ZM6镁合金化学镀镍预处理工艺及镀层耐蚀性

高艳蕊,刘楚明,傅圣利,李慧中,舒心,高永浩

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:采用浸锌预处理工艺,研究在碱式碳酸镍体系中ZM6镁合金表面化学镀镍层性能。用扫描电镜(SEM)、能谱仪(EDS)和X线衍射仪(XRD)研究浸锌层和镀镍层的形貌、成分及镀层结构,采用极化曲线测试镀层的耐蚀性。研究结果表明,浸锌溶液中加入Sn2+可在ZM6镁合金表面获得均匀致密的浸锌层,后续在碳酸镍体系中施镀1 h后所得非晶态Ni-P镀层均匀致密,无明显缺陷,厚度为8.74 μm,磷质量分数达9.29%;在3.5% NaCl溶液中,镀层的自腐蚀电位为-0.609 V,腐蚀电流密度约为基体的1/10,耐腐蚀性能良好。

关键词:ZM6镁合金;浸锌;化学镀镍;耐蚀性

中图分类号:TG178 文献标志码:A 文章编号:1672-7207(2011)05-1248-06

Pretreatment process and corrosion resistance of electroless nickel plating on ZM6 magnesium alloy

GAO Yan-rui, LIU Chu-ming, FU Sheng-li, LI Hui-zhong, SHU Xin, GAO Yong-hao

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Nickel coating was prepared on ZM6 magnesium alloy by electroless nickel plating in nickel carbonate bath with pretreatment of zinc immersion. The morphology and composition of zinc coating and electroless nickel coating were studied by scanning electronic microscopy (SEM) and energy dispersive spectroscopy (EDS). The structure of nickel coating was studied by X-ray diffraction spectroscopy (XRD). Potentiodynamic polarization analysis was used to study the corrosion resistance of the coating. The results indicate that a compact, well-distributed zinc coating is obtained on the surface of ZM6 alloy in a new zinc immersion solution with addition of Sn2+. The subsequent amorphous electroless nickel coating is uniform and the thickness is 8.74 μm after 1 h deposition. Phosphorus mass fraction is 9.29%. The corrosion potential is -0.609 V, and the corrosion current density is about 1/10 of substrate in 3.5% NaCl solution.

Key words: ZM6 magnesium alloy; zinc immersion; electroless nickel plating; corrosion resistance

镁合金具有密度小、比强度高、降噪减振、可回收等优异特性,已受到汽车、航空航天、电子、通讯等行业广泛关注.然而,由于镁合金的化学活性较 高,耐蚀性和耐磨性差,限制了其广泛应用[1-4]。在镁合金基材上化学镀镍不仅可以使其获得较强的耐蚀性和耐磨性,而且具有可焊性和导电性以及金属的质感和外观[5]。镁合金的化学镀镍主要有浸锌法和直接化学镀镍2种方法。直接化学镀镍结合力较弱,在镀前先浸锌(标准电位为-0.76 V),有利于提高镀层和基体的结合力[6]。Dennis等[7-8]认为浸锌工艺的关键在于控制锌在镁合金表面局部阴极区域的择优生长,以获得均匀的锌的分布。孙忠武等[9]研究了Ni2+等合金离子对浸锌层的影响,加入Ni2+对覆盖率影响不大,但能细化晶粒,使Zn层更加致密,且能提高结合力。但Sn2+对浸锌层影响的研究少见报道。一般认为含Cl-和SO42-的镀液对镁合金具有较强的腐蚀,故常采用碱式碳酸镍为主盐的化学镀镍工艺。目前,国内外对镁合金化学镀镍的研究主要集中在AZ91和AZ31等镁合金上[4, 10-11]。ZM6(Mg-RE-Zn-Zr)合金系作为耐热高强度铸造镁合金,人们对其研究主要集中在高温力学性能和腐蚀性能方面[12-13],对其表面化学镀镍研究较少。故本文作者选取ZM6镁合金为基底,采用浸锌预处理,在碱式碳酸镍体系中进行化学镀镍,研究Sn2+对浸锌层生长过程的影响及镀镍层的耐蚀性能。

