文章编号:1004-0609(2014)07-1785-07

热处理过程中锂离子电池正极材料LiNi0.5Co0.2Mn0.3O2的结构变化及电化学性能

李运姣1, 2,任苗苗1, 2,韩 强1, 2,明宪权2,李普良2,许 虎1, 2,李 林1, 2

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 中信大锰矿业有限责任公司,南宁 530028)

摘 要:将前驱体Ni0.5Co0.2Mn0.3(OH)2以及前驱体和碳酸锂的混合物分别进行热处理,初步探讨其在高温热处理过程中的结构变化以及热处理方式对材料电化学性能的影响。采用X射线衍射(XRD)、热重-差热分析(TG-DSC)、扫描电镜(SEM)以及恒流充放电测试技术对合成材料物理性能和电化学进行测试和表征。结果表明:前驱体在热处理过程中,其结构经历由Me(OH)2→NiCoOOH→Mn(Ni,Co)2O4的转变过程;而前驱体与碳酸锂的混合物则经历由两相混合物→三元材料+Li2CO3→三元材料的结构转变过程;相比于单一高温平台热处理而言,采用低高温双平台热处理所合成的材料可有效降低阳离子混排,使其具有更好的电化学性能。电化学测试结果表明:在3.0~4.4 V电压范围内,其在25 ℃、0.5C下首次放电比容量为160.5 mA·h/g,60次循环后,容量保持率达98.9%。

关键词:锂离子电池;正极材料;结构变化;电化学性能

中图分类号:TM912.9;O614.111 文献标志码:A

Structrural change and electrochemical performance of LiNi0.5Co0.2Mn0.3O2 as cathode material for lithium ion batteries

LI Yun-jiao1, 2, REN Miao-miao1, 2, HAN Qiang1, 2, MING Xian-quan2, LI Pu-liang2, XU Hu1, 2, LI Lin1, 2

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Citic Dameng Mining Industries Limited, Nanning 530028, China)

Abstract: The Ni0.5Co0.2Mn0.3(OH)2 precursor and the mixture of Ni0.5Co0.2Mn0.3(OH)2 precursor with Li2CO3 were heat-treated, respectively, during heat-treatment, their structural change and the effects of the heat treatment method were studied. The physical and dectrochemical properties of powders were characaterized by X-ray diffraction, thermogravimetry-differential thermal analysis, scanning electron microscopy and galvanostatic charge-discharge cycling. The structural change of the precursor during the heat-treatments is as follows: Me(OH)2→NiCoOOH→Mn(Ni,Co)2O4. Comparing with single stage heating program, it is proved by the experimental results that the two-stage-heating program can be effectively used to reduce the cation mixing, thus, significantly improve the electrochemical performance of the material. LiNi0.5Co0.2Mn0.3O2 heat-treated by two-stage heating program shows a high initial discharge capacity of 160.5 mA·h/g in the voltage range of 3.0-4.4 V at 25 ℃ and 0.5C, and the capacity retention rate is 98.9% after charge-discharge cycle of 60.

Key words: lithium ion battery; cathode material; structural change; electrochemical performance

新型锂离子电池是20世纪90年代发展起来的新一代绿色高能电池,广泛应用于便携式电子设备、军用设备和电动交通工具等,而正极材料是决定锂离子电池性能的关键材料之一。目前,制备工艺简单、具有较好循环性能的LiCoO2[1-2]已大规模商业化,但由于钴资源匮乏、毒性较大、高电压稳定性差,从而限制了其在动力电池方面的应用。因此,开发价格低廉且综合性能优良的新型正极材料成为当务之急。研究者曾经认为LiNiO2和LiMn2O4是最佳替代产品,但LiNiO2合成条件苛刻、热稳定性较差[3],而LiMn2O4由于Jahn-Teller效应和锰溶解导致其循环衰减较快,且高温性能较差[4]。于是,众多研究者将目光集中在用过渡金属来替代LiCoO2中的钴,从而获得LiNixCo1-xO2和LiNixMn1-xO2[5-6]等。其中,LiNixCo1-xO2由于高可逆容量和出色的热稳定性被研究者广泛关 注[7-8]。但存在如下两个问题:1) 由于Ni2+和 Li+混排使得合成计量比为LiNixCo1-xO2变得尤为困难;2) 循环过程中材料的结构稳定性较差。

