文章编号:1004-0609(2010)06-1161-09

喷砂工艺对钛阳极表面形貌、电催化活性和寿命的影响

姜俊峰,孟惠民,孙冬柏

(北京科技大学 材料科学与工程学院 腐蚀与防护中心,北京 100083)

摘 要:通过扫描电镜、X射线衍射、阳极极化曲线和加速寿命等试验研究基体喷砂预处理对Ti/IrO2·Ta2O5阳极的表面形貌、析氧电催化活性和寿命的影响。结果表明:钛阳极表面形貌受喷砂工艺压力和磨料粒度的影响,喷砂压力对钛基体的粗糙度Ra贡献大,在磨料粒度相同的情况下,粗糙度近似与压力成正比;基体的粗糙度Ra的不同影响涂层的表面形貌和晶粒尺寸,随着Ra增大,涂层中活性组元IrO2的晶粒得以细化;基体的粗糙度Ra值对晶粒形核生长、阳极的电催化活性和寿命的影响是重要的,但并非Ra越大,晶粒析出越多,直接的影响因素是基体表面微观凸起的数量;表面微观凸起的数量影响到阳极的电催化活性,IrO2晶化的量越多,析氧电流就越大;基体的粗糙度Ra并非与钛阳极的寿命成正比;基体的粗糙度Ra为3.6 μm的阳极析氧催化活性和寿命分别提高7%~36%和63%~72%,兼具最佳的析氧催化活性和最长的寿命。

关键词:钛阳极;喷砂;析氧;催化活性;加速寿命;粗糙度

中图分类号:TG174 文献标志码:A

Effect of sand-blasting pretreatment on surface morphology, electrocatalytic activities and service life of Ti/IrO2·Ta2O5 anodes

JIANG Jun-feng,MENG Hui-min,SUN Dong-bai

(Corrosion and Protection Center, School of Materials Science and Engineering,University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The effect of sand-blasting pretreatment of titanium substrate on the surface morphologies, electrocatalytic activities and service life of Ti/IrO2·Ta2O5 anodes was investigated by scanning electron microscopy(SEM), X-ray diffractometry(XRD), anodic polarization curve test and accelerated life test. The results show that the morphologies of Ti/IrO2·Ta2O5 anodes are impacted by different pressures and grain size of sand-blasting. The pressure of sand-blasting contributes more to the roughness of Ti substrates than to the grain size of sand-blasting. The roughness of Ti substrate is directly proportional to the pressure of sand-blasting with on the same grain size. The crystallite grains of IrO2 become finer with increasing roughness of Ti base. The roughness of base metal has an influence on the nucleation and growth of IrO2 crystal grain, as well as the electrocatalytic activity and service life, however, not the biggest degree of roughness results in the most precipitation of IrO2, but the quantity of micro-ridges of coatings surface also contributes to the electrochemical activities and lifetime of Ti based anodes. The more the quantity of crystallization of IrO2 is, the more the oxygen evolution is. The roughness degree is not positively correlative to the lifetime of the anode. Among the four anodes, the anode coated on Ti substrate with roughness of 3.6 μm shows the best catalytic activity for oxygen evolution and the longest service life, which are improved by 7%~36% and 63%-72%, respectively.

Key words: titanium anode; sand-blasting; oxygen elution; electrocatalytic activity; accelerated life; roughness

近年来,Ti基IrO2-Ta2O5电极由于具有优良的析氧电催化活性和电化学稳定性,在腐蚀性强、工作环境恶劣的电解行业中获得了广泛的应用[1-5]。但值得注意的是,作为工业产品,其质量较不稳定[6],所以提高电极的稳定性,改善析氧活性,成为IrO2-Ta2O5电极研究的重点。为提高氧化物阳极的性能,涂层与基体金属间的紧密结合是一个很重要的因素。因此,在氧化物阳极涂制前,必须对基体进行严格的预处理,如除油、喷砂及酸蚀等[7]。钛基体的粗化包括喷砂和酸蚀两个步骤,其中喷砂形成的是宏观的粗糙。一般认为[7-8]:喷砂可以去除钛表面的氧化膜,露出新鲜表面;喷砂粗化会使表面处于压应力状态,有利于涂层与基体表面的结合;基体金属表面粗糙度的提高增加阳极的真实表面积,降低真实电流密度,从而可以改善电极的电化学性能。从钛阳极失效的角度分析认为,金属钛表面粗化有利于通过涂层与钛的机械镶嵌提高两者之间的结合力,从而减缓钛的钝化,改善其导电性,延长其使用寿命。

