文章编号:1004-0609(2009)07-1252-05

可溶性阳极电刷镀纳米晶Ni-Fe合金镀层的退火再强化

戴品强,陈晓文,项忠楠,许伟长

(福州大学 材料科学与工程学院,福州 350108)

摘 要:采用可溶性Ni阳极电刷镀方法制备纳米晶Ni-Fe合金镀层,利用XRD、SEM、TEM、显微硬度计等测试方法分析低温退火对镀层结构和性能的影响。结果表明:纳米晶Ni-Fe合金镀层的硬度随退火温度的升高而提高,在200 ℃时达到最大值,存在明显的退火再强化;继续提高退火温度导致镀层硬度降低;400 ℃退火后的镀层硬度与镀态的接近;纳米晶Ni-Fe合金镀层退火过程没有出现晶粒异常长大,表现出比纯Ni镀层更高的热稳定性。

关键词:电刷镀;Ni-Fe合金镀层;退火再强化;热稳定性

中图分类号:TG 174.4 文献标识码:A

Annealing hardening of nanocrystalline Ni-Fe alloy coatings synthesized by brush plating using soluble anode

DAI Pin-qiang, CHEN Xiao-wen, XIANG Zhong-nan, XU Wei-chang

(College of Materials Science and Engineering, Fuzhou University, Fuzhou 350002, China)

Abstract: Nanocrystalline Ni-Fe alloy coatings were synthesized by brush plating using soluble anode. Microhardness test and techniques of XRD, SEM and TEM were applied to characterize the microstructures and mechanical properties of Ni-Fe alloy coatings. The results show that the microhardness of Ni-Fe alloy coatings increases with increasing annealing temperature and reaches a peak value at 200 ℃, showing a significant hardening during annealing. With further increasing annealing temperature, the microhardness decreases gradually, but the microhardness of the coating after being annealed at 400 ℃ is still as high as that of the as-deposited sample. The abnormal grain growth is not observed during annealing of Ni-Fe alloy coatings, which indicates a better thermal stability.

Key words: brush plating; Ni-Fe alloy coating; annealing hardening; thermal stability

电刷镀作为表面工程的主要技术之一,已得到广泛的应用,取得了很大的经济效益和社会效益[1?2]。过去人们对电刷镀的研究主要集中在镀液配方、刷镀工艺、宏观性能和应用等方面,对镀层微观组织结构的研究较少。最近,徐滨士等[3]采用TEM和X射线衍射分析电刷镀Ni镀层的结构,发现快速镍镀层的晶粒尺寸为39 nm,而采用可溶性阳极制备的快速镍晶粒尺寸为41 nm,并可以通过加入Fe合金化进一步降低晶粒尺寸[4]。电刷镀纳米晶镀层不仅晶粒细小,而且还具有较高的热稳定性[4?5]。因此,徐滨士等[3]认为电刷镀技术是一种未被清楚认识的纳米技术。梁志杰[1]认为电刷镀镀层的再强化是第二相的析出或是N原子扩散到位错附近形成柯氏(Cottrel)气团引起的,但未见详细的实验依据。以往对电刷镀镀层退火再强化的认识不足,其原因之一是尚未认识到许多电刷镀镀层实际上是纳米晶结构。近年来,HUANG等[6]发现纳米晶金属低温退火存在再强化现象。大塑性变形法制备的纳米晶Al,存在大量位错,退火再强化的原因是低温退火使位错源减少,需要提高外力才能激活位错 源,宏观表现为强化。而电沉积纳米晶Ni中也存在退火再强化现象,但镀态的纳米晶Ni不存在大量的位 错[7],WANG等[8]认为再强化的可能原因是晶界结构驰豫,但尚缺乏实验依据。LI等[9]研究低温退火对电沉积纳米晶Ni-20%Fe合金硬度的影响,其结果是在300 ℃以下退火时,硬度随温度的提高而缓慢降 低,而在300 ℃以上退火时,硬度随温度的提高而迅速降低。因此,纳米晶金属的退火再强化与材料的成分有关。目前,关于低温退火对电刷镀纳米晶合金镀层硬度和组织结构的影响的研究尚未见报道。了解低温退火对电刷镀镀层性能的影响对提高镀层的性能和服役行为具有重要的意义。本文作者在前期工作的基础上,研究低温退火对电刷镀纳米晶Ni-Fe合金镀层硬度的影响,采用TEM、XRD等方法进一步分析退火温度对镀层微观结构的影响及其与硬度的关系。

