基于人工神经网络的A357合金力学性能预测

来源期刊:中国有色金属学报(英文版)2013年第3期

论文作者:杨夏炜 朱景川 农智升 何 东 来忠红 刘 颖 刘法伟

文章页码:788 - 795

关键词:A357合金;力学性能;人工神经网络;热处理参数

Key words:A357 alloy; mechanical properties; artificial neural network; heat treatment parameters

摘 要:A357铝合金零件一般都需要经过热处理(T6状态)以获得优异的力学性能。这类零件的性能取决于固溶温度、固溶时间、人工时效温度及人工时效时间。在本研究中,建立了基于反向传播(BP)算法的人工神经网络 (ANN)模型,对A357合金的力学性能进行预测,研究了热处理工艺对该合金性能的影响。结果表明,所建立的BP模型能够对A357合金的力学性能进行有效且精度高的预测。良好的神经网络预测能力能够直观地反映A357合金的热处理工艺参数对其力学性能的影响。绘制抗拉强度和伸长率的等值线图形有助于清晰地找到抗拉强度和伸长率之间的关系,可为实际生产中热处理工艺参数的选择提供技术支持。

Abstract: The workpieces of A357 alloy were routinely heat treated to the T6 state in order to gain an adequate mechanical property. The mechanical properties of these workpieces depend mainly on solid-solution temperature, solid-solution time, artificial aging temperature and artificial aging time. An artificial neural network (ANN) model with a back-propagation (BP) algorithm was used to predict mechanical properties of A357 alloy, and the effects of heat treatment processes on mechanical behavior of this alloy were studied. The results show that this BP model is able to predict the mechanical properties with a high accuracy. This model was used to reflect the influence of heat treatments on the mechanical properties of A357 alloy. Isograms of ultimate tensile strength and elongation were drawn in the same picture, which are very helpful to understand the relationship among aging parameters, ultimate tensile strength and elongation.

Trans. Nonferrous Met. Soc. China 23(2013) 788-795

Xia-wei YANG1,2, Jing-chuan ZHU1,2, Zhi-sheng NONG1,2, Dong HE1,2, Zhong-hong LAI1,2, Ying LIU3, Fa-wei LIU4

1. National Key Laboratory for Precision Hot Processing of Metals, Harbin Institute of Technology, Harbin 150001, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

3. Beijing Hangxing Machine Manufacturing Company, Beijing 100013, China;

4. Physical Test Centre, Shenyang Aircraft Corporation, Shenyang 110034, China

Received 15 December 2011; accepted 28 March 2012

Abstract: The workpieces of A357 alloy were routinely heat treated to the T6 state in order to gain an adequate mechanical property. The mechanical properties of these workpieces depend mainly on solid-solution temperature, solid-solution time, artificial aging temperature and artificial aging time. An artificial neural network (ANN) model with a back-propagation (BP) algorithm was used to predict mechanical properties of A357 alloy, and the effects of heat treatment processes on mechanical behavior of this alloy were studied. The results show that this BP model is able to predict the mechanical properties with a high accuracy. This model was used to reflect the influence of heat treatments on the mechanical properties of A357 alloy. Isograms of ultimate tensile strength and elongation were drawn in the same picture, which are very helpful to understand the relationship among aging parameters, ultimate tensile strength and elongation.

Key words: A357 alloy; mechanical properties; artificial neural network; heat treatment parameters

1 Introduction

A357 (Al-7Si-0.6Mg) alloy has been widely used in aerospace, automotive industries and other aspects due to its excellent castability, good corrosion resistance and high specific strength in heat treated conditions [1,2]. The workpieces are routinely heat treated to the T6 state in order to develop an adequate mechanical property. T6 heat treatment includes solution heat treatment, quench and age hardening. In the past few decades, the mechanical properties of A357 alloy treated under different conditions have been extensively studied [3-5]. CESCHINI et al [3] studied the relationship among the microstructural features, the hardness and the ultimate tensile strength of A357 alloy. Sixteen heat treatments of A357 alloy were designed to study the effect of various heat treatment parameters on the mechanical properties. The results showed that quenching rate plays a crucial role in determining the mechanical properties [4]. ROMETSCH and SCHAFFER [5] had modeled the yield strength aging curves for A356 and A357 aluminum alloys below the solvus temperature of the main hardening precipitation. Therefore, it is too difficult to use a single mathematical model to describe the relationship between heat treatment parameters and mechanical properties of A357 alloy.

