文章编号:1004-0609(2015)12-3414-08

Cu-金刚石复合镀层的制备

马如龙,彭超群,王日初,王小锋,张 纯,谭时雨

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用复合电镀技术,在酸性硫酸盐镀铜电镀液中加入粒径为20 μm的金刚石粉体制备Cu-金刚石复合镀层。通过正交试验优化Cu-金刚石复合电镀的工艺参数,采用扫描电镜(SEM)、能谱仪(EDS)和显微硬度计研究CuSO4·5H2O浓度、阴极电流密度、金刚石粉体浓度和镀液温度对镀层质量的影响。采用X射线分析仪(XRD)、扫描电镜(SEM)和摩擦实验机表征优化后复合镀层的相结构、表面形貌及摩擦性能。结果表明:优化的镀液组成和工艺参数为CuSO4·5H2O 190 g/L,H2SO4 60 g/L,阴极电流密度10 A/dm2,金刚石粉体浓度20 g/L,镀液温度20 ℃;优化后的复合镀层晶粒均匀,金刚石粉体质量分数为21.50%,具有较好的显微硬度和摩擦性能。

关键词:复合电沉积;硫酸铜;浓度;阴极电流密度;金刚石粉体;Cu-金刚石;复合镀层;摩擦性能

中图分类号:TQ153.4 文献标志码:A

Preparation of Cu-diamond composite coating by composite electroplating

MA Ru-long, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, ZHANG Chun, TAN Shi-yu

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The Cu-diamond composite coating was prepared by composite electroplating when diamond particles with diameter of 20 μm were put into acidic sulfate copper plating solution. The optimized technological conditions of Cu-diamond composite electroplating were obtained by orthogonal test. The effects of CuSO4·5H2O concentration, cathode current density, diamond concentration and temperature on the quality of Cu-diamond composite coatings were investigated by SEM, EDS and microhardness tester. The phase structure, surface morphology and tribological properties were investigated by XRD, SEM and friction-abrasion testing machine. The results show that the optimized technological conditions are CuSO4·5H2O 190 g/L, H2SO4 60 g/L; cathode current density, 10A/dm2; diamond concentration, 20 g/L; temperature, 20 ℃. The Cu-diamond composite coating containing 21.50% diamond particles has homogeneous grains, better microhardness and tribological performance.

Key words: composite electroplating; CuSO4·5H2O; concentration; cathode current density; diamond powder; Cu-diamond; composite coating; tribological performance

复合电镀是指利用电镀方法将一种或多种不溶性的固体颗粒均匀、分散地嵌入到金属基镀层中的一种技术[1-2]。金刚石属于硬质材料,采用复合电沉积技术制备的金刚石制品具有良好的使用性能,已开发了各种磨具和非磨削工具[3-4]。其中,金刚石线锯是一种常用的线性切割工具,常用于切割石材、陶瓷、硅片和铝合金等材料[5-7]。采用电镀法制备金刚石线锯通常采用钢丝作为基体,Ni和Ni基合金作为基质金属。Cu是一种常用金属,具有原料丰富、价格低廉、导电性优良以及易于机械加工等诸多优点,在工业生产中占有重要地位。利用Cu-金刚石复合镀层代替Ni-金刚石复合镀层制备金刚石线锯的预镀层可以节省大量成本,具有重要的研究价值,因此,有必要对其开展相关研究。目前,研究较多的金刚石复合镀层的基质金属主要为Ni基[8-13],对Cu基金刚石复合镀层的研究较少。复合镀层的性能主要受复合电镀的工艺参数影响,要获得具有良好性能的复合镀层,必须对工艺参数进行研究。对于铜基复合镀层制备工艺已经有一些研究:谷硕[14]采用电沉积制备Cu-SiC复合镀层,研究主要工艺参数对镀层摩擦磨损性能的影响;李鹏[1]通过在酸性硫酸铜镀液中加入纳米级AlN颗粒,研究Cu-AlN复合电镀的工艺参数和复合镀层的耐磨耐蚀性能。本文作者采用正交试验法,通过在酸性镀铜液中加入微米级金刚石粉体,研究硫酸铜浓度、阴极电流密度、金刚石粉体浓度和镀液温度对镀层质量的影响,在此基础上优化Cu-金刚石复合电镀的工艺参数,并采用X射线衍射分析仪、扫描电镜和摩擦实验机表征优化后复合镀层的相结构、表面形貌及摩擦性能,为后续研究提供参考。