人们研究基体粗化对阳极寿命的影响。如ZINOLA等[9]研究不同表面预处理的镍基Tl2O3+ Co3O4阳极的电解稳定性。结果表明,基体经抛光处理后的阳极涂层在80 h时便发生了电位跃升,而基体经砂纸打磨后的涂层寿命却超过500 h。试验后还发现,抛光处理的氧化物涂层在电解中发生剥落,而基体经砂纸打磨后阳极的寿命大大提高。这是由于基体经抛光处理后与涂层间的结合力低下造成的。胡吉明等[10]也研究发现,钛基经喷砂处理后可有效地提高所得氧化物阳极的寿命。实验观察到,在电解过程中,基体未经喷砂处理所得阳极涂层发生粉末状剥落。由此可见,喷砂处理对钛基体与氧化物涂层间的结合力的提高是阳极寿命延长的主要原因。

尽管人们意识到钛基体喷砂预处理对阳极寿命会有重要的影响,但文献中绝大多数没有提到具体的喷砂工艺参数[11-13],或仅有一种喷砂工艺参数[7],而无不同工艺参数的比较,有的只经过砂纸打磨[14],甚至不经过粗化直接进行酸蚀[3, 15]。不同的喷砂工艺参数对钛电极使用寿命以及其电催化活性是否存在着影响,没有得到研究者的足够重视,目前尚无研究结果报道。由于文献中提到的的基体喷砂预处理的过程不同,钛电极使用寿命和催化活性数据之间并不具有可比性,因此,对此进行研究的意义是不言而喻的。鉴于此,本文作者首次对比基体不同喷砂工艺参数的预处理,研究喷砂预处理对钛阳极表面形貌、电化学性能和寿命的影响,以期探得到最佳的喷砂工艺参数。

1 实验

1.1 钛基体预处理

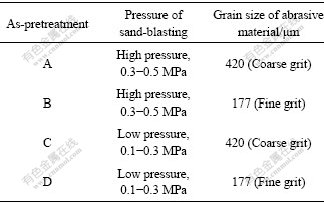

纯钛板的喷砂处理:磨料采用Al2O3,磨料粒度以及喷砂机喷嘴压力如表1所列,喷射角度为45?掠射,喷嘴与钛板表面距离保持在1.5 cm左右,粗化时间15~30 s。喷砂后先用大量自来水冲洗再用去离子水清洗,以除去表面残留的砂粒和金属屑。根据喷砂工艺采用的压力和磨料粒度的不同处理后的钛板分别记为A、B、C和D。酸蚀预处理:将喷砂处理后的钛板浸入10%(质量分数)草酸溶液中,在90~95 ℃下浸蚀2 h,取出清洗备用。

表1 Ti基体不同喷砂预处理过程参数

Table 1 As-pretreatment parameters of Ti base during sand-blasting

1.2 电极制备

采用传统的热分解法制备Ti/IrO2·Ta2O5氧化物涂层电极[16], Ir与Ta的摩尔比为7?3,用软毛刷将涂覆液均匀涂刷在经过预处理的钛基体上,于120 ℃干燥10 min,然后转入箱式电阻炉中,在450 ℃下烧结10 min,重复以上过程7次,最后一次于450 ℃下烧结1 h。

1.3 粗糙度、结构与形貌分析

钛基体粗糙度(Ra)测定采用HSR200-3型金刚石触针电感式轮廓测量仪(华中理工大学)。采样长度0.8 mm,采样间隔2.5 μm,电感量程30 μm,每个试样在2个不同方向上各测量一次,取平均值。

采用X射线衍射(XRD)分析涂层的物相结构,同时测量IrO2的晶粒大小,测试采用日本理学(Rigaku)D/MAX-RB,Cu Kα1(λ=1.540 6?),步宽为0.02?。

