文章编号: 1004-0609(2006)06-1046-06

致密高温质子导电陶瓷SrCe0.9Y0.1O3-α的制备

吴敏艳1, 丁伟中1, 方建慧2, 张玉文1, 马金昌1

(1. 上海大学 上海市钢铁冶金重点实验室, 上海 200072; 2. 上海大学 理学院, 上海 200346)

摘 要: 采用溶胶-凝胶法制备了粒径为30~60nm的SrCe0.9Y0.1O3-α超细粉, 并用此粉体制得了致密高温质子导电陶瓷, 研究了成型压力对素坯的影响, 陶瓷的烧结行为及微观结构。 结果表明: 当成型压力为20~250MPa时, 素坯的相对密度会呈现峰值(54.25%); 根据陶瓷的线性收缩率的变化趋势, 将烧结分为烧结初期(〈1150℃), 烧结中期(1150~1250℃)和烧结后期(>1250℃)3个阶段; 采用RCS(速控烧结)烧结制度在较短的烧结时间里获得相对密度为98 %且平均晶粒尺寸小于1μm的致密陶瓷; SEM观察发现陶瓷断口的孔洞中出现了新物相, 推测其主要成分可能是SrCO3。

关键词: SrCe0.9Y0.1O3-α; 高温质子导电陶瓷; 致密; 溶胶-凝胶法 中图分类号: TB321; TB43

文献标识码: A

Preparation of dense high temperature proton conducting

ceramics SrCe0.9Y0.1O3-α

WU Min-yan1, DING Wei-zhong1, FANG Jian-hui2,

ZHANG Yu-wen1, MA Jin-chang1

(1. Shanghai Key Laboratory for Ferro Metallurgy,

Shanghai University, Shanghai 200072, China;

2. School of Science, Shanghai University, Shanghai 200346, China.)

Abstract: The fine SrCe0.9Y0.1O3-α powders with the size range of 30-60nm were prepared by sol-gel method, and then were used to prepare dense proton conducting ceramics. The influences of compaction pressures on green relative densities, sintering behavior and microstructure were studied. The green relative density reaches the peak value(54.25%) at the compaction pressure range of 20~250MPa. According to the linear shrinkage rate of ceramics, the sintering process can be divided into three stages: initial stage(〈1150℃), medial stage(1150-1250℃) and final stage(>1250℃). The dense ceramic with relative density of 98% and average grain size of less than 1μm can be achieved within a shorter dwelling time by rate-controlled sintering(RCS) process. The new phases like flowers appear in the hole of ceramics fracture through SEM analysis. The components are supposed to be SrCO3.

Key words: SrCe0.9Y0.1O3-α; high temperature proton conducting ceramics; dense; sol-gel method

上世纪80年代初, Iwahara等[1]成功地制备了1000℃高温下稳定的、 具有较高质子传导能力的材料——稀土掺杂的钙钛矿型复合氧化物陶瓷, 这种质子导体在干燥空气中为氧离子与电子空穴混合导体, 而在含氢气或水蒸气的条件下, 质子便作为主要的载流子参与导电。 由于这种质子导体可用于生产氢气的水蒸气电解池[1, 2]、 分离氢气的气体分离器[3-5]、 氢气或水蒸气传感器[6-8]、 燃料电池[9, 10]以及各种薄膜反应器 [11, 12] 等, 因而引起人们的广泛重视。

掺杂SrCeO3系的氧化物陶瓷是一类研究较为成熟的高温质子导体。 Iwahara等[1]采用固相合成法制备了SrCe0.95M0.05O3-α(M=Yb, Y, Sc)一系列陶瓷粉, 由于其合成温度高(1300~1450℃), 因此陶瓷粉的烧结性能并不理想。 近年来, 人们更倾向于采用湿化学法制备了初始陶瓷粉。 Dionysiou等[13]用柠檬酸sol-gel法合成了SrCe0.95Tb0.05-O3-α (SCT)粉体, 样品在1000℃时, 杂质相基本消失, 形成了单一的钙钛矿相结构, 在1500℃保温24h得到了非常致密的氧化物陶瓷, 且具有优良的电导性质。 张建敏等[14, 15]用柠檬酸sol-gel方法合成了SrCe0.95Yb0.05O3-α(SCYb), 并研究了其烧结特性。 结果表明, 经530℃焙烧所得粉体粒径为30~50nm, 烧结温度降至1400℃, 保温时间缩短为10h。 由此可见, 柠檬酸sol-gel法不仅大大降低了(陶瓷)粉体的合成温度, 而且也使陶瓷的初始粉体粒径减小到纳米级。 一方面, 粉体的细化加快了烧结速率, 粉体烧结的驱动力是来自粉料表面能引起的表面应力