1 实验

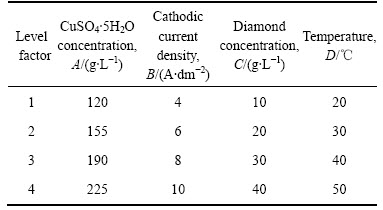

镀液采用硫酸盐镀铜电镀液,镀液组成为CuSO4·5H2O(120~225 g/L)和H2SO4(60 g/L),实验所用溶液均采用分析纯试剂和蒸馏水配制而成。采用正交试验,实验因素水平如表1所列。实验基体采用工作面为10 mm×10 mm的不锈钢,其余部分固封。将工作面依次经400号、600号和800号砂纸打磨光亮,首先在10% NaOH(质量分数,下同)溶液超声除油,用蒸馏水漂洗至中性,其次放入10% H2SO4溶液超声去除氧化皮和锈蚀并活化金属表面,最后用蒸馏水漂洗至中性,超声时间均为2 min,风干待用。金刚石粉体(粒径20 μm)在施镀前进行预处理,主要步骤为:将金刚石在10% NaOH溶液中煮沸10 min除油后,用蒸馏水漂洗至中性,再在10% HNO3溶液中煮沸10 min活化粉体表面,用蒸馏水漂洗至中性,风干待用。施镀前将含金刚石粉体的复合镀液采用JJ-1型定时电动搅拌器机械搅拌24 h使其润湿。以500 mL烧杯为镀槽,采用JJ-1型定时电动搅拌器机械搅拌,并固定搅拌速度(使金刚石粉体充分悬浮在镀液中),以不锈钢为阴极、光亮的铜板为阳极,采用WYJ-15V/10A型直流稳压电源提供电流进行施镀,电镀时间为15 min,实验过程中采用Kw-1000DC型恒温水浴锅进行保温,精度为±2 ℃。进行摩擦磨损实验时实验基体采用工作面为30 mm×25 mm的不锈钢,电镀时间为120 min,其他条件与上述相同。

表1 正交试验因素水平

Table 1 Factors and levels of orthogonal test

采用Quanta-200型扫描电镜观察复合镀层表面形貌,并结合能谱仪计算复合镀层中的金刚石含量,通过复合镀层横截面的测量得到镀层厚度并计算电沉积速率;采用HVS-1000型自动显微硬度计测试复合镀层中基质金属的显微硬度,载荷为0.49 N,每个样品测试5个点,取其平均值;通过D/MAX-RBX衍射分析仪表征Cu-金刚石复合镀层的结构,并计算金刚石粉体含量以校正能谱仪面扫描分析测得的金刚石含量;采用UMT-3型摩擦试验机测试复合镀层的摩擦因数和质量磨损,转速、载荷和时间分别为180 r/min、-10 N和30 min。

