文章编号:1004-0609(2010)06-1102-08

均匀化对7050铝合金板材淬火敏感性的影响

刘文军,张新明,刘胜胆,周新伟

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:通过光学显微镜、透射电镜以及力学性能测试,研究均匀化制度对7050铝合金板材组织演变的影响。将合金固溶后在不同速率淬火,研究均匀化制度对该合金淬火敏感性的影响。结果表明:固溶后慢速率淬火过程中,平衡相η主要位于再结晶晶粒中Al3Zr粒子的相界、再结晶晶界、亚晶晶界以及亚晶中与位错交互作用的少量Al3Zr粒子上形核析出;均匀化时间较短时(室温,120 ℃/h升温至465 ℃,8 h),合金中析出少量Al3Zr粒子,固溶后的试样发生完全再结晶,此时合金淬火敏感性最好,但硬度较低;延长保温时间至20 h(室温,120 ℃/h升温至465 ℃,20 h),试样中析出大量Al3Zr粒子,但分布不均匀,从而导致轧制固溶后的试样依然明显再结晶,合金淬火敏感性较差;采用快速升温的双级均匀化制度((室温,120 ℃/h升温至465 ℃,20 h)+(475 ℃,8 h)),Al3Zr粒子有所长大,淬火敏感性最差;采用慢速随炉升温((室温,18 ℃/h升温至465 ℃)+(475 ℃,8 h))的双级均匀化制度,合金中将弥散析出大量细小的Al3Zr粒子,固溶后的再结晶得到有效抑制,较多η相在亚晶界上的非均匀形核析出在一定程度上增加了合金的淬火敏感性,但该制度处理的合金仍优于再结晶程度较高的快速升温双级均匀化制度的。

关键词:7050铝合金;均匀化制度;Al3Zr;淬火敏感性;组织演变

中图法分类号:TG146 文献标志码:A

Effect of homogenization on quenching sensitivity

of 7050 aluminum alloy plates

LIU Wen-jun, ZHANG Xin-ming, LIU Sheng-dan, ZHOU Xin-wei

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The microstructure evolution of 7050 aluminum alloy plates after homogenization was studied by optical microscopy, transmission electron microscopy, hardness and electric conductivity measurements. The influence of such processing on the quenching sensitivity was investigated by different homogenization methods. The results show that the equilibrium η phase mainly precipitates at areas such as the grain boundaries, sub-grain boundaries, incoherent Al3Zr particles within the recrystallization region and some Al3Zr particles which interact with the dislocations during slow quenching. For short time homogenization treatment (RT, 120 ℃/h to 465 ℃, 8 h), the recrystallization is observed at most of the areas and the alloy shows good quenching sensitivity but low hardness. When the holding time increases to 20 h (RT, 120 ℃/h to 465 ℃, 20 h), the recrystallization would be partly inhibited with higher quenching sensitivity. The two-stage homogenization with fast heating rate ((RT, 120 ℃/h to 465 ℃, 20 h)+(475 ℃, 8 h)) can not improve the quenching sensitivity and the Al3Zr particles coarsen slightly. And when the ramp heating (RT, 18 ℃/h to 465 ℃+ 475 ℃, 8h) is concerned, the recrystallization is inhibited efficiently by finer size and higher density of Al3Zr particles,and the equilibrium η phase mainly precipitates at the sub-grain boundaries and some Al3Zr particles interact with the dislocations, in addition better quenching sensitivity is achieved.