Recently, artificial neural network has been widely used in describing the mechanical properties of metals and alloys [6-8]. The artificial neural network (ANN) method is capable of treating the non-linear problems and complex relationships. FOROUZAN and AKBARZADEH [6] have developed an artificial neural network (ANN) model with a back-propagation learning algorithm to predict the yield strength, elongation and ultimate tensile strength during hot rolling, cold rolling and annealing of AA3004 aluminum alloy. The results showed that this approach can be well used to predict the mechanical properties of AA3004 alloy sheets. An ANN model is used for the analysis and prediction of the correlation between heat treatment parameters and mechanical properties in titanium alloys [7], and a very good performance of the network has been achieved. YU et al [8] established a neural network to acquire the relationships between the mechanical properties and the processing parameters of forged Ti-6Al-4V alloy.

The ANN approach in the prediction of the heat treatment parameters and mechanical properties has not yet been widely used for cast aluminum alloy. In this work, a series of tensile tests were carried out on heat-treated A357 alloy samples to establish the network database used in the artificial neural network. The ANN model was constructed to predict the mechanical properties of A357 alloy by using the heat treatment parameters as the input variables, while the ultimate tensile strength and elongation as the output. Finally, the isograms of ultimate tensile strength and elongation were applied to understanding the relationship among artificial aging process parameters, ultimate tensile strength and elongation.

2 Experimental

The main chemical composition (mass fraction, %) of commercial A357 aluminum alloy used in the present investigation is as follows: 6.83Si, 0.51Mg, 0.18Ti, 0.04Cu, 0.03Fe, 0.04Be and Al balance. The blanks of cylindrical tensile bar of A357 alloy were obtained by using permanent mold casting, and then these bars were subjected to different heat treatments. The heat treatment parameters (T6 conditions) used in this work are as follows: solid-solution temperature (535 °C and 545 °C), solid-solution time (8 h and 12 h), quenching temperature (60 °C), artificial aging temperature range (155-175) °C and artificial aging time range (5-15) h. After heat treatments, the tensile specimens were machined according to ASTM E8M standard specification [9] with 45.0 mm in gauge length and 9 mm in diameter. Tensile tests were carried out using an Instron tensile tester at room temperature. Ultimate tensile strength and elongation to failure were measured.

3 Overview of ANN and establishment of ANN model

3.1 Overview of ANN

An artificial neural network (ANN) is a computational model which has been applied extensively in many professions such as statistics, cognitive psychology, image processing, manufacturing and communications [10,11]. It is made up of a number of interconnected groups of nodes and the model is composed of three layers: an input layer, a hidden layer or a few hidden layers and an output layer [12]. Each layer has a certain number of neurons that operate in parallel and communicate with each other through linking weights. The input layer consists of all the input factors. The data from the input layer are calculated through the hidden layer, following output vector is processed in the output layer.

The most basically and commonly used ANN is multilayer feed forward network with back propagation (BP) learning algorithm. It is a supervised learning method. The value of predefined error function is calculated by comparing the actual output values with the desired data, the error is then feed back through the network, and the learning algorithm adjusts the weights of each connection in order to reduce the error. After adequate circulation in this process, the error will reach the predefined value. In this situation, the network is considered learning a certain target function [13,14].

3.2 Establishment of ANN model

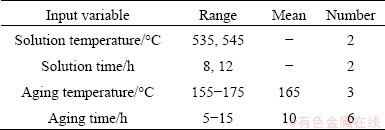

In the present study, the artificial neural network (ANN) with a back-propagation (BP) learning algorithm was established to predict the mechanical properties of the heat-treated A357 alloy. Solid-solution temperature, solid-solution time, artificial aging temperature and artificial aging time were used as the input variables, while ultimate tensile strength and elongation were taken as the output data. In this investigation, the quenching temperature was not served as input data of neural network due to it was defined as a constant for heat treatment process of A357 alloy. Table 1 shows an overview of the input variables used to predict mechanical properties of A357 alloy.