1 实验

1.1 实验材料和工艺

本试验采用ZM6合金,成分为Mg-2.6Nd-0.6Zn- 0.8Zr,制成毛坯后进行T6处理。试样的长度×宽度×高度为20 mm×15 mm×5 mm,经1 000号碳化硅水磨砂纸打磨后清洗干燥待用。化学镀镍工艺流程为预磨试片一碱洗一浸锌一化学镀镍—吹干。各步之间用蒸馏水清洗。经优化后浸锌溶液成分和操作条件为:20~30 g/L氧化锌,0.05 mol/L Sn2+,75~85 mL/L羟基亚乙基二磷酸(HEDP),12~20 mL/L乙二胺,5~9 mL/L磷酸,适量氢氧化钠,pH 9.0~10,温度80~85 ℃,时间30 s。化学镀镍液成分和操作条件为:10~15 g/L碱式碳酸镍,20~30 g/L次亚磷酸钠,20~25 mL/L氢氟酸,15~18 mL/L乳酸,3~4 mL/L光亮剂,pH 4.0~4.5,温度80~85 ℃,时间1 h。

1.2 形貌观察与性能测试

采用扫描电子显微镜(SEM)和能谱仪(EDS)对镀层表面进行形貌观察和成分分析,并通过X线衍射仪(XRD)检测化学镀层的物相结构。采用极化曲线测定评价镀镍层的耐蚀性。利用CHI660电化学工作站测试ZM6镁合金基体镀镍前后在3.5%(质量分数) NaCl溶液中的塔菲尔极化曲线,工作面积为1 cm2,饱和甘汞电极为参比电极,铂电极为辅助电极。

2 结果与讨论

2.1 基体显微组织

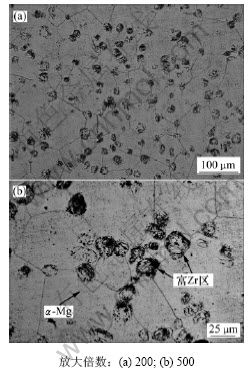

图1所示为ZM6基体材料经T6处理后的显微组织。由图1可见:晶粒粒径约为60 μm,第二相成团簇状分布于晶内与晶界处。Chang等[12]认为ZM6合金主要由Mg基体和富Zr区组成。由于第二相电位较基体高,成为有效阴极相,这一组织结构特点对预处理和化学镀过程都会产生一定的影响。

图1 ZM6合金T6处理后显微组织

Fig.1 Optical microstructure of ZM6 magnesium alloy after T6 treatment

2.2 浸锌层生长过程

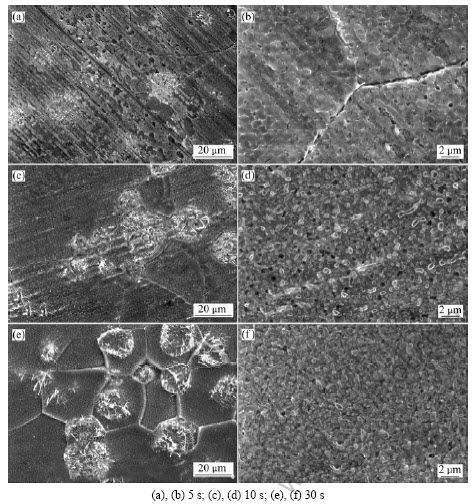

图2所示为浸锌过程中时间分别为5,10和30 s时的表面形貌。图2(a)和(b)结合基体显微组织(图1(b))表明:在5 s时第二相位置上有白色物质出现,浸锌层疏松多孔沿基体划痕生长,晶粒成片状分布,尺寸约1 μm。图2(c)和(d)表明:浸锌10 s后,白色物质在第二相上增多,并开始在晶界处沉积;Zn晶粒较5 s时细小,呈颗粒状分布。这是由于置换反应速度变慢,Zn生长速度变慢。从图2(e)和(f)可看出:浸锌30 s后白色物质在第二相和晶界处明显增多,且Zn沉积致密。

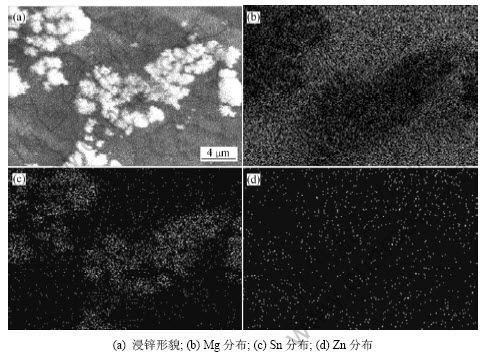

浸锌进行5 s时元素面扫描图谱见图3。其中:图3(a)所示为浸锌进行5 s时浸锌层的表面形貌,图3(b),(c)和(d)所示分别为图3(a)中Mg,Sn和Zn 3种元素的分布,即图中白点部分代表该元素在该区域的分布。从各元素分布位置可以看到Sn主要沉积在第二相位置上,Mg主要分布在基体中,而Zn几乎均匀分布于基体和第二相中。