2 结果与讨论

2.1 工艺参数对复合镀层质量的影响

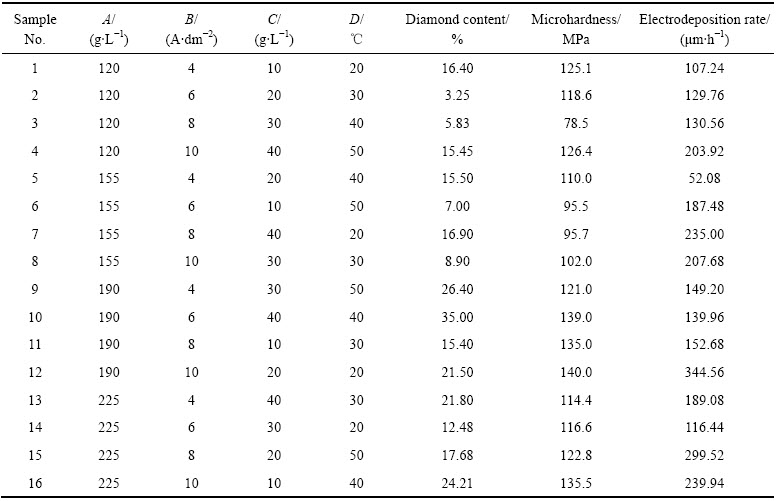

根据L16(44)正交设计表设计工艺参数,具体实验参数和结果如表2所列。本实验以复合镀层金刚石含量、显微硬度和电沉积速率为镀层评价指标。在一般情况下,金刚石含量越高,复合镀层硬度越大,其耐磨性越高。在保证镀层质量的前提下,电沉积速率越大,生产效率越高。因此,对上述指标的要求是:金刚石含量尽可能大,硬度尽可能高,电沉积速率尽可能大。从表2可以看出,2号和3号试样的金刚石含量较低,为3.25%和5.83%,10号金刚石含量最高,为35.00%;3号试样显微硬度最低,为78.5 MPa,而10号和12号显微硬度较高,分别为139.0和140.0 MPa;5号试样电沉积速率最低,为52.08 μm/h,12号试样沉积速度最大,为344.56 μm/h。

表2 工艺参数正交设计表

Table 2 Orthogonal design of process parameters

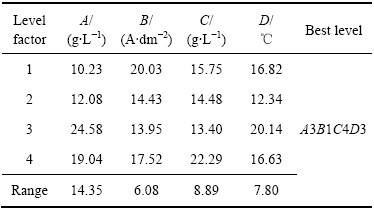

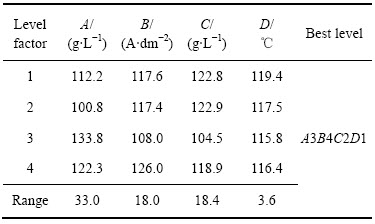

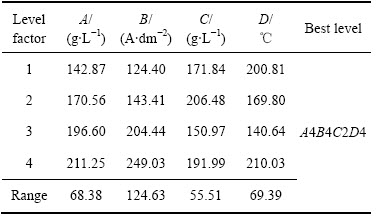

根据表2的数据,运用正交试验分析法可分析电镀工艺参数对复合镀层金刚石含量、显微硬度和电沉积速率的影响主次及较优水平,各试样的正交试验分析结果见表3~5。从表3~5可以看出,对金刚石含量影响主次顺序分别为硫酸铜浓度、金刚石粉体浓度、温度和阴极电流密度;对显微硬度影响主次顺序分别为硫酸铜浓度、金刚石粉体浓度、阴极电流密度和温度;对电沉积速率影响主次顺序分别为阴极电流密度、温度、硫酸铜浓度和金刚石粉体浓度。

表3 金刚石粉体含量的直观分析表

Table 3 Orthogonal tests results of diamond powder content

表4 显微硬度的直观分析表

Table 4 Orthogonal tests results of microhardness

表5 电沉积速率的直观分析表

Table 5 Orthogonal tests results of electrodeposition rate

硫酸铜浓度是影响复合镀层金刚石粉体含量的最主要因素。由表3可以看出,随硫酸铜浓度升高,金刚石粉体含量先升高后降低。对于解释复合电沉积过程,CELIS等[15]考虑流体动力学和界面电场因素的影响,提出了MTM(Mathematical model)模型。该模型认为微粒与金属发生共沉积主要经历以下过程:1) 镀液中的微粒表面首先吸附镀液中的离子形成吸附层;2) 微粒在电场和对流作用下迁移到阴极表面;3) 在微粒表面吸附的离子被还原的同时,微粒被嵌入到基质金属中形成复合镀层。由以上过程可知,微粒表面吸附的离子是微粒嵌入镀层的重要因素。当铜离子浓度较低时,随镀液中铜离子浓度的升高,吸附在金刚石粉体表面的铜离子增多,金刚石粉体表面所带正电荷越多,电场对其作用力也越强。这促进了金刚石粉体向阴极表面迁移,并随着其表面铜离子逐渐还原而被嵌入镀层中,金刚石含量逐渐增大;当铜离子浓度继续增大时,由于金刚石粉体表面面积有限,金刚石粉体表面铜离子浓度不再增大,而铜沉积速度依然增大,且远大于金刚石粉体嵌入复合镀层的速度,使得金刚石粉体含量降低[13]。

