工业纯铁表面自纳米化及其表征

孙建春1, 2,盛光敏1,王越田1,卢昊1,韩靖1

(1. 重庆大学 材料科学与工程学院,重庆,400044;

2. 重庆科技学院 冶金与材料工程学院,重庆,401331)

摘 要:利用高能喷丸(High energy shot peening, HESP)法在工业纯铁的表面获得一定厚度的纳米晶层,实现工业纯铁表面自纳米化。通过金相显微镜观测、扫描电子显微镜分析、显微硬度测试以及X线衍射计算分析,对工业纯铁表面自纳米化层的组织结构和性能进行研究分析。研究结果表明:采用HESP方法实现工业纯铁表面纳米化的主要工艺参数是:喷丸弹丸为直径1 mm的铸铁,喷丸压力为0.6 MPa,喷枪距离试样表面为5 cm,所获得的纳米晶的厚度随着喷丸时间的增加而增加;剧烈变形层由于晶粒得到了细化,其显微硬度大大提高,在距喷丸面10 μm处,其显微硬度(HV)达到296.6,随着距喷丸面距离的增加,剧烈变形层的硬度不断减小;只要喷丸1 min,即可在工业纯铁表面获得平均晶粒粒径为68.4 nm、微观畸变为0.050%的纳米晶层;随着喷丸时间的延长,晶粒粒径越来越小,而微观应变越来越大;喷丸14 min可在工业纯铁表面获得平均晶粒粒径为28.5 nm、微观畸变为0.175%的纳米晶层。

关键词:工业纯铁;自纳米化;表征

中图分类号:TG142.71 文献标志码:A 文章编号:1672-7207(2011)01-0062-05

Surface self-nanocrystallization of commercial iron and its characterization

SUN Jian-chun1, 2, SHENG Guang-min1, WANG Yue-tian1, LU Hao1, HAN Jing1

(1. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

2. College of Metallurgy and Materials Engineering, Chongqing University of Science and Technology,

Chongqing 401331, China)

Abstract: The commercial iron was successfully surface nanocrystallizated with high energy shot peening (HESP) method. The performance and microstructure of self-surface nanocrystalline layer on the commercial iron were studied and analyzed through microscope observation, scanning electron microscopy (SEM) analysis, microhardness test and X-ray diffraction (XRD) analysis. The results indicate that a nanocrystalline layer of commercial iron can be obtained by HESP method with the following parameters: with 1 mm diameter cast iron shotting ball, 0.6 MPa shotting press and 5 cm distance between the air shotting gun and the sample. The thickness of the nanocrystalline layer increases with the shotting time. And the microhardness (HV) of the nanocrystalline Fe is 296.6 because of containing nano-sized grains. After 1 min shotting, a nanocrystalline layer with the average grain size of 68.4 nm and microstrain of 0.050% is prepared on the commercial iron. While shotting after 14 min, a nanocrystalline layer with the average grain size of 28.5 nm and microstrain of 0.175% is prepared on the commercial iron.

Key words: commercial iron; self-nanocrystallization; characterization

纳米材料的制备一直是纳米领域的研究热点,也是研究难点。虽然发展了多种纳米材料的制备手段,其制备技术也取得了很大进步,但是,受制备工艺复杂、成本高、材料外形尺寸小、内部孔洞和污染等因素的影响,整体的、具有纳米级粒度的金属材料至今难以获得[1-4]。因此,如何采用更为简单、低成本的手段制备含缺陷少的纳米材料成为该领域的追求目标。近年来,采用表面机械研磨处理(Surface mechanical attrition treatment, SMAT)成为一种纳米材料制备新方法,采用该方法获得的纳米晶样品,表层一定深度内的晶粒粒径在100 nm以内,且具有纳米、亚微米和变形晶粒层逐渐过渡的梯度结构和无污染、无孔洞等特点[5-9]。由于SMAT法所制备的纳米材料具有上述特点,所以存在许多潜在的应用价值,目前已在扩散焊接、表面合金化以及渗氮等方面取得了一定应用[10-13]。采用SMAT法已成功实现多种金属及合金表面自纳米 化[6-13]。在用SMAT法制备纳米材料时,超声喷丸(Ultrasonic shot peening, USSP)法得到较多应用,而高能喷丸(High energy shot peening, HESP)法应用较少。虽然有人用USSP实现了纯铁的表面自纳米化[14-15],但目前还未见利用HESP法实现纯铁表面自纳米化的报道。本文作者采用HESP法在工业纯铁表面获得一定厚度的剧烈塑性变形层,通过对这层剧烈塑性变形层的组织结构及性能进行分析与表征,确认在纯铁表面得到的是有一定厚度的纳米晶层,实现了工业纯铁的表面自纳米化。