F=2E/r

式中 r为表面曲率半径; E为表面能。 另一方面, 粉体的细化有利于获得晶粒组织细小且均匀的陶瓷基体。 要制备性能良好的精细陶瓷, 仅仅使初始粉体粒度超细化是不够的, 还需要选择合适的成型压力和烧结制度等。 比较全面地从初始陶瓷粉体的制备到烧结成型, 全过程考察各种因素对高温质子导体显微结构的影响。 本文作者采用溶胶-凝胶法制备了超细粉SrCe0.9Y0.1O3-α, 探讨了成型压力和烧结制度对致密陶瓷的制备及其微观结构的影响, 并对陶瓷断口晶界处的孔洞中生长出的花状晶体进行了分析。

1 实验

1.1 原料与试剂

Y2O3(99.99%)、 Sr(NO3)2(AR)、 Ce(NO3)3·6H2O(AR)、 氨水(AR)、 柠檬酸(C6H8O7·H2O)(AR)均由中国医药(集团)上海化学试剂公司提供; 浓HNO3(AR)由上海前进试剂厂生产。

1.2 质子导电陶瓷的制备

按所需摩尔比称取Ce(NO3)3·6H2O、 Sr(NO3)2和Y2O3, 然后将Y2O3溶解在适量的浓硝酸中后得到Y(NO3)3, 再与Ce(NO3)3 和Sr(NO3)2溶液混合, 以柠檬酸作为络合剂, 在不断搅拌过程中逐滴加入氨水, 调节pH=8, 使溶液保持弱碱性。 在保持pH=8的条件下将溶胶置于水浴槽中静置48h, 水浴温度为60℃。 等到水溶胶中的水分不断蒸发后就得到浅黄色透明的凝胶。 用微波炉快速(3~5min)干燥湿凝胶, 获得灰黑色蓬松粉体。 将粉体在1000℃下煅烧2h获得超细粉SrCe0.9Y0.1O3-α。 以干压成型法将粉体压制为厚度为1.2mm, 直径为11mm的小圆片。 在成型过程中需添加1%的阿拉伯树胶作为粘结剂。 压力为20~250MPa, 烧结温度为1100~1300℃。

1.3 试样表征

采用Riguku公司的D/MAX 2550型X射线衍射仪表征物相的组成。 利用JEOL Ltd公司的JEM-200CX型透射电子显微镜观察粉体的形貌、 颗粒度大小及团聚情况。 陶瓷的形貌及微观结构用Hitachi公司的S-570 SEM进行表征分析。 陶瓷的相对密度可通过真实密度与理论密度的相对值获得, 真实密度的测量方法采用阿基米德法。

2 结果与讨论

2.1 试样的物相组成及形貌分析

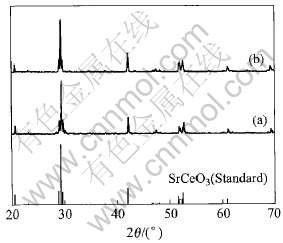

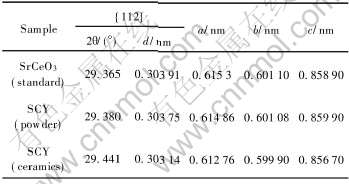

SrCe0.9Y0.1O3-α的初始粉体和烧结体的X射线衍射分析如图1所示。 由图1可看出, 1000℃可以合成纯度较高的钙钛矿型粉体, 粉体在烧结过程中不伴随相的改变而改变, 这可以避免因相变引起的应力释放而导致陶瓷的开裂。 与粉体的X射线衍射峰型相比, 1300℃烧结后, 陶瓷的X射线衍射峰型更加尖锐, 说明晶格更加饱满, 晶粒进一步长大。 表1所列为SrCe0.9Y0.1O3-α的主晶面的X射线衍射数据以及晶胞参数数据。 由表1可知, SrCe0.9Y0.1O3-α(SCY)衍射峰的晶面间距(d)值均发生了偏移, 粉体的d值偏移较少, 陶瓷的d值偏移较大, 且晶胞参数a, b, c中(除了粉体中的c值)都比标准的SrCeO3小, 这可能是由于掺杂了10%(摩尔分数)的Y后引起了晶格的畸变。 由X射线衍射的晶胞参数及固溶体SrCe0.9Y0.1O3-α的分子式计算出其理论密度为5.716g/cm3。