钛基体和氧化物涂层的表面形貌经扫描电子显微镜(SEM)下观察得到,测试在LEO-1450型扫描电镜上进行。

1.4 电化学测试

采用经典三电极体系,以Pt片为对电极,饱和甘汞电极(SCE)为参比电极。测试溶液为0.5 mol/L H2SO4水溶液,测试温度为室温。阳极极化曲线测试在1.1~1.5V (vs SCE,下同)间进行,电位扫描速率为0.5 mV/s,扣除溶液电阻Rs(由EIS解析所得)。电化学测试在CHI660B电化学工作站(上海辰华生产)上完成。

1.5 加速寿命试验

制备得到的阳极为工作电极,Ti板为阴极,电解液采用0.5 mol/L H2SO4水溶液,水浴恒温60 ℃,阳极电流密度恒定在4 A/cm2,试验过程中记录槽压随时间的变化,槽压升高大于5 V时认为阳极失效。

2 结果与讨论

2.1 喷砂对钛基体形貌的影响

图1所示为钛基体经喷砂预处理后的表面形貌。其中图1(a)~(d)分别为按照表1中的参数喷矿预处理的钛基体的形貌。图2所示为钛基体经喷砂预处理及10%(质量分数)草酸溶液于90~95 ℃下浸蚀2 h后的SEM像。由图1可看出,低压力下喷砂处理的基体表面(图1(c)和(d))较为均匀平整,高压力处理的表面塑性变形强烈(见图1(a)和(b)),磨料冲击出来的坑道更深。压力相同时,磨料的粒度越大,即目数越小,这种变形越明显(见图1(a)、(b)、(c)与(d))。机械粗化的作用也直接影响到酸蚀后的基体表面形貌。由图2可看出,高压力喷砂处理的基体经过酸蚀,其表面出现的腐蚀坑较深的为高压力喷砂处理后酸蚀的基体(见图2(a)和(b)),相比于低压力喷砂处理后酸蚀的基体(见图2(c)和(d)),喷砂压力相同时,磨料越细,其酸蚀后的腐蚀坑多级孔洞越多,但深度不如粗砂处理的基体。

图1 钛基体经不同压力和磨料粒度喷砂预处理后的SEM像

Fig.1 SEM images of Ti base after sand-blasting pre-treatment under different sand-blasting pressures and grain sizes of abrasive materials: (a) 0.3-0.5 MPa, 420 μm; (b) 0.3-0.5 MPa, 177 μm; (c) 0.1-0.3 MPa, 420 μm; (d) 0.1-0.3 MPa, 177 μm

图2 钛基体经喷砂预处理及10%草酸于90~95 ℃酸蚀2 h后的SEM像

Fig.2 SEM images of Ti base acid etched in 10% oxalic acid at 90-95 ℃ for 2 h after different sand-blasting pretreatments:(a) 0.3-0.5 MPa, 420 μm; (b) 0.3-0.5 MPa, 177 μm; (c) 0.1-0.3 MPa, 420 μm; (d) 0.1-0.3 MPa, 177 μm

粗糙度Ra测试结果从图1(a)到(d)依次为:3.96、3.56、1.97和1.46。由此可见,粗糙度跟喷砂压力和磨料粒度均相关,压力对钛基体的粗糙度贡献更大,磨料粒度相同的情况下,粗糙度近似与压力成正比,如Ra(a)/Ra(c)≈2.

2.2 钛阳极的形貌

涂覆后烧结得到的钛阳极表面也保留基体经喷砂和酸蚀预处理后的形貌特征。图3所示为Ti/IrO2?Ta2O5电极表面的SEM像。由图3可看出,基体粗糙度大(Ra为3.5~4.0 μm)的钛阳极表面有很多的凸起,凸起处覆盖的涂层表面形成微裂纹,其宽度、密集程度和深度比平坦处大得多(见图3(a)和(b))。基体粗糙度小(Ra为1.4~2.0 μm)的钛阳极表面非常平整,但粗砂处理的钛阳极(见图3(c))涂层开裂严重,细砂处理的微裂纹数量最多(见图3(d))。存在于凸起处和裂缝中的白色颗粒经能谱分析为偏析的IrO2晶粒。同时可以观察到,基体粗糙度Ra<2.0 μm的电极表面析出晶粒较大。