Key words: 7050 aluminum alloy; homogenization treatment; Al3Zr; quenching sensitivity; microstructure evolution

7×××系铝合金作为综合性能优秀的航空航天材料已被广泛应用,国内外对该系合金的开发和研究也一直没有停止[1-5]。早在20世纪80年代初,Thompson等[6]就已指出Al-Zn-Mg-Cu系铝合金中微量添加的Cr和Zr等元素将导致合金慢速率淬火时性能受到损失,淬火时η平衡相 (MgZn2)的非均匀形核析出是造成合金淬火敏感性较大的直接原因[6-11],DESCHAMPS 等[13-14]在前人的基础上进一步研究了合金中含Zr粒子的分布对6×××系和7×××系铝合金淬火敏感性的影响,认为慢速率淬火时η平衡相主要在Al3Zr粒子上形核析出,与Al3Zr粒子一起呈带状分布,另有报道指出,再结晶晶粒中与基体非共格的Al3Zr粒子是η相非均匀形核的主要位置[15-16]。在已有的研究中,关于热处理制度对合金淬火敏感性影响的文献相对较少,尤其关于均匀化制度对合金淬火敏感性的影响未见报道;固溶后慢速率淬火时,亚晶组织中的η平衡相的析出行为鲜见报道。因此,本文作者从均匀化角度出发,分析均匀化制度对合金固溶后慢速率淬火时η平衡相析出行为影响,阐明其与合金淬火敏感性的联系,具有理论价值,同时为实际生产中的均匀化制度选择提供参考依据。

1 实验

实验用7050铝合金的铸锭名义成分如表1所列。铸锭上切取厚12 mm的试样于空气炉中进行4种均匀化热处理,分别为快速升温的单级均匀化制度(室温,120 ℃/h升温至465 ℃,8 h);在保温8 h基础上延长保温时间20 h,即(室温,120 ℃/h至465 ℃,20 h);在单级制度基础上增加二级保温的快速升温双级均匀化制度(室温,(120 ℃/h升温至465 ℃,20 h)+(475 ℃,8 h));以及采用慢速率升温的双级均匀化(室温,(18 ℃/h升温至465 ℃)+(475 ℃,8 h))。为表述方便,4种均匀化制度分别用制度a、b、c和d表示。对均匀化后水淬样品立即制备透射试样进行微观组织观察;随后对样品进行统一轧制制度的热变形处理(开轧温度420 ℃,总轧制变形量85%,并严格控制轧制道次和每道次变形量,减少轧制制度不同造成的储能差异);固溶处理在空气炉中进行(固溶制度472 ℃,60 min),随后采用空气和室温水两种介质进行淬火处理(通过比较空气淬火试样时效后性能损失反映合金淬火敏感性差异),实测淬火速率分别为1和300 ℃/s左右,淬火试样进行电导率测定后立刻置于油浴炉中进行时效(121 ℃,24 h);最后对时效态试样分别进行电导率、硬度测试,并结合金相和TEM对样品进行组织观察,分析实验结果。

表1 7050铝合金的名义成分

Table 1 Nominal composition of Al 7050 alloy in present study (mass fraction, %)

实验中所采用的主要设备如下:XJP-6A 型光学显微镜,TecnaiG220透射电镜以及HV10-B硬度测试仪,TEM试样采用双喷减薄制备,双喷电解液配比为20%(体积分数)HNO3+80%CH3OH,温度控制在-20 ℃以下。

2 实验结果

2.1 合金的组织形貌

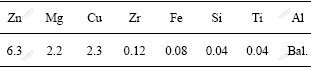

图 1和2所示为经过4种均匀化处理后水淬试样的TEM像。由图1可知:不同的均匀化制度将直接影响Al3Zr粒子的大小和分布,本实验涉及的4种均匀化制度中,经制度a均匀化处理后(室温,120 ℃/h升温至465 ℃,8 h),合金中的Al3Zr粒子析出最少,分布非常稀疏;随着保温时间延长至20 h(制度b),晶内已经观察到大量的Al3Zr粒子;对于引入第二级高温的快速升温双级均匀化制度(即制度c),试样中Al3Zr粒子尺寸将出现长大;而对于引入慢速率升温过程的双级均匀化制度d,组织观察显示Al3Zr粒子析出均匀弥散(见图1)。

图1 不同均匀化处理后晶内Al3Zr粒子的TEM像

Fig.1 TEM images of Al3Zr particles within grains after different homogenization treatments: (a) RT, 120 ℃/h to 465 ℃, 8 h; (b) RT, 120 ℃/h to 465 ℃, 20 h; (c) RT, (120 ℃/h to 465 ℃, 20 h)+(475 ℃, 8 h); (d) RT, (18 ℃/h to 465 ℃)+(475 ℃, 8 h)