硫酸铜浓度也是影响复合镀层硬度的最主要因素。复合材料显微硬度由基质金属显微硬度和金刚石含量两个因素决定[16],沉积基质金属越平整,嵌入镀层的微粒含量越高,复合镀层的显微硬度越高。王美娟等[13]研究镀液离子浓度对Ni-金刚石复合镀层质量的影响表明,在低浓度镍离子下的镀层有较多较小的晶核,镀层表面较为平整、细密,在高浓度镍离子下的镀层表面较粗糙。因此,当硫酸铜浓度低时,铜沉积层较致密,其硬度较高,但其金刚石含量较低,金刚石对镀层的弥散强化效应将会降低,因此,复合镀层硬度变化是两者综合作用的结果。

阴极电流密度是影响电沉积速率的最主要因素。由表5可以看出,随着阴极电流密度增大,基质金属电沉积速率不断增大。这是因为阴极电流密度增大,阴极过电位也会相应增大,电场增强,从而提高铜离子的沉积速度,但阴极电流密度过大,可能导致析氢加剧,氢气在阴极的析出将导致镀层质量降低,使其变得粗糙、不平整,而且阻碍微粒与基质金属的共沉积[17]。

显微硬度和镀层中金刚石粉体的含量为本实验最主要的两个指标,因此,将影响这两个指标的因素作为首要考虑因素,其次是沉积速率。考虑到工业生产成本要求,金刚石粉体浓度可适当降低。综合以上实验结果的分析,最佳电镀工艺条件为A3B4C2D1,即12号试样的综合性能最佳,其工艺参数为硫酸铜浓度190 g/L,阴极电流密度10 A/dm2,金刚石粉体浓度20 g/L,镀液温度20 ℃。该条件下复合镀层具有优良的综合性能,其金刚石含量为21.50%,显微硬度为140.0 MPa,电沉积速率为344.56 μm/h。因此,选取12号试样作为后续研究的对象,并以3、5和10号试样做对比。

2.2 复合镀层的显微组织

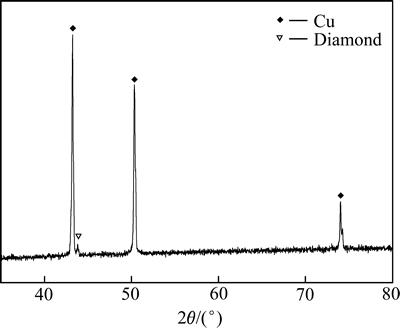

图1所示为12号试样的XRD谱。由图1可以看出,复合镀层中只含有Cu和金刚石两种物相,说明在电镀过程中,Cu和金刚石之间没有发生反应生成新相,这有利于金刚石保持原有性质并发挥作用。

图1 12号试样的XRD谱

Fig. 1 XRD pattern of Sample 12

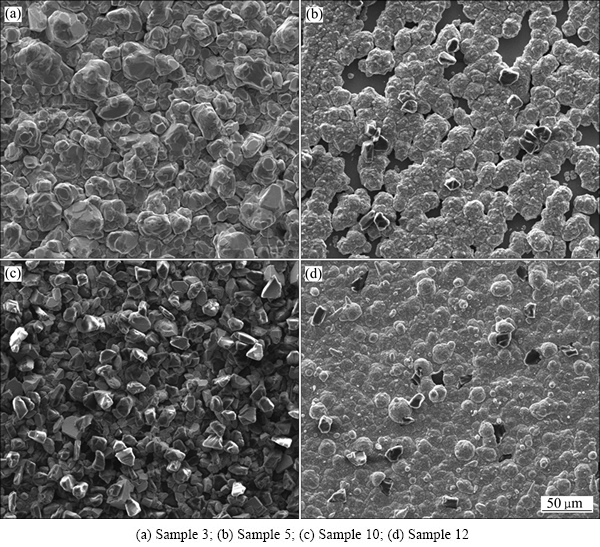

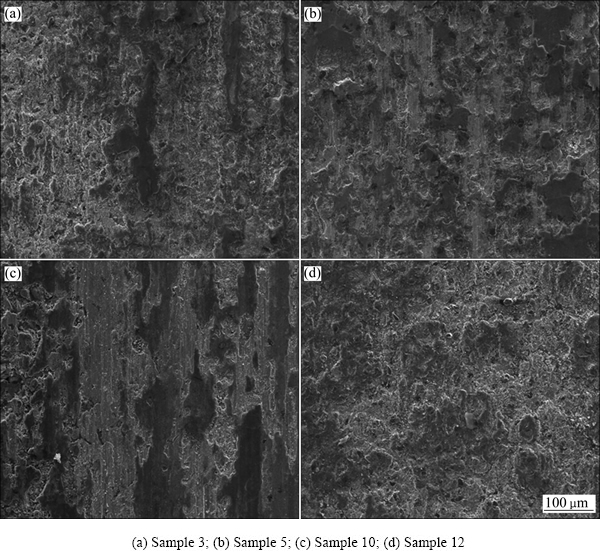

图2所示为不同试样的SEM像。由图2可以看出,3号试样表面为粒状和胞状组织共存,表面不平整,基本观察不到金刚石,金刚石含量最低,这是导致其硬度较低的主要原因;5号试样为典型的胞状组织,且有部分基体裸露,其电沉积速率最低;10号试样为粒状或块状组织,这是由于铜的生长机制改变所致;12号试样镀层表面呈胞状组织,微粒分布较均匀,可观察到不规则形状的金刚石粉体较均匀地镶嵌在镀层中,但复合镀层组织不是很平整,需进一步改善。研究表明,金刚石粉体的嵌入可以阻碍和延迟基质金属的位错滑移运动,抑制塑性变形,使复合镀层得以强化,同时,金刚石粉体本身具有较高强度和硬度,均匀分布在基质金属中产生强化效应,可有效提高镀层的硬度和耐磨性[1]。

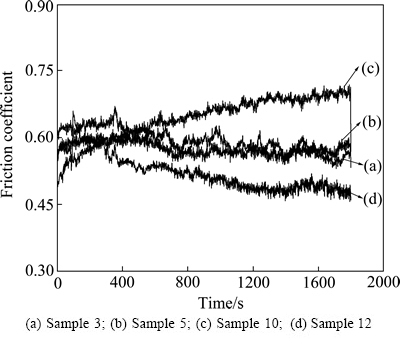

2.3 复合镀层的摩擦性能

图3所示为4个试样在干摩擦条件下与Al2O3陶瓷球对磨,其摩擦因数与时间的关系曲线。从图3可以看出,随着时间延长,3、5和12号的摩擦因数都先逐渐降低后趋于稳定,而10号的摩擦因数逐渐上升并趋于稳定。采用摩擦试验机计算出3、5、10和12号试样的平均摩擦因数分别为0.5939、0.5756、0.6428和0.5218,采用电子天平称取磨屑质量得出其磨损量分别为2.1、0.4、3.2和1.2 mg。可见,3号试样由于金刚石含量很少,摩擦时铜和对磨件之间直接接触,发生粘着磨损,摩擦因数和磨损量较高;5号试样由于其阴极电流密度低,沉积速度低,故沉积镀层较平整、致密,同时金刚石含量较高,因此,其摩擦因数和磨损量较小;10号试样由于金刚石含量太高,铜基体无法很好地包裹住金刚石,因此,受力时金刚石粉体容易脱离复合镀层,导致其磨损量较大;12号试样由于金刚石含量适中,因此,其摩擦因数较低,磨损量较小,具有较好的耐磨性。

图2 不同试样的SEM像

Fig. 2 SEM images of different samples

许多研究发现,金刚石粉体可改变复合镀层的组织结构,并对摩擦性能产生影响[18-19]。复合镀层中的金刚石粉体可强化基体,阻碍位错运动,使镀层不易软化而导致磨损发生[1],同时,金刚石颗粒在基质金属表面形成突起,起到支撑载荷的作用,从而提高镀层的耐磨性[18]。通常情况下,在保证基质金属对金刚石粉体支撑条件下,复合镀层中金刚石含量越高,其承载能力越强,但复合镀层中金刚石含量并不是越多越好,因此,金刚石的含量存在一个最佳范围[19]。

图3 不同样品摩擦因数与时间关系

Fig. 3 Relationship between friction coefficient of different samples and time

图4所示为镀层磨损后的表面形貌。从图4可以看出,3号试样磨痕较深,磨损表面发生剥落,属于粘着磨损,且由于作用在基质金属上的正向应力增大,导致局部过热,在复合镀层表面形成粘结,是导致其磨损量较大的重要原因。10号试样镀层出现与滑动方向明显平行的磨损划痕,镀层表面也存在金属-金属粘结现象,表现为磨粒磨损和粘着磨损共同作用;5号和12号磨损表面未出现明显的划痕,但发现有较多的不连续磨损和小坑洞,磨损机制为疲劳磨损和粘着磨损。

