DOI: 10.11817/j.issn.1672-7207.2017.06.013

湿式除尘风机三相除尘运行参数研究

赵海鸣1, 2,谢信1,夏毅敏1, 2,廖小乐1

(1. 中南大学 机电工程学院,湖南 长沙,410083;

2. 中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:针对湿式除尘风机内部气液固三相流场的特点,在FLUENT中采用欧拉法描述气相湍流流动,采用拉格朗日法描述粉尘与液滴的运动,同时考虑气、液、固三相之间的耦合关系,运用Euler/DPM/DPM模型对其内部流场进行数值模拟。将数值计算结果与实验结果进行比较,验证该数值模型用于模拟风机三相流场的可行性与准确性,为进一步优化湿式除尘风机提供依据,并在此基础上研究湿式风机的除尘效率与粉尘粒度、风机转速及液气比等参数的相互关系。研究结果表明:粉尘粒度越大、风机转速越高、液气比越大,除尘效率越高;当粉尘粒度由15 μm减少到1 μm时,除尘效率从99%降至65%;当风机转速由1 500 r/min增加到1 700 r/min时,粒度为3~10 μm的颗粒除尘效率可提高3%~5%;提高增大液气比(0.1~0.4 L/m3)可明显提高小粒度粉尘颗粒(1~10 μm)的除去效率。

关键词:湿式除尘风机;气液固;三相流;除尘效率;数值模拟

中图分类号:TH43 文献标志码:A 文章编号:1672-7207(2017)06-1505-08

Research on operation parameters of three-phase flow in wet dust collecting fan

ZHAO Haiming1, 2, XIE Xin1, XIA Yimin1, 2, LIAO Xiaole1

(1. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083,China;

2. State Key Laboratory of High Performance Complex Manufacturing,Central South University, Changsha 410083, China)

Abstract: Based on the feature of gas-liquid-solid three-phase flow in wet dust collecting fan, the method of Eulerian was used to simulate gas turbulent flow and the method of Lagrange was used to describe the motion of dust and droplet in FLUENT software. Considering the coupling relationship of gas-liquid-solid three-phase, the Euler/DPM/DPM three-phase model was used to simulate the three-phase flow of fan. Through comparing the numerical calculating results with experiment results, the veracity and feasibility of the model were verified to simulate the three-phase flow in wet dust collecting fan, which furtherly provides the basis for optimizing wet dust collecting fan. On this basis,the relationship between the separation efficiency and operation parameters such as the particle sizes, rotating speed and gas-liquid ratio were obtained by the numerical simulation. The results show that the greater the particles sizes and the higher the rotating speed and gas-liquid ratio, the higher the separation efficiency. The separation efficiency decreases from 99% to 65% when particle size decreases from 15 μm to 1 μm. The separation efficiency among the particle size range of 3-10 μm will increase by 3%-5% when the rotating speed increase from 1 500 r/min to 1 700 r/min. Increasing gas-liquid ratio (0.1-0.4 L/m3) can evidently promote the separation efficiency of small diagram dust particle (1-10 μm).

Key words: wet dust collecting fan; gas-liquid-solid; three-phase; separation efficiency; numerical simulation