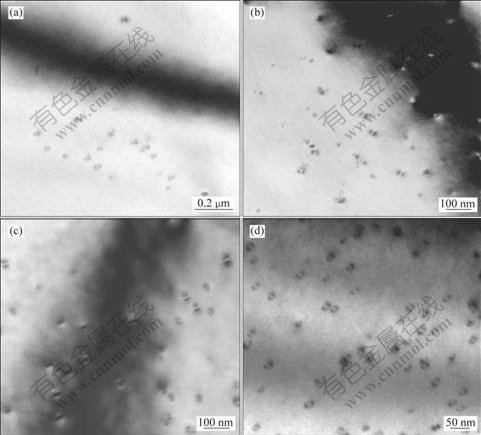

图2 均匀化处理后合金晶界附近Al3Zr粒子的析出TEM像

Fig.2 TEM images of Al3Zr particles precipitated near grain boundary after different homogenization treatments: (a) RT, (120 ℃/h to 465 ℃, 20 h)+(475 ℃, 8 h); (b) RT, (18 ℃/h to 465 ℃)+(475 ℃, 8 h)

文献[17]研究表明Al3Zr粒子可在η平衡相上形核析出,因此,引入慢速率升温的均匀化过程,不仅在低温时有更高的能量起伏促进形核率增加,更重要的是在试样慢速升温过程中弥散析出的η平衡相将促进晶内Al3Zr粒子的非均匀形核析出,改善晶界处无析出区宽度(见图2(b))。采用制度d均匀化后合金中Al3Zr粒子析出更为弥散细小,且晶界附近无析出区相对较窄,因此,采用慢速率升温过程可有效改善Al3Zr粒子的析出分布。

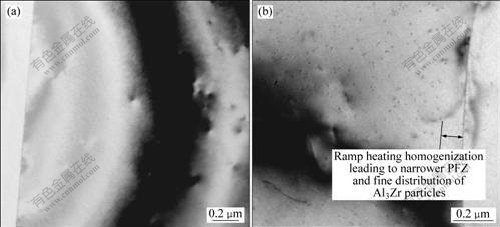

金相组织观察显示,均匀化造成的Al3Zr粒子分布差异将直接影响合金轧制固溶后的组织形貌(见图 3)。4种均匀化制度对应的固溶态试样再结晶分数分别为99%、51%、47%、24%,这说明采用慢速率升温的双级均匀化制度d可有效抑制再结晶。

图3 4种均匀化制度对合金固溶后再结晶程度的影响

Fig.3 Influence of homogenization treatment on recrystallization of alloys after solution: (a) RT, 120 ℃/h to 465 ℃, 8 h; (b) RT, 120 ℃/h to 465 ℃, 20 h; (c) RT, (120 ℃/h to 465 ℃, 20 h)+(475 ℃, 8 h); (d) RT, (18 ℃/h to 465 ℃)+(475 ℃, 8 h)