图3 Ti/IrO2·Ta2O5经不同喷砂酸蚀预处理后涂覆所得电极的SEM像

Fig.3 SEM images of Ti/IrO2·Ta2O5 electrodes coated on Ti substrates as-pretreated by different sand-blashings and acid etched in 10% oxalic acid at 90-95 ℃ for 2 h: (a) 0.3-0.5 MPa, 420 μm; (b) 0.3-0.5 MPa, 177 μm; (c) 0.1-0.3 MPa, 420 μm; (d) 0.1-0.3 MPa, 177 μm

图4所示为图3中相应电极失效后的表面形貌。由图4可看出,失效电极表面平坦处和裂缝中的白色IrO2晶粒均已消失,表明加速试验过程中表层的IrO2发生了溶解。图4(a)左上角还残存着完全尚未脱落的涂层,呈球状大颗粒堆积(见图4(a)中的A区域),这是由于长期析氧对涂层表面冲刷溶蚀而成;还可以观察到涂层局部出现剥离,暴露出酸蚀后的钛基体典型的蜂窝状形貌(B区域)。因此,在加速寿命试验过程中,钛阳极的失效是发生涂层外表面的溶解和剥离,新生态的氧可藉由宽化的裂缝与基体接触,使之发生钝化。电极B失效后表面裂缝宽度和数量未见增加,基本保持新鲜表面的形貌特征,加速寿命试验证实它具有最长的寿命。而基体经低压力喷砂预处理的电极C和D失效后表面涂层剥离严重,说明粗糙度Ra小导致涂层跟基体的结合力不足(见图4(c)和(d))。

图4 图3中相应电极失效后的表面形貌

Fig.4 Surface morphologies of corresponding electrodes after inactivation in Fig.3: (a) 0.3-0.5 MPa, 420 μm; (b) 0.3-0.5 MPa, 177 μm; (c) 0.1-0.3 MPa, 420 μm; (d) 0.1-0.3 MPa, 177 μm

为了弄清涂层表面上偏析的IrO2晶粒生长情况,分别对涂覆1层、3层、5层和7层后再经烧结后的钛阳极表面形貌进行对比(见图5)。由图5可看出,以阳极B为例,涂覆1层的表面没有观察到IrO2晶粒析出,这是由于烧结时间过短(10 min),氧化物还没有得到晶化;从3层起,IrO2晶粒析出,析出的部位主要分布于涂层的凸起处,从热力学的角度来看,凸起处对应的能量较高,晶粒优先在此处形核生长。为了进一步对比基体粗糙度对IrO2晶粒生长的影响,将阳极A、B、C和D涂覆3层的表面形貌加以比较(见图6)。由图6可看出:基体Ra<2.0 μm的阳极表面,没有晶粒析出(阳极C)或极少晶粒析出(阳极D);而对于粗糙度最大的阳极A(Ra=4.0 μm),析出的晶粒也明显少于阳极B的(Ra=3.56 μm)。由此可见,基体Ra对晶粒形核生长的影响是重要的,但并非Ra越大,晶粒析出越多,直接的影响因素是基体表面微观凸起的数量。

图5 电极B涂覆不同层数表面的SEM像

Fig.5 SEM images of surfaces of electrode B after painting various layers: (a) 1 layer; (b) 3 layers; (c) 5 layers; (d) 7 layers

图6 电极涂覆3层后表面的SEM像

Fig.6 SEM images of surface of electrodes after painting 3 layers: (a) Anode A; (b) Anode B; (c) Anode C; (d) Anode D