风机作为除尘器的动力源,是除尘系统中必不可少的关键设备。传统的风机仅为除尘系统中的气流提供动力,不能参与除尘,并且为了减少叶轮的磨损,风机安装在除尘器的出口位置。湿式除尘器由于具有较好的除尘效果,工业应用广泛[1],但其排出的烟气带水现象,容易引起风机叶轮黏灰,产生异常振动,而且会严重腐蚀风机叶片[2]。而湿式除尘风机由于采用开式的叶轮设计,解决了传统风机怕水、怕尘的难题,并可直接参与除尘。利用湿式风机除尘是对湿式除尘的一大创新,其具有除尘效率高、寿命长、免维护等突出优点。湿式除尘风机既可单独用于通风除尘,也可与其他装置组成复合型除尘器参与除尘。目前,国内外对湿式除尘风机三相流场及运行参数的研究很少,利用数值模拟技术研究该风机三相流场变化规律、除尘影响因素及相互间关系显得十分必要。湿式风机除尘的过程为气液固三相湍流流动,其内部各相之间的相互作用、相互耦合关系十分复杂,难以精确描述。近年来,国内外学者提出的三相流动模型有拟均相模型[3]、三流体模型[4]、欧拉-离散相模型[5-7]等,其中拟均相模型和三流体模型能合理象地考虑气液固三相之间的相互作用,但将固体颗粒视为拟流体,与其分散性的本质特点相违背;欧拉-离散相模型针对气液固各相流动的特点,采用Euler-Lagrange方法,在Euler坐标系中描述连续相的运动,在Lagrange坐标系中描述离散相的运动,同时考虑离散相与连续相之间的耦合作用,这种模型能够较好地模拟多相流动,模拟结果与实验结果基本吻合。本文作者在 FLUENT中将湿式除尘风机内气体相视为连续相在Euler坐标系下计算其流场,而将粉尘颗粒和液滴视为离散相在Lagrange坐标下描述其运动轨迹,同时考虑颗粒相与连续相间的耦合作用,运用Euler/DPM/DPM模型模拟风机的三相流场。将数值计算结果与实验测定结果进行对比,验证模型对湿式风机三相流场计算的可行性与准确性,并在此数值模型的基础上进一步对湿式除尘风机的运行参数进行分析。

1 物理模型及简化

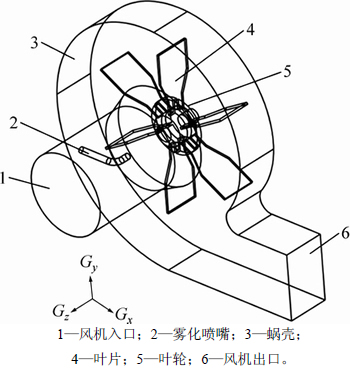

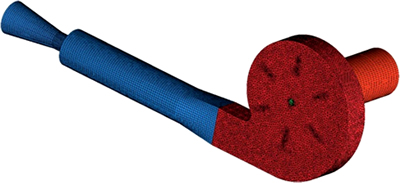

湿式除尘风机结构如图1所示。

湿式除尘风机采用开式的叶轮设计,无前后轮盘,而将叶片直接焊接在轮盘上,故可获得较高的叶片强度,满足机械除尘的要求。同时,无前后轮盘的叶轮结构既可以防止泥浆的粘结,又利于在叶片上喷涂耐磨涂层,提高叶片的耐磨性。湿式除尘风机入口处安装有雾化喷嘴,其将雾化液滴直接喷到叶轮之上,在叶轮上形成一层水膜,同时在叶轮强烈撞击和扰动的作用下,液滴会进一步雾化、破碎,这使得风机蜗壳内充满气溶胶状的极细液滴,并且由于叶轮离心力作用及液体凝聚,到达蜗壳内壁面形成一层水膜。进入风机的粉尘颗粒中一部分会被高速旋转的叶片撞击而被其上黏附的水膜捕集,一部分与蜗壳内的雾化液滴发生惯性碰撞而被捕集,另一部分粉尘颗粒在离心力的作用下甩向蜗壳壁面被水膜捕集。

图1 湿式除尘风机结构示意图

Fig. 1 Structure schematic diagram of wet dust collecting fan

由于湿式除尘风机内部三相除尘过程较复杂,其内部流动包括气相湍动与输运、多相流动与液滴蒸发、液体包裹粉尘捕集、粉尘碰壁捕集、液滴的雾化、破碎与凝并等。若对上述过程进行全部模拟,将使数值计算过程极复杂,也不能达到预期效果,特进行如下假设与简化:1) 气体相视为不可压缩的流体;2) 假设粉尘、液滴为惰性球体;3) 不考虑颗粒间的破碎及聚并;4) 不考虑粉尘与液滴之间的传质与传热。