图1 1000℃煅烧后粉体(a)和1300℃烧结后陶瓷(b)的X射线衍射谱

Fig.1 XRD patterns of powders calcined at 1000℃ (a) and ceramics sintered at 1300℃ (b)

表1 SrCe0.9Y0.1O3-α主晶面的X射线衍射数据以及晶胞参数

Table 1 XRD data and cell parameters of main crystal plane of SrCe0.9Y0.1O3-α

图2所示为将1000℃煅烧后的粉体放入无水乙醇经过超声波分散后的TEM像。 由图2可看出, 粉体的表观形貌基本呈球形, 颗粒粒径为30~60nm。

图2 1000℃煅烧后粉体的TEM像

Fig.2 TEM image of powders calcined at 1000℃

2.2 成型压力对素坯密度的影响

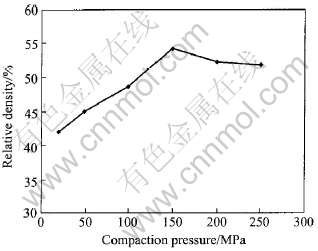

陶瓷的素坯密度会影响烧结性能, 素坯密度越高, 则在相同的烧结温度下达到的相对密度就越高[16]。 将制备好的超细粉SrCe0.9Y0.1O3-α在20~250MPa压力下压制成型得到不同密度的素坯, 素坯的相对密度随成型压力的变化如图3所示。 由图3可看出, 素坯的相对密度起初随着压力的增加而增加, 达到150MPa时, 相对密度达到最大值(54.25%)。 随着压力的进一步增加, 素坯的相对密度却略微减少。 当压力为250MPa时, 出现了裂纹。 因此, 在实验条件下, 为获得最大的初始密度, 合适的成型压力应为150MPa。

图3 成型压力对素坯相对密度的影响

Fig.3 Influence of compaction pressures on relative densities of green

2.3 烧结制度对陶瓷显微结构的影响

2.3.1 烧结温度与陶瓷线性收缩率的关系

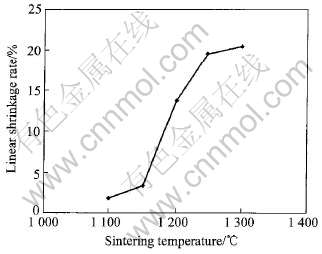

不同烧结温度下陶瓷的收缩率变化如图4所示。 由图4可看出, 当温度低于1150℃时, 坯体的线性收缩率(Δ L/L)很小; 当温度为1150~1250℃时, 收缩率迅速增加; 当温度达到1250℃时, 坯体的线性收缩率达到19.6 %, 此时坯体的相对密度已经达到了95 %; 当温度达到1250℃时, 陶瓷的线性收缩率继续增加, 但增加幅度明显减小; 当温度达到1300℃时, 坯体的相对密度达到了98 %, 可以认为坯体已达到致密化的程度。

图4 烧结温度对线性收缩率的影响

Fig.4 Influence of sintering temperature on linear shrinkage rate

因此, 可以将该陶瓷的烧结过程分为3个阶段: 1)烧结初期(〈1150℃)是一个很弱的收缩过程, 相当于粉末颗粒的粘滞效应; 2)烧结中期(1150 ~ 1250℃), 陶瓷坯体发生了较大的收缩, 颗粒间的孔隙大量减小或消失; 3)烧结后期(>1250℃), 收缩逐渐稳定, 疏松的孔隙基本消失。

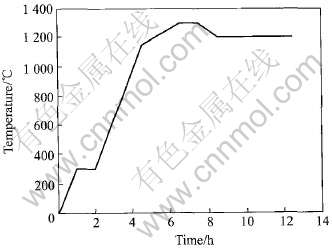

2.3.2 升温曲线与显微结构

一般经典的烧结理论认为, 晶粒的迅速长大是发生在烧结的后期。 因此采用传统的等温烧结必然会引起晶粒的过分长大。 为此, Palmour等[17]提出了RCS(速控烧结)理论, 该理论的主要思想是通过变化升温速率在抑制晶界迁移的同时, 保持晶界的扩散处于活跃状态。 因此, 本研究制定的烧结过程中3个阶段的升温曲线如图5所示。 由图5可看出, 在烧结初期(〈1150℃), 控制炉温迅速上升(>300℃/h), 为了使坯体中的粘结剂挥发干净, 将坯体在300℃保温1h; 在烧结中期(1150~1300℃), 将坯体缓慢升温(75℃/h); 在烧结后期(1300℃), 坯体停留时间较短(1h), 然后降至较低的温度(1200℃)再保温4h。