2.2 性能测试

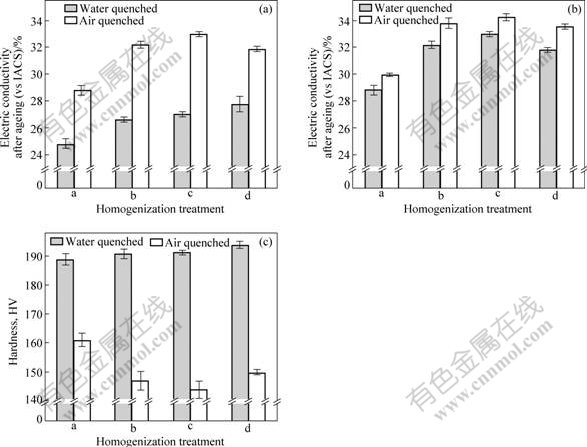

图4所示为两种淬火制度对应的固溶态及时效态的电导率以及时效态维氏硬度值测试结果。由图4可知,相对固溶后室温水淬火,空气淬火态试样的电导率都明显增加,增加幅度分别为16.3%、20.7%、22.7%和15.2%,其中以制度c的增加幅度最大。此外,制度a处理后的合金的电导率最低,表明合金中缺陷密度最小,与再结晶程度相对应;时效态试样硬度测试结果显示,均匀化制度对室温水淬火试样硬度影响不明显,都在190HV左右,其中制度a的硬度值最小,制度d的最大;空气淬火态试样硬度下降的差异较大,其中经制度c处理后的空气淬火硬度损失最大,降低至140HV左右,而采用制度a处理合金的硬度只下降到160HV。硬度和电导率测试结果表明,经过制度a处理的合金具有最低的淬火敏感性,制度d的其次,制度c的最高。

图4 均匀化制度对合金固溶态、时效态电导率及时效态硬度的影响

Fig.4 Influences of homogenization treatments on electric conductivities and hardness after solution and ageing treatments: (a) Electric conductivity after solution; (b) Electric conductivity after ageing; (c) Hardness of aged specimens

3 分析与讨论

从组织角度考虑,均匀化制度将改变Al3Zr粒子的大小和分布,同时对固溶后试样再结晶数量、晶粒大小以及亚晶组织的微观形貌亦产生影响。而合金慢速率淬火时,η平衡相将于界面能较高的位置(如晶界)非均匀形核析出长大,这些粗大粒子的析出对合金性能没有任何强化作用,同时降低过饱和固溶体中主要溶质原子(Mg和Zn等)含量,进而影响后续时效的强化效果。

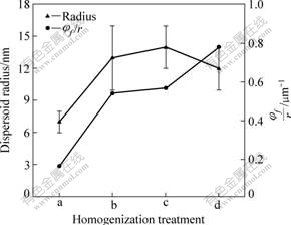

通过统计均匀化中析出的弥散Al3Zr粒子半径和体积分数,并借助Zener方程[18-19]来计算Al3Zr粒子对晶界的阻碍力,即

式中:φf为析出粒子的体积分数;γ表示粒子钉扎住的晶界界面能;k为常数;r为半径。由式(1)可知,当弥散析出粒子的体积分数增加以及析出粒子的半径减小时,对晶界的钉扎作用越明显,因此,计算得到的φ?/r值越大(见图 5),经过同样轧制固溶制度后的再结晶晶粒或亚晶晶粒的尺寸会越小。计算结果显示,采用制度a处理后合金中析出的Al3Zr粒子阻碍晶界迁移的能力最小,金相组织观察也显示(见图 3),采用该均匀化制度的试样发生了完全再结晶;而经制度b处理后合金的φ?/r值略小于经制度c处理后合金的φf/r,固溶后试样再结晶分数较为接近;经制度d处理后合金的φ?/r值最大。因此,从抑制再结晶的角度来说,最好的均匀化制度是慢速率升温的双级均匀化制度,这与金相观察结果一致。

图5 均匀化制度对Al3Zr粒子半径及φ?/r值的影响

Fig.5 Effects of homogenization treatments on mean radius and φ?/r of Al3Zr dispersoids