2 数值计算方法

2.1 气相湍流流动方程

工程上数值模拟计算常用的湍流模型有Standard κ-ε模型、RNG κ-ε模型、Realizable κ-ε模型和RSM模型。其中,Standard κ-ε模型采用各向同性假设,对强旋流、强分离流模拟较差,适合初始迭代;RNG κ-ε模型与Realizable κ-ε模型是Standard κ-ε模型的改进模型,可以更好地处理高应变率及流线弯曲程度较大流动;RSM模型考虑了各向异性效应,包含更多的物理机理,应用范围更广,但由于方程间强耦合性,收敛稍差,且计算量大,对计算机要求高[8]。

该湿式除尘风机内部为复杂的高速旋转的湍流流场,旋转效应显著。Realizable κ-ε模型能够较好地模拟风机的气动特性[9],所以,本文采用Realizable κ-ε湍流模型对风机的内部流场进行模拟。

Realizable κ-ε湍流模型的输运方程如下[10]:

(1)

(1)

(2)

(2)

式中:ρ为流体密度;xi和xj为各坐标分量;σk和σε分别为湍动能k和耗散率ε的湍流普朗特数;Gk为由平均速度梯度所产生的湍动能;Gb为由浮力影响所产生的湍动能;YM为可压缩湍动脉动膨胀对总的耗散率的影响;μ为分子黏性系数;μt为湍流黏性系数;Sk和Sε为用户针对该模型所自定义的源项。

2.2 离散相颗粒运动控制方程

在湿式除尘风机中,粉尘颗粒与液滴的体积均相对于气体相所占的比例远小于10%,故对粉尘颗粒与液滴采用离散相模型描述,此模型便于模拟颗粒相的复杂运动轨迹,并且可以免去计算中的伪扩散[11]。

离散相(包括粉尘颗粒、液滴颗粒)的作用力平衡方程在笛卡尔坐标系下(x方向)为[12]

(3)

(3)

式中:FD(u-up)为颗粒的单位质量曳力,

(4)

(4)

u为气相速度;up为颗粒速度;ρ为空气密度;ρp为颗粒密度;μ为空气动力黏度;dp为颗粒直径;CD为阻力系数;Re为相对雷诺数(颗粒雷诺数);Fx为其他作用力,包括附加质量力、辐射力、布朗力等,本文忽略不计。

2.3 离散相与连续相耦合方程

湿式除尘风机内部的粉尘颗粒与液滴会影响气体相湍流的分布,模拟中要考虑离散相与连续相之间有相互作用,在DPM模型中粉尘颗粒、液滴与气体相的作用可表示为[13]

(5)

(5)

式中:u为气相速度(m/s);up为颗粒速度(m/s);ρ为流体密度(kg/m3);ρp为颗粒密度(kg/m3);μ为流体动力黏度(Pa·s);dp为颗粒直径(m);CD为阻力系数;Re为相对雷诺数;Fouther为其他相间作用力; 为颗粒质量流率;Δt为时间步长。

为颗粒质量流率;Δt为时间步长。

2.4 网格划分及边界条件

采用Solidworks和ICEM CFD对湿式除尘风机进行建模和网格划分。为了便于后续实验对比,风机模型的尺寸与实验风机的尺寸一致,并带有与实验装置相同的进出口测试管道,风机叶轮直径为1 000 mm,叶片宽度为220 mm,叶片为径向出口直叶片、数量为6片。由于湿式风机内部结构及流动状况复杂,对蜗壳区域和叶轮区域采用四面体网格的Octree网格划分方法,并对叶轮区域进行网格加密,其他区域采用六面体网格的Block网格划分方法。通过对网格进行无关性验证,得到网格模型扭曲度不小于0.38,网格总数约为207万,网格模型如图2所示。湿式除尘机实验装置示意图见图3。

