.

[3]马书文. 铬渣治理与资源化综述[J]. 无机盐工业, 1997(2): 19-22.

MA Shu-wen. Review of chromium slag treatment and its resource utility[J]. Inorganic Salt Industry, 1997, 29(2): 19-22.

[4]Mollah M Y A, Tsai Y N, Hess T R. An FTIR SEM investigation of solidification stabilization of chromium using Portland Cement type V and type IP[J]. J Hazard Mater, 1992, 30: 173-183.

[5]Kindness A, Macias A, Glasser F P. Immobilization of chromium in cement matrices[J]. Waste ManageMnt, 1994, 14: 3-11.

[6]Allan M L, Kukacka L E. Blast furnace slag-modified grouts for in situ stabilization of chromium-contaminated soil[J]. Waste ManageMnt, 1995, 15(3): 193-202.

[7]丁翼. 中国铬盐生产状况与展望[J]. 化工进展, 2004, 23(4): 345-348.

DING Yi. Present status and prospect of chromate production in China[J]. Chemical Industry and Engineering Progress, 2004, 23(4): 345-348.

[8]兰嗣国, 张剑霞, 还博文. 熔融还原解毒后铬渣的稳定性研究[J]. 环境工程, 1997, 15(1): 44-51.

LAN Si-guo, ZHANG Jian-xia, HUAN Bo-wen. Reseraches on detoxified chromium slag stability by reduction in molten condition[J]. Environmental Engineering, 1997, 15(1): 44-51.

[9]方荣利, 金成昌. 去除铬渣毒性的研究[J]. 重庆环境科学, 1998, 20(1): 45-48.

FANG Rong-li, JIN Cheng-chang. Study on toxicity removal of chromium residual[J]. Chongqing Environmental Science,1998, 20(1): 45-48.

[10]匡少平, 徐倩. 利用自养煤矸石技术治理铬渣初步研究[J]. 环境工程, 2003, 21(5): 43-45.

KUANG Shao-ping, XU Qian. Study on treating chromium slag using gangue autotrophic technology[J]. Environmental Engineering, 2003, 21(5): 43-45.

[11]Karl R G, Jan R. Recovery of Chromium from Slag[P]. Germany WO 0079014, 2000.

[12]纪柱, 王承武, 赵巧珍. 铬渣的物相组成及鉴定[J]. 无机盐工业, 1981, 13(6): 51-56.

JI Zhu, WANG Cheng-wu, ZHAO Qiao-zhen. Cr6+ structure in chromium slag[J]. Inorganic Salt Industry, 1981, 13(6): 51-56.

[13]潘金芳, 冯晓西, 张大年. 化工铬渣中铬的存在形态研究[J]. 上海环境科学, 1996, 15(3): 15-17.

PAN Jin-fang, FENG Xiao-xi, ZHANG Da-nian. Study on forms of chromium in chromic slag[J]. Shanghai Environmental Sciences, 1996, 15(3): 15-17.

[14]华振明, 高忠爱, 祁梦兰, 等. 固体废物的处理与处置(修订版)[M]. 北京: 高等教育出版社, 2002.

HUA Zhen-ming, GAO Zhong-ai, QI Meng-lan, et al. Treatment and Disposal of Solid Waste (revised edition)[M]. Beijing: Higher Education Press, 2002.

[15]梁英教, 车荫昌. 无机物热力学数据手册[M]. 沈阳: 东北大学出版社, 1993. 457-465.

LIANG Ying-jiao, CHE Yin-chang. Handbook of Inorganic Substance Thermodynamics Parameter[M]. Shenyang: Northeastern University Press, 1993. 457-465.

[16]Chase M W. NIST-JANAF Thermochemical Tables[M]. 4th ed. Maryland: American Chemical Society and the American Institute of Physics for the National Institute of Standards and Technology, 1998.

[17]闫振甲, 何艳君. 工业废渣生产建筑材料实用技术[M]. 北京: 化学工业出版社, 2002. 168-177.

YAN Zhen-jia, HE Yan-jun. Practical Technologies of Manufacturing Building Materials Used by Industrial Waste[M]. Beijing: Chemical Engineering Press, 2002. 168-177.

基金项目: 国家自然科学基金资助项目(50234040)

收稿日期: 2005-08-03; 修订日期: 2006-02-05

通讯作者: 石玉敏,博士; 电话:010-88850188-221; 传真: 010-88857979; E-mail: shiym2005@hotmail.com, shiyumin@gmail.com

(编辑龙怀中)