1999年,LIU等[9]首次提出LiNixCoyMn1-x-yO2的三元过渡金属复合氧化物,其具有α-NaFeO2层状结构,它所形成的固溶体具有明显的协同效应,使得该材料综合了LiCoO2的优良循环性能、LiNiO2的高放电容量以及LiMn2O4稳定的结构和低廉的成本,尤其是其出色的大倍率放电和较好的热稳定性,逐渐被众多研究者所青睐,被认为是最具开发应用前景的正极材料。

目前,镍钴锰三元正极材料的研究主要集中在材料的合成以及电化学性能与结构的关系上。随着研究的深入,该材料也逐渐走向实用化。在实际电池中,正极材料的形貌、粒径分布比及振实密度等物性特征对材料的加工性能及电池的电性能有着很大的影响[10-11]。与传统的高温固相法相比[12],液相共沉淀法所制备的镍钴锰复合氢氧化物具有振实密度高、化学计量准确、粒度分布均匀等特点[13-15],为后续合成性能优良的三元材料提供了较好的基础。对于后续的热处理方式,有不少文献报道中选择先低温平台处理、再高温处理[16-18],也有不少文献选择只经过高温热处理[19-20],而对于镍钴锰复合氢氧化物及其与锂源的混合物在热处理过程中的结构变化以及热处理方式对于三元复合材料性能的影响未见有详细的研究报道。

在此,本文作者以LiNi0.5Co0.2Mn0.3O2三元材料的制备为例,通过将共沉淀法所制备的Ni0.5Co0.2Mn0.3(OH)2前驱体及其与Li2CO3的混合物在不同温度下分别进行热处理,考察热处理过程中其结构和形貌的变化以及热处理方式对材料的循环及倍率性能的影响。

1 实验

1.1 三元材料的合成及热处理

以湖南邦普循环科技有限公司提供的三元前驱体Ni0.5Co0.2Mn0.3(OH)2(化学成分见表1)为原料,考察热处理过程材料结构的变化规律。将表1所列三元前驱体(试样A)及其与碳酸锂(99.5%,江西赣锋锂业股份有限责任公司生产)的混合物(按n(Li)/n(Me)=1.06进行混合,试样B),分别置于管式炉中于200~800 ℃下热处理4 h(空气气氛,升温速率为3 ℃/min),保温结束后随炉冷却至室温,取样品进行XRD和SEM分析,考察材料在热处理过程中结构与形貌的变化规律。

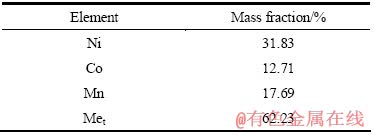

表1 湖南邦普三元前驱体的化学成分

Table 1 Chemical compositions of precursors provided by Hunan brunp

1.2 材料的分析与表征

采用SDTQ600TG-DTA分析仪对样品进行热重和差热分析,温度范围为室温至1000 ℃,升温速率为10 ℃/min,空气气氛;采用日本Rint-2000型X射线衍射仪分析样品的物相组成(Cu Kα辐射,扫描速率6 (°)/min,管电压40 kV,管电流250 mA,扫描范围2θ为10°~80°);利用扫描电镜(SEM, JEOL, JSM-5600LV)对样品的表面形貌进行分析。

1.3 材料的电性能测试

将正极活性三元材料、乙炔黑和聚偏乙烯(PVDF)按质量比80:10:10混合均匀,加入适量的1-甲基-2吡咯烷酮(NMP),研磨成粘稠状混合物后,均匀涂布在铝箔上,120 ℃烘箱中真空干燥12 h后,制成d=14 mm的圆片,即正极片,再将正极片与负极片(Li,d=14 mm)、电解液(1 mol/L 的LiPF6(DMC+EMC+EC (体积比为1:1:1) )和隔膜(Celgand 2400)在充满氩气的手套箱中组装成2016型扣式电池,电池静置12 h后,采用武汉蓝电电池循环测试系统进行充放电性能测试,充放电倍率为0.5C(1C=248 mA/g),电压测试范围为3.0~4.4 V。