图2 湿式除尘风机网格模型

Fig. 2 Grid model of wet dust collecting fan

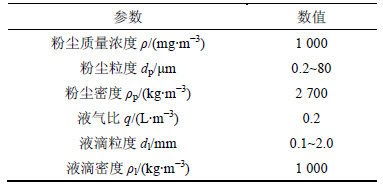

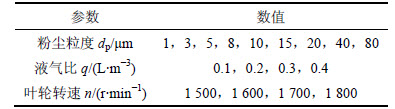

边界条件设为:1) 进口管道为压力入口边界条件,湍流强度为3.4%,水力直径为0.5 m;2) 出口管道满足出风口边界条件,通过调整压力损失系数,以达到节流阀的效果,其湍流强度为3.2%,水力直径为0.35 m;3) 风机叶轮满足旋转壁面边界条件,其他静止壁面为无滑移壁面边界条件;4) 风机入口和出口为内部面,将其设为采样面,用于在数值计算中采集风机进出口全压及粉尘浓度,便于与实验结果进行对比;5) 数值计算所加入的粉尘与液滴颗粒粒度及其分布(颗粒粒度服从Rosin-Rammler分布[14-15])均与实验条件一致,计算参数如表1所示。

2.5 流场计算

在运用FLUENT流体软件进行数值计算过程中,先对风机内部单相湍流流场进行求解,控制方程采用realizable κ-ε双方程模型及standard wall function壁面函数;压力速度耦合采用SIMPLE算法,动量方程采用一阶迎风格式,能量方程和湍流耗散方程采用二阶迎风格式;叶轮区域设为旋转区,采用多参考系模型,旋转区与静止区通过interface面连接;收敛残差为10-4。对湿式风机三相除尘进行数值模拟时,先计算风机气相流场,计算收敛后加入粉尘与液滴颗粒相,交替求解连续相与离散相的控制方程,直至两者均收敛。

表1 计算参数

Table 1 Calculation parameters

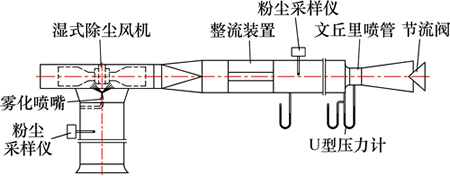

图3 湿式除尘风机实验装置示意图

Fig. 3 Installation of schematic diagram of wet dust collecting fan’s test

3 数值计算实验验证

3.1 实验装置及方法

风机的性能测试包括气动特性测试及除尘效率测试,实验装置按GB/T 1236—2000“工业通风机-用标准化风道进行性能试验”[16]及GB/T 15187—2005“湿式除尘器性能测定方法”[17]的规定进行设计,如图3所示。风机的实验装置采用带有进出口管道的D型试验装置,出口管道安装ISO文丘里喷管用于测定流量,U型压力计测量不同管道截面处的压力,末端安装的节流阀可调节管道的阻力;粉尘浓度仪用于除尘效率测试中测量风机进出口的粉尘浓度,并将实验中测试点所测数据按标准中给出的方法计算风机的全压及除尘效率。

3.2 数值计算的可行性验证

3.2.1 单相湍流数值计算的可行性验证

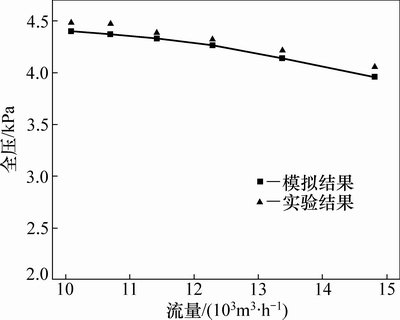

当风机运行转速为额定转速1 500 r/min时,通过调节风机出口管道处的节流阀改变管道的阻力,从而获得风机的气动特性曲线,将实验结果与模拟结果进行对比,如图4所示。从图4可见:所选的流动计算模型能有效预测湿式除尘风机内气相的流动过程。单相湍流模型对湿式除尘风机内气相流动过程的准确预测是除尘效率数值计算准确性的基础。