图2 浸锌层生长过程中表面形貌变化

Fig.2 Surface morphology of zinc coatings for different time during growing

图3 浸锌进行5 s时表面元素分布

Fig.3 SEM micrograph and elements distributions of zinc coating surface for 5 s

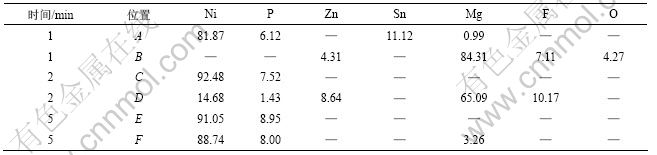

表1所示为对浸锌层生长过程中不同位置EDS分析结果。由表1可以看出:随浸锌时间增加,Sn含量在第二相中明显增加,在基体相中变化不大,这与浸锌层形貌中第二相上Sn变化规律相吻合。Zn含量在基体和第二相中均增加,Mg与之相反。

表1 浸锌层生长过程中不同时间EDS分析结果(质量分数)

Table 1 EDS results of zinc coating for different time during growing %

浸锌合金液中的锌和羟基亚乙基二磷酸(HEDP)以络合离子[Zn(HEDP)2]2-形式存在,基体刚浸入浸锌液时主要发生氧化膜的溶解,之后镁与浸锌液中的H+直接反应,放出H2气体,[Zn(HEDP)2]2-络离子解离出Zn2+,得到电子并在镁表面沉积,形成封闭的浸锌层后将阻止内部镁的溶解,逐渐停止放出H2气体。加入合金离子使得浸锌层的元素覆盖率明显提高,而且合金离子电位都较正,会先在镁合金上沉积,形成晶核并与基材形成电偶,促进了反应进行,使得锌易沉积于合金离子周围[9]。本文所用浸锌液中锡和HEDP以络合离子[Sn(HEDP)2]2-形式存在,[Sn(HEDP)2]2-的析氢过电位比[Zn(HEDP)2]2-的高,Sn与第二相中Mg置换强烈,第二相上优先沉积Sn,故可抑制Zn在第二相上的择优生长,使其均匀沉积。

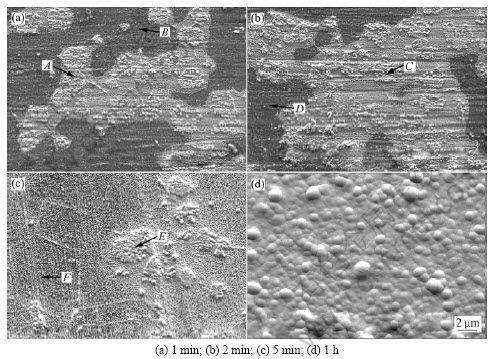

2.3 镀层生长过程

图4所示为化学镀时间分别为1 min,2 min,5 min和1 h时镀层表面形貌;表2所示为化学镀时间分别为1,2和5 min时镀层不同位置EDS分析结果。镍初始沉积具有电化学性质,Ni优先在第二相上沉积。结合图4和表2并对比基体显微组织(图1(a))可以看出:化学镀1 min后(见图4(a)),第二相位置(A处)和部分基体上有白色物质沉积,晶界处隐约可见。经EDS分析知A处主要含Ni,Sn和P元素,B处主要含Mg,F,Zn和O等元素。化学镀2 min(见图4(b))后,白色区域继续由第二相向基体扩展,C处Ni含量较A处增加,且不含Sn元素, 说明第二相上逐渐沉积的Ni将Sn覆盖。D处开始有少量Ni和P出现,说明已经发生了镍的化学沉积。化学镀5 min(见图4(c))后,白色沉积已经覆盖几乎整个表面,晶界清晰可见。E处Nit P含量较C处的变化不大,F处Ni和P含量较D处的增加明显。化学镀1 h后(见图4(d)),镀层为均匀细小的胞状物,无明显缺陷及孔隙,经EDS分析可知磷含量达9.29%(质量分数),属于高磷镀层。