图4 不同镀层磨损表面形貌的SEM像

Fig. 4 Worn surfaces SEM images of different samples

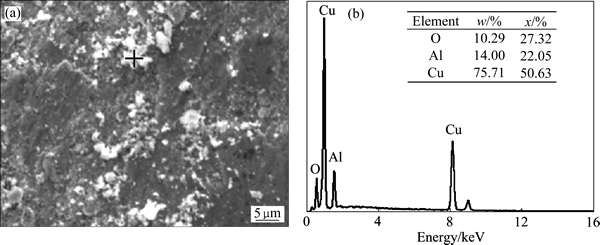

图5 12号试样磨损表面的SEM像和EDS分析

Fig. 5 Wear coatings SEM image(a) and EDS analysis(b) of Sample 12

图5所示为12号试样镀层磨损表面的能谱成分分析。从图5可以看出,磨屑含有一定量的氧原子和铝原子,分析认为在摩擦过程中产生热量使得铜软化,局部高温氧化生成CuO,而铝原子来自于对磨件Al2O3的脱落。氧化铜能在镀层表面形成氧化膜,在摩擦过程中起润滑作用,这是镀层的摩擦因数随时间延长而逐渐降低并趋于稳定的重要原因。

3 结论

1) 在镀液组成CuSO4·5H2O(120~225 g/L)和H2SO4(60 g/L)、阴极电流密度4~10 A/dm2、金刚石粉体浓度10~40 g/L和镀液温度20~50 ℃工艺条件下,硫酸铜浓度是影响复合镀层中金刚石粉体含量和显微硬度的最主要因素,适当较高的硫酸铜浓度有利于提高其金刚石粉体含量和显微硬度;阴极电流密度是影响复合镀层沉积速度的最主要因素,电流密度越高,电沉积速度越快。

2) 优化的工艺条件如下:CuSO4·5H2O 190 g/L,H2SO4 60 g/L,阴极电流密度10 A/dm2,金刚石粉体浓度20g/L,镀液温度20 ℃。优化后的Cu-金刚石复合镀层晶粒均匀,金刚石粉体质量分数为21.50%,具有较好的显微硬度和摩擦性能。

REFERENCES

[1] 李 鹏. 电沉积Cu-A1N复合镀层的制备和性能的研究[D]. 合肥: 合肥工业大学, 2010.

LI Peng. Study on preparation and properties of Cu-AlN with high performance coating by eletrodeposition[D]. Hefei: Hefei University of Technology, 2010.

[2] 王美娟. 金刚石粉体对Ni电结晶初期行为的影响[J]. 中国有色金属学报, 2013, 23(3): 765-772.

WANG Mei-juan. Effect of diamond powder on Ni electrocrystallization behavior at initial stages[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(3): 765-772.

[3] 吕正茂, 李成明, 吕反修. 金刚石复合镀层的研究现状[J]. 表面技术, 2003, 32(6): 1-3, 10.

Zheng-mao, LI Cheng-ming,

Zheng-mao, LI Cheng-ming,  Fan-xiu. Study on composite coatings with diamond[J]. Surface Technology, 2003, 32(6): 1-3, 10.

Fan-xiu. Study on composite coatings with diamond[J]. Surface Technology, 2003, 32(6): 1-3, 10.

[4] 王秦生. 超硬材料电镀制品[M]. 北京: 中国标准出版社, 2001.

WANG Qin-sheng. Superhard materials electroplating products[M]. Beijing: China Standard Press, 2001.

[5] 王美娟. 固结磨粒金刚石线锯的研究进展[J]. 中国有色金属学报, 2013, 23(5): 1368-1379.

WANG Mei-juan. Research progress on fixed diamond wire saw[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1368-1379.

[6] 向 波, 贺跃辉, 谢志刚. 电镀金刚石线锯的研究现状[J]. 材料导报, 2007, 21(8): 25-29.

XIANG Bo, HE Yue-hui, XIE Zhi-gang. Research progress in electroplated diamond wire saw[J]. Materials Review, 2007, 21(8): 25-29.

[7] 高 伟, 刘镇昌. 用复合电镀法制造环形电镀金刚石线锯[J]. 金刚石与磨料磨具工程, 2004, 2: 48-51.

GAO Wei, LIU Zhen-chang. Manufacturing looped diamond wire saw using combined electroplating method[J]. Diamond and Abrasives Engineering, 2004, 2: 48-51.

[8] HITOSHI O, MOHD S, TETSUO S. Effect of electrodeposition conditions on hardness of Ni-B/diamond composite films[J]. Surface and Coatings Technology, 2012, 212: 180-184.

[9] BURKAT G K, FUJIMURA T, DOLMATOV V Y. Preparation of composite electrochemical nickel-diamond and iron-diamond coatings in the presence of detonation synthesis nanodiamonds[J]. Diamond and Related Materials, 2005, 14(11/12): 1761-1764.

[10] MAZAHERI H, ALLAHKARAM S R. Deposition, characterization and electrochemical evaluation of Ni-P-nano diamond composite coatings[J]. Applied Surface Science, 2012, 258(10): 4574-4580.

[11] HOU K H, HAN T, SHEU H H. Preparation and wear resistance of electrodeposited Ni-W/diamond composite coatings[J]. Applied Surface Science, 2014, 308: 372-379.

[12] ZHOU Hai-fei, DU Nan, ZHU Li-wei, SHANG Jian-ku, QIAN Zhou-hai, SHEN Xiao-ming. Characteristics investigation of Ni-diamond composite electrodeposition[J]. Electrochimica Acta, 2015, 151: 157-167.

[13] 王美娟, 王日初, 彭超群. Ni-金刚石复合镀层的制备[J]. 中南大学学报(自然科学版), 2013, 44(7): 2688-2695.

WANG Mei-juan, WANG Ri-chu, PENG Chao-qun. Preparation of Ni-diamond composite coating by composite electroplating[J]. Journal of Central South University (Science and Technology), 2013, 44(7): 2688-2695.

[14] 谷 硕. Cu-SiC纳米复合镀层的制备及性能预测研究[D]. 大庆: 东北石油大学, 2013.

GU Shuo. Preparation and forcasting properties of Cu-SiC nano-composite coatings[D]. Daqing: Northeast Petroleum University, 2013.

[15] CELIS J P, ROOS J R, BUELENS C. A mathematical model for the electrolytic codeposition of particles with a metallic matrix[J]. Journal of the Electrochemical Society, 1987, 134(6): 1402-1408.

[16] CHEN Li, WANG Li-ping, ZENG Zhi-xiang, ZHANG Jun-yan. Effect of surfactant on the electrodeposition and wear resistance of Ni-Al2O3 composite coatings[J]. Materials Science and Engineering: A, 2006, 434(1/2): 319-325.

[17] 谭澄宇, 郑学斌, 赵旭山, 刘 宇, 李劲风. Cu-ZrW2O8复合镀层的制备[J]. 中南大学学报(自然科学版), 2008, 39(2): 234-238.

TAN Cheng-yu, ZHENG Xue-bin, ZHAO Xu-shan, LIU Yu, LI Jing-feng. Preparation of Cu-ZrW2O8 composite coatings by electric deposition[J]. Journal of Central South University (Science and Technology), 2008, 39(2): 234-238.

[18] 邵建兵, 朱永伟, 黎向峰, 林 魁, 陈拥军. Ni-P-金刚石化学复合镀层耐磨性能研究[J]. 金刚石与磨料磨具工程, 2008(5): 25-29.

SHAO Jian-bing, ZHU Yong-wei, LI Xiang-feng, LIN Kui, CHEN Yong-jun. Study on the anti-wear behavior of eletroless Ni-P-diamond composite coatings[J]. Diamond and Abrasives Engineering, 2008(5): 25-29.

[19] 谢 华, 钱匡武, 陈文哲. Ni-P-金刚石化学复合镀层的耐磨性[J]. 机械工程材料, 2002, 26(10): 19-22, 25.

XIE Hua, QIAN Kuang-wu, CHEN Wen-zhe. Wear-resistance of electroless Ni-P-diamond composite coating[J]. Materials for Mechanical Engineering, 2002, 26(10): 19-22, 25.

(编辑 王 超)

收稿日期:2015-03-13;修订日期:2015-09-21

通信作者:王小锋,讲师,博士;电话:0731-88836638;E-mail: lwangxiaofeng@163.com