Table 1 Input variables used to predict mechanical properties of A357 alloy

The data from tensile tests were divided into two sub-sets: a training set and a testing set. The training set accounts for five-sixths of the original dataset; the remaining dataset was left for testing set. To speed up the convergence of the training network it is necessary to normalize the original data. The transformation equation is given by

(1)

(1)

where X is the primary datum from tensile tests; x (norm), X (max) and X (min) are the normalized value, the maximum value and the minimum value of X, respectively. From Eq. (1), we know that x (norm) value is in the range of [0.1, 0.9].

In the output layer of the BP model, a linear function was taken as the transfer function. The transfer functions in the hidden layers were sigmoid functions (tan-sigmoid and log-sigmoid), which are given using the following equations:

(2)

(2)

(3)

(3)

In this work, using mean square error (MSE) as the evaluation criterion, performance of network training based on BP artificial neural network was evaluated. It tries to minimize the average squared error between the desired and actual output values over all the example pairs, and the function of MSE can be defined as

(4)

(4)

where d(i) is the desired data from tensile tests; a(i) is the actual value from the ANN; N is the number of desired data in this study.

It is very important for an ANN to decide how to train the network. In this section, we concerned two different types of training [15]: incremental training and batch training. In incremental training, the weights and biases of the network are updated each time after an input is presented to the network. In batch training, the weights and biases are only updated after all the inputs and targets are presented to the network. The order of the input vectors appearing is important for incremental training, but for batch training, it is not important. According to the above description of the two basic types of network training, we have used batch training in this work.

There is no theoretical method to determine the values of parameters of the ANN model because each problem with an ANN has different features. According to traditional research, the values of these parameters were selected by trail-and-error, which was used in this work. In the traditional ANN literatures [16-19], the learning rate and the momentum constants are usually set to be 0-1. It is very important for an ANN to select an appropriate learning rate. The value of the learning rate controls the size of the adjustments made during the training process. If the learning rate is too high, the algorithm learns quickly but it will result in an unstable state. If the value of learning rate is too low, the algorithm will take a long time to learn. Therefore, an appropriate learning rate not only ensures the stability of the network but also guarantees an acceptable training time of the network. In our case, we choose the value of 0.1 as the learning rate. A momentum factor is used to speed up the convergence of network training. When the momentum constant is equal to 0, a weight change is obtained solely by the gradient descent approach. When the momentum constant is equal to 1, change in weights is set to equal the last weight change, and the part of the change generated by the gradient is simply ignored. A higher value of momentum factor is helpful to attain the best performance of the network. Here, we choose the value of 0.6 for the momentum factor.

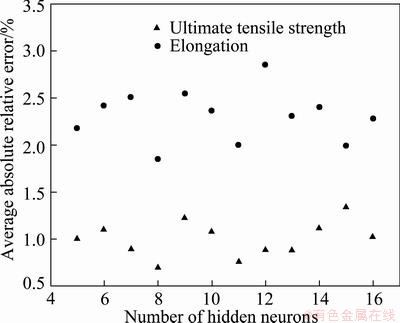

Generally, one hidden layer suffices to meet the requirements of prediction accuracy [18]. In this investigation, the average absolute relative error was used to assess performance of the training and testing network. In order to determine the optimal architecture, several neural networks were trained with different number of neurons in one hidden layer, as shown in Fig. 1. In Fig. 1, 8 neurons, 11 neurons and 15 neurons in one hidden layer all have significantly lower error of elongation than other number of neurons. 8 neurons and 11 neurons in one hidden layer are both significantly lower error of ultimate tensile strength than other number of neurons. And it also can be seen from Fig. 1, the ANN with 8 neurons in one hidden layer can meet the requirements of the minimum error for both the ultimate tensile strength and the elongation at the same time.