2 结果与分析

2.1 前驱体及其与碳酸锂混合物的热重-差热分析

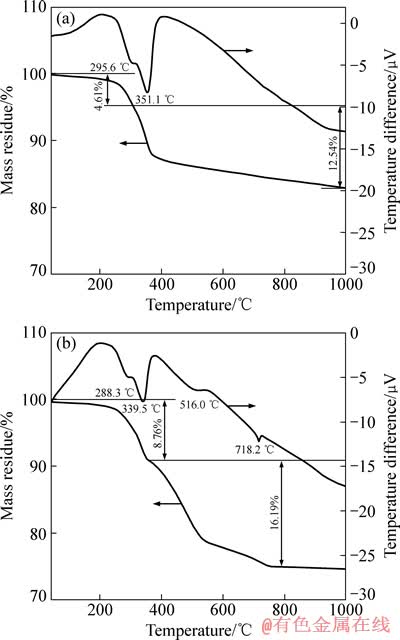

三元前驱体(试样A)及其与碳酸锂的混合物(试样B)的TG-DTA曲线如图1所示。图1(a)所示为试样A的TG-DTA曲线,在常温到300 ℃之间,试样A质量损失为4.61%,对应于附着水的脱除和前驱体氧化脱水形成复合羟基氧化物的过程,后者反应过程如方程式(1)所示,理论质量损失为1.09%,与295.6 ℃处的小吸热峰相对应。300 ℃后主要按方程式(2)进行进一步氧化和脱水,DTA曲线在351.1 ℃有一个明显的吸热峰,TG曲线有持续的质量损失,约为12.54%,与理论质量损失12.88%吻合。从图1(a)的曲线可看到,整个前驱体的氧化脱水过程主要集中在280~350 ℃之间。而对于三元前驱体和Li2CO3的混合物的TG-DTA曲线(见图1(b)),在280~350 ℃之间的DTA曲线上存在与图1(a)类似的两个吸热峰,质量损失为8.76%,与理论质量损失9.13%基本吻合,应为前驱体分解的过程,对应方程式(1)和(2)逐步进行反应;350~750 ℃之间可能为Li2CO3与前驱体分解后的氧化物按照方程式(3)发生反应,并伴随CO2逐步脱除,实际质量损失16.19%与理论质量损失16.69%基本相符;其中350~550 ℃之间有明显的质量损失,DTA曲线上伴随出现吸热峰,原因可能是Li2CO3与前驱体分解后的氧化物发生反应,以及少量残余前驱体分解的综合作用,718.2 ℃的吸热峰可能为少量未反应的Li2CO3熔融(Li2CO3的熔点为723 ℃)所致。750 ℃之后,TG曲线变化平缓,没有明显的质量损失,其对应的DTA曲线无吸热峰的存在,表明反应已基本完成,这一阶段应为材料晶体结构不断完善的过程。整个过程以方程式(4)进行,实际质量损失24.95%与理论质量损失24.90%保持一致。

4Ni0.5Co0.2Mn0.3(OH)2+O2=4Ni0.5Co0.2Mn0.3OOH+2H2O (1)

12Ni0.5Co0.2Mn0.3OOH=4(Ni0.5Co0.2Mn0.3)3O4+6H2O+O2 (2)

4(Ni0.5Co0.2Mn0.3)3O4+6Li2CO3+O2=12LiNi0.5Co0.2Mn0.3O2+6CO2 (3)

4Ni0.5Co0.2Mn0.3(OH)2+2Li2CO3+O2=4LiNi0.5Co0.2Mn0.3O2+2CO2+4H2O (4)

热重差热分析结果表明,前驱体及其与碳酸锂的混合物在整个加热过程中均有质量损失和热量的变化,350 ℃以下二者的TG-DTA曲线相似,在280~350 ℃之间均出现相应质量损失和热量变化,为前驱体的分解过程;350 ℃之后,前者的TG-DTA曲线没有明显的变化,后者出现了两个吸热峰和明显的质量损失。由此可以推测:三元前驱体与碳酸锂之间的化学反应发生在350~800 ℃之间。

图1 三元前驱体和三元前驱体与碳酸锂混合物的TG-DTA曲线

Fig. 1 TG-DTA curves of Ni0.5Co0.2Mn0.3(OH)2 (a) and mixture of Ni0.5Co0.2Mn0.3(OH)2 and Li2CO3 (b)