图5 RCS制度下的升温曲线

Fig.5 Heating-up curve by RCS process

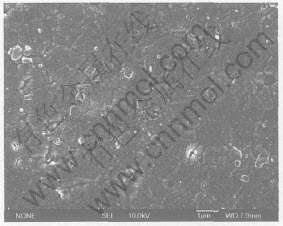

烧结好的SrCe0.9Y0.1O3-α陶瓷经过表面抛光在1100℃下热腐蚀后的SEM像如图6所示。 由图6可看出, 其微观组织结构紧密(测得相对密度为98 %), 平均晶粒尺寸小于1μm。 说明采用这种烧结制度, 可以在较短烧结时间内获得致密且晶粒较小的陶瓷显微结构。

图6 SrCe0.9Y0.1O3-α陶瓷的SEM像

Fig.6 SEM image of SrCe0.9Y0.1O3-α ceramics

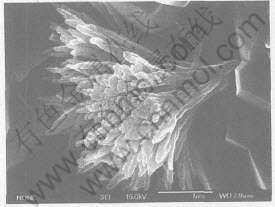

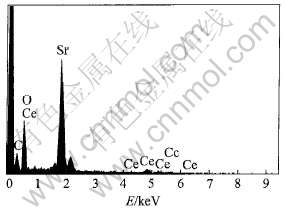

2.4 陶瓷断口晶界处的新相

在25000倍的扫描电镜下观察上述陶瓷断口形貌, 发现在陶瓷边界处的孔洞里出现了一些不同于周围正常晶体形状的花状物(图7)。 这些花状物零星地分散在陶瓷基体的孔洞中。 由花状晶体的能谱分析(图8)可知, 它的组成元素为Sr, C, O和Ce, 其中Sr与O的摩尔比约为1∶3, 而Ce的含量较少, 推测花状晶体的主要成分可能为SrCO3。 从晶体形状来看, SrCO3的晶体呈针状, 集合体呈纤维状, 这与所观察到的花状晶体形状是相吻合的。 同时进一步证实了上述判断。 从产生的可能性来看, 由于在陶瓷成型过程中, 添加的粘结剂和润滑剂都是有机物, 在烧结过程中会产生一定的CO2气体。 残留在基体封闭孔洞中的CO2就和SrO反应生成SrCO3。 然而, 生成反应SrO+CO2(g)=SrCO3的热力学计算表明, 平衡温度为1155℃,而低于平衡温度的吉布斯自由能均为负值。 当坯体在1300℃下烧结时, SrCO3会热分解, 因此, 现在基体中的SrCO3应该是在冷却过程中形成的。

图7 陶瓷断口孔洞中花状晶体的SEM像

Fig.7 SEM image of crystals like flower in hole of ceramics fracture

图8 花状晶体的EDAX谱

Fig.8 EDAX pattern of crystals like flower

3 结论

1) 以溶胶凝胶法制得纳米陶瓷粉SrCe0.9Y0.1-O3-α, 经1000℃煅烧制得粉体的粒径为30~60nm。

2) 当成型压力为20~250MPa时, 素坯的相对密度在150MPa时达到最大值54.25%。

3) 陶瓷的烧结基本分为3个阶段: 线性收缩率很小的烧结初期(〈1150℃), 线性收缩率迅速增加的烧结中期(1150~1250℃)和线性收缩率增加变缓的烧结后期(>1250℃)。

4) 采用RCS烧结制度在较短的烧结时间里获得相对密度为98%, 平均晶粒度小于1μm的致密陶瓷。

5) 在陶瓷断口的晶界出现了花状晶体, 主要成分为SrCO3, 可能是在烧结冷却阶段形成的。

REFERENCES

[1]Iwahara H, Esaka T, Uchida H, et al. Proton conduction in sintered oxides and its application to steam electrolysis for hydrogen production[J]. Solid State Ionics, 1981, 3-4: 359-363.