Fig. 1 Average absolute relative error for different hidden neurons

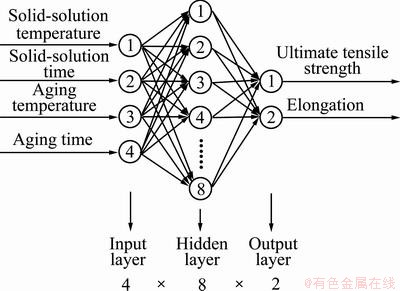

After training, it was found that the network with these features proved a better network precision: a momentum rate of 0.6, a learning rate of 0.1, a MSE of 10-5 and the epochs of 10000. In addition, 8 neurons were used in one hidden layer. A schematic representation of the ANN model is shown in Fig. 2.

4 Results and discussion

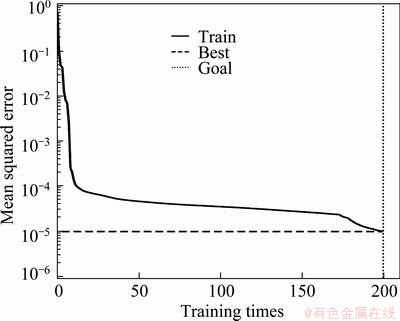

In this investigation, an artificial neural network (ANN) model with a back-propagation (BP) learning algorithm was developed to predict ultimate tensile strength and elongation of A357 alloy. Figure 3 presents the result of mean square error (MSE) of training. It can be seen that the training process lasted until the error goal was met and the training terminated at 200 epochs. Each epoch is a step that passes through inputs, hiddens and outputs in the training process of an artificial neural network. Here, the value of goal error was set as 10-5 and the value of MSE for network training reached 9.89×10-6 at epoch 200.

Fig. 2 Schematic representation of BP artificial neural network

Fig. 3 Training error curve

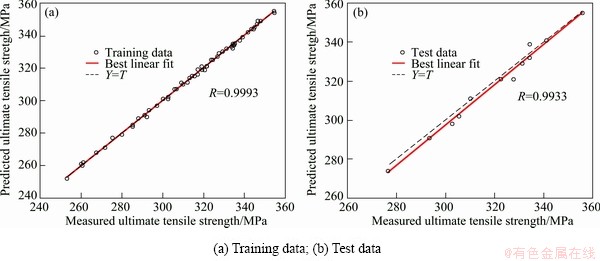

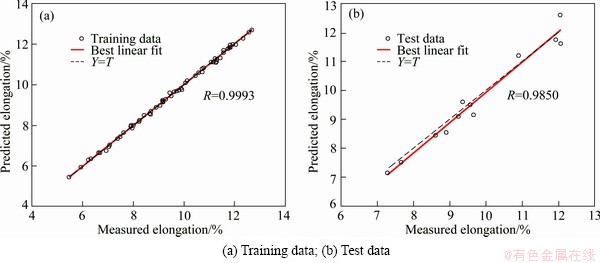

Figures 4 and 5 show comparisons of predicted results by BP network with experimental data gained from tensile tests. The two figures show that the predicted values are in good agreement with the experimental data of ultimate tensile strength and elongation. The maximum relative errors(MRE) of ultimate tensile strength and elongation between the measured results of testing data and the predicted values of BP network are 2.25% and 4.15%, respectively. The average absolute relative errors (AARE) of ultimate tensile strength and elongation between the measured results of testing data and the predicted values of BP network are 0.70% and 1.85%, respectively. This level of error shows a satisfactory result and is smaller than the error of experimental variations and accuracy of instrumentation.