2.3 喷砂工艺对电极相结构的影响

图7所示为不同喷砂预处理钛阳板的XRD谱。由图7可以看出,各钛阳极均出现了微弱的金红石相TiO2衍射峰,这说明在电极热分解制备过程中Ti基体发生了轻微的氧化。随着Ra的减小,活性组元IrO2的(110)、(101)和(211)晶面衍射强度逐渐增强,可见基体Ra<2.0 μm的钛阳极表面有更多的IrO2晶粒析出。通过XRD数据计算电极表面IrO2的(110)面晶粒尺寸,从电极A到D分别为10.9、10.9、13.9、12.9 nm,电极C和D表面氧化物晶粒的长大现象最为明显,也与SEM(见图3)观察结果是相符的。由此可见,Ra增大,IrO2的晶粒得以细化。

图7 不同喷砂预处理钛阳极的XRD谱

Fig.7 XRD patterns of Ti anodes pretreated by different sand-blasting pretreatments: (a) Anode A; (b) Anode B; (c) Anode C; (d) Anode D

通过钛阳极失效前后XRD图谱的对比(见图8)可以看出,失效后的钛阳极均出现微弱的锐钛矿相TiO2衍射峰,表明Ti基体发生了钝化。钛阳极A(见图8(a))、C(见图8(c))和D(见图8(d))失效后Ti峰增强,IrO2峰减弱,说明失效后的阳极表面残留着活性涂层,但涂层厚度减薄,导致Ti基体峰增强;但钛阳极B的Ti峰无明显变化(见图8(b)),IrO2的(110)、(101)和(211)晶面衍射强度明显增强。这可能是基体这一粗糙度所得的钛阳极失效机制有所不同所致。

图8 钛阳极失效前后的XRD谱

Fig.8 XRD patterns of Ti anodes before and after deactivation: (a) Anode A; (b) Anode B; (c) Anode C; (d) Anode D

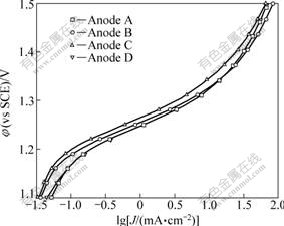

2.4 喷砂工艺对阳极电催化活性的影响

钛阳极的析氧电催化活性大小可以通过阳极极化曲线对比得到。电位升至析氧电位以上时,阳极开始析氧反应,同一电位下电流密度越大,表示其电催化活性越高。图9所示为Ti/IrO2?Ta2O5阳极的极化曲线。由图9可看出,钛阳极B具有最大的析氧电流,钛阳极C的最小。为更清晰地比较,在析氧充分的电位(φ(vs SCE)=1.4 V)条件下对比各个电极的析氧电流密度(见图10)。阳极A和D的电催化活性相当(分别为31.1和31.4 mA/cm2),电极C的最小(24.4 mA/cm2),电极B的最高(33.3 mA/cm2),与阳极A、C和D相比,阳极B的电催化活性提高7%~36%。结合图6可知,IrO2晶化的量越多,析氧电流越大。

图9 在0.5 mol/L H2SO4中喷砂处理后Ti/IrO2·Ta2O5电极的阳极极化曲线

Fig.9 Anodic polarization curves of Ti/IrO2·Ta2O5 electrodes as-prepared by different sand-blasting in 0.5 mol/L H2SO4

图10 析氧电位下(φ(vs SCE)=1.4 V)各电极的电流密度

Fig.10 Current density of anodes as-prepared by different sand-blasting at φ of 1.4 V

2.5 喷砂工艺对阳极寿命的影响

各阳极加速寿命数据和稳定槽压列于表2中。由表2可看出,随着基体Ra的增大,阳极加速寿命明显提高;基体Ra=3.56 μm时,阳极寿命相较于Ra<2.0 μm的阳极提高了63%~72%;基体Ra<2.0 μm的阳极寿命较低,且磨料的粒度大小对寿命几乎无影响。对比图3(c)和(d)可知,基体Ra<2.0 μm时,涂层跟基体的结合力较弱是导致二者寿命低的主要原因。尽管阳极A的基体粗糙度最大,但其基体酸蚀后的腐蚀坑口径较宽,多级孔洞较少,涂层跟基体的机械镶嵌作用不如阳极B的紧密,其寿命略低于阳极B的。因此,并非粗糙度越大寿命越高。阳极B、C和D的槽压均稳定在(5.5±0.3) V之间,但阳极A的略高,从电解、电镀工业运营电成本的角度来看,基体粗糙度Ra为3.56 μm的钛阳极B也是最佳的选择。