1 实验

采用纯度为99.99%的电解Ni板作为电刷镀阳极,电刷镀电源为TD?150型恒压刷镀电源,在自制的可调速自动电刷镀机上制备纳米晶镀层,基体为40 mm×80 mm×0.4 mm的铜片。Ni-Fe合金镀层的镀液为氨基磺酸盐体系溶液,含适量的氯化亚铁,溶液呈深绿色,pH值为3.0。作为比较用的纯Ni镀层的镀液不含氯化亚铁。电刷镀工艺参数为:施镀电压4~8 V,阴阳极相对运动速度6~11 m/min,施镀温度318~ 338 K,刷镀时间90 min。

电刷镀层的退火处理在含有Ar气气氛的管式电阻炉中进行,保温时间为30 min,冷却方式为空冷。200 ℃等温退火实验在油浴中进行,保温时间为 10~3 000 s。采用HX?1000型维氏显微硬度计测定镀层的硬度值,载荷为0.5 N,载荷保持时间为15 s。X射线衍射实验在X’Pert MPD Pro型多功能X射线多晶衍射仪上进行,并用Scherrer公式计算镀层的平均晶粒尺寸D。采用Tecnai G2 F20 S-TWIN型场发射透射电镜对镀层的微观组织结构进行观察和分析。采用XL30 ESEM-TMP型环境扫描电镜附带的能谱仪(EDS)对刷镀层进行成分分析。

2 结果与讨论

2.1 退火温度对Ni-Fe合金镀层显微硬度的影响

采用可溶性阳极电刷镀制备纯Ni镀层和3种不同Fe含量的Ni-Fe合金镀层,其晶粒尺寸和镀态硬度如表1所列。由表1可见,所制备的电刷镀层均为纳米晶镀层,在Ni镀层中加入Fe,可进一步细化晶粒,提高镀层硬度。

表1 电刷镀Ni及Ni-Fe合金镀层的晶粒尺寸和显微硬度

Table 1 Grain size and microhardness of Ni and Ni-Fe alloy coatings

不同温度退火后纳米晶Ni-Fe合金镀层和纳米晶Ni镀层的显微硬度如图1所示。在较低温度下退火时,纳米晶Ni-Fe合金镀层和Ni镀层的硬度都随退火温度的升高而提高,纯Ni镀层在150 ℃退火后达到最大值,而Ni-Fe合金镀层在200 ℃退火后达到最大值。可见,电刷镀纳米晶镀层存在明显的退火再强化现象。镀层硬度达到最大值后,继续提高退火温度,硬度开始下降。Ni-Fe合金镀层在400 ℃退火后仍有较高的硬度,与镀态的相近,说明电刷镀纳米晶Ni-Fe合金镀层具有很高的热稳定性。电刷镀纳米晶镀层经过200 ℃退火后可以明显提高硬度,提高幅度约为20%。这种现象具有重要的实际意义,即可以通过低温退火这种简单的热处理方法提高镀层的硬度,从而提高镀层的耐磨性。而在200 ℃退火后对基体的硬度一般不会有影响,并可能提高镀层与基体的结合力。可见,可以通过合金化、纳米化和退火再强化作用明显提高电刷镀层的硬度和耐磨性。

图1 退火温度对电刷镀纳米晶镀层硬度的影响

Fig.1 Effect of annealing temperature on microhardness for nanocrystalline alloy coating

2.2 退火时间对Ni-Fe合金镀层显微硬度的影响

对Ni-13.49%Fe合金镀层在200 ℃进行不同时间的等温退火,保温时间对硬度的影响如图2所示。由图2可见,镀层硬度随保温时间的延长而提高,在保温的初期(10~300 s)硬度升高很快,呈现明显的强化现象,这一阶段与模拟的非平衡晶界弛豫导致的硬度变化[10]相符,表明退火初始阶段(10~300 s)晶界有序化对硬度的影响很明显,但此时晶粒尺寸仅略有长大。这表明在该时间范围内硬度上升不是晶粒尺寸变化引起的,而是由晶界结构驰豫引起的。

图2 在200 ℃下退火时间对Ni-13.49%Fe合金镀层显微硬度的影响

Fig.2 Effect of annealing time on microhardness of Ni- 13.49%Fe alloy coatings annealed at 200 ℃

2.3 退火温度对纳米晶Ni-Fe合金镀层微观组织结构的影响

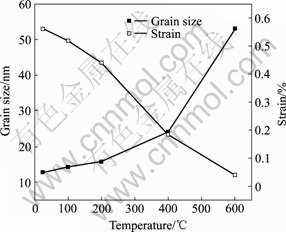

退火温度和退火时间对Ni-13.49%Fe镀层晶粒尺寸和点阵畸变的影响分别如图3和4所示。由图3和4可见,晶粒尺寸在400 ℃以下退火时长大缓慢,超过400 ℃后才快速长大。而保温时间对晶粒尺寸的影响主要是在退火的初期晶粒尺寸发生快速长大,而后基本不变。点阵畸变的变化与晶粒尺寸的变化相对应,随着晶粒尺寸的增大,点阵畸变减少。