Ni与第二相上Mg发生置换,Sn电位比Ni(标准电位为-0.25)的正[14],故Sn在镀液中不与Ni发生置

图4 化学镀时间不同时镍层的表面形貌

Fig.4 Surface morphology of electroless nickel coatings of different time

表2 不同时间镀层EDS分析结果

Table 2 EDS results of electroless nickel coating for different time

换。化学镀前期B和D处检测到F元素。F元素是从镀液中带入的,高温下氟化反应完全,形成的MgF2膜可保护镁基体免遭受镀液腐蚀[15]。

2.4 镀层截面成分分析

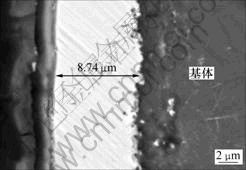

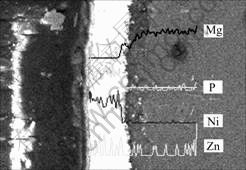

图5所示为化学镀1 h后镀镍层截面形貌。从图5可见:镀层无明显缺陷,无分界和夹杂现象,与基体相互咬合,结合良好。镀层厚度为8.74 μm,即镀速为8.74 μm/h。图6所示为化学镀1 h后镀镍层截面线扫描图。从图6可以看出:Ni和P含量在镀层的不同深度变化不大,说明分布较为均匀。

图5 化学镀1 h后镀镍层截面形貌

Fig.5 Cross-section morphology of electroless nickel coating for 1 h

图6 化学镀1 h后镍层截面线扫描

Fig.6 Line scanning curve of cross-section of electroless nickel coating for 1 h

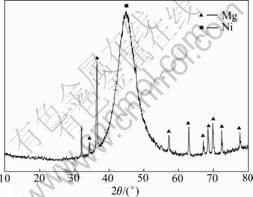

2.5 镀层物相分析

图7所示为ZM6镁合金基体上化学镀1 h后Ni-P层的XRD谱。从图7可见:在2θ约为45°时出现Ni的漫散射宽化峰,说明镀层为非晶态结构;镀层较薄受基体的影响出现了α-Mg衍射峰。

2.6 镀层耐蚀性分析

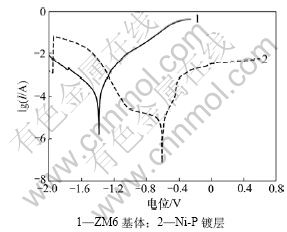

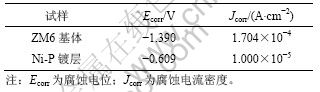

图8所示为ZM6基体与Ni-P镀层(施镀1 h)在 3.5% NaCl溶液中极化曲线对比图,其拟合结果见表3。

图7 化学镀1 h后镀层XRD谱

Fig.7 XRD pattern of electroless coating for 1 h

图8 ZM6基体与Ni-P镀层在3.5% NaCl溶液中动电位极化曲线对比

Fig.8 Polarization curves of ZM6 alloy and Ni-P coating in 3.5% NaCl solution

表3 ZM6基体和Ni-P镀层极化曲线拟合结果

Table 3 Fitting results of polarization curves for ZM6 alloy and Ni-P coating

可以看出镀镍层耐蚀性较基体明显提高,腐蚀电位Ecorr正移了781 mV,腐蚀电流密度Jcorr减小1个数量级。肉眼观察测试后表面形貌发现ZM6基体表面出现点蚀,镀层却仍呈现金属光泽且无点蚀发生。这是由于镀层中的P在阳极极化的过程中加速了Ni的溶解,产生微小的蚀孔,进而在镀层表面形成富P的磷化膜,具有很强的耐腐蚀能力,可对基体起到良好的防护 作用[16]。

3 结论

(1) 浸锌溶液中加入Sn2+,Sn抑制Zn在第二相上的择优生长,获得了均匀的Zn分布,浸锌层在生长过程中逐渐变得细致。

(2) 碱式碳酸镍体系中ZM6镁合金表面可获得均匀致密、与基体结合良好的非晶态Ni-P镀层,磷质量分数为9.29%,属于高磷镀层。

(3) 镀层电位正移781 mV,腐蚀电流较基体降低1个数量级,可对ZM6基体起良好防护作用。

参考文献:

[1] Mordike B L, Ebert T. Magnesium properties-application- potential[J]. Materials Science and Engineering A, 2001, 302: 37-45.

[2] Dabalà M, Brunelli K, Napolitani E, et a1. Cerium-based chemical conversion coating on AZ63 magnesium alloy[J]. Surface and Coatings Technology, 2003, 172: 227-232.

[3] 许光明, 包卫平, 崔建忠, 等. 不同磁场作用下ZK60镁合金的凝固组织[J]. 东北大学学报: 自然科学版, 2004, 25(1): 48-50.