表2 阳极槽压及寿命

Table 2 Stable bath voltage and lifetime of anodes

3 结论

1) 粗糙度跟喷砂压力和磨料粒度有关,喷砂压力对钛基体的粗糙度的影响较大,在磨料粒度相同的情况下,粗糙度近似与压力成正比。

2) 基体粗糙度大(Ra为3.5~4.0 μm)的钛阳极表面有很多的凸起,凸起处的涂层形成的微裂纹宽度、密集程度和深度比平坦处要大得多。基体粗糙度小(Ra为1.4~2.0 μm)的钛阳极表面则非常平整,但粗砂处理的钛阳极涂层开裂严重,细砂处理的微裂纹最多。随着Ra的增大,活性组元IrO2的晶粒细化。基体Ra值对晶粒形核生长的影响是重要的,但并非Ra越大,晶粒析出越多,直接的影响因素是基体表面微观凸起的数量。

3) 表面微观凸起的数量影响到阳极的电氧催化活性,IrO2晶化的量越多,析氧电流越大。基体Ra为3.6 μm左右时,比Ra过高(4.0 μm)或过低(<2.0 μm)的阳极析氧催化活性提高了7%~36%。

4) 基体粗糙度并非与钛阳极的寿命正相关。基体Ra>3.5 μm,阳极寿命均较高,比基体Ra<2.0 μm的阳极的寿命提高了63%~72%;但基体Ra达到4.0μm,阳极寿命反而略有下降,这与其基体酸蚀后表面腐蚀坑口径较宽,多级孔洞较少,涂层跟基体的机械镶嵌作用反而不如Ra=3.5 μm的阳极紧密有关;Ra<2.0 μm时,磨料的粒度对寿命几乎无影响。

5) 基体粗糙度Ra为3.6 μm左右的钛基体涂制的阳极兼具最大的析氧催化活性和最长的寿命。

REFERENCES

[1] 辛永磊, 许立坤, 李先国, 王均涛, 李相波, 陈光章. 表面活性剂对Ti/IrO2+Ta2O5阳极性能的影响[J]. 材料开发与应用, 2005, 23(5): 43-47.

XIN Yong-lei, XU Li-kun, LI Xian-guo, WANG Jun-tao, LI Xiang-bo, CHEN Guang-zhang. The effect of surfactant on the properties of Ti/IrO2+Ta2O5 anode[J]. Development and Application of Materials, 2005, 23(5): 43-47.

[2] 钟祥华, 唐 电, 邵艳群, 王 欣. 钛基热氧化对钛阳极组织与性能的影响[J]. 金属热处理, 2008, 33(8): 146-149.

ZHONG Xiang-hua, TANG Dian, SHAO Yan-qun, WANG Xin. Effects of thermal oxidization for titanium substrates on the structures and properties of a titanium anode[J]. Heat Treatment of Metals, 2008, 33(8): 146-149.

[3] 颜 琦. 50%IrO2-50%Ta2O5被覆钛阳极涂层的组织结构研究[J]. 福建工程学院学报, 2008, 6(1): 21-24.

YAN Qi. The study on Ti anodes coated with 50% IrO2-50%Ta2O5[J]. Journal of Fujian University of Technology, 2008, 6(1): 21-24.

[4] CHEN Yong-yi, ZHANG Teng, WANG Xin, SHAO Yan-qun, TANG Dian. Phase structure and microstructure of a nanoscale TiO2-RuO2-IrO2-Ta2O5 anode coating on titanium[J]. Journal of the American Ceramic Society, 2008, 91(12): 4154-4157.

[5] 姜俊峰, 徐海波, 王廷勇, 王 佳, 许立坤, 成 光. TiN基IrO2+Ta2O5涂层电催化性能研究[J]. 稀有金属材料与工程, 2007, 36(2): 344-348.

JIANG Jun-feng, XU Hai-bo, WANG Ting-yong, WANG Jia, XU Li-kun, CHENG Guang. Study on Electrocatalytic properties of TiN based IrO2+Ta2O5 coating anode[J]. Rare Metal Materials and Engineering, 2007, 36(2): 344-348.