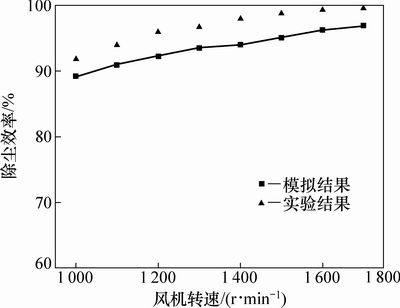

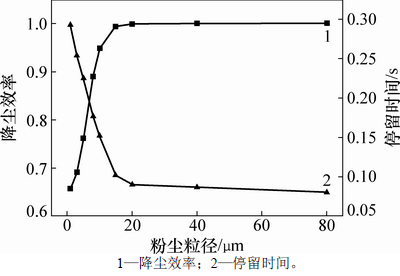

3.2.2 三相流数值计算的可行性验证

将相同运行条件下湿式风机除尘效率的计算值与实验值进行对比,如图5所示。从图5可见:仿真计算值偏低,这可能是三相流模型忽略了相间的传质及颗粒之间的破碎、聚并等情况所致;模拟结果与实验结果一致,且计算误差较小,说明基于Euler/DPM/ DPM数值模型用于模拟湿式除尘风机三相流场的可行性与准确性,其可用于进一步研究运行参数对风机除尘效率的影响。

图4 风机气动特性模拟结果与实验结果比较

Fig. 4 Comparison of fan aerodynamic characteristics between simulation results and experimental results

图5 除尘效率的模拟结果与实验结果比较

Fig. 5 Comparison of separation efficiency between simulation results and experimental results

4 运行参数对除尘效率的影响

4.1 运行参数取值

影响湿式除尘风机除尘效率的运行参数主要有粉尘颗粒粒度、液气比、风机转速,因此,分别对这3种运行参数进行数值分析。运行参数如表2所示。

表2 运行参数

Table 2 Operation parameters

4.2 不同粉尘粒度下的除尘效率

图6所示为在标准运行工况下(风机转速n=1 700 r/min,液气比q=0.2 L/m3),不同粉尘粒度时的颗粒轨迹图。

由图6可知:进入风机内的大、中粒度粉尘颗粒大部分会直接撞到风机叶轮上而被其上的水膜捕集,并最终在叶轮的作用力下甩向蜗壳内壁,小部分会在离心力的作用下直接被甩至风机蜗壳内壁而被捕捉。小粒度颗粒跟随气体流动性很强,不容易与风机叶轮及蜗壳壁面发生碰撞,其中一部分颗粒将沿蜗壳方向从风机出口逃逸。随着颗粒减小,其在风机内的运动轨迹变长,停留时间增加,从风机出口逃逸的数量增多,除尘效率降低。

由图7可知:大、中粒度的粉尘颗粒(粒度dp>15 μm)除尘效率为100%,在风机内的停留时间极短;粒度小于15 μm的颗粒随粒度减少,停留时间逐渐增大,除尘效率随之下降;对于粒度为1 μm的微小颗粒,除尘效率仍可达到65%,可见,湿式风机的除尘效率很高。