2.2 前驱体及其与碳酸锂混合物的XRD谱分析

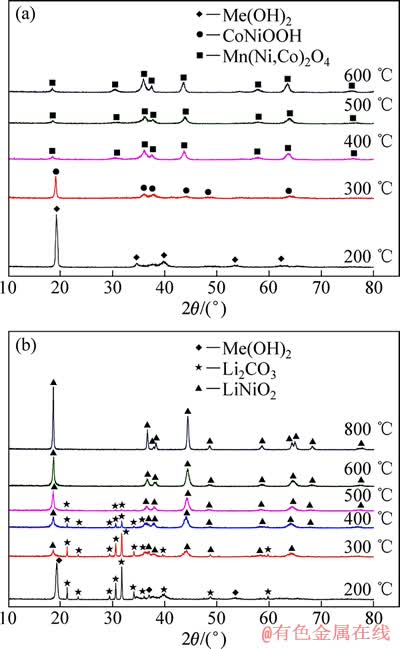

图2所示为三元前驱体Ni0.5Co0.2Mn0.3(OH)2及其与碳酸锂混合物在不同热处理温度下的XRD谱。从图2(a)的三元前驱体在不同热处理温度下的XRD谱可以看出:在200 ℃时,具有与XU等[21]曾报道过的Me(OH)2(Me=Ni,Co,Mn)结构,当温度升至300 ℃时,脱去部分结晶水,开始形成CoNiOOH结构,这与前面TG-DTA的分析结果吻合;温度升至400 ℃时,CoNiOOH结构进一步脱水转变成具有Mn(Ni,Co)2O4结构的复合氧化物;温度高于400 ℃时,前驱体维持Mn(Ni,Co)2O4结构不再变化,衍射峰越来越强,晶体结构越来越完善,这与此温度区间DTA曲线上没有出现吸热或放热峰一致。

图2 三元前驱体及其与碳酸锂的混合物热处理后的XRD谱

Fig. 2 XRD patterns of precursor (a) and mixture of precursor and Li2CO3 (b) after heat-treatment at different temperatures

对于前驱体与碳酸锂的混合物,从测得的XRD谱(见图2(b))中可以看出:在200 ℃时,前驱体与Li2CO3的特征峰均存在;300~500 ℃时,混合物料未直接以复合金属氧化物和碳酸锂的形式存在,而是直接逐渐出现嵌锂复合金属氧化物的特征峰,衍射峰较弱,同时Li2CO3的特征峰逐渐变弱,可能是由Li2CO3的晶形造到破坏并逐渐反应消耗所致;当温度升至600 ℃时,Li2CO3衍射峰消失,嵌锂复合金属氧化物基本形成,随着温度的升高,这些特征峰越来越明显,衍射峰逐渐尖锐清晰,结晶度较好,且分裂峰(006)/(102)、(018)/(110)的分裂程度明显,材料的层状结构较理想。此XRD分析结果与图1(b)中的TG-DTA结果吻合得很好。

通过上述研究发现,在500~600 ℃热处理时,嵌锂复合金属氧化物LiNi0.5Co0.2Mn0.3O2已基本形成。在750 ℃以上,主要为三元材料晶体结构不断完善的过程。

2.3 前驱体及其与碳酸锂混合物的SEM分析

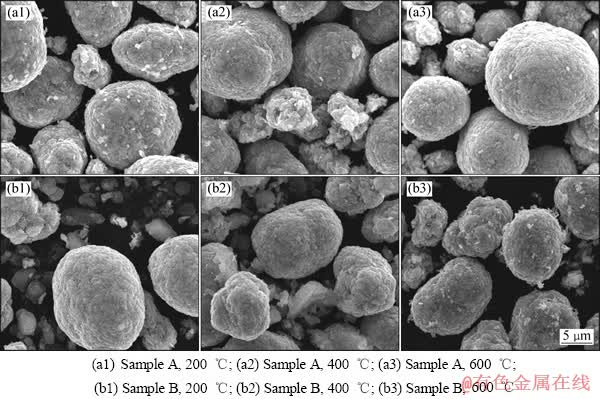

图3 不同热处理温度下前驱体和前驱体与碳酸锂的混合物的SEM像

Fig. 3 SEM images of precursor (a) and mixtures of precursor and Li2CO3 (b) after heat treatment at different temperatures