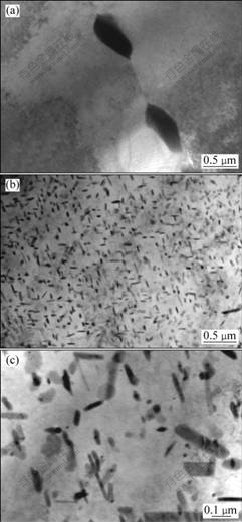

为探求不同均匀化试样再结晶晶粒中平衡相的析出规律,分析均匀化过程中析出的Al3Zr粒子对合金淬火敏感性的影响,选择经制度a和b处理后空气淬火试样中的再结晶晶粒进行微观组织观察,其结果如图6所示。经制度b处理后合金中析出大量的η平衡treatments: (a) RT, 120 ℃/h to 465 ℃, 8 h; (b), (c) RT, 120 ℃/h to 465 ℃, 20 h相(见图6(b)),文献显示这些粒子是η粒子[1, 20-22],进一步的TEM像观察(见图6(c))发现,这些粒子上都附着Al3Zr粒子;而经过制度a处理后合金中只是在晶界处出现较大的η相粒子(见图6(a)),其在Al3Zr粒子上的析出很难观察到。由此可以认为,对于再结晶组织,慢速率淬火时,η平衡相的析出与Al3Zr粒子的密度的关系密切;当均匀化时间较短时,由于晶内Al3Zr较少,因此η平衡相主要在晶界处析出;而当再结晶晶粒内部存在大量Al3Zr粒子时(制度b和c),η平衡相借助于非共格Al3Zr粒子相界的非均匀形核析出,对合金淬火敏感性影响极大,从而导致经制度b、c处理合金的淬火敏感性较高,而采用制度a处理合金的完全再结晶淬火敏感性反而最低。

图6 不同制度处理后固溶空气淬火试样晶内的TEM像

Fig.6 TEM images within recrystallized grains of solution specimens prepared by air quenching after different homogenization

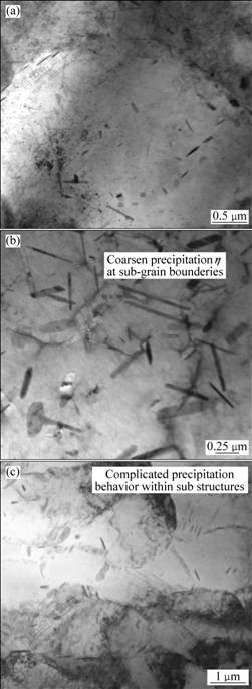

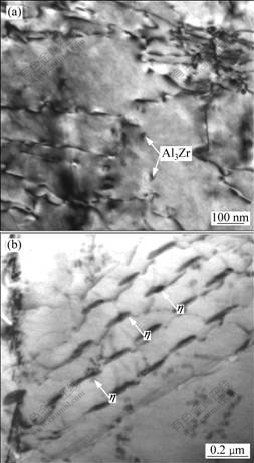

经过制度d处理的合金固溶后再结晶分数较低(只有24%),但合金依然表现出较明显的性能损失,因此,未再晶组织对合金淬火敏感性的影响也较明显。图 7所示分别为经制度b、c和d处理后固溶,空气淬火试样的未再结晶区域的 TEM像。由图7可知,经过制度b处理的未再结晶组织中,平衡相主要在亚晶界上析出,而亚晶内部析出较少;经制度c处理的试样不但在亚晶界而且在亚晶内的一部分Al3Zr粒子上亦有析出;而经制度d处理的试样,亚晶组织中的析出行为最为复杂,因该制度下Al3Zr粒子的φ?/r远大于前两种均匀化制度,这些弥散粒子对晶界和位错的钉扎作用非常明显,导致固溶后再结晶分数非常小,回复占主导地位,此时试样中将保留更多的位错等缺陷,亚晶的尺寸相对于经制度b、c处理的合金而言更小,平均尺寸小于1 μm(见图7(c));而经制度b、c处理的合金对应的亚晶尺寸在1~3 μm左右。因此,经过制度d处理的对应试样的未再结晶区域提供给η平衡相的非均匀形核位置相对非常多(主要为亚晶界),导致合金慢速率淬火时性能的下降较大。

图7 不同均匀化制度对固溶空气淬火试样中亚晶组织的TEM像

Fig.7 TEM images within sub-grain of air quenched specimens by different homogenization treatments: (a) RT, 120 ℃/h to 465 ℃, 20 h; (b) RT, (120 ℃/h to 465 ℃, 20 h)+ (475 ℃, 8 h); (c). RT, (18 ℃/h to 465 ℃)+(475 ℃, 8 h)