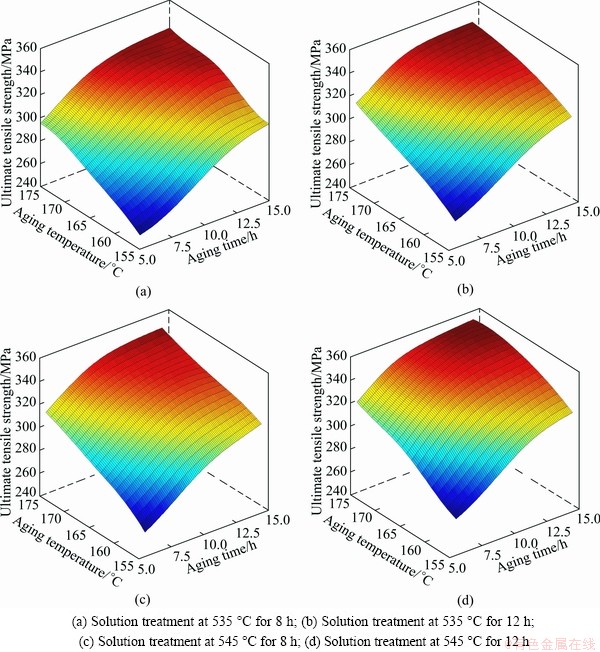

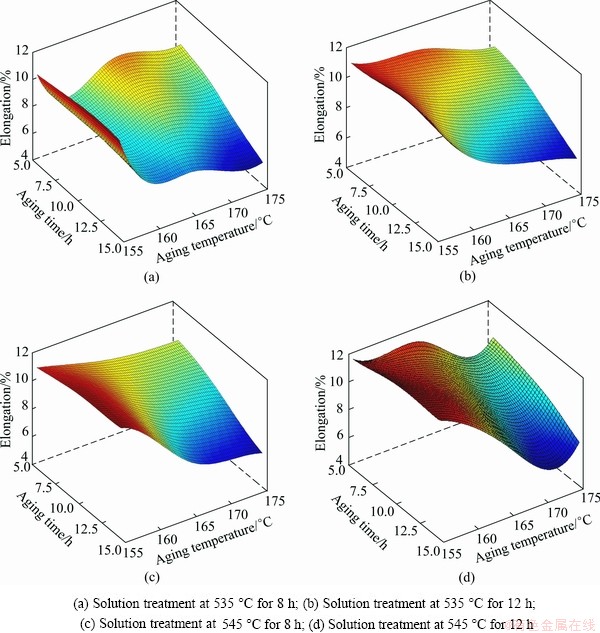

As demonstrated from the above results, the BP model can give a good prediction of the mechanical properties of heat-treated A357 alloy. On the basis of this BP model, all the data in the solid-solution temperature range of 535-545 °C, solid-solution time range of 8-12 h, artificial aging temperature range of 155-175 °C and artificial aging time range of 5-15 h were estimated. Effects of the heat treatment processes on the mechanical properties of the heat-treated A357 alloy were studied. The effects of aging temperature and aging time on ultimate tensile strength of the as-cast A357 alloy with different solid-solution conditions are shown in Fig. 6. The dependency of the elongation values of the as-cast A357 alloy on the aging time in the investigated temperature range is presented in Fig. 7.

Fig. 4 Comparison of predicted and measured ultimate tensile strength

Fig. 5 Comparison of predicted and measured elongation

Fig. 6 Effects of aging temperature and aging time on ultimate tensile strength of heat-treated A357 alloy with different solid solution temperature and solid solution time

As can be seen from Fig. 6 and Fig. 7, under the same aging conditions, solution treatment parameters (solid-solution temperature and solid-solution time) have little influence on mechanical properties (ultimate tensile strength and elongation) of as-cast A357 alloy. In this investigation, since only two solid-solution temperatures and two solid-solution times were chosen as the solution treatment parameters, but the effects of solution treatment parameters on mechanical properties of the heat-treated A357 alloy were not definitely ascertained. Under the same solid-solution conditions, for a given aging temperature the values of ultimate tensile strength increase with the aging time increasing and for a certain aging time the values of ultimate tensile strength increase with rise in aging temperature (Fig. 6), which is also in agreement with result in Refs. [2,20]. The elongation value of heat-treated A357 alloy decreases with the aging temperature increasing as well as aging time increasing (Fig. 7), which is also observed in Refs. [2,20].