4.3 不同转速下的除尘效率

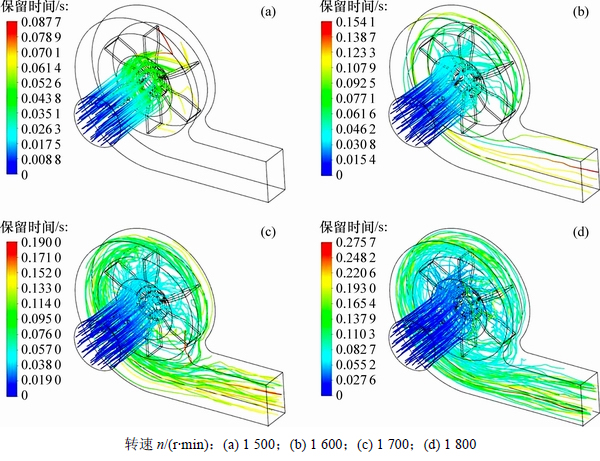

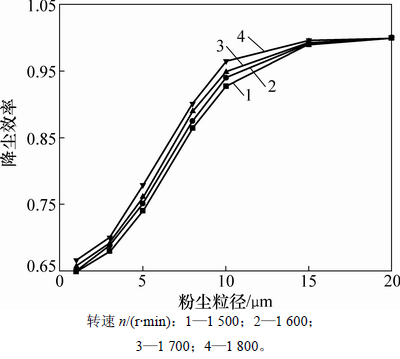

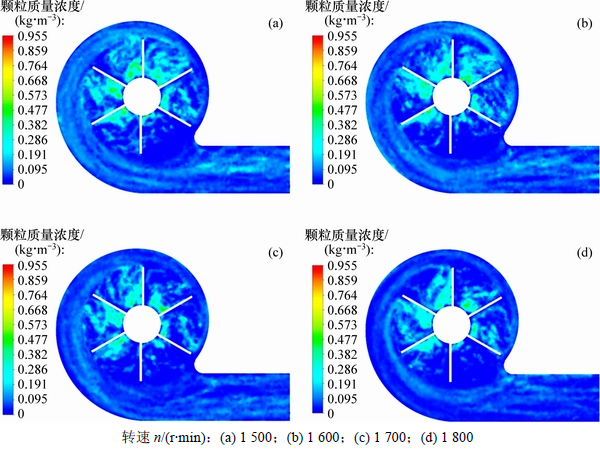

当液气比q=0.2 L/m3,在不同转速、不同粉尘粒度时,粉尘颗粒的除去效率见图8。

从图8可知:风机转速增大,除尘效率随之增大;对于粒度大于15 μm的粉尘颗粒,其除去效率变化缓慢,再增加风机转速,除去效率变化不大。不同转速下5 μm粉末颗粒质量浓度分布见图9。从图9可知:叶轮的扰动及离心力作用增强,粉尘颗粒在风机叶片压力面及蜗壳附近的聚集程度增大,更多的粉尘被叶片及蜗壳壁上的水膜捕捉,风机出口粉尘浓度降低,除尘效率增大。而对于大、中粒度颗粒(粒度dp>15 μm)而言,风机转速1 500 r/min时除去效率达99%,提高风机转速对除去效率基本没有影响。对于小粒度颗粒,提高风机转速可提高其除去效率。但过高的风机转速易引起除尘设备振动,不利于除尘器安全运行[18],因此,在实际应用中,应控制风机转速在适宜的范围内。

图6 不同粒度粉尘颗粒在风机内分布

Fig. 6 Particle trajectory for different size particles in fan

图7 不同粒度的除尘效率与停留时间分布

Fig. 7 Separation efficiency and residence time for different size particles

在风机叶轮的强力扰动及离心力作用下,粉尘颗粒在风机叶片的压力面及蜗壳附近分布较集中;随着风机转速增加,粉尘颗粒所受叶轮的扰动及离心力作用增强,粉尘颗粒在风机叶片压力面及蜗壳附近的聚集程度增大,更多的粉尘被叶片及蜗壳壁上的水膜捕捉,风机出口粉尘浓度降低,除尘效率增大。而对于大、中粒度颗粒(粒度dp>15 μm)而言,风机转速1 500 r/min时除去效率达99%,提高风机转速对除去效率基本没有影响。对于小粒度颗粒,提高风机转速可提高其除去效率。但过高的风机转速易引起除尘设备振动,不利于除尘器安全运行[18],因此,在实际应用中,应控制风机转速在适宜的范围内。

图8 不同风机转速下除尘效率

Fig. 8 Separation efficiency at different fan rotation speeds

图9 不同转速下5 μm粉尘颗粒质量浓度分布

Fig. 9 5 μm particle mass concentration distribution of different rotating speeds in fan