此外,相对于经制度c处理的合金而言,在经制度b、c处理的合金中,平衡相析出得更多(见图7(b)),分析认为合金均匀化过程中析出的Al3Zr粒子由于尺寸变大,与基体间的错配度将上升,从而提高界面能降低平衡相析出需要的自由能,尤其当这些粒子与位错或位错塞积交互作用时,晶格畸变的增加更促使了平衡相的非均匀析出(见图8)。

图8 Al3Zr粒子与位错交互作用下亚晶内η相的非均匀形核长大的微观形貌

Fig.8 Microstructures showing interaction between dislocation and Al3Zr particles (a) and heterogeneous pricepitation of η phase (b) in sub-grain of air quenched specimens

由此看来,慢速率淬火时,平衡η相非均匀形核的主要位置如下:1) 再结晶晶粒中非共格的Al3Zr粒子上;2) 再结晶晶界及亚晶界;3) 某些与位错交互作用的较大尺寸Al3Zr粒子上。

而均匀化制度可改变Al3Zr粒子的析出密度、分布和尺寸,进而导致合金的再结晶分数以及亚晶组织形貌差异,这些都将影响合金的淬火敏感性。总的说来,就降低合金淬火敏感性而言,最好的均匀化制度为制度a,此外选用慢速升温过程的双级均匀化制度可有效抑制再结晶,降低合金淬火敏感性(制度d)。

4 结论

1) 均匀化制度将直接影响Al3Zr粒子的析出形貌,均匀化时间较短时,合金中基本没有Al3Zr粒子析出,引入高温的双级均匀化制度会导致Al3Zr粒子一定程度的长大,而采用慢速率升温均匀化过程可以获得弥散细小的Al3Zr粒子,并使得晶界附近无沉淀析出带变窄。

2) Al3Zr粒子的弥散析出可以明显抑制合金的再结晶,当合金中Al3Zr粒子析出较少时(制度a),固溶后合金发生完全再结晶,采用制度d处理试样的再结晶可得到有效抑制。

3) 再结晶晶粒中的Al3Zr粒子因丧失与基体间的共格关系,成为有效的η平衡相非均匀形核位置,极大地增加合金的淬火敏感性;亚晶中较大的Al3Zr粒子以及与位错和晶界交互作用的Al3Zr粒子有可能促进η平衡相的非均匀形核。此外,再结晶晶界、亚晶界等晶格畸变较大的区域,亦是可能的η平衡相非均匀形核位置。

4) 合理的均匀化制度可有效改善合金淬火敏感性,从慢速率淬火后试样的硬度测试结果来看,引入慢速率升温的双级均匀化制度有利于降低合金的淬火敏感性能,此外,Al3Zr析出最少的制度a对应淬火敏感性能最低。

References

[1] BURKE J. The kinetics of phase transformation in metal[M]. London: Pergamon Press , 1965: 100.

[2] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南工业大学出版社, 1989.

WANG Zhu-tang, TIAN Rong-zhang. Aluminum alloy and processing handbook[M]. Changsha: Central South University Technology Press, 1989.

[3] STARKE E A, STALEY J T. Application of modern aluminum alloys to aircraft[J]. Progress in Aerospace Sciences, 1996, 32(2/3): 131-172.

[4] BUHA J, LUMLEY R N, CROSKY A G. Secondary ageing in an aluminium alloy 7050[J]. Mater Sci Eng A, 2008, 492(1/2): 1-10.

[5] 李成功, 巫世杰, 戴圣龙, 杨守杰. 先进铝合金在航空航天工业中的应用与发展[J]. 中国有色金属学报, 2002, 12(Al Special): 14-21.

LI Cheng-gong, WU Shi-jie, DAI Sheng-long, YANG Shou-ji. Application and development of advanced aluminum alloy in aerospace industry[J]. Changsha: The Chinese Journal of Nonferrous Metals, 2002, 12(Al Special): 14-21.

[6] THOMPSON D S, SUBRAMANYA B S, LEVY S A. Quench rate effects in Al-Zn-Mg-Cu alloys[J]. Metall Mater Trans B, 1971, 2(4): 1149-1160.