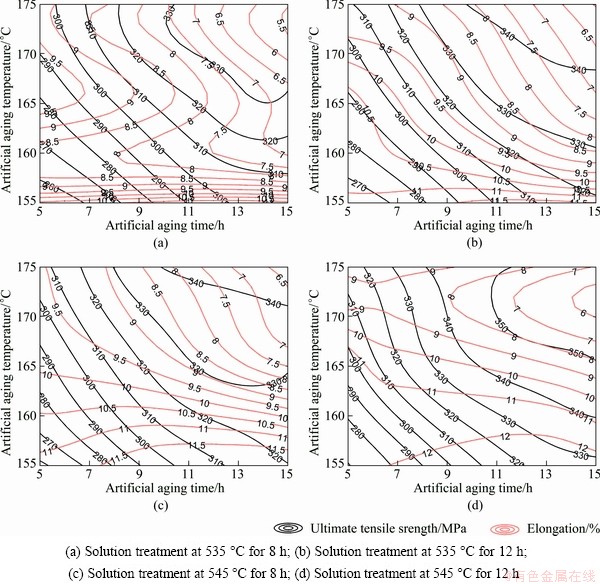

The best comprehensive mechanical properties of materials will need not only ideal ultimate tensile strength but also good elongation. Based on data collected from Fig. 6 and Fig. 7, the isograms of ultimate tensile strength and elongation were drawn in the same picture. Figure 8 shows the isograms of ultimate tensile strength and elongation of heat-treated A357 alloy with different solid solution temperatures and solid solution time. As shown in Fig. 8, there is a phenomenon of the higher ultimate tensile strength value corresponds to the lower elongation value and vice versa. Therefore, values of the ultimate tensile strength and the elongation must be taken into account to attain good mechanical properties of heat-treated A357 alloy. The heat treatment parameters can be chosen based on the performance requirements on the workpieces under specific environmental conditions. Figure 8(a) shows that the value of ultimate tensile strength of this alloy is about 320 MPa and the elongation is about 8% after 8 h solution treatment at 535 °C and 10 h to 12 h and aging treatment at 165 °C. If the tensile strength must be greater than 330 MPa and the elongation must be over 8.5%, the aging treatment parameters can be chosen as follows: 10 h aging treatment at 170 °C or 11 h aging treatment at 165 °C (see Fig. 8(b)). Similarly, we can also obtain the specific mechanical properties from Figs. 8(c) and (d). These isograms are very helpful for us to choose proper heat treatment processes of A357 alloy with various applications.

5 Conclusions

1) An artificial neural network (ANN) model with the back-propagation learning algorithm was established to predict the mechanical properties of cast A357 alloy in T6 state. The results show that the average absolute relative error of ultimate tensile strength between the ANN prediction results and experimental data is 0.70%.

Fig. 7 Effects of aging temperature and aging time on elongation of heat-treated A357 alloy with different solid-solution temperatures and solid-solution time

Fig. 8 Isograms of ultimate tensile strength and elongation of heat-treated A357 alloy with different solid-solution temperatures and solid-solution time

While for the elongation, the average absolute relative error is 1.85%. Therefore, the BP model proposed in this article can be used as an accurate model for the prediction of mechanical properties of A357 alloy. Further, a large amount of manpower and time can be saved by using this BP model.

2) Under the same aging conditions, solution treatment parameters did not have a great influence on mechanical properties of heat-treated A357 alloy. But under the same solid-solution conditions, and at a given aging temperature, the value of ultimate tensile strength increases with the aging time increasing and for a certain aging time the value of ultimate tensile strength increases with rise in the aging temperature. The elongation value decreases with the aging temperature increasing or the aging time increasing.

References

[1] KUMAR G, HEGDE S, PRABHU K N. Heat transfer and solidification behavior of modified A357 alloy [J]. J Mater Process Technol, 2007, 182(1-3): 152-156.

[2] ALEXOPOULOS N D, PANTELAKIS SP G. Quality evaluation of A357 cast aluminum alloy specimens subjected to different artificial aging treatment [J]. Mater Des, 2004, 25(5): 419-430.

[3] CESCHINI L, ALESSANDRO M, ANDREA M. Correlation between ultimate tensile strength and solidification microstructure for the sand cast A357 aluminum alloy [J]. Mater Des, 2009, 30(10): 4525-4531.

[4] ES-SAID O S, LEE D, PROST W D, GAMBERINI A, MESSIERI S. Alternative heat treatments for A357-T6 aluminum alloy [J]. Eng Fail Anal, 2002, 9(1): 99-107.

[5] ROMETSCH P A, SCHAFFER G B. An age hardening model for Al-7Si-Mg casting alloys [J]. Mater Sci Eng A, 2002, 325(1-2): 424-434.