图3 退火温度对Ni-13.49%Fe合金镀层晶粒尺寸和点阵畸变的影响

Fig.3 Effect of annealing temperature on grain size and strain of Ni-13.49%Fe alloy coatings

图4 在退火温度200 ℃下退火时间对Ni-13.49%合金镀层晶粒尺寸和点阵畸变的影响

Fig.4 Effect of annealing time on grain size and strain of Ni-13.49%Fe alloy coatings annealed at 200 ℃

图5所示为纳米晶Ni-13.49%Fe合金镀层及其在不同温度退火后的TEM明场像。与镀态纳米晶Ni- 13.49%Fe合金的组织形貌(图5(a))相比较,经过100 ℃和200 ℃退火后的纳米晶合金的晶粒长大不明显(图5(b)~(c))。在300 ℃开始有明显的长大,但仍在纳米级范围内,且分布比较均匀,不存在纯Ni中的晶粒异常长大现象[11?12]。从300 ℃开始出现细小的孪晶(图5中箭头所示),随着退火温度的升高,晶粒长大,孪晶数量增加,尺寸增大。EBRAHIMI等[13]采用TEM观察电沉积纳米晶Ni-15%Fe合金的晶粒长大过程,也未发现异常晶粒长大,他们认为这是由于镀液中未添加糖精引起的。而在本文中Ni-Fe合金镀液中含有少量糖精。因此,纳米晶金属材料退火过程的晶粒长大机制有待进一步研究,异常晶粒长大未必是纳米晶长大的本质特性。

图5 Ni-13.49%Fe合金镀层在不同温度退火后的TEM明场像

Fig.5 Bright field TEM images of Ni-13.49%Fe alloy coatings at different annealing temperatures: (a) As-deposited; (b) 100 ℃; (c) 200 ℃; (d) 300 ℃; (e) 400 ℃; (f) 500 ℃

2.4 纳米晶Ni-Fe合金镀层的低温退火强化机制

经TEM观察,纳米晶Ni-Fe合金镀层不同温度退火后的微观组织中,直到500 ℃退火仍未出现第二相,也未见高密度的位错,因此,在纳米晶Ni-Fe合金镀层中,第二相的析出和Cottrel气团不是再强化的微观机制。最近,人们发现电沉积法和大塑性变形法制备的纳米金属在适当温度退火后硬度都有所升高,这两种方法制备的纳米金属初始结构有所不同。大塑性变形法制备的纳米金属晶界含有过剩位错,而电沉积纳米金属位错很少[14?15]。THUVANDER等[16]认为其原因可能是一些极细晶区和非晶区的消失。而分子动力学模拟表明,低温退火导致非平衡晶界结构驰豫,使晶界不易发射位错,从而提高强度[10]。本文作者对微观结构观察的结果表明,纳米晶Ni-Fe合金镀层热稳定性高,加热过程晶粒长大较缓慢,不存在异常晶粒长大,且在退火过程中可以形成孪晶。电刷镀纳米晶Ni-Fe合金镀层在200 ℃低温退火强化的幅度比较大,晶粒长大虽然缓慢,但仍有所长大,而退火孪晶不会导致硬度有大的变化。非平衡晶界的驰豫只能通过分子动力学模拟判断。因此,纳米晶镀层的退火再强化微观机理比较复杂,其可能的原因有非平衡晶界的驰豫和退火孪晶。而硬度下降缓慢的原因主要是镀层的热稳定性高和退火孪晶。

3 结论

1) 在纳米晶Ni镀层中加入Fe元素,对镀层起到明显的固溶强化和细晶强化作用。随着Fe含量的升高,纳米晶Ni-Fe合金镀层的晶粒尺寸减小,硬度升高。

2) 纳米晶Ni-Fe合金镀层的硬度随退火温度的升高而提高,经200 ℃退火后达到最大值,存在明显的退火再强化,然后随退火温度的继续升高而下降。

3) 纳米晶Ni-Fe合金镀层具有较高的热稳定性,退火时晶粒长大均匀,不存在异常长大,并形成孪晶。

REFERENCES

[1] 梁志杰. 现代表面镀覆技术[M]. 北京: 国防工业出版社, 2005: 40?41.