XU Guang-ming, BAO Wei-ping, CUI Jian-zhong, et al. Microstructure of ZK60 magnesium alloy in different magnetic fields[J]. Journal of Northeastern University: Natural Science, 2004, 25(1): 48-50.

[4] Rajan A, Zhou W. Electroless nickel-plating on AZ91D magnesium alloy: Effect of substrate microstructure and plating parameters[J]. Surface and Coatings Technology, 2004, 179: 124-134.

[5] 周婉秋, 单大勇, 曾荣昌, 等. 镁合金的腐蚀行为与表面防护方法[J]. 材料保护, 2002, 35(7): 1-3.

ZHOU Wan-qiu, SHAN Da-yong, ZENG Rong-chang, et al. Corrosion behavior and surface protection method of magnesium alloy[J]. Journal of Materials Protection, 2002, 35(7): 1-3.

[6] 王建泳. 镁合金表面化学镀镍工艺的研究[D]. 上海: 上海大学环境与化学工程学院, 2006: 37-38.

WANG Jian-yong. Research on electroless nickel plating on magnesium alloy[D]. Shanghai: Shanghai University. Department of Environment and Chemical Engineering, 2006, 37-38.

[7] Dennis J K, Wan M K Y Y, Wake S J. Plating on magnesium alloy diecastings[J]. Trans IMF, 1985, 63: 74-80.

[8] Dennis J K, Wan M K Y Y, Wake S J. Plating on magnesium alloy diecastings: The role of fluoride of pH[J]. Trans IMF, 1985, 63: 81-84.

[9] 孙忠武, 钱建刚, 黄巍, 等. 镁合金浸锌合金溶液中合金离子对浸锌层的影响[J]. 材料保护, 2009, 42(1): 30-31.

SUN Zhong-wu, QIAN Jian-gang, HUANG Wei, et al. Effect of alloy ion in zinc dipping solution on zinc coating in magnesium alloy[J]. Journal of Materials Protection, 2009, 42(1): 30-31.

[10] An?k M, K?rpe E. Effect of alloy microstructure on electroless Ni-P deposition behavior on alloy AZ91[J]. Surface and Coatings Technology, 2007, 201: 4702-4710.

[11] 徐二领, 董云会. 两种镍盐体系中镁合金表面化学镀Ni-P层的结构性能[J]. 材料保护, 2008, 41(7): 23-25.

XU Er-ling, DONG Yun-hui. Struction and property of electroless nickel coatings on magnesium alloy in two kinds of main salt solution[J]. Journal of Materials Protection, 2008, 41(7): 23-25.

[12] CHANG Jian-wei, FU Peng-huai, GUO Xing-wu, et al. The effects of heat treatment and zirconium on the corrosion behaviour of Mg-3Nd-0.2Zn-0.4Zr (wt.%) alloy[J]. Corrosion Science, 2007, 49: 2612-2627.

[13] CHANG Jian-wei, GUO Xing-wu, FU Peng-huai, et al. Effect of heat treatment on corrosion and electrochemical behaviour of Mg-3Nd-0.2Zn-0.4Zr (wt.%) alloy[J]. Electrochimica Acta, 2007, 52: 3160-3167.

[14] 李荻. 电化学原理[M]. 北京: 北京航天航空大学出版社, 1998: 73.

LI Di. Electrochemistry theory[M]. Beijing: Beihang University Press, 1998: 73.

[15] 胡波年, 陈珏伶, 余刚, 等. 镁合金在镀液中的腐蚀行为[J]. 中国有色金属学报, 2005, 15(3): 463-470.

HU Bo-nian, CHEN Jue-ling, YU Gang, et al. Corrosion behavior of magnesium alloy in electroless nickel plating bath[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 463-470.

[16] 霍宏伟, 李明升, 尹红生, 等. AZ91D镁合金化学镀镍前处理工艺及腐蚀行为研究[J]. 表面技术, 2006, 35(5): 42-43.

HUO Hong-wei, LI Ming-sheng, YIN Hong-sheng, et al. Investigation of pretreatment process and corrosion behavior of electroless nickel plating on AZ91D magnesium alloy[J]. Surface Technology, 2006, 35(5): 42-43.

(编辑 杨幼平)

收稿日期:2010-06-10;修回日期:2010-08-28

基金项目:国防应用研究项目(JPPT-115-2-794);中南大学贵重仪器设备开放共享基金资助项目(2010年)

通信作者:刘楚明(1960-),男,湖南张家界人,教授,博士生导师,从事镁合金材料性能、组织及加工工艺研究;电话:0731-88877502;E-mail: cmLiu@csu.edu.cn