[6] FOROUZAN S, AKBARZADEH A. Prediction of effect of thermo-mechanical parameters on mechanical properties and anisotropy of aluminum alloy AA3004 using artificial neural network [J]. Mater Des, 2007, 28(5): 1678-1684.

[7] MALINOV S, SHA W, MCKEOWN J J. Modelling the correlation between processing parameters and properties in titanium alloys using artificial neural network [J]. Comput Mat Sci, 2001, 21(3): 375-394.

[8] YU W X, LI M Q, LUO J, SU S B, LI C Q. Prediction of the mechanical properties of the post-forged Ti-6Al-4V alloy using fuzzy neural network [J]. Mater Des, 2010, 31(7): 3282-3288.

[9] ‘Standard test methods for tension testing of metallic materials’, ASTM International Standard E8M-04 [M]. United States: ASTM International, 2004: 1-24.

[10] BOSE N K, LIANG P. Neural network fundamentals with graphs, algorithms and applications [M]. New York: McGraw-Hill Co., 1998: 102-120.

[11] MEHROTRA K, MOHAN C K, RANKA S. Elements of artificial neural networks [M]. Massachusetts: MIT Press, 1996: 56-64.

[12] LIPPMANN R P. An introduction to computing with neural nets [J]. IEEE ASSP Magazine, 1987, 4: 4-22.

[13] ZURADA J. Introduction to artificial neural systems [M]. Boston: PWS Publishing Company, 1992: 75-95.

[14] DAYHOFF J E. Neural network architectures: An introduction [M]. New York: VNR Press, 1990: 105-114.

[15] DEMUTH H, BEALE M. Neural network toolbox user’s guide [M]. Massachusetts: The Math Works Inc, 2000: 135-143.

[16] ALMEIDA L M, LUDERMI T B. A multi-objective memetic and hybrid methodology for optimizing the parameters and performance of artificial neural networks [J]. Neurocomputing, 2010, 73(7-9): 1438-1450.

[17] FENG L H, LU J. The practical research on flood forecasting based on artificial neural networks [J]. Expert Syst Appl, 2010, 37(4): 2974-2977.

[18] AHMAD J S, TWOMEY J. ANN constitutive model for high strain-rate deformation of Al 7075-T6 [J]. J Mater Process Technol, 2007, 186(1-3): 339-345.

[19] KANTI K M, RAO P S. Prediction of bead geometry in pulsed GMA welding using back propagation neural network [J]. J Mater Process Technol, 2008, 200(1-3): 300-305.

[20] APELIAN D, SHIVKUMAR S, SIGWORTH G. Fundamental aspects of heat treatment of cast Al-Si-Mg alloys [J]. AFS Trans, 1989, 137: 730-734.

杨夏炜1,2, 朱景川1,2, 农智升1,2, 何 东1,2, 来忠红1,2, 刘 颖3, 刘法伟4

1. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001;

3. 北京航星机器制造公司,北京 100013;

4. 沈阳飞机工业(集团)有限公司 理化测试中心,沈阳 110034

摘 要:A357铝合金零件一般都需要经过热处理(T6状态)以获得优异的力学性能。这类零件的性能取决于固溶温度、固溶时间、人工时效温度及人工时效时间。在本研究中,建立了基于反向传播(BP)算法的人工神经网络 (ANN)模型,对A357合金的力学性能进行预测,研究了热处理工艺对该合金性能的影响。结果表明,所建立的BP模型能够对A357合金的力学性能进行有效且精度高的预测。良好的神经网络预测能力能够直观地反映A357合金的热处理工艺参数对其力学性能的影响。绘制抗拉强度和伸长率的等值线图形有助于清晰地找到抗拉强度和伸长率之间的关系,可为实际生产中热处理工艺参数的选择提供技术支持。

关键词:A357合金;力学性能;人工神经网络;热处理参数

(Edited by Hua YANG)

Corresponding author: Jing-chuan ZHU; Tel: +86-451-86413792; Fax: +86-451-86413922; E-mail: fgms@hit.edu.cn

DOI: 10.1016/S1003-6326(13)62530-3