图3所示为不同热处理温度下前驱体及其与碳酸锂的混合物的SEM像。从图3可看出,对于前驱体,具有较好的球形形貌,二次颗粒是由片状和针状的一次颗粒堆积而成,颗粒均匀,随着温度不断升高,由于颗粒内原子扩散系数增大,原子的扩散能力越来越强,使得颗粒表面轮廓由粗糙逐渐变得更加致密;对于前驱体与碳酸锂的混合物,仍具有较好的球形形貌。在低于400 ℃的热处理温度下,能看到明显不规则片状的Li2CO3颗粒,当温度高于600 ℃时,则无明显碳酸锂颗粒出现,应该是Li2CO3熔化并和前驱体开始相互作用的结果,这与前面的XRD谱分析相吻合。在热处理温度变化过程中,一次片状或针状颗粒变为方形颗粒,表面变得更加致密,二次颗粒形貌并不会发生大的变化,进一步证实了成品三元材料的最终形貌是由前驱体形貌所决定的[22]。

2.4 三元正极材料的制备及其电性能测试

基于上述TG-DTA和XRD研究结果,采用一段和两段热处理制度进行三元正极材料的制备。将三元前驱体与碳酸锂以n(Li)/n(Me)=1.06的配比,用混料机混合均匀后,分别采用900 ℃下保温10 h、15 h(空气气氛,升温速率为3 ℃/min)的一段热处理,和500 ℃先保温5 h,再900 ℃保温10 h(空气气氛,升温速率为3 ℃/min)的两段热处理制度下进行热处理,将所得三元正极材料(分别编号为TER-1.06-S10、TER-1.06-S15和TER-1.06-D)进行电化学性能测试。

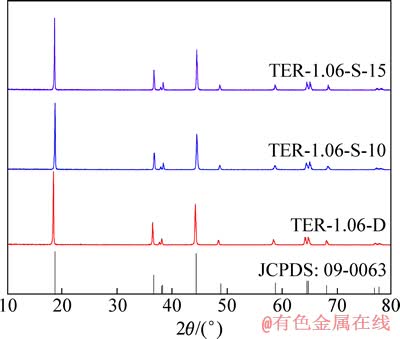

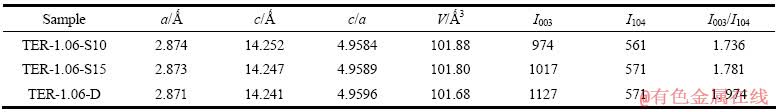

图4所示为两种热处理方式所制备材料的XRD谱。从图4中可看出:3种样品均具有α-NaFeO2的层状结构,锂离子占据3a位置,过渡金属离子Ni/Co/Mn占据3b位置,同时氧原子占据6c位置。由于Li+(0.76  )和Ni2+(0.69

)和Ni2+(0.69  )[23]的原子半径较接近,容易出现“阳离子混排”。I003/I104(R)可用来推测层状结构中阳离子混排情况,当R>1.2时,阳离子混排较小,该比值越大,表明层状结构越理想[24]。结合表2,高温单一平台处理过的两个样品(TER-1.06-S10/ TER-1.06-S15)的I003/I104为1.736和1.781,均低于两段热处理后的样品(TER-1.06-D)的I003/I104=1.974,表明低高温双平台处理过的样品阳离子混排更小,其层状结构更加理想。同时,两组分裂峰(006)/(102)、(018)/(110)的分裂程度越明显,表明材料的层状结构越理想。c/a值通常用来表征层状材料的六方晶系特征,当c/a>4.899,材料结晶稳定性能良好[25]。两种烧样方式所制备的材料的晶格参数没有太大的差别,相比而言,低高温双平台处理过的样品更为理想,这与I003/I104分析结果是一致的。

)[23]的原子半径较接近,容易出现“阳离子混排”。I003/I104(R)可用来推测层状结构中阳离子混排情况,当R>1.2时,阳离子混排较小,该比值越大,表明层状结构越理想[24]。结合表2,高温单一平台处理过的两个样品(TER-1.06-S10/ TER-1.06-S15)的I003/I104为1.736和1.781,均低于两段热处理后的样品(TER-1.06-D)的I003/I104=1.974,表明低高温双平台处理过的样品阳离子混排更小,其层状结构更加理想。同时,两组分裂峰(006)/(102)、(018)/(110)的分裂程度越明显,表明材料的层状结构越理想。c/a值通常用来表征层状材料的六方晶系特征,当c/a>4.899,材料结晶稳定性能良好[25]。两种烧样方式所制备的材料的晶格参数没有太大的差别,相比而言,低高温双平台处理过的样品更为理想,这与I003/I104分析结果是一致的。