LIANG Zhi-jie. Modern surface plating techniques[M]. Beijing: National Defence Industry Press, 2005: 40?41.

[2] 吕钊钦, 聂成芳, 王乃钊, 李光提. 电刷镀新技术研究与应用[J]. 机械工程材料, 1999, 23(3): 22?25.

L? Zhao-qin, NIE Cheng-fang, WANG Nai-zhao, LI Guang-ti. Study and application on new technology of brush electroplating[J]. Materials for Mechanical Engineering, 1999, 23(3): 22?25.

[3] 谭 俊, 徐滨士. 电刷镀纳米晶镀层的组织及其强化机理[J]. 中国表面工程, 2007, 20(1): 11?14.

TAN Jun, XU Bin-shi. Microstructure and strengthening mechanism of nanocrystalline coatings by brush plating[J]. China Surface Engineering, 2007, 20(1): 11?14.

[4] 项忠楠, 戴品强, 王 涛, 林志福, 葛 敏. 可溶性阳极电刷镀镍铁合金镀层的研究[J]. 中国表面工程, 2007, 20(5): 45?49.

XIANG Zhong-nan, DAI Pin-qiang, WANG Tao, LIN Zhi-fu, GE Min. Study of brush plated Ni-Fe alloy coating using soluble anode[J]. China Surface Engineering, 2007, 20(5): 45?49.

[5] 项忠楠, 戴品强, 陈晓文. 电刷镀镍铁合金镀层的纳米晶结构及其热稳定性[J]. 材料热处理学报, 2008, 29(5): 153?157.

XIANG Zhong-nan, DAI Pin-qiang, CHEN Xiao-wen. Nanostructure and the thermal stability of Ni-Fe alloy coating synthesized by brush plating[J]. Transactions of Materials and Heat Treatment, 2008, 29(5): 153?157.

[6] HUANG X X, HANSEN N, TSUJI N. Hardening by annealing and softening by deformation in nanostructured metals[J]. Science, 2006, 312: 249?251.

[7] DALLA TORRE F, van SWYGENHOVEN H, VICTORIA M. Nanocrystalline electrodeposited Ni: Microstructure and tensile properties[J]. Acta Materialia, 2002, 50(15): 3957?3970.

[8] WANG Y M, CHENG S, WEI Q M, MA E, NIEH T G, HAMZA A. Effects of annealing and impurities on tensile properties of electrodeposited nanocrystalline Ni[J]. Scripta Materialia, 2004, 51(11): 1023?1028.

[9] LI H Q, EBRAHIMI F. An investigation of thermal stability and microhardness of electrodeposited nanocrystalline nickel-21% iron alloys[J]. Acta Materialia, 2003, 51(13): 3905?3913.

[10] HASNAOUI A, van SWYGENHOVEN H, DERLET P M. On non-equilibrium grain boundaries and their effect on thermal and mechanical behaviour: A molecular dynamics computer simulation[J]. Acta Materialia, 2002, 50(15): 3927?3939.

[11] KLEMENT U, DA SILVA M. Individual grain orientations and texture development of nanocrystalline electrodeposits showing abnormal grain growth[J]. Journal of Alloys and Compounds, 2007, 434/435: 714?717.

[12] CHAUHAN M, MOHAMED F A. Investigation of low temperature thermal stability in bulk nanocrystalline Ni[J]. Mater Sci Eng A, 2006, 427(1/2): 7?15.

[13] EBRAHIMI F, LI H Q. Grain growth in electrodeposited nanocrystalline fcc Ni-Fe alloys[J]. Scripta Materialia, 2006, 55(3): 263?266.

[14] KRASILNIKOV N, LOJKOWSKI W, PAKIELA Z, VALIEV R. Tensile strength and ductility of ultra-fine-grained nickel processed by severe plastic deformation[J]. Mater Sci Eng A, 2005, 397(1/2): 330?337.

[15] DALLA TORRE F, SP?TIG P, SCH?UBLIN R, VICTORIA M. Deformation behaviour and microstructure of nanocrystalline electrodeposited and high pressure torsioned nickel[J]. Acta Materialia, 2005, 53: 2337?2349.

[16] THUVANDER M, ABRAHAM M, CEREZO A, SMITH G D W. Thermal stability of electrodeposited nanocrystalline nickel and iron-nickel alloys[J]. Materials Science and Technology, 2001, 17(6): 961?970.

基金项目:福建省自然科学基金计划资助项目(E0810006);福州大学创新团队资助项目

收稿日期:2008-10-06;修订日期:2009-03-28

通讯作者:戴品强,教授,博士;电话:13860693956;E-mail: pqdai@126.com

(编辑 李向群)