4.4 不同液气比下的除尘效率

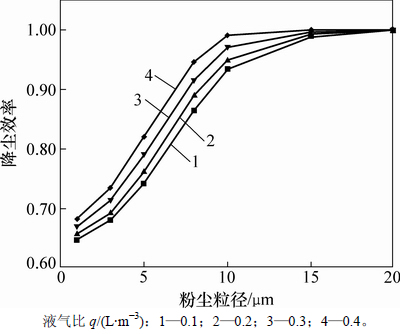

在风机转速n=1 700 r/min,粉尘颗粒粒度不同时时,液气比与除尘效率的关系见图10。

图10 不同颗粒粒度下液气比与除尘效率关系

Fig. 10 Relationships between gas-liquid ratio and separation efficiency

由图10可知:当粉尘粒度由1 μm增加到15 μm时,相同粒度粉尘除去效率随着液气比的增加而增加;液气比的增加可明显地提高粒度范围为1~10 μm的颗粒除去效率;当粉尘粒度大于15 μm时,除尘效率趋于平稳,再增加粉尘粒度,除尘效率变化不大。

5 结论

1) 针对湿式除尘风机内部气液固三相流场的特点,运用Euler/DPM/DPM三相流数值模型模拟湿式除尘风机的三相流场,将仿真结果与实验结果进行对比,验证了此数值模型用于模拟风机三相流场的可行性与准确性。

2) 不同粒度的颗粒在风机内除去效率有较大不同:在标准工况下,大、中粒度颗粒(粒度dp>15μm)除去效率基本达到100%;粒度为1~10 μm的颗粒随粒度的减少,除去效率下降;湿式风机对1 μm微小颗粒除去效率降低到65%。

3) 增加风机转速,粉尘颗粒除尘效率随之增加。当风机转速为1 500 r/min时,对粒度大于15 μm的颗粒除去效率达99%,提高转速对除去效率基本没有影响;当风机转速由1 500 r/min增加到1 700 r/min时,3~10 μm颗粒除尘效率可提高3~5%。

4) 增加液气比,粉尘颗粒除去效率随之增加。液气比的增加可明显提高粒度为1~10 μm的粉尘颗粒除去效率,而较大粒度的颗粒除去效率改变不大。增加液气比是提高小粒度颗粒除去效率的重要方法。

参考文献:

[1] 李小川, 胡亚非, 张巍, 等. 基于液相调节的除尘器阻力特性[J]. 煤炭学报, 2013, 38(2): 336-340.

LI Xiaochuan, HU Yafei, ZHANG Wei, et al. Resistance characteristics of dust separator based on liquid phase adjustment[J]. Journal of China Coal Society, 2013, 38(2): 336-340.

[2] 董芃, 李军, 翟明, 等. 湿式除尘器在运行中存在问题分析[J]. 电站系统工程, 2006, 22(6): 29-30.

DONG Peng, LI Jun, ZHAI Ming, et al. Analysis on the problems of wet dust catchers in operation[J]. Power System Engineering, 2006, 22(6): 29-30.

[3] WEN Jiangping, XU Shonglin. Local hydrodynamics in a gas-liquid-solid three-phase bubble column reactor[J]. Chemical Engineering Journal, 1998, 70(1): 81-84.

[4] JIA Xiaoqiang, WEN Jianping, FENG Wei. Local hydrodynamics modeling of a gas-liquid-solid three-phase airlift loop reactor[J]. Industrial & Engineering Chemistry Reasearch, 2007, 46(24): 5210-5220.

[5] MAJID A, YAN Changqi, SUN Zhongning, et al. CFD simulation of dust particle removal efficiency of a venturi scrubber in CFX[J]. Nuclear Engineering and Design, 2013, 256: 169-177.

[6] 李立清, 胡蔷, 黄贵杰, 等. 环栅喷淋泡沫塔欧拉-离散相模型三相除尘模拟[J]. 中国电机工程学报, 2012, 32(5): 68-77.

LI Liqing, HU Qiang, HUANG Guijie, et al. Numerical simulation of three-phases flow in the scrubber for a cascade-ring foam tower using a combined euler-discrete phase model method[J]. Proceedings of the CSEE, 2012, 32(5): 68-77.

[7] 王飞, 李彩亭, 曾光明, 等. 伞罩型湿式脱硫除尘器气液固三相流数值模拟[J]. 化学工程, 2009, 37(4): 31-34.