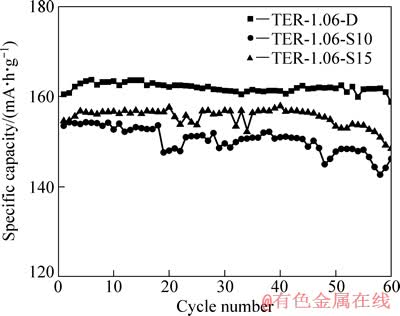

图5所示电压为两种热处理方式所制备的样品在3.0~4.4 V范围内在0.5C充放电条件下的循环曲线。

其中,高温单一平台热处理过的样品TER-1.06-S10和TER-1.06-S15室温下首次放电比容量分别为153.5和154.6 mA·h/g,60个循环后,容量命保持率为95.2%和96.1%,而低高温双平台热处理后的样品TER-1.06-D,其首次比容量达160.5 mA·h/g,60个循环后,容量保持率为98.9%,均优于高温单平台热处理样品的。这可能是因为Ni2+从3b位置运动至Li+的3a位置,必然要受到原子扩散所需要克服的能垒阻碍,先进行低温热处理时,减少提供给能够克服这个能垒的原子所需能量,使原子扩散能力有所减弱,在低温下初步形成α-NaFeO2层状结构材料,这种阳离子混排的行为就会减少,再经过高温处理使晶体更加完善,结晶度更好,即采用低高温双平台处理有效降低阳离子混排,减小锂离子的脱出和嵌入的影响,使得电性能有较好的改善,相比直接的高温单平台展现出更好的性能。

图4 不同热处理方式所制备样品的XRD谱

Fig. 4 XRD patterns of samples prepared by different heat treatment methods

图5 不同热处理方式所制备样品的循环性能

Fig. 5 Cycle performance of samples prepared by different heat treatment methods at rate of 0.5C

表2 不同热处理方式所制备样品的晶胞参数

Table 2 Lattice parameter of samples prepared by different heat treatment methods

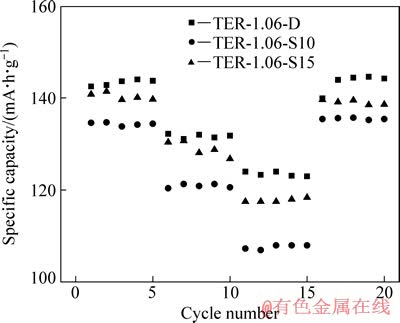

图6所示为不同热处理方式下的倍率性能。低高温双平台处理后的样品(TER-1.06-D)在1C、3C、5C放电倍率下容量分别达到142.5、132.2和124.0 mA·h/g,显示出较好的倍率性能。经过大倍率放电后,返回1C放电时,该材料容量仍然能达到139.9 mA·h/g,说明该材料经过大倍率放电材料因电化学反应而损失的容量较少。而高温单平台处理后的两个样品(TER-1.06-S10和TER-1.06-S15)在1C、3C和5C放电倍率下分别为134.6(140.8)、120.4(130.4)和107.3(112.5) mA·h/g,其倍率性能不如低高温双平台处理后样品的倍率性能。

图6 不同热处理方式所制备样品的倍率性能

Fig. 6 Rate capability of samples prepared by different heat treatment methods at 25 ℃

3 结论

1) 采用液相共沉淀所制备的Ni0.5Co0.2Mn0.3(OH)2三元前驱体在热处理过程中,其结构经历了由Me(OH)2→CoNiOOH→Mn(Ni,Co)2O4的变化,二次颗粒形貌上基本保持一致,表面变得更加致密。

2) 三元前驱体与Li2CO3的混合物料在热处理过程中,300~500 ℃之间初步形成具有α-NaFeO2结构的嵌锂复合金属氧化物,同时有Li2CO3的存在;当温度高于600 ℃时,混合物料基本完成向LiNi0.5Co0.2- Mn0.3O2的转变,其最终材料的形貌与前驱体的形貌大体相似,具有较强的继承性。

3) 基于前驱体与Li2CO3的混合物料采用一段和两段热处理制度制备三元正极材料的研究结果表明:与一段高温热处理制度相比,采用低高温平台的两段热处理制度可有效降低阳离子的混排,0.5C首次放电容量可达160.5 mA·h/g,60个循环后,容量保持率高达98.9%,表现出较高的放电容量和出色的循环性能。

REFERENCES

[1] ANTAYA M, DAHN J R, PRESTON J S, ROSSEN E, REIMERS J N. Preparation and characterization of LiCoO2 thin films by laser ablation deposition[J]. Journal of the Electrochemical Society, 1993, 140(3): 575-578.