[7] WILLIAMS J C, STARKE E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[8] CONSERVA M, DI R E, CALONI O. Comparison of the influence of chromium and zirconium on the quench sensitivity of Al-Zn-Mg-Cu alloy s[J]. Metall Mater Trans B, 1971, 2(4): 1227-1232.

[9] CONSERVA M, FIORINI P. Interpretation of quench-sensitivity in Al-Zn-Mg-Cu alloys[J]. Metall Mater Trans B, 1973, 4(3):857-862.

[10] DORWARD R, BEERNTSEN D J. Grain structure and quench-rate effects on strength and toughness of AA7050 Al-Zn-Mg-Cu-Zr alloy plate[J]. Metall Mater Trans A, 1995, 26(9): 2481-2484.

[11] ROBINSON J S, CUDD R L, TANNER D A. Quench sensitivity and tensile property inhomogeneity in 7010 forgings[J]. Journal of Materials Processing Technology, 2001, 119(Issue 1/3): 261-267.

[12] LIU S D, ZHANG X M, CHEN M A. Effect of Zr content on quench sensitivity of AIZnMgCu alloys[J]. Trans Nonferrous Met Soc China, 2007, 17(4): 787-792.

[13] DESCHAMPS A, BR?CHET Y. Influence of quench and heating rates on the ageing response of an Al-Zn-Mg-(Zr) alloy[J]. Mater Sci and Eng A, 1998, 251(12): 200-207.

[14] DESCHAMPS A, BR?CHET Y. Nature and distribution of quench-induced precipitation in an Al-Zn-Mg-Cu alloy[J]. Scripta Materialia, 1998, 39(11): 1517-1522.

[15] KIKUCHI S, YAMAZAKI H, OTSUKA T. Peripheral-recrystallized structures formed in Al-Zn-Mg-Cu-Zr alloy materials during extrusion and their quenching sensitivity[J]. Journal of Materials Processing Technology, 1993, 38(4): 689-701.

[16] 张新明, 张 翀, 刘胜胆. 轧制变形量对7A55铝合金淬火敏感性的影响[J]. 中南大学学报:自然科学版, 2007, 38(4):589-594.

ZHANG Xin-ming, ZHANG Chong, LIU Sheng-dan. Effect of rolling reduction on quench sensitivity of aluminium alloy 7A55[J]. Journal of Central South University: Science and Technology, 2007, 38(4): 589-594.

[17] ROBSON J D. Optimizing the homogenization of zirconium containing commercial aluminium alloys using a novel process model[J]. Mater Sci and Eng A, 2002, 338(12): 219-229.

[18] WU L M, WANG W H, HSU Y F. Effects of homogenization treatment on recrystallization behavior and dispersoid distribution in an Al-Zn-Mg-Sc-Zr alloy[J]. Journal of Alloys and Compounds, 2008, 456(1/2): 163-169.

[19] HORNBOGEN E. Combined reactions[J]. Metall Mater Trans A, 1979, 10(8): 947-972.

[20] BUHA J, LUMLEY R N, CROSKY A G. Secondary ageing in an aluminium alloy 7050[J]. Mater Sci Eng A, 2008, 492(12): 1-10.

[21] 刘胜胆, 张新明, 黄振宝. 7055铝合金的淬火敏感性研究[J]. 中南大学学报: 自然科学版, 2006, 37(5): 846-849.

LIU Sheng-dan, ZHANG Xin-ming, HUANG Zhen-bao. Quench sensitivity of 7055 aluminum alloy[J]. Journal of Central South University: Science and Technology, 2006, 37(5): 846-849.

[22] TANNER D A, ROBINSON J S. Effect of precipitation during quenching on the mechanical properties of the aluminium alloy 7010 in the W-temper[J]. Journal of Materials Processing Technology, 2004, 153/154: 998-1004.

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2005CB623700)

收稿日期:2009-08-25;修订日期:2009-11-22

通信作者:张新明,教授,博士;电话:0731-88830265;E-mail:xmzhang@mail.csu.edu.cn