1 实验材料及方法

1.1 纯铁自纳米化工艺

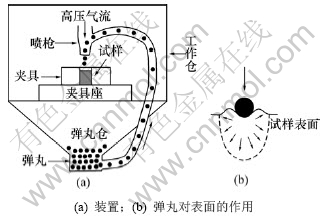

高能喷丸处理原理图见图1。本文所用被喷材料为冷轧工业纯铁,喷丸前材料组织为等轴状α-铁(见图2)。试验时,将其加工成直径×高为10 mm×20 mm圆柱形。HESP过程的主要工艺参数为:所用弹丸为直径1 mm的铸铁,喷丸时空气压力为0.6 MPa,喷枪距离试样表面5 cm。喷丸主要工艺流程为:试样断面磨平→抛光→有机溶剂清洗→喷丸。根据HESP的原理,当其他参数一定时,剧烈变形层的厚度只取决于喷丸时间。为了研究喷丸时间与变形层厚度的关系,结合文献[8]的研究结果,喷丸时间取1,3,5,6,7,8,9,10,12和14 min。

1.2 自纳米化层的表征

首先采用OLYMPUS-GX41型金相显微镜对喷丸过后的变形层进行观察,通过金相显微镜对喷丸所产生的剧烈塑性变形层的厚度、分布及形貌等进行观察,同时对不同喷丸时间得到的变形层厚度进行测量,以观察变形层厚度与时间的关系。此外,利用HV-1000G型显微硬度计对变形层从表面到基体范围内显微硬度进行测量。利用Vega Tescan扫描电子显微镜对剧烈塑性变形层的形貌进行进一步观察,用D/MAX-1400型X线衍射仪对不同喷丸时间得到的剧烈变形层和原始试样进行分析。

图1 高能喷丸处理原理图

Fig.1 Schematic illustration of HESP treatment set-up

图2 剧烈塑性变形层形貌

Fig.2 Microstructure of sever plastic deformed layer

2 结果与讨论

2.1 变形层厚度与时间的关系

从图2可以看出,采用HESP的方法在工业纯铁表面形成了一层剧烈的塑性变形层,从表面往基体延伸的过程中,变形层的变形程度越来越小,整个剧烈塑性变形层具有3个明显的特征:最外层已看不出晶界,整个变形层连成一片(纳米晶区);中间是条纹状的剧烈变形层,条纹之间有明显的界面(亚微米区);第3层是剧烈变形层和基体的过渡带,晶粒变长(变形晶粒区)。3个晶粒区之间仍然连成一片,之间无明显界面;整个剧烈变形层与基体之间虽然存在过渡带,但也无明显界面。

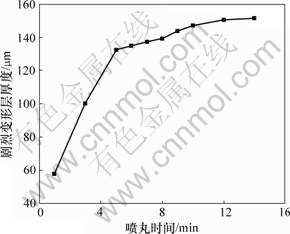

图3所示为剧烈塑性变形层与喷丸时间的关系。从图3可以看出:随着喷丸时间的增加,剧烈塑性变形层的厚度不断增加,但是喷丸6 min以后,增加的幅度非常小;喷丸10 min以后,剧烈变形层的厚度基本不发生变化。之所以剧烈变形层的厚度不再增加。其原因主要有2个:一是在不断喷丸过程中,塑性变形不断进行,产生加工硬化现象,进一步塑性变形受到一定阻碍;二是纯铁具有良好塑性,受到高能喷丸作用,金属不断往两边流动,产生的剧烈变形层无法停留在试样表面,而是流向试样边缘。这2个原因互相作用,导致工业纯铁的剧烈变形层并不是随喷丸时间增加而不断变厚,正是这个原因,导致纯铁剧烈变形层厚度小于采用同样制备方法得到的不锈钢和钛合金剧烈变形层的厚度[6, 11]。

图3 剧烈变形层厚度与喷丸时间的关系

Fig.3 Relationship between thickness of sever plastic deformed layer and shot time

2.2 变形层形貌与晶粒粒径

图4所示为剧烈塑性变形层的SEM照片。从图4可以看出喷丸使得工业纯铁的晶粒发生了非常剧烈的变形,呈沟壑状,已无明显晶界。在剧烈变形层内没有出现较大粒径孔洞。

图5所示为喷丸6 min试样的XRD图谱。从图5可以看出:喷丸6 min试样较原始试样的衍射峰发生了明显的宽化。衍射峰发生宽化的原因主要有3个,即试验条件、晶粒细化以及微观畸变等。当材料内部同时存在晶粒细化和微观畸变时,实际衍射线形的半高宽与材料的晶粒粒径和微观畸变满足下式[16]:

式中:K为晶体形状因素,使用半高宽时取0.89,使用积分宽时取0.94;λ为入射波长,取Cu靶Kα1,波长λ=0.154 056 nm;θ为布拉格角;W(s)=WHMD-WI为物理加宽线形的半高宽;WHMD为实际衍射线形的半高宽;WI为仪器加宽值;D为去卷积参数。

图4 剧烈变形层的SEM照片

Fig.4 SEM images of sever plastic deformed layer

图5 喷丸6 min和原始样的XRD谱

Fig.5 XRD patterns of pre-shoted and as-shoted iron

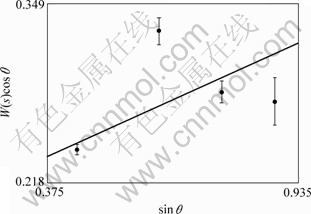

因此,利用最小二乘法拟合出 ~

~  曲线,由该直线的斜率和截距即可求得平均晶粒

曲线,由该直线的斜率和截距即可求得平均晶粒

粒径和微观畸变。图6所示为利用JADE软件对喷丸6 min剧烈变形层晶粒粒径和微观畸变的计算结 果,直线的斜率即为平均晶粒粒径,平均晶粒粒径为43.9 nm;截距即为微观畸变,剧烈变形层的微观畸变为0.065 2%。根据计算结果,喷丸6 min可在工业纯铁表面获得一定厚度的纳米晶层。

图6 喷丸6 min试样晶粒粒径和微观应变计算结果

Fig.6 Grain size and micro-strain of plastic deformed layer

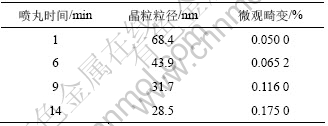

用同样的方法对喷丸1,9和14 min的剧烈变形层XRD结果进行计算,计算结果见表1。从表1可以看出:采用高能喷丸法,只要喷丸1 min即可在工业纯铁表面获得纳米晶;但随着喷丸时间的延长,晶粒粒径越来越小,而微观应变越来越大。文献[14-15]采用超声喷丸60 min在纯铁表面获得平均晶粒粒径为12 nm,微观应变为0.12%的自纳米化层,晶粒粒径要比由本文方法所得的小。主要原因在于:这2种方法都属于SMAT法,都是通过使材料发生剧烈变形来细化晶粒,因此,只有当变形量积累到一定程度时晶粒才能被细化到纳米尺度,积累的塑性变形量越大,晶粒越细小,表1所示结果正好验证了这一点。虽然高能喷丸弹丸的能量高于超声喷丸的能量,但喷丸时间较短,所以,积累的塑性变形量小于采用超声喷丸过程的塑性变形量,故晶粒粒径较由超声喷丸法所得的晶粒大,这是2种方法的主要区别。

表1 喷丸面的晶粒粒径和微观应变计算结果

Table 1 Mean grain size and microstrain on shoted surface

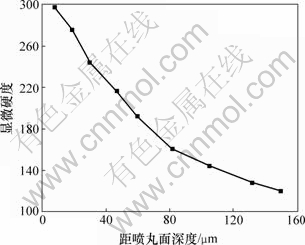

2.3 变形层显微硬度

图7所示为显微硬度(HV)与从表面到基体的距离之间的关系。从图7可以看出:在最外层由于是一层纳米晶,其显微硬度非常高,随着距离表面的距离增加,晶粒粒径不断增大,变形层的显微硬度不断降低。由于表面形成了一层纳米晶,在距表面10 μm,硬度达到了296.6左右。导致显微硬度增加的原因主要是晶粒细化和加工硬化(形变强化)。根据Hall-Petch关系可知:晶粒细化会导致材料强化,使材料的显微硬度提高。当材料受到外力作用发生塑性变形时,位错要沿着某个滑移面运动,当运动至晶界受阻便塞集起来,从而造成应力集中,导致材料强度硬度提高。由于纯铁表面被纳米化,晶粒大大细化,导致晶界数量激增,所以,其硬度有大幅度提高。

图7 自纳米化层的显微硬度与距表面距离的关系

Fig.7 Relationship between microhardness of self-nanocrystalline layer and distance

3 结论

(1) 采用本文喷丸工艺,即用弹丸为直径1 mm的铸铁,喷丸压力0.6 MPa,喷枪距离试样表面5 cm,可以在工业纯铁表面形成一定厚度的纳米晶。喷丸6 min可得到厚度为120 μm的剧烈变形层;进一步增加喷丸时间,剧烈变形层厚度增加量较小。

(2) 剧烈变形层由于晶粒得到了细化,其显微硬度大大提高。在距喷丸面10 μm处,其硬度达到296.6;随着距喷丸面距离的增加,剧烈变形层的显微硬度呈梯度减小。

(3) 采用本文喷丸工艺,只要喷丸1 min,即可在工业纯铁表面获得平均晶粒粒径为68.4 nm、微观畸变为0.050%的纳米晶层;随着喷丸时间的延长,晶粒粒径越来越小,而微观应变越来越大;喷丸14 min可在工业纯铁表面获得平均晶粒粒径为28.5 nm、微观畸变为0.175%的纳米晶层。

参考文献:

[1] Froes F H, Senkov O N, Baburaj E G. Synthesis of nanocrystalline materials-an overview[J]. Materials Science and Engineering A, 2001, 301: 44-53.