[2] SUN Y K, OH I H, HONG S A. Synthesis of ultrafine LiCoO2 powders by the sol-gel method[J]. Journal of Materials Science, 1996, 31(14): 3617-3621.

[3] DAHN J, VON SACKEN U, JUZKOW M, AL-JANABY H. Rechargeable LiNiO2/carbon cells[J]. Journal of the Electrochemical Society, 1991, 138(8): 2207-2211.

[4] HOSONO E, KUDO T, HONMA I, MATSUDA H, ZHOU H. Synthesis of single crystalline spinel LiMn2O4 nanowires for a lithium ion battery with high power density[J]. Nano Letters, 2009, 9(3): 1045-1051.

[5] BR GER J, MENG Y S, HINUMA Y, KUMAR S, KANG K, SHAO-HORN Y, CEDER G, CLARE P. Effect of high voltage on the structure and electrochemistry of LiNi0.5Mn0.5O2: A joint experimental and theoretical study[J]. Chemistry of Materials, 2006, 18(20): 4768-4781.

[6] 肖 劲, 曾雷英, 彭忠东, 赵 浩, 胡国荣. 锂离子电池正极材料LiNi0.5Mn0.5O2的循环性能[J]. 中国有色金属学报, 2006, 16(8): 1439-1444.

XIAO Jin, ZENG Lei-ying, PENG Zhong-dong, ZHAO Hao, HU Guo-rong. Cycle performance of LiNi0.5Mn0.5O2 as cathode materiacs for lithium ion battery[J]. The Chinese Journal of Nonaferrous Metals, 2006, 16(8): 1439-1444.

[7] 蔡振平, 刘人敏, 吴国良, 金维华. 锂离子电池正极材料LiNi0.5Co0.5O2的制备及性能[J]. 电池, 2002, 32(S1): 58-60.

CAI Zhen-ping, LIU Ren-min, WU Guo-liang, JIN Wei-hua. Synthesis and properties of LiNi0.5Co0.5O2 cathode materials for lithium ion batteries[J]. Battery Bimonthly, 2002, 32(S1): 58-60.

[8] GONG Zheng-liang, LIU Han-san, GUO Xiao-jian, ZHANG Zhong-ru, YANG Yong. Effects of preparation methods of LiNi0.8Co0.2O2 cathode materials on their morphology and electrochemical performance[J]. Journal of Power Sources, 2004, 136(1): 139-144.

[9] LIU Zhao-lin, YU Ai-shui, LEE J Y. Synthesis and characterization of LiNi1-x-yCoxMnyO2 as the cathode materials of secondary lithium batteries[J]. Journal of Power Sources, 1999, 81/82: 416-419.

[10] VAN BOMMEL A, DAHN J. Synthesis of spherical and dense particles of the pure hydroxide phase Ni1/3Mn1/3Co1/3(OH)2[J]. Journal of the Electrochemical Society, 2009, 156(5): A362-A365.

[11] YANG Shun-yi, WANG Xian-you, YANG Xiu-kang, LIU Zi-ling, WEI Qi-liang, SHU Hong-bo. High tap density spherical Li[Ni0.5Mn0.3Co0.2]O2 cathode material synthesized via continuous hydroxide coprecipitation method for advanced lithium-ion batteries[J]. International Journal of Electrochemical, 2012: Article ID323560, 9p.

[12] LI D C, SASAKI Y, KAGEYAMA M, KOBAYAKAWA K, SATO Y. Structure, morphology and electrochemical properties of LiNi0.5Mn0.5-xCoxO2 prepared by solid state reaction[J]. Journal of Power Sources, 2005, 148: 85-89.

[13] LEE M H, KANG Y J, MYUNG S T, SUN Y K. Synthetic optimization of Li [Ni1/3Co1/3Mn1/3]O2 via co-precipitation[J]. Electrochimica Acta, 2004, 50 (4): 939-948.