[2]Yajima T, Iwahara H. Studies on proton behavior in doped perovskite type oxides: (Ⅱ)Dependence of equilibrium hydrogen concentration and mobility on dopant content in Yb-doped SrCeO3[J]. Solid State Ionics, 1992, 53-56: 983-988.

[3]Guan J, Dorris S E, Balachandran U, et al. Transport properties of SrCe0.95Y0.05O3-δ and its application for hydrogen separation[J]. Solid State Ionics, 1998, 110(3-4): 303-310.

[4]Balachandran U, Ma B, Maiya P S, et al. Development of mixed-conducting oxides for gas separation[J]. Solid State Ionics, 1998, 108(1-4): 363-370.

[5]Song S J, Lee T H, Wachsman E D, et al. Defect structure and transport properties of Ni-SrCeO3 cermet for hydrogen separation membrane[J]. Journal of the Eletrochemical Society, 2005, 152(11): 125-129.

[6]Kosacki I, Anderson H. Nanostructured oxide thin films for gas sensors[J]. Sensors and Actuators B, 1998, 48(1-3): 263-269.

[7]Katahira K, Matsumoto H, Iwahara H, et al. A solid electrolyte steam sensor with an electrochemically supplied hydrogen standard using proton-conducting oxides[J]. Sensors and Actuators B, 2000, 67(1-2): 189-193.

[8]Matsumoto H, Hayshi H, Shimura J, et al. Hydrogen isotope sensor using high temperature proton conducors[J]. Solid State Ionics, 2004, 175(1-4): 491-495.

[9]Schober T, Krug F, Schilling W. Criteria for the application of high temperature proton conductors in SOFCs[J]. Solid State Ionics, 1997, 97(1-4): 369-373.

[10]Hirabayashi D, Tomita A, Teranishi S, et al. Improvement of a reduction-resistant Ce0.8Sm0.2O1.9 electrolyte by optimizing a thin BaCe1-xSmxO3-α layer for intermediate-temperature SOFCs[J]. Solid State Ionics, 2005, 176(9-10): 881-887.

[11]Pliangos C, Raptis C, Badas T, et al. Electrochemical promotion of NO reduction by C3H6 on Rh/YSZ catalyst-electrodes[J]. Solid State Ionics, 2000, 136-137: 767-773.

[12]宿新泰, 刘瑞泉, 王吉德. SrCe0.95Yb0.05O3-α在中温区的电化学性质及其在常压合成氨中的应用[J]. 化学学报, 2003, 61(4): 505-509.

SU Xin-tai, LIU Rui-quan, WANG Ji-de. Electrochemical properties of SrCe0.95Yb0.05O3-α at intermediate temperature and its application to ammonia synthesis at atmosphereic pressure[J]. Acta Chi Mica Sinica, 2003, 61(4): 505-509.

[13]Dionysios D, Xiwang Q. Preparation and characterization of proton conducting terbium doped strontium cerate membranes[J]. Journal of Membrane Science, 1999, 154(2): 143-153.

[14]张建敏, 王吉德, 王疆英, 等. 柠檬酸盐法制备纳米晶SrCe0.95Yb0.05O3-α[J]. 中国粉体技术, 2000, 6(3): 19-21.

ZHANG Jian-min, WANG Ji-de, WANG Jiang-ying, et al. Preparation of nanocrystalline SrCe0.95Y0.05O3-α by using citrate method[J]. China Powder Science and Technology, 2000, 6(3): 19-21.

[15]张建敏, 王吉德, 岳凡, 等. 纳米晶SrCe0.95Y0.05-O3-α烧结特性的研究[J]. 化学研究与应用, 2000, 12(6): 664-667.

ZHANG Jian-min, WANG Ji-de, YUE Fan, et al. Sintering process study of the SrCe0.95Y0.05O3-α nano-powder[J]. Chemical Research and Application, 2000, 12(6): 664-667.

[16]高濂, 李蔚. 纳米陶瓷[M]. 北京: 化学工业出版社, 2002.

GAO Lian, LI Wei. Nano-ceramics[M]. Beijing: Chemical Industry Publishers, 2002.

[17]Palmour H Ⅲ, Johnson R D. Sintering and Related Phenomena[M]. New York: Gordon & Breach Publishers, 1967.

基金项目: 上海市教委重点基金资助项目(01AZ01)

收稿日期: 2005-09-27; 修订日期: 2005-12-25

通讯作者: 丁伟中, 教授, 博士; 电话: 021-56331618; E-mail: wzhding@public7. sta. net. cn

(编辑李艳红)