[2] Erb U, El-Sherik A M, Palumbo G, et al. Synthesis, structure and properties of electroplated nanocrystalline materials[J]. Nanostructural Materials, 1993, 2(4): 383-390.

[3] Birringer R, Gleiter H, Klein H P, et al. Nanocrystalline materials: an approach to a novel solid structure with gas-like disorder[J]. Physics Letter A, 1984, 102: 365-371.

[4] Estrin Y, Kim H S. Strength and strain hardening of nanocrystalline materials[J]. Materials Science and Engineering A, 2008, 483/484: 127-130.

[5] 刘刚, 周蕾. 工程金属材料的表面纳米化技术[J]. 纳米科技, 2006, 3(2): 51-56.

LIU Gang, ZHOU Lei. Surface nanocrystallization technique of the engineering metallic materials[J]. Nanoscience & Technology, 2006, 3(2): 51-56.

[6] 韩靖, 盛光敏, 胡国雄. 高能喷丸0Cr18Ni9Ti不锈钢纳米化机理[J]. 中南大学学报: 自然科学版, 2009, 40(3): 644-649.

HAN Jing, SHENG Guang-min, HU Guo-xiong. Self- nanocrystallized mechanism for 0Cr18Ni9Ti by means of high energy shot peening[J]. Journal of Central South University: Science and Technology, 2009, 40(3): 644-649.

[7] Park K T, Shin D H. Annealing behavior of submicrometer grained ferrite in a low carbon steel fabricated by severe plastic deformation[J]. Materials Science and Engineering A, 2002, 334(1/2): 79-86.

[8] Wadsack R, Pippan R, Schedler B. Structural refinement of chromium by severe plastic deformation[J]. Fusion Engineering and Design, 2003, 66/68: 265-269.

[9] YONG Xing-ping, LIU Gang, ZHOU Lei, et al. Characterization and properties of nanostructured surface layer in a low carbon steel subjected to SMAT[J]. Journal of Materials Science and Technology, 2003, 19(1): 1-4.

[10] Valiev R Z, Korznikov A V, Mulyukov R R. Structure and properties of ultrafine-grained materials produced by severe plastic deformation[J]. Materials Science and Engineering A, 1993, 168(2): 141-148.

[11] HAN Jing, SHENG Guang-min, ZHOU Xiao-ling, et al. Pulse pressuring diffusion bonding of Ti alloy/austenite stainless steel processed by surface self-nanocrystallization[J]. ISIJ International, 2009, 49(1): 86-91.

[12] HAN Jing, SHENG Guang-min, ZHOU Xiao-ling. Diffusion bonding of surface self-nanocrystallized Ti-4Al-2V and 0Cr18Ni9Ti by means of high energy shot peening[J]. ISIJ International, 2008, 48(9): 1238-1245.

[13] 王丽梅, 佟伟平. 表面纳米化38CrMoAl钢的低温离子氮碳共渗[J]. 纳米加工工艺, 2007, 4(5): 42-48.

WANG Li-mei, TONG Wei-ping. Ion nitriding and carburization process in surface-nanocrystallized 38CrMoAl steel at low temperature[J]. Nano-processing and Technique, 2007, 4(5): 42-48.

[14] TAO Nai-rong, WANG Zhen-bo, TONG Wei-ping, et al. An investigation of surface nanocrystallization mechanism in Fe by surface mechanical attrition treatment[J]. Acta Mater, 2002, 50(18): 4603-4616.

[15] TAO Nai-rong, SUI Man-ling, LU Jian, et al. Surface nanocrystalliation of iron by ultrasonic shot peening[J]. Nanostructural Materials, 1998, 11(4): 433-440.

[16] 张泽南. X射线衍射在纳米材料物理性能测试中的应用[J]. 浙江工业大学学报, 2002, 30(1): 31-55.

ZHANG Ze-nan. Application of XRD analysis to test physical properties of nano-materials[J]. Journal of Zhejiang University of Technology, 2002, 30(1): 31-55.

(编辑 杨幼平)

收稿日期:2010-01-05;修回日期:2010-04-28

基金项目:国家自然科学基金资助项目(50675234)

通信作者:孙建春(1977-),男,江苏淮安人,博士研究生,讲师,从事材料表面改性及纳米材料研究;电话:023-65023714;E-mail: kwensun@163.com