[14] VAN BOMMEL A, DAHN J. Analysis of the growth mechanism of coprecipitated spherical and dense nickel, manganese, and cobalt-containing hydroxides in the presence of aqueous ammonia[J]. Chemistry of Materials, 2009, 21(8): 1500-1503.

[15] 陆 雷, 钟伟攀, 杨 晖. 高致密球形LiNi0.8Co0.1Mn0.1O2 颗粒的合成及性能研究[J]. 无机材料学报, 2012, 27(3): 258-264.

LU Lei, ZHONG Wei-pan, YANG Hui. Synthesis and charaterization of spherical LiNi0.8Co0.1Mn0.1O2 particles with a high tap-density[J]. Journal of Inorganic Materials, 2012, 27(3): 258-264.

[16] HU Shao-kang, CHENG Geng-hao, CHENG Ming-yao, HWANG B-J, SANTHANAM R. Cycle life improvement of ZrO2-coated spherical LiNi1/3Co1/3Mn1/3O2 cathode material for lithium ion batteries[J]. Journal of Power Sources, 2009, 188(2): 564-569.

[17] KIM S K, JEONG W T, LEE H K, SHIM J. Characteristics of LiNi1/3Co1/3Mn1/3O2 cathode powder prepared by different method in lithium rechargeable batteries[J]. International Journal of Electrochemical Science, 2008, 3(10): 1504-1511.

[18] 禹筱元, 胡国荣, 刘业翔. 层状LiNi1/3Co1/3Mn1/3O2 正极材料的多元掺杂改性[J]. 中国有色金属学报, 2010, 20(6): 1170-1176.

YU Xiao-yuan, HU Guo-rong, LIU Ye-xiang. Modification of layered LiNi1/3Co1/3Mn1/3O2 cathode materials with doping muetiple components[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1170-1176.

[19] NGALA J K, CHERNOVA N A, MA M, MAMAK M, ZAVALIJ P Y, WHITTINGHAM M S. The synthesis, characterization and electrochemical behavior of the layered LiNi0.4Mn0.4Co0.2O2 compound[J]. Journal of Materials Chemistry, 2004, 14(2): 214-220.

[20] 杨 志, 李新海, 王志兴, 彭文杰, 郭华军. 高振实密度球形 LiNi0.5Co0.3Mn0.2O2 粉末的合成及性能[J]. 中国有色金属学报, 2010, 20(1): 106-111.

YANG Zhi, LI Xin-hai, WANG Zhi-xing, PENG Wei-jie, GUO Hua-jun. Synthesis and charaterization of high tap-density spherical LiNi0.5Co0.3Mn0.2O2 powders[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(1): 106-111.

[21] XU Yao-hua, FENG Qi, KAJIYOSHI K, YANAGISAWA K, YANG Xiao-jing, MAKITA Y, KASAISHI S, OOI K. Hydrothermal syntheses of layered lithium nickel manganese oxides from mixed layered Ni(OH)2-manganese oxides[J]. Chemistry of Materials, 2002, 14(9): 3844-3851.

[22] LEE M H, KANG Y J, MYUNG S T, SUN Y K. Synthetic optimization of LiNi1/3Co1/3Mn1/3O2 via co-precipitation[J]. Electrochimica Acta, 2004, 50 (4): 939-948.

[23] LEE K S, MYUNG S T, AMINE K, YASHIRO H, SUN Y K. Structural and electrochemical properties of layered Li[Ni1-2xCoxMnx]O2 (x=0.1-0.3) positive electrode materials for Li-ion batteries[J]. Journal of the Electrochemical Society, 2007, 154(10): A971-A977.

[24] ZHANG Chuan-fu, YANG Ping, DAI Xi, XIONG Xuan, ZHAN Jing, ZHANG Yin-Liang. Synthesis of LiNi1/3Co1/3Mn1/3O2 cathode material via oxalate precursor[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(3): 635-641.

[25] CHO J, KIM G, LIM H S. Effect of preparation methods of LiNi1-xCoxO2 cathode materials on their chemical structure and electrode performance[J]. Journal of the Electrochemical Society, 1999, 146(10): 3571-3576.

(编辑 李艳红)

基金项目:广西自治区“八桂学者”专项经费资助(2011A025)

收稿日期:2013-11-06;修订日期:2014-04-16

通信作者:李运姣,教授,博士;电话:0731-88830476;传真:0731-88710171;E-mail:yunjiaoli6601@hotmail.com