[6] ARDIZZONE S, BIANCHIC L, CAPPELLETTI G, IONITA M, MINGUZZI A, RONDININI S, VERTOVA A. Composite ternary SnO2-IrO2-Ta2O5 oxide electrocatalysts[J]. Journal of Electroanalytical Chemistry, 2006, 589(1): 160-166.

[7] 初立英, 许立坤, 吴连波, 王廷勇, 王均涛, 陈光章. 草酸浸蚀对氧化物阳极形貌及电催化性能的影响[J]. 金属学报, 2005, 41(7): 763-768.

CHU LI-ying, XU Li-kun, WU Lian-bo, WANG Ting-yong, WANG Jun-tao, CHEN Guang-zhang. Effect of oxalic acid etching on morphology and electrocatalytic activity of oxide anodes[J]. Acta Metallurgica Sinica, 2005, 41(7): 763-768.

[8] 陈学定, 韩文政. 表面涂层技术[M]. 北京: 机械工业出版社, 1994: 72-73.

CHEN Xue-ding, HAN Wen-zheng. Surface coating technology[M]. Beijing: China Machine Press, 1994: 72-73.

[9] ZINOLA C F, ARVIA A J A. semiempirical quantum chemistry approach to possible structures and energies of hydrogen atoms adsorbed on Pt(100) and Pt(111) clusters at a simulated Pt/aqueous electrochemical interface[J]. Electrochimica Acta, 1996, 41(14): 2267-2273.

[10] 胡吉明, 张鉴清, 曹楚南. Ti基IrO2+Ta2O5阳极的电化学特性[J]. 材料研究学报, 2002, 16(4): 365-370.

HU Ji-ming, ZHANG Jian-qing, CAO Chu-nan. Electrochemical characteristics of Ti based IrO2+Ta2O5 anodes[J]. Chinese Journal of Materials Research, 2002, 16(4): 365-370.

[11] LI Bao-song, LIN An, GAN Fu-xing. Preparation and electrocatalytic properties of Ti/IrO2-Ta2O5 anodes for oxygen evolution[J]. Trans Nonferrous Met Soc China, 2006, 16(5): 1193-1199.

[12] YE Zhi-guo, MENG Hui-min, SUN Dong-bai. New degradation mechanism of Ti/IrO2 +MnO2 anode for oxygen evolution in 0.5M H2SO4 solution[J]. Electrochimica Acta, 2008, 53(18): 5639-5643.

[13] ROSSI A, BOODTS J F C. Ir-based oxide electrodes: oxygen evolution reaction from mixed solvents[J]. Journal of Applied Electrochemisrty, 2002, 32(7): 735-741.

[14] 叶文艺, 赖彩娥, 刘慧勇. 钛基锡锰钌氧化物阳极的电化学性能[J].氯碱工业, 2009, 45(1): 11-15.

YE Wen-yi, LAI Cai-e, LIU Hui-yong. Electrochemical behavior of tin,manganese, and ruthenium oxide anodes based on titanium[J]. Chlot-Alkali Industry, 2009, 45(1): 11-15.

[15] XU Li-kun, XIN Yong-lei, WANG Jun-tao. A comparative study on IrO2-Ta2O5 coated titanium electrodes prepared with different methods[J]. Electrochimica Acta, 2009, 54(6): 1820-1825.

[16] 胡吉明, 孟惠民, 张鉴清, 曹楚南. 制备条件对钛基IrO2+Ta2O5涂层阳极性能的影响[J]. 金属学报, 2002, 38(1): 69-73.

HU Ji-ming, MENG Hui-min, ZHANG Jian-qing, CAO Chu-nan. Effect of preparation conditions on the properties of Ti based IrO2+Ta2O5 anodes[J]. Acta Metallurgica Sinica, 2002, 38(1): 69-73.

____________________________

基金项目:国家高技术研究发展计划资助项目(2007AA05Z103)

收稿日期:2009-05-19;修订日期:2009-10-27

通信作者:孟惠民,教授,博士;电话:010-62332548,13671230955;E-mail:ecm@mater.ustb.edu.cn

(编辑 李艳红)