文章编号: 1004-0609(2005)03-0410-05

Ca对原位自生Mg2Si/ZM5复合材料

组织与性能的影响

陈 晓1, 2, 傅高升2, 钱匡武1, 2

(1. 中南大学 材料科学与工程学院, 长沙 410083;

2. 福州大学 机械工程学院, 福州 350002)

摘 要: 通过真空感应炉中氩气保护, 在ZM5熔体中加入Si获得原位反应自生Mg2Si/ZM5复合材料。 采用金相显微镜、 环境扫描电镜、 拉伸实验等研究了Ca对该材料组织与性能的影响规律。 结果表明: Ca的加入改变了Mg2Si/ZM5复合材料中Mg2Si相的形貌, 使其从不规则的汉字状变成较细小的多角形, 从而改善了材料的力学性能; 当加入0.05%Ca(质量分数)时, 复合材料的室温力学性能最好, 屈服强度提高了10.4%, 延伸率提高了52.4%; 在200℃高温下, 当含Ca 0.05%~0.10%(质量分数)时其屈服强度和延伸率最好, 分别提高了30.1%和92.3%。

关键词: 镁合金; 金属基复合材料; 力学性能; 原位反应; Ca变质

中图分类号: TG146.2; TG113 文献标识码: A

Influence of Ca addition on microstructure and mechanical properties of in-situ Mg2Si/ZM5 magnesium matrix composite

CHEN Xiao1, 2, FU Gao-sheng2, QIAN Kuang-wu1, 2

(1. School of Materials Science and Engineering, Central South University,

Changsha 410083, China;

2. School of Mechanical Engineering, Fuzhou University, Fuzhou 350002, China)

Abstract: The in-situ Mg2Si/ZM5 magnesium matrix composite was fabricated by adding Si into the molten ZM5 magnesium alloy under argon atmosphere in vacuum induction furnace. The effects of Ca on microstructure and mechanical properties of in-situ Mg2Si/ZM5 magnesium matrix composite were investigated by opitical microscope, environmental scanning electron microscope, tensile test machine, etc. It is found that with the increasing Ca addition in composites, Mg2Si is transformed from a irregular Chinese script morphology to fine granular morphology, thus improving the mechanical properties of the material. When Ca addition is about 0.05%(mass fraction), excellent properties can be obtained, i.e., the increase of yield strength and elongation of the material is about 10.4% and 52.4%, respectively. At 200℃, when Ca addition is about 0.05%-0.10%(mass fraction), the yield strength and elongation of the material can reach the highest values, the extent of increase is about 52.4% and 92.3%, respectively.

Key words: magnesium alloy; metal matrix composite; mechanical property; in-situ reaction; Ca modification

镁基复合材料密度小, 仅为铝或铝基复合材料的66%左右, 具有高的比强度和比刚度以及优良的力学和物理性能, 在高新技术领域中比传统金属材料和铝基复合材料的应用潜力更大, 因此, 自20世纪80年代末以来, 镁基复合材料已经逐渐成为金属基复合材料领域的研究热点之一[1-8].采用原位反应法获得自生增强相的自生复合材料, 由于增强相在基体内反应生成, 具有尺寸小, 界面洁净无污染, 热稳定性好, 与基体相容性好, 制备成本低等优点, 已成为镁基复合材料中的一个重要发展方向[9-11]。

Mg2Si相具有熔点高(1085℃), 密度低(1.99×103kg/m3) , 硬度高(4500MN/m2), 热膨胀系数低(7.5×10-6K-1)和弹性模量高(120GPa) [12-15], 是镁基复合材料很好的增强相之一。 但若在传统的铸造Mg合金中利用原位反应自生成Mg2Si增强相, 则由于所生成的Mg2Si相非常粗大, 极大地割裂了基体, 使材料性能显著降低。 如能在熔体中添加某些物质来细化自生Mg2Si相, 必将大大改善复合材料的组织和性能, 并将可以降低成本, 推动自生 Mg2Si/Mg基复合材料的应用。 为此, 本文作者研究了Ca对铸造原位反应自生Mg2Si/ZM5复合材料中Mg2Si相的变质作用及其对该复合材料力学性能的影响。