WANG Fei, LI Caiting, ZENG Guangming, et al. Numerical simulation of gas-liquid-solid three-phase flow field in canopy wet desulfurization dust catcher[J]. Chemical Engineering, 2009, 37(4): 31-34.

[8] 王福军. 计算流体动力学分析[M]. 北京: 清华大学出版社, 2004: 121-137.

WANG Fujun. Computational fluid dynamics analysis[M]. Beijing: Tsinghua University Press, 2004: 121-137.

[9] 张义云, 祁大同, 闻苏平. 通风机出气性能试验中采用文丘里喷管的分析与研究[J]. 流体机械, 2007, 35(5): 33-36.

ZHANG Yiyun, QI Datong, WEN Suping. Investigation on the usage of venturi nozzle in fan outlet performance test[J]. Fluid Machinery, 2007, 35(5): 33-36.

[10] 李琛, 马玉山, 高强, 等. 基于Realizable κ-ε模型的控制阀流场特性研究[J]. 宁夏大学学报, 2014, 35(4): 328-331.

LI Chen, MA Yushan, GAO Qiang, et al. Study on control valve flow field characteristics based on Realizable κ-ε turbulent model[J]. Journal of Ningxia University, 2014, 35(4): 328-331.

[11] SUNDARESAN S, CATE A T. Analysis of unsteady forces in ordered arrays of monodisperse spheres[J]. Journal of Fluid Mechanics, 2006, 552(552): 257-287.

[12] REN Ting, WANG Zhongwei, COOPER G. CFD modelling of ventilation and dust flow behaviour above an underground bin and the design of an innovative dust mitigation system[J]. Tunnelling and Underground Space Technology, 2014, 44(1): 241-254.

[13] 赵喆, 田贺忠. 颗粒轨道模型用于烟气脱硫喷淋塔两相流数值模拟[J]. 环境科学, 2005, 26(6): 33-37.

ZHAO Zhe, TIAN Hezhong. Particle trajectory model used in numerical simulation of flue gas desulfurization spray tower[J]. Environmental Science, 2005, 26(6): 33-37.

[14] ZHAO Haiming, LI Mi, JI Yaqian, et al. Study on gas-liquid-solid three-phase flow field of radial-straight-vane wet fan[J]. Applied Mechanics and Materials, 2014, 607: 273-277.

[15] 赵新学, 金有海, 孟玉青, 等. 旋风分离器壁面磨损的数值分析[J]. 流体机械, 2010, 38(4): 18-22.

ZHAO Xinxue, JIN Youhai, MENG Yuqing, et al. Numerical analysis on the erosion of cyclone separator’s surface wall[J]. Fluid Machinery, 2010, 38(4): 18-22.

[16] GB/T 12362000, 工业通风机-用标准化风道进行性能试验[S].

GB/T 12362000, Industrial fans-performance testing using standardized airways[S].

[17] GB/T 15187—2005, 湿式除尘器性能测定方法[S].

GB/T 15187—2005, Measuring method for performances of wet dust collectors[S].

[18] 李小川, 胡亚非, 张巍, 等. 湿式除尘器综合运行参数的影响[J]. 中南大学学报(自然科学版), 2013, 44(2): 862-866.

LI Xiaochuan, HU Yafei, ZHANG Wei, et al. Effect of operation parameters of wet dust collector[J]. Journal of Central South University (Science and Technology), 2013, 44(2): 862-866.

(编辑 陈灿华)

收稿日期:2016-07-07;修回日期:2016-09-19

基金项目(Foundation item):国家高技术研究发展计划(863计划)项目(2012AA041801);国家重点研发计划项目(2016YFC0209302) (Project(2012AA041801) supported by the National High Technology Research and Development Program(863 Program) of China; Project2016YFC0209302) supported by the National Key Research and Development)

通信作者:赵海鸣,教授,从事超声探测、高效除尘技术研究;E-mail:zhm0097@126.com