1 实验

选用纯Mg、 纯Al、 纯Si、 纯Zn、 Mg-30Ca中间合金、 Al-10Mn中间合金作为原材料。 基体合金采用ZM5镁合金, 在基体合金中添加1.00%(质量分数)的Si, 以便获得Mg2Si增强相(体积分数约为2.5%)增强的自生Mg2Si/ZM5复合材料。 合金熔炼在真空感应炉中进行, 采用Ar气为保护气体, 基体合金熔化后加入 Si, 待Si熔化后于800℃左右加入Mg-30Ca中间合金进行变质处理, 30min后将800℃的合金液浇入放置在真空炉中的金属型内, 获得所需的自生Mg2Si/ZM5复合材料, 所得试样尺寸为120mm×20mm×80mm。 用金相显微镜(OM)和Philips XL30型环境扫描电镜(ESEM)进行组织分析; 室温和200℃的高温拉伸实验在Instron1185电子拉伸机上进行, 板状拉伸试样尺寸为25mm×5mm×3mm, 拉伸速率为0.5mm/min。

2 结果与分析

2.1 Ca对自生Mg2Si/ZM5复合材料组织的影响

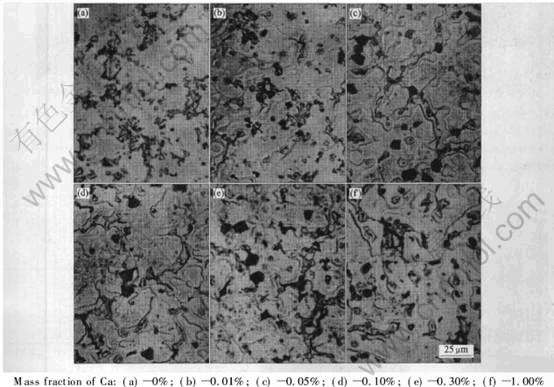

图1、 2所示分别为Ca变质后自生Mg2Si/ZM5复合材料的铸态和T4处理态(415℃, 16h, 水淬)的金相显微组织。 从图中可以看出, 未加Ca变质时Mg2Si相为不规则的汉字状; 加入0.01%

图1 不同Ca含量自生Mg2Si/ZM5复合材料铸态的显微组织

Fig.1 As-cast microstructures of in-situ Mg2Si/ZM5 magnesium matrix composites with different Ca additions

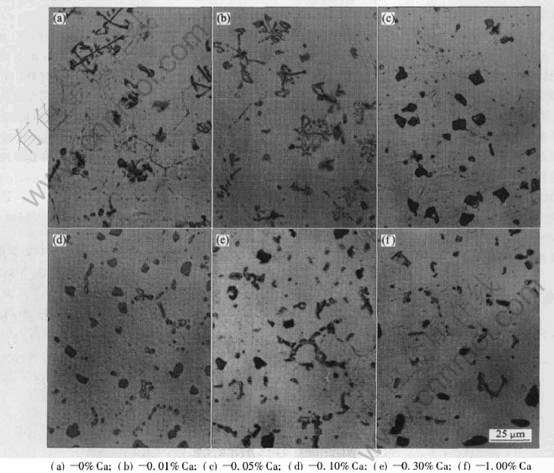

Ca时Mg2Si相变化不大, 加入0.05%后其形貌从不规则的汉字状转为细小的多角形, 继续增加Ca含量, Mg2Si 相的变化不大, 但Ca量增加到0.30%后, 在T4处理的组织中除Mg2Si 相外, 还观察到少量沿晶界分布的第二相(如图2(d)所示)。

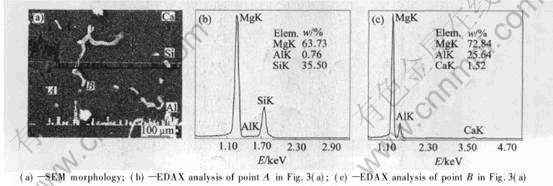

图3所示为含0.30%Ca的自生Mg2Si/ZM5复合材料经T4处理后元素的线分布和能谱分析结果。 能谱分析结果表明, 除未溶的Mg2Si相外, 还有沿晶界分布含有Ca的第二相存在; 元素线分布结果表明, 除沿晶界分布的第二相中有Ca外, Mg2Si相边缘也有Ca聚集, 这表明Ca是一种表面活性剂, 结晶时能吸附在Mg2Si相界面上[16], 从而改变Mg2Si相结晶条件, 使其从不规则的汉字状转变为多角形。

图2 不同Ca含量自生Mg2Si/ZM5复合材料固溶处理态的显微组织

Fig.2 Microstructures of in-situ Mg2Si/ZM5 magnesium matrix composites as solution treated with different Ca additions

图3 含0.30%Ca自生Mg2Si/ZM5复合材料的SEM组织及能谱分析

Fig.3 EDAX analysis of in-situ Mg2Si/ZM5 magnesium matrix composite with 0.30% Ca addition

2.2 Ca对自生Mg2Si/ZM5复合材料力学性能的影响

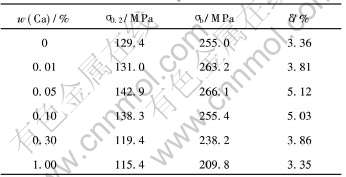

经Ca变质处理的Mg2Si/ZM5复合材料经T6处理(415℃, 16h, 水淬; 215℃, 8h)后的室温拉伸性能列于表1。 可以看出, 加入0.05%和0.10%Ca变质后, 复合材料的屈服强度和延伸率都得到明显提高; 0.05%Ca变质时, 提高的幅度最大, 分别为10.4%和52.4%, 这主要是由于Ca的变质作用使Mg2Si 相从不规则的汉字状转变为规则的多角形, 减少了应力集中, 从而使材料的屈服强度和延伸率都得到提高, 但Ca含量过多时(超过0.10%), 将会形成沿晶界分布的具有不规则外形的含Ca相, 反而使材料的屈服强度和延伸率下降。 少量的Ca对抗拉强度影响不大, 但Ca含量过多(超过0.10%)时, 所形成的沿晶界分布的不规则形状含Ca相, 将会使材料的抗拉强度下降。

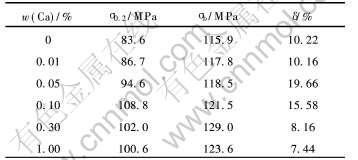

经Ca变质处理后的Mg2Si/ZM5复合材料经

表1 室温下Ca含量对含1.0%Si的Mg2Si/ZM5复合材料力学性能的影响

Table 1 Effects of Ca additions on mechanical properties of in-situ Mg2Si/ZM5 magnesium matrix composites with 1.0%Si at room temperature

T6处理后, 在200℃下的拉伸力学性能列于表2。 可以看出, 加入Ca后, 复合材料的屈服强度和抗拉强度都得到提高。 开始时, 材料的强度随Ca量的增加而增加, 在0.10%Ca左右时达到最大值(屈服强度提高了30.1%), 而后随Ca量的增加, 强度开始下降, 但都比末加Ca变质的高; 经0.05%~0.10%Ca变质后, 复合材料的延伸率明显提高; 0.05%Ca变质后, 延伸率提高了92.3%; 但当Ca量达到0.3%时, 材料的延伸率开始下降。 在200℃ 温度下, 复合材料的强度都得到提高, 除了Ca的

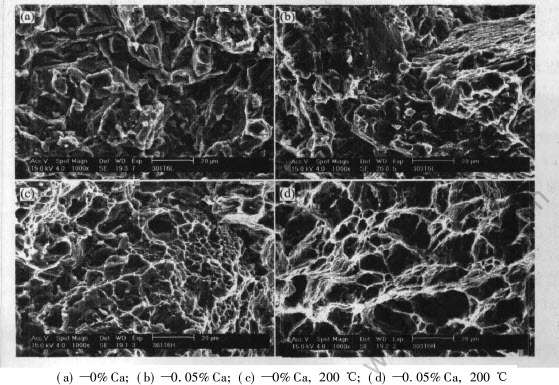

图4 自生Mg2Si/ZM5复合材料拉伸断口的ESEM形貌

Fig.4 ESEM morphologies of tensile fractography of in-situ Mg2Si/ZM5 magnesium matrix composites with different Ca additions

变质作用使Mg2Si相从不规则的汉字状转变为规则的多角形, 减少了应力集中外, 沿晶界分布的含Ca耐热相也有一定的强化作用。 但当这种沿晶界分布的相过多时, 会使材料的延伸率和强度下降。

表2 高温下Ca含量对含1.0%Si的Mg2Si/ZM5复合材料力学性能的影响

Table 2 Effects of Ca additions on mechanical properties of in-situ Mg2Si/ZM5 magnesium matrix composites with 1.0%Si at 200℃

图4(a)所示为原位反应Mg2Si/ZM5复合材料室温拉伸断口形貌。 为解理断裂, 加入0.05%Ca变质后, 出现了韧窝(图4(b)所示), 使延伸率得到提高; 图4(c)、 4(d)所示为200℃高温拉伸时的断口, 存在大量的韧窝, 0.05%Ca变质处理后(图4(d)所示)韧窝比末变质的深(图4(c)所示), 其对应的延伸率也较高。

3 结论

1) Ca能显著改善原位反应自生Mg2Si/ZM5复合材料中Mg2Si相的形状与分布, 使Mg2Si相形貌从不规则的汉字状变为细小的多角形; Ca含量为0.05%时就有很好的变质效果; Ca含量超过0.10%时, T4处理后出现沿晶界分布的含Ca相。

2) Ca能显著改善原位反应自生Mg2Si/ZM5复合材料的室温屈服强度和延伸率。 当Ca含量为0.05%时, 其性能最好, 该复合材料的屈服强度提高了10.4%, 延伸率提高了52.4%。

3) Ca能显著改善原位反应自生Mg2Si/ZM5复合材料在200℃下的屈服强度和延伸率。 当Ca含量为0.05%~0.10%时, 该复合材料的屈服强度和延伸率最高, 分别提高了30.1%和92.3%。

REFERENCES

[1]Inem B, Pollard G. Interface structure and fractography of a magnesium-alloy, metal-matrix composite reinforced with SiC particles[J]. Mater Sci, 1993, 28(16): 4427-4434.

[2]Sohn K S, Kwangjun E, Lee S, et al. Mechanical property and fracture behavior of squeeze-cast Mg matrix composites[J]. Metall Mater Trans A, 1998, 29A(10): 2543-2554.

[3]Hu H. Squeeze casting of magnesium alloys and their composite[J]. Mater Sci, 1998, 33(6): 1579-1589.

[4]Hu H. Grain microstructure evolution of Mg (AM50A)/SiCp metal matrix composites[J]. Scripta Mater, 1998, 39(8): 1015-1022.

[5]Oo M K K, Ling P S, Gupta M. Characteristics of Mg-based composites synthesized using a novel mechanical disintegration and deposition technique[J]. Metall Mater Trans A, 2000, 31A: 1873-1881.

[6]Saravanan R A, Surappa M K. Fabrication and characterisation of pure magnesium-30vol%SiCp particle composite[J]. Mater Sci Eng A, 2000, A276(1): 108-116.

[7]Lee D M, Suh B K, Lee J S, et al. Fabriaction, microstructures, and tensile properties of magnesium alloy AZ91/SiCp composites produced by powder metallurgy[J]. Mater Sci Tech, 1997, 13(7): 590-595.

[8]ZHENG Ming-Yi, WU Kun, YAO Zhong-kai, et al. Interfacial reaction in squeeze cast SiCw/AZ91 composites with different binders[J]. Trans Nonferous Met Soc China, 2001, 11(2): 217-221.

[9]Wood J V, Davies P, Kellie J L K. Properties of reactively cast aluminium-TiB2 alloys[J]. Mater Sci Tech, 1993, 9(9): 833-840.

[10]Murthy V S R, Rao B S. Microstructure development in the directed melt-oxidized (DIMOX) Al-Mg-Si alloys[J]. Mater Sci, 1995, 30(12): 3091-3097.

[11]Jiang Q C, Li X L, Wang H Y. Fabrication of TiC particle reinforced magnesium matrix composites [J]. Scripta Mater, 2003, 48(6): 713-717.

[12]Zhang J, Fan Z, Wang Y Q, et al. Microstructural development of Al-15vol% Mg2Si in-situ composite with mischmetal addition[J]. Mater Sci Eng A, 2000, A281(1): 104-112.

[13]Mabuchi M, Higashi K. Strengthening mechanisms of Mg-Si alloy[J]. Acta Materialia, 1996, 44(11): 4611-4618.

[14]Mabuchi M, Kubota K, Higashi K. Elevated temperature mechanical properties of magnesium alloys[J]. Mater Sci Tech, 1996, 12(1): 35-39.

[15]Mabuchi M, Kubota K, Higashi K. Tensile strength, ductility and fracture of magnesium-silicon alloys [J]. Mater Sci, 1996, 31(6): 1529-1535.

[16]Pekguleryuz M O, Aveksian M M. Magnesium alloying, some potentials for alloy development[J]. Light Metals, 1992, 42(12):679-686. (in Japanese)

(编辑陈爱华)

基金项目: 福建省自然科学基金资助项目(E0310008); 福建省科技三项费用资助项目(K02019)

收稿日期: 2004-05-25; 修订日期: 2005-01-05

作者简介: 陈 晓(1971-), 男, 讲师, 博士研究生.

通讯作者: 陈 晓, 讲师; 电话: 0591-87893010; 传真: 0591-87892531; E-mail: chx